EP1962016A2 - Burner plate - Google Patents

Burner plate Download PDFInfo

- Publication number

- EP1962016A2 EP1962016A2 EP20080101726 EP08101726A EP1962016A2 EP 1962016 A2 EP1962016 A2 EP 1962016A2 EP 20080101726 EP20080101726 EP 20080101726 EP 08101726 A EP08101726 A EP 08101726A EP 1962016 A2 EP1962016 A2 EP 1962016A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- combustion region

- burner plate

- combustion

- plate according

- burner

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/46—Details, e.g. noise reduction means

- F23D14/48—Nozzles

- F23D14/58—Nozzles characterised by the shape or arrangement of the outlet or outlets from the nozzle, e.g. of annular configuration

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/02—Premix gas burners, i.e. in which gaseous fuel is mixed with combustion air upstream of the combustion zone

- F23D14/04—Premix gas burners, i.e. in which gaseous fuel is mixed with combustion air upstream of the combustion zone induction type, e.g. Bunsen burner

- F23D14/08—Premix gas burners, i.e. in which gaseous fuel is mixed with combustion air upstream of the combustion zone induction type, e.g. Bunsen burner with axial outlets at the burner head

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/12—Radiant burners

- F23D14/16—Radiant burners using permeable blocks

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/46—Details, e.g. noise reduction means

- F23D14/48—Nozzles

- F23D14/56—Nozzles for spreading the flame over an area, e.g. for desurfacing of solid material, for surface hardening, or for heating workpieces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24C—DOMESTIC STOVES OR RANGES ; DETAILS OF DOMESTIC STOVES OR RANGES, OF GENERAL APPLICATION

- F24C3/00—Stoves or ranges for gaseous fuels

- F24C3/04—Stoves or ranges for gaseous fuels with heat produced wholly or partly by a radiant body, e.g. by a perforated plate

- F24C3/047—Ranges

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2203/00—Gaseous fuel burners

- F23D2203/10—Flame diffusing means

- F23D2203/105—Porous plates

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2900/00—Special features of, or arrangements for burners using fluid fuels or solid fuels suspended in a carrier gas

- F23D2900/14—Special features of gas burners

- F23D2900/14062—Special features of gas burners for cooking ranges having multiple flame rings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2900/00—Special features of, or arrangements for burners using fluid fuels or solid fuels suspended in a carrier gas

- F23D2900/14—Special features of gas burners

- F23D2900/14064—Burner heads of non circular shape

Definitions

- the invention relates to a burner plate for gas-fired appliances and a multi-circuit gas cooker with such a burner plate.

- EP 0 718 551 A2 is a radiant burner with a gas-permeable burner plate made of ceramic or metal for gas-fired appliances, especially for hobs or single cookers whose heating surface is made of glass ceramic, known in which the gas-permeable burner plate having regions with different gas permeability. Certain areas of the burner plate may not have gas permeability. The regions of the burner plate can be designed with different gas permeability as circular or annular and concentrically arranged zones or spirally extending. Certain regions of the burner plate can be designed with different gas permeability as circular cutouts or sectors and / or segments.

- the burner plate in particular for hobs or single cookers with a heating surface made of glass ceramic, in particular for infrared gas burners, has a first combustion region and a second combustion region, which can be controlled separately from each other.

- the first focal area is in circumferential Direction at least partially unevenly shaped, z. B. with n-fold rotational symmetry.

- the burner plate which is also designed in several parts, can produce a non-negligible heat output.

- the burner plate can be designed to be permeable to gas, for example through holes, pores, etc. In other areas, the burner plate does not need to be gas-permeable or to have little or less gas permeability.

- the burner plate is preferably designed as a ceramic.

- the second combustion region is at least partially unevenly formed in the circumferential direction.

- the combustion areas do not have to be of the same shape.

- the second combustion region at least partially surrounds the first combustion region, in particular if it completely surrounds it.

- At least one of the combustion region has an at least partially annular portion, at the inner and / or outer periphery at regular intervals further part (firing) areas of the same or regular shape join.

- the first firing region has a shape in which the further partial firing regions adjoin an outer circumference of the annular subregion.

- the annular portion may be closed or open.

- each of these partial regions is of the same shape; in the case of further partial regions of regular shape, for example, partial regions of different shapes may alternate regularly.

- the present invention is not limited to a regular arrangement.

- the annular portion is made oval or rectangular.

- the second combustion region has a basic shape similar to the first combustion region, possibly with different dimensions (length, width, angle, etc.), in particular if partial combustion regions adjoin an outer circumference of an annular subregion.

- the second combustion region has a basic shape that is complementary to the first combustion region at its inner circumference surrounding the first combustion region. It is advantageous if the first and the second combustion region together result in a substantially gapless, in particular annular, focal region.

- the partial firing regions adjoining the annular partial firing region are formed at least one firing region in the form of sectors, in particular angular sectors or ring segments.

- advantageously also other partial combustion areas adjoining the annular partial combustion area are possible, eg. In the form of subcircles (inter alia semicircles), parts of surfaces with sinusoidal edge, rectangles, so on.

- the multi-circuit gas cooker has such a burner plate, wherein the first combustion region is connected to at least one first heating circuit and the second combustion region is connected to at least one second heating circuit.

- FIG. 1 a burner plate 1 for gas-fired appliances, in particular for hobs or single cookers with a heating surface of glass ceramic (not shown), shown having a first combustion region 2, which completely covers an inner burner ring 3 to a center circle of radius R1, and a second Burning area 4, which completely covers an outer burner ring 5.

- the two combustion rings 3, 5 and combustion regions 2, 4 can be controlled separately from each other with gas.

- the two combustion rings 3, 5 can be designed as separate components or in one piece.

- the inner combustion region 2 is formed in the circumferential direction about the center M at least partially non-uniform, ie z. B. non-circular or annular, but rotationally symmetric (here with 6-fold rotational symmetry).

- the second combustion region 4 also has an at least partially non-uniform shape in the circumferential direction.

- the second, outer combustion region 4 at its inner circumference enclosing the first, inner combustion region 2 has a basic shape complementary to the first combustion region 2.

- the inner combustion region 2 has an inner annular Operabrenn Scheme 6 with thickness R2-R1, adjoin the outer periphery corresponding to radius R2 at regular intervals Operabrenn Schemee 7 in the form of angular sectors of height R3-R2.

- An inner circle with radius R1 of the combustion ring 3 thus does not serve as a focal region.

- the second combustion region 4 has complementary to an outer circumferential annular part (burning) area 8 of thickness R4-R3, on the inner circumference at regular intervals further part (burning) areas 9 in the form of angular sectors of height R2-R3 integrally connect.

- the inner burner ring 3 for example, in the outer burner ring 5 are suitably used.

- the angular sectors 7, 9 fit into one another and together form a ring-shaped combustion region of thickness (R3-R2), if necessary with different focal intensity, when the control or gas supply is common.

- the inner and outer combustion regions 2, 4 together form a substantially continuous or continuous combustion region in annular form with thickness R4-R1, possibly with different focal intensity or a corresponding, substantially continuous heat distribution at the bottom of the pot.

- the second, outer burner ring 5 can be switched off; the first, inner burner ring 3 then operates as in a single-circuit gas burner.

- the heating power and - characteristic of a dual-circuit or multi-circuit gas burner can be adjusted easily, evenly and sensitively.

- a heated usable area of an internal burner inner combustion area 2 can be expanded further outward in comparison to an internal burner with a ring-shaped or circular combustion area, which allows a more uniform and sensitive heating of cookware even when operating only with an internal burner.

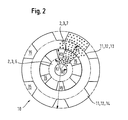

- FIG. 2 shows a further burner plate 10, in which the inner combustion region 2 or torch 3 equal to that FIG. 1 is constructed.

- the outer combustion region 11 or combustion ring 12 now has a basic shape similar to the first combustion region 2, namely centrally without combustion region, with an inner annular combustion region 13 of thickness R5-R3 and at its outer circumference at regular intervals circumferentially integrally then further partial combustion regions 14 in Shape of sectors of height R6-R5 with parallel to each other Pages.

- the sectors 14 may also be considered as ring cutouts.

- the first combustion ring 3 may be circular, the second combustion ring 12 annular.

- the heating power and - characteristic of a dual-circuit or multi-circuit gas burner can be adjusted easily, evenly and sensitively.

- z. B. may be an outer contour of the inner combustion region and / or combustion ring instead of angular sectors in the circumferential direction in waveform, z. B. as a sinusoidal wave, or as a result of hemisphere, etc.

- multi-circuit burners can be used with more than two combustion rings.

- the outer periphery of a burner plate needs not to be circular, for example, oval or rectangular outer contours are possible.

- the maximum outer circumference of a combustion region also need not be circular, for example, oval or rectangular shapes are possible.

- the burner plate is not limited to gas burners, but can also be used for other hobs.

- the inside and outside of the combustion areas may be non-uniform, including angular symmetry, contoured.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Gas Burners (AREA)

- Surface Treatment Of Glass (AREA)

Abstract

Description

Die Erfindung betrifft ein Brennerplatte für gasbeheizte Geräte und einen Mehrkreis-Gaskocher mit einer solchen Brennerplatte.The invention relates to a burner plate for gas-fired appliances and a multi-circuit gas cooker with such a burner plate.

Beispielsweise aus

Es ist die Aufgabe der Erfindung, eine Möglichkeit zur einfachen und gleichmäßigen Hitzeverteilung bei Mehrkreis-Gasbrennern bereitzustellen.It is the object of the invention to provide a possibility for simple and uniform heat distribution in multi-circuit gas burners.

Die Aufgabe wird durch eine Brennerplatte nach Anspruch 1 und einen Mehrkreis-Gaskocher nach Anspruch 10 gelöst. Vorteilhafte Ausgestaltungen sind insbesondere den Unteransprüchen entnehmbar.The object is achieved by a burner plate according to claim 1 and a multi-circuit gas cooker according to

Die Brennerplatte, insbesondere für Kochfelder oder Einzelkochstellen mit einer Heizfläche aus Glaskeramik, insbesondere für Infrarot-Gasbrenner, weist einen ersten Brennbereich und einen zweiten Brennbereich auf, die getrennt voneinander ansteuerbar sind. Der erste Brennbereich ist in umlaufender Richtung zumindest teilweise ungleichmäßig geformt, z. B. mit n-zähliger Rotationssymmetrie. An einem Brennbereich kann die, auch mehrstückig ausgeführte, Brennerplatte, eine nicht vernachlässigbare Heizleistung erzeugen. Am Brennbereich kann die Brennerplatte beispielsweise durch Löcher, Poren usw. gasdurchlässig gestaltet sein. In anderen Bereichen braucht die Brennerplatte nicht gasdurchlässig oder nur wenig oder weniger gasdurchlässig zu sein.The burner plate, in particular for hobs or single cookers with a heating surface made of glass ceramic, in particular for infrared gas burners, has a first combustion region and a second combustion region, which can be controlled separately from each other. The first focal area is in circumferential Direction at least partially unevenly shaped, z. B. with n-fold rotational symmetry. At a combustion area, the burner plate, which is also designed in several parts, can produce a non-negligible heat output. At the combustion area, the burner plate can be designed to be permeable to gas, for example through holes, pores, etc. In other areas, the burner plate does not need to be gas-permeable or to have little or less gas permeability.

Die Brennerplatte ist vorzugsweise als Keramik ausgeführt.The burner plate is preferably designed as a ceramic.

Vorteilhafterweise weist ist der zweite Brennbereich in umlaufender Richtung zumindest teilweise ungleichmäßig geformt. Die Brennbereiche müssen nicht von gleicher Form sein.Advantageously, the second combustion region is at least partially unevenly formed in the circumferential direction. The combustion areas do not have to be of the same shape.

Es ist vorteilhaft, wenn der zweite Brennbereich den ersten Brennbereich zumindest teilweise umgibt, insbesondere, wenn er ihn vollständig umgibt.It is advantageous if the second combustion region at least partially surrounds the first combustion region, in particular if it completely surrounds it.

Es ist vorteilhaft, wenn zumindest einer der Brennbereich einen zumindest teilweise ringförmigen Teilbereich aufweist, an dessen Innen- und / oder Außenumfang sich in regelmäßigen Abständen weitere Teil(brenn)bereiche gleicher oder regelmäßiger Form anschließen. Es ist dann insbesondere vorteilhaft, wenn der erste Brennbereich eine Form aufweist, bei der die weiteren Teilbrennbereiche sich an einem Außenumfang des ringförmigen Teilbereich anschließen. Der ringförmige Teilbereich kann geschlossen oder offen sein. Bei weiteren Teilbereichen gleicher Form ist jeder dieser Teilbereiche von gleicher Form, bei weiteren Teilbereichen regelmäßiger Form können sich beispielsweise Teilbereiche unterschiedlicher Form regelmäßig abwechseln. Jedoch ist die vorliegende Erfindung nicht auf eine regelmäßige Anordnung beschränkt.It is advantageous if at least one of the combustion region has an at least partially annular portion, at the inner and / or outer periphery at regular intervals further part (firing) areas of the same or regular shape join. It is particularly advantageous if the first firing region has a shape in which the further partial firing regions adjoin an outer circumference of the annular subregion. The annular portion may be closed or open. In the case of further partial regions of the same shape, each of these partial regions is of the same shape; in the case of further partial regions of regular shape, for example, partial regions of different shapes may alternate regularly. However, the present invention is not limited to a regular arrangement.

Alternativ ist der ringförmige Teilbereich oval oder rechteckig ausgeführt.Alternatively, the annular portion is made oval or rectangular.

Es ist vorteilhaft, wenn der zweite Brennbereich eine zum ersten Brennbereich gleichartige Grundform, ggf. mit unterschiedlichen Dimensionierungen (Länge, Breite, Winkel usw.), aufweist, insbesondere, wenn Teilbrennbereiche sich an einem Außenumfang eines ringförmigen Teilbereichs anschließen.It is advantageous if the second combustion region has a basic shape similar to the first combustion region, possibly with different dimensions (length, width, angle, etc.), in particular if partial combustion regions adjoin an outer circumference of an annular subregion.

In einer alternativen Ausgestaltung ist es vorteilhaft, wenn der zweite Brennbereich an seinem den ersten Brennbereich umschließenden Innenumfang eine zum ersten Brennbereich komplementäre Grundform aufweist. Es ist dann vorteilhaft, wenn der erste und der zweite Brennbereich zusammen einen im wesentlichen lückenlosen, insbesondere ringförmigen, Brennbereich ergeben.In an alternative embodiment, it is advantageous if the second combustion region has a basic shape that is complementary to the first combustion region at its inner circumference surrounding the first combustion region. It is advantageous if the first and the second combustion region together result in a substantially gapless, in particular annular, focal region.

Es ist vorteilhaft, wenn die sich am ringförmigen Teilbrennbereich anschließenden Teilbrennbereiche zumindest einem Brennbereich in Form von Sektoren, insbesondere Winkelsektoren oder Ringsegmenten, ausgebildet sind. In einer Alternative sind vorteilhafterweise auch andere am ringförmigen Teilbrennbereich anschließende Teilbrennbereiche möglich, z. B. in Form von Teilkreisen (u. a. Halbkreisen), Teilen von Flächen mit sinusförmigem Rand, Rechtecken, uns so weiter.It is advantageous if the partial firing regions adjoining the annular partial firing region are formed at least one firing region in the form of sectors, in particular angular sectors or ring segments. In an alternative, advantageously also other partial combustion areas adjoining the annular partial combustion area are possible, eg. In the form of subcircles (inter alia semicircles), parts of surfaces with sinusoidal edge, rectangles, so on.

Der Mehrkreis-Gaskocher weist eine solche Brennerplatte auf, wobei der erste Brennbereich an zumindest einen ersten Heizkreis angeschlossen ist und der zweite Brennbereich an zumindest einem zweiten Heizkreis angeschlossen ist.The multi-circuit gas cooker has such a burner plate, wherein the first combustion region is connected to at least one first heating circuit and the second combustion region is connected to at least one second heating circuit.

In der folgenden Beschreibung wird die Erfindung anhand von Ausführungsbeispielen schematisch genauer dargestellt. Dabei werden gleiche Bauteile durchgängig mit gleichen Bezugszeichen versehen.

- Figur 1

- zeigt in Draufsicht eine erste Ausführungsform einer Brennerplatte;

- Figur 2

- zeigt in Draufsicht eine zweite Ausführungsform einer Brennerplatte.

- FIG. 1

- shows in plan view a first embodiment of a burner plate;

- FIG. 2

- shows in plan view a second embodiment of a burner plate.

In

Der innere Brennbereich 2 ist in umlaufender Richtung um den Mittelpunkt M zumindest teilweise ungleichförmig ausgebildet, also z. B. nicht kreis- oder ringförmig, aber rotationssymmetrisch (hier mit 6-zähliger Rotationssymmetrie). Auch der zweite Brennbereich 4 weist eine in umlaufender Richtung zumindest teilweise ungleichmäßige Form auf.The inner combustion region 2 is formed in the circumferential direction about the center M at least partially non-uniform, ie z. B. non-circular or annular, but rotationally symmetric (here with 6-fold rotational symmetry). The second combustion region 4 also has an at least partially non-uniform shape in the circumferential direction.

Dazu weist der zweite, äußere Brennbereich 4 an seinem den ersten, inneren Brennbereich 2 umschließenden Innenumfang eine zum ersten Brennbereich 2 komplementäre Grundform auf.For this purpose, the second, outer combustion region 4 at its inner circumference enclosing the first, inner combustion region 2 has a basic shape complementary to the first combustion region 2.

Speziell weist der innere Brennbereich 2 einen inneren ringförmigen Teilbrennbereich 6 mit Dicke R2-R1 auf, an dessen Außenumfang entsprechend Radius R2 in regelmäßigen Abständen Teilbrennbereiche 7 in Form von Winkelsektoren der Höhe R3-R2 anschließen. Ein innerer Kreis mit Radius R1 des Brennrings 3 dient somit nicht als Brennbereich.Specifically, the inner combustion region 2 has an inner annular Teilbrennbereich 6 with thickness R2-R1, adjoin the outer periphery corresponding to radius R2 at regular intervals Teilbrennbereiche 7 in the form of angular sectors of height R3-R2. An inner circle with radius R1 of the combustion ring 3 thus does not serve as a focal region.

Der zweite Brennbereich 4 weist komplementär dazu einen äußeren umlaufend ringförmigen Teil(brenn)bereich 8 der Dicke R4-R3 auf, an deren Innenumfang in regelmäßigen Abständen weitere Teil(brenn)bereiche 9 in Form von Winkelsektoren der Höhe R2-R3 einstückig anschließen. In zweistückiger Ausführung der Brennerplatte 10 kann der innere Brennring 3 beispielsweise in den äußeren Brennring 5 passend eingesetzt werden. Die Winkelsektoren 7, 9 passen ineinander und bilden zusammen bei gemeinsamer Ansteuerung bzw. Gaszufuhr einen ringförmigen Brennbereich der Dicke (R3-R2), ggf. mit unterschiedlicher Brennstärke.The second combustion region 4 has complementary to an outer circumferential annular part (burning) area 8 of thickness R4-R3, on the inner circumference at regular intervals further part (burning) areas 9 in the form of angular sectors of height R2-R3 integrally connect. In two-piece execution of the Burner

Bei gemeinsamer Ansteuerung bzw. Gaszufuhr bilden der innere und der äußere Brennbereich 2, 4 zusammen einen im wesentlichen lückenlosen bzw. kontinuierlichen Brennbereich in Ringform mit Dicke R4 - R1, ggf. mit unterschiedlicher Brennstärke bzw. eine entsprechende im wesentlichen kontinuierliche Wärmeverteilung am Topfboden. Üblicherweise kann bei einem Zweikreis-Gasbrenner der zweite, äußere Brennring 5 abgeschaltet werden; der erste, innere Brennring 3 arbeitet dann wie bei einem Einkreis-Gasbrenner.In the case of a common activation or gas supply, the inner and outer combustion regions 2, 4 together form a substantially continuous or continuous combustion region in annular form with thickness R4-R1, possibly with different focal intensity or a corresponding, substantially continuous heat distribution at the bottom of the pot. Usually, in a dual-circuit gas burner, the second, outer burner ring 5 can be switched off; the first, inner burner ring 3 then operates as in a single-circuit gas burner.

Durch diese Ausführungsform kann die Heizleistung und - charakteristik eines Zweikreis- oder Mehrkreis-Gasbrenners einfach, gleichmäßig und empfindlich eingestellt werden. Insbesondere kann eine beheizte Nutzfläche eines Innenbrenners (innerer Brennbereich 2) im Vergleich zu einem Innenbrenner mit ring- oder kreisförmigem Brennbereich weiter nach außen ausgedehnt werden, was eine gleichmäßigere und empfindlichere Erwärmung von Kochgeschirr auch beim Betrieb nur mit einem Innenbrenner ermöglicht.By this embodiment, the heating power and - characteristic of a dual-circuit or multi-circuit gas burner can be adjusted easily, evenly and sensitively. In particular, a heated usable area of an internal burner (inner combustion area 2) can be expanded further outward in comparison to an internal burner with a ring-shaped or circular combustion area, which allows a more uniform and sensitive heating of cookware even when operating only with an internal burner.

Bei gleichzeitigem Betrieb der beiden Brennbereiche 2, 11 weisen diejenigen Bereiche 15 (von denen hier nur einige exemplarisch mit Bezugsziffern versehen sind) der Brennringe 3, 12 keine oder keine wesentliche Flammenentwicklung auf, die sich zwischen den jeweiligen weiteren, sektorförmigen Teilbrennbereichen 7, 14 befinden. Der erste Brennring 3 kann kreisförmig ausgebildet sein, der zweite Brennring 12 ringförmig.With simultaneous operation of the two combustion regions 2, 11, those regions 15 (of which only a few are provided by way of example with reference numerals) of the combustion rings 3, 12 have no or no significant development of flame, which are located between the respective further, sector-shaped partial combustion regions 7, 14 , The first combustion ring 3 may be circular, the second combustion ring 12 annular.

Auch durch diese Ausführungsform kann die Heizleistung und - charakteristik eines Zweikreis- oder Mehrkreis-Gasbrenners einfach, gleichmäßig und empfindlich eingestellt werden.Also, by this embodiment, the heating power and - characteristic of a dual-circuit or multi-circuit gas burner can be adjusted easily, evenly and sensitively.

Durch diese Anordnung erhöht sich im Vergleich zu herkömmlichen Brennringen als auch zu denen der Ausführungsform aus

Selbstverständlich ist die Erfindung nicht auf die oben beschriebenen Ausführungsbeispiele beschränkt. So können hier als ohne wesentlich Brennleistung beschriebene Bereiche eine Brennleistung erzeugen, die dann aber geringer ist als diejenige der hier beschriebenen Brennbereiche. Auch können andere Formen verwendet werden: z. B. kann eine äußere Kontur des inneren Brennbereichs und / oder Brennrings statt Winkelsektoren in Umlaufrichtung in Wellenform vorliegen, z. B. als sinusförmige Welle, oder als Folge von Halbkugel usw.. Auch können Mehrkreisbrenner mit mehr als zwei Brennringen verwendet werden. Ferner braucht der äußere Umfang einer Brennerplatte nicht kreisförmig zu sein, es sind beispielsweise auch ovale oder rechteckige Außenkonturen möglich. Der maximale äußere Umfang eines Brennbereichs braucht ebenfalls nicht kreisförmig zu sein, es sind beispielsweise ovale oder rechteckige Formen möglich. Auch ist die Brennerplatte nicht auf Gasbrenner beschränkt, sondern kann auch für andere Kochfelder verwendet werden. Zudem können auch Innen- und Außenseite der Brennbereiche ungleichförmig, einschließlich winkelsymmetrisch, konturiert sein.Of course, the invention is not limited to the embodiments described above. Thus, here described as areas without significant burning power produce a burning power, which is then less than that of the combustion areas described here. Also other forms can be used: z. B. may be an outer contour of the inner combustion region and / or combustion ring instead of angular sectors in the circumferential direction in waveform, z. B. as a sinusoidal wave, or as a result of hemisphere, etc. Also, multi-circuit burners can be used with more than two combustion rings. Further, the outer periphery of a burner plate needs not to be circular, for example, oval or rectangular outer contours are possible. The maximum outer circumference of a combustion region also need not be circular, for example, oval or rectangular shapes are possible. Also, the burner plate is not limited to gas burners, but can also be used for other hobs. In addition, the inside and outside of the combustion areas may be non-uniform, including angular symmetry, contoured.

- 11

- Brennerplatteburner plate

- 22

- innerer Brennbereichinternal focal area

- 33

- innerer Brennringinner focal ring

- 44

- äußerer Brennbereichouter burning area

- 55

- äußerer Brennringouter ring

- 66

- innerer ringförmiger Teilbrennbereichinner annular part burning area

- 77

- innerer winkelsektorähnlicher Teilbrennbereichinner angular sector-like partial burning area

- 88th

- äußerer ringförmiger Teilbrennbereichouter annular partial burning area

- 99

- äußerer winkelsektorähnlicher Teilbrennbereichouter angle sector-like partial burning area

- 1010

- Brennerplatteburner plate

- 1111

- äußerer Brennbereichouter burning area

- 1212

- äußerer Brennringouter ring

- 1313

- innerer ringförmiger Brennbereichinner annular burning area

- 1414

- äußerer sektorähnlicher Teilbrennbereichouter sector-like partial burning area

- R1R1

- Radiusradius

- R2R2

- Radiusradius

- R3R3

- Radiusradius

- R4R4

- Radiusradius

- R5R5

- Radiusradius

- R6R 6

- Radiusradius

Claims (10)

dadurch gekennzeichnet, dass

der erste Brennbereich (2) eine in umlaufender Richtung zumindest teilweise ungleichmäßige Form aufweist.Burner plate (1, 10), in particular for hobