EP2000218A1 - Event à régulation automatique pour un récipient d'alimentation de peinture - Google Patents

Event à régulation automatique pour un récipient d'alimentation de peinture Download PDFInfo

- Publication number

- EP2000218A1 EP2000218A1 EP07109834A EP07109834A EP2000218A1 EP 2000218 A1 EP2000218 A1 EP 2000218A1 EP 07109834 A EP07109834 A EP 07109834A EP 07109834 A EP07109834 A EP 07109834A EP 2000218 A1 EP2000218 A1 EP 2000218A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- vessel

- air inlet

- valve

- openings

- seat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/24—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with means, e.g. a container, for supplying liquid or other fluent material to a discharge device

- B05B7/2402—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device

- B05B7/2405—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device using an atomising fluid as carrying fluid for feeding, e.g. by suction or pressure, a carried liquid from the container to the nozzle

- B05B7/2408—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device using an atomising fluid as carrying fluid for feeding, e.g. by suction or pressure, a carried liquid from the container to the nozzle characterised by the container or its attachment means to the spray apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B7/00—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas

- B05B7/24—Spraying apparatus for discharge of liquids or other fluent materials from two or more sources, e.g. of liquid and air, of powder and gas with means, e.g. a container, for supplying liquid or other fluent material to a discharge device

- B05B7/2402—Apparatus to be carried on or by a person, e.g. by hand; Apparatus comprising containers fixed to the discharge device

- B05B7/2478—Gun with a container which, in normal use, is located above the gun

Definitions

- the present invention relates to a vessel used for storing a liquid or viscous material to be supplied to a liquid application tool, said vessel having an air inlet.

- Such a vessel is known and commonly used for various applications. For example, it can be used for storing paint or another liquid product or viscous material.

- the vessel is mounted onto a pneumatic or otherwise powered liquid application tool, such as for example a spray gun.

- the vessel is sealed with a closure lid, which typically clicks onto an upper rim of the vessel or can be held on by a screw-type thread or other various mounting and sealing means.

- the vessel, and in particular the closure lid is punctured or otherwise opened before or after mounting the vessel onto the liquid application tool.

- an air inlet is provided for equalizing the pressure difference that builds up in the vessel as the liquid is applied.

- air can flow to the interior of the vessel thereby facilitating a supply of the liquid.

- a drawback of the known vessels is that the vessel needs to be punctured or otherwise opened in order to provide the air inlet. Once punctured or opened, the vessel is no longer integral and can serve only to supply the material to the application tool in a relatively upright orientation. Once opened, it becomes difficult to leave unused product in the vessel as air continues to enter the vessel. Moreover the product will leak out of the vessel when the latter is removed from the application tool and turned upside down. With the known vessels it is therefore necessary to remove the punctured lid and replace it with a non-punctured one, or transfer the contents entirely by pouring the material into a new, genuine vessel for temporary storage away from the application tool.

- the objective of the invention is to provide a vessel where it is no longer necessary to puncture the latter for the purpose of providing an air inlet.

- a vessel according to the present invention is characterised in that said air inlet comprises a plurality of openings, each opening having a surface area of at the most 15 mm 2 , said air inlet being provided with a closure valve made of flexible elastomer material, said valve being resiliently mounted on said air inlet in such a manner as to cover said plurality of openings and to open upon a predetermined pressure difference between a first pressure inside said vessel and a second pressure outside said vessel.

- the use of the closure valve applied on the air inlet provides for air supply regulation by means of the pressure difference present over the valve.

- the spraying will cause the liquid amount present inside the vessel to diminish, thereby creating a lower pressure in the interior of the vessel compared to the exterior thereof.

- the pressure difference will cause the valve to open and let air flow into the interior of the vessel.

- the pressure difference will no longer be present thereby closing the valve. In this manner, the valve is automatically regulated.

- said vessel comprises a closure lid having a seat on which said air inlet is applied.

- said air inlet is applied on the closure lid.

- a first preferred embodiment of a vessel according to the present invention is characterised in that said openings are applied along a circumference of a circle and wherein said valve has a circularly shaped member covering said openings.

- the circular distribution of the openings stimulates a well distributed air flow.

- a second preferred embodiment of a vessel according to the present invention is characterised in that a further opening is applied in the centre of said circle, said valve having a stem extending from said member and penetrating into said further opening. In such a manner the stem is surrounded by the air flow openings.

- said closure lid comprises a conically shaped part on which said seat is applied in such a manner as to form a flat surface, said plurality of openings being applied through said seat.

- a screen can be applied to filter the material as it leaves the vessel.

- the filtering screen may cover the seat or may bypass it.

- a third preferred embodiment of a vessel according to the present invention is characterised in that said seat is formed by a protrusion extending inside said vessel. In such a manner and even with a conically shaped closure lid, the valve acts on flat surface.

- the invention also relates to a closure lid as part of a vessel according to the present invention.

- the vessel 1 illustrated in figure 1 is mounted on a spray gun 4 provided with a handle 5 for controlling the spray volume.

- a spray gun is used as a liquid application tool. It will however be clear that other application tools than a spray gun can be used.

- the vessel is provided for storing and conveying paint to the spray gun. It will however be clear that the present invention is not limited to vessels for storing paint and that the vessels may contain any other liquid or viscous material to be supplied to the application tool.

- the vessel also comprises a reservoir 2, which is closed by means of a closure lid 3. The closure lid is preferably clicked on a rim of the reservoir with a pressure fit interlocking design.

- the vessel can also comprise a mixing cup which is removably mounted thereto.

- the mixing cup is used for preparing a mixture, in particular paint, prior to pouring it into the vessel, which is subsequently mounted onto the application tool.

- the removably mounted mixing cup enables to incorporate the mixing cup as part of the vessel, thereby avoiding the need to transfer the liquid to another vessel prior to the application thereof. This extends the utility of a mixing cup, reduces waste, and reduces the cost and the number of steps in the liquid (paint) preparation process.

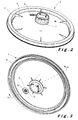

- FIG 2 which shows a top view of the closure lid 3, the latter comprises a closure rim 6 for fixing the closure lid on the reservoir 2.

- the closure rim is upright with respect to the closure lid surface 11 extending from the closure rim towards a central opening 7 applied on a protrusion and provided for mounting the vessel 1 on the spray gun 4.

- Triangularly shaped reinforcement elements 8 extend as from the closure rim's upright part towards the central opening over a short section of the closure lid surface 11. The reinforcement elements reinforce the connection between the closure rim 6 and the closure lid surface 11 and also the whole closure lid, in such a manner as to firmly sustain the weight of the liquid when the vessel is applied on the application tool.

- the closure lid further comprises an air inlet 9.

- the air inlet crosses the closure lid surface 11 and comprises a plurality of openings 10.

- the air inlet is applied approximately half way between the closure rim 6 and the central opening 7.

- the openings are applied along a circumference of a circle.

- the air inlet is preferably applied on a seat 12.

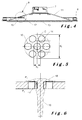

- the seat 12 forms a triangularly shaped protrusion (as seen in the sectioned view of figure 4 ) inside the vessel and with respect to the cover lid surface 11.

- the air inlet location may be adjusted for various reasons, such as to incorporate the aforementioned filtering screen.

- the air inlet is applied on the closure lid.

- the air inlet could also be applied on the reservoir 2, preferably in the upper part thereof.

- the openings 10 are applied in the flat surface part of the seat which extend substantially parallel with respect to line 13. In such a manner, the air penetrates perpendicularly through the openings 10 and turbulences are avoided which would be generated in case that the openings would be applied in the conical surface.

- the air inlet 9 is as if to say applied in a cavity, applied on the closure lid's surface 11.

- FIG 5 which shows a detailed view of the openings

- the dimension of the diameter d1 is determined in function of the liquid to be applied and the amount of air flow needed into the interior of the vessel.

- the diameter of each opening can vary between 0.2 mm to 4 mm.

- At the most each of the plurality of openings have a surface of 15 mm 2 .

- diameter d2 may also vary according to the liquid to be applied and air flow needed into the vessel interior.

- the air inlet is further provided with a closure valve 14 made of a flexible elastomer material such as silicone rubber, fluorosilicone, fluoroelastomers or perfluoroelastomers.

- a closure valve 14 made of a flexible elastomer material such as silicone rubber, fluorosilicone, fluoroelastomers or perfluoroelastomers.

- the choice of the elastomer material of which the valve is made is in function of the liquid that will be present in the vessel. Indeed, care has to be taken that the latter material is chemically resistant to this liquid.

- the valve assembly may also be mounted in the reservoir if the air inlet is applied there.

- the air inlet is preferably provided with a further opening 14 as illustrated in figures 5 and 6 .

- This further opening 14 is applied in a centre of the circle C within which the openings 10 are applied.

- the valve comprises preferably a stem 15 on which a circularly shaped member 16 is mounted as illustrated in figure 6 .

- the circularly shaped member is dimensioned in such a manner that it covers the plurality of openings.

- Such a type of valve is also called an umbrella valve.

- the circularly shaped member 16 extends on the inner side of the closure lid, whereas the stem 15 penetrates through the further opening 14 in order to reach the outer side of the closure lid 3.

- the stem 15 is somewhat compressed inside the further opening 14 so that it bulges out at the outer side, thereby firmly fixing the valve to the air inlet.

- the valve thus covers the openings and opens upon a pressure difference between a first pressure P1 inside the vessel and a second pressure P2 outside the vessel.

- the gun When the user activates the handle 5 of the spray gun, the gun will open thereby causing a pressure drop inside the vessel. As the pressure P1, inside the vessel is then lower than the pressure P2 outside the vessel, a pressure difference will be established over the air inlet, causing the valve to open and thus allowing air from the outside to flow via the plurality of openings 10 inside the vessel. As soon as the handle is released, the pressure difference becomes negligible, thereby causing the valve to close. The valve is thus self regulating and as the valve closes after release of the handle, the vessel is closed and there is no need to change the closure lid, even if the liquid remains stored in the vessel.

- the closure lid and the reservoir are preferably made of plastic disposable material so as to provide a low cost product. Moreover, there is also no need to clean the reservoir. It has to be noted that a silicone valve may swell upon exposure to certain solvents which may be present in the liquid. However this will not affect the operation of the valve as the member 16 does not cross the boundaries of the seat.

- the valve can be designed in such a manner that it opens at predetermined pressure differential between the interior and exterior of the vessel.

- the valve design can be optimized to open at as low as 5 millibar of pressure or as high as 100 millibar, depending on needs of the application.

- the valve has also a self sealing feature, as even without pressure difference the stem holds the valve closed due to the pretension in the stem.

- the self regulating properties of the valve cause the air volume passing through the plurality of openings to be directly dependent on the amount of liquid sprayed.

- the size of the valve and seat openings can be increased or multiple valve mountings could be used.

Landscapes

- Closures For Containers (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07109834A EP2000218A1 (fr) | 2007-06-07 | 2007-06-07 | Event à régulation automatique pour un récipient d'alimentation de peinture |

| ES08760690T ES2402594T3 (es) | 2007-06-07 | 2008-06-06 | Orificio de purga auto-regulable para recipiente de suministro de pintura |

| EP08760690A EP2160252B1 (fr) | 2007-06-07 | 2008-06-06 | Évent autorégulateur pour cuve d'alimentation en peinture |

| PCT/EP2008/057121 WO2008148887A1 (fr) | 2007-06-07 | 2008-06-06 | Évent autorégulateur pour cuve d'alimentation en peinture |

| CA002689229A CA2689229A1 (fr) | 2007-06-07 | 2008-06-06 | Event autoregulateur pour cuve d'alimentation en peinture |

| US12/663,238 US20100288772A1 (en) | 2007-06-07 | 2008-06-06 | Self regulating vent for a paint supply vessel |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07109834A EP2000218A1 (fr) | 2007-06-07 | 2007-06-07 | Event à régulation automatique pour un récipient d'alimentation de peinture |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP2000218A1 true EP2000218A1 (fr) | 2008-12-10 |

Family

ID=38459585

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07109834A Withdrawn EP2000218A1 (fr) | 2007-06-07 | 2007-06-07 | Event à régulation automatique pour un récipient d'alimentation de peinture |

| EP08760690A Active EP2160252B1 (fr) | 2007-06-07 | 2008-06-06 | Évent autorégulateur pour cuve d'alimentation en peinture |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08760690A Active EP2160252B1 (fr) | 2007-06-07 | 2008-06-06 | Évent autorégulateur pour cuve d'alimentation en peinture |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20100288772A1 (fr) |

| EP (2) | EP2000218A1 (fr) |

| CA (1) | CA2689229A1 (fr) |

| ES (1) | ES2402594T3 (fr) |

| WO (1) | WO2008148887A1 (fr) |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| PT1835997E (pt) | 2004-12-16 | 2012-09-17 | Saint Gobain Abrasifs Sa | Copo de abastecimento de líquidos e conjunto de revestimento para pistolas pulverizadoras |

| US11040360B2 (en) | 2006-06-20 | 2021-06-22 | Saint-Gobain Abrasives, Inc. | Liquid supply assembly |

| PL2029285T3 (pl) | 2006-06-20 | 2013-04-30 | Saint Gobain Abrasives Inc | Zespół doprowadzający ciecz |

| GB0811050D0 (en) * | 2008-06-17 | 2008-07-23 | U Pol Ltd | A Connector for a gravity feed spray gun, a gravity feed spray gun and a method of preparing a spray paint |

| US9335198B2 (en) | 2011-05-06 | 2016-05-10 | Saint-Gobain Abrasives, Inc. | Method of using a paint cup assembly |

| US9586220B2 (en) | 2011-06-30 | 2017-03-07 | Saint-Gobain Abrasives, Inc. | Paint cup assembly |

| IN2014DN03195A (fr) * | 2011-10-27 | 2015-05-22 | Graco Minnesota Inc | |

| US10882064B2 (en) | 2011-12-30 | 2021-01-05 | Saint-Gobain Abrasives, Inc./Saint-Gobain Abrasifs | Convertible paint cup assembly with air inlet valve |

| US10857553B2 (en) | 2013-12-05 | 2020-12-08 | 3M Innovative Properties Company | Container for a spraying device |

| US9796492B2 (en) | 2015-03-12 | 2017-10-24 | Graco Minnesota Inc. | Manual check valve for priming a collapsible fluid liner for a sprayer |

| US10576490B2 (en) * | 2015-07-08 | 2020-03-03 | 3M Innovative Properties Company | Spray gun cups, receptacles, and methods of use |

| WO2017123714A1 (fr) | 2016-01-15 | 2017-07-20 | 3M Innovative Properties Company | Raccord fluidique à large embouchure pour pistolets pulvérisateurs tenus à la main |

| WO2017123709A1 (fr) | 2016-01-15 | 2017-07-20 | 3M Innovative Properties Company | Réservoirs de pistolet pulvérisateur, réceptacles, couvercles et procédés d'utilisation |

| US10689165B2 (en) | 2016-01-15 | 2020-06-23 | 3M Innovative Properties Company | Reservoir systems for hand-held spray guns and methods of use |

| US10688510B2 (en) * | 2016-01-15 | 2020-06-23 | 3M Innovative Properties Company | Spray gun cups, receptacles, and methods of use |

| US11040361B2 (en) | 2016-01-15 | 2021-06-22 | 3M Innovative Properties Company | Modular spray gun lid assemblies and methods of design and use |

| USD811525S1 (en) * | 2016-03-24 | 2018-02-27 | 3M Innovative Properties Company | Retention collar for spray gun cup |

| USD793530S1 (en) * | 2016-03-24 | 2017-08-01 | 3M Innovative Properties Company | Lid for spray gun cup |

| EP3402606B1 (fr) | 2016-01-15 | 2021-02-24 | 3M Innovative Properties Company | Système de raccord pour pistolets de pulvérisation portables |

| ITUB201653118U1 (it) | 2016-03-01 | 2017-09-01 | Cartotecnica Basic S N C Di Traverso Ruggero E C | Serbatoio di vernice a gravità per pistola di verniciatura |

| EP4316777A3 (fr) | 2017-07-14 | 2024-04-03 | 3M Innovative Properties Company | Ensemble de distribution de fluide pour pistolet de pulvérisation |

| IT201800009634A1 (it) * | 2018-10-19 | 2020-04-19 | Walmec Spa | Migliorato serbatoio per vernice |

| IT201800010567A1 (it) * | 2018-11-26 | 2020-05-26 | Walmec Spa | Serbatoio di prodotto spruzzabile per alimentare un aerografo |

| US11326830B2 (en) | 2019-03-22 | 2022-05-10 | Robert W. Jacobi | Multiple module modular systems for refrigeration |

| US20220234062A1 (en) | 2019-05-31 | 2022-07-28 | Graco Minnesota Inc. | Handheld fluid sprayer |

| JP1651759S (fr) * | 2019-07-04 | 2020-01-27 | ||

| CN212550094U (zh) * | 2019-12-23 | 2021-02-19 | 青岛汉柏塑料科技有限公司 | 喷枪液体贮存器封盖和喷枪液体贮存器 |

| USD971725S1 (en) | 2020-03-12 | 2022-12-06 | 3M Innovative Properties Company | Container lid |

| USD937968S1 (en) | 2020-03-12 | 2021-12-07 | 3M Innovative Properties Company | Container |

| CN111438020B (zh) * | 2020-04-22 | 2024-09-13 | 青岛汉柏塑料科技有限公司 | 贮存杯以及喷枪液体贮存器 |

| USD952097S1 (en) * | 2020-07-14 | 2022-05-17 | Yuyao Yufeng Scutcheon Plastic Factory | Paint spraying pot lid |

| USD1029185S1 (en) * | 2022-02-23 | 2024-05-28 | Huaian Hohear Tech. Co., Ltd. | Paint spraying system |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3858810A (en) * | 1973-07-31 | 1975-01-07 | Larry E Seeley | Spray paint container and attachment therefor |

| US3955720A (en) * | 1972-11-15 | 1976-05-11 | Malone David C | Low pressure dispensing apparatus with air pump |

| US4388997A (en) * | 1981-04-20 | 1983-06-21 | Champion Spark Plug Company | Vent for paint cups |

| WO2003006170A2 (fr) * | 2001-07-09 | 2003-01-23 | 3M Innovative Properties Company | Ensemble d'amenee de liquide |

| DE202004003376U1 (de) * | 2004-03-04 | 2005-07-14 | Sata Farbspritztechnik Gmbh & Co.Kg | Farbbechersystem für eine Farbspritzpistole |

| WO2005118151A1 (fr) * | 2004-01-16 | 2005-12-15 | Illinois Tool Works Inc. | Godet a peinture antistatique |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE491243A (fr) * | 1948-09-21 | |||

| US2788926A (en) * | 1954-12-17 | 1957-04-16 | Lester G Morrison | Paint cup |

| US3211324A (en) * | 1963-10-10 | 1965-10-12 | Raymond C Henery | Liner for paint receptacle of paint spray gun |

| US3990609A (en) * | 1976-03-12 | 1976-11-09 | Champion Spark Plug Company | Attachment for paint spray gun systems |

| US4796776A (en) * | 1987-02-19 | 1989-01-10 | Northland Aluminum Products, Inc. | Pressure cooker for microwave ovens |

| US5238140A (en) * | 1992-06-18 | 1993-08-24 | Maze David L | Medication storage and dispensing device |

| US5558846A (en) * | 1994-12-05 | 1996-09-24 | Ciba Geigy Corporation | Apparatus for disinfecting contact lenses having improved vent means |

| US6820824B1 (en) * | 1998-01-14 | 2004-11-23 | 3M Innovative Properties Company | Apparatus for spraying liquids, disposable containers and liners suitable for use therewith |

| US5944211A (en) * | 1997-08-26 | 1999-08-31 | Anchor Hocking Plastics/Plastics Inc. | Container system including an air evacuation valve |

| US6435426B1 (en) * | 1999-05-11 | 2002-08-20 | William H. Copp, Jr. | Floating gasket plate for paint cup on spray gun |

| US6235010B1 (en) * | 1999-08-06 | 2001-05-22 | Becton Dickinson And Company | Closed system specimen collection container |

| FR2859118B1 (fr) * | 2003-08-26 | 2007-03-09 | Michel Camilleri | Godet jetable a monter sur un pistolet pour la preparation, l'application et la conservation d'une peinture |

| US9079201B2 (en) * | 2010-01-22 | 2015-07-14 | Finishing Brands Holdings Inc. | Liquid supply system for a gravity feed spray device |

-

2007

- 2007-06-07 EP EP07109834A patent/EP2000218A1/fr not_active Withdrawn

-

2008

- 2008-06-06 ES ES08760690T patent/ES2402594T3/es active Active

- 2008-06-06 EP EP08760690A patent/EP2160252B1/fr active Active

- 2008-06-06 CA CA002689229A patent/CA2689229A1/fr not_active Abandoned

- 2008-06-06 US US12/663,238 patent/US20100288772A1/en not_active Abandoned

- 2008-06-06 WO PCT/EP2008/057121 patent/WO2008148887A1/fr active Application Filing

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3955720A (en) * | 1972-11-15 | 1976-05-11 | Malone David C | Low pressure dispensing apparatus with air pump |

| US3858810A (en) * | 1973-07-31 | 1975-01-07 | Larry E Seeley | Spray paint container and attachment therefor |

| US4388997A (en) * | 1981-04-20 | 1983-06-21 | Champion Spark Plug Company | Vent for paint cups |

| WO2003006170A2 (fr) * | 2001-07-09 | 2003-01-23 | 3M Innovative Properties Company | Ensemble d'amenee de liquide |

| WO2005118151A1 (fr) * | 2004-01-16 | 2005-12-15 | Illinois Tool Works Inc. | Godet a peinture antistatique |

| DE202004003376U1 (de) * | 2004-03-04 | 2005-07-14 | Sata Farbspritztechnik Gmbh & Co.Kg | Farbbechersystem für eine Farbspritzpistole |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2008148887A1 (fr) | 2008-12-11 |

| EP2160252A1 (fr) | 2010-03-10 |

| EP2160252B1 (fr) | 2013-01-09 |

| ES2402594T3 (es) | 2013-05-07 |

| US20100288772A1 (en) | 2010-11-18 |

| CA2689229A1 (fr) | 2008-12-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2000218A1 (fr) | Event à régulation automatique pour un récipient d'alimentation de peinture | |

| JP4477488B2 (ja) | スプレーガン用の適応型の袋状貯蔵器 | |

| EP1424135B1 (fr) | Pistolet pulvérisateur manuel et réservoir associé | |

| EP1954402B1 (fr) | Réservoir de liquide, ensemble de pulvérisation, et procédé d'utilisation associé | |

| AU2004315547B2 (en) | Fluid reservoir for a paint spray gun | |

| EP3651911B1 (fr) | Ensemble de distribution de fluide pour pistolet de pulvérisation | |

| US7175110B2 (en) | Manual spray gun and associated disposable cup | |

| US20040217201A1 (en) | Spray gun container | |

| AU2011202432B2 (en) | Discharge cap for bottle-like container | |

| EP2303466B1 (fr) | Connecteur pour un pistolet vaporisateur à alimentation par gravité, pistolet vaporisateur à alimentation par gravité, et procédé de préparation d une peinture vaporisée | |

| US20090200336A1 (en) | Elastomeric dispensing container | |

| EP0352348A1 (fr) | Dispositif déformable pour éjecter des matériaux retenus | |

| US20080135793A1 (en) | Closure for can filler port and can vent | |

| US10919676B2 (en) | Lid with ventilation system | |

| WO2022190691A1 (fr) | Récipient distributeur de fluide | |

| JP2004210351A (ja) | 液体注出容器 | |

| KR102136588B1 (ko) | 압력 개폐식 정량캡 | |

| CA1332591C (fr) | Contenant comprimable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20090611 |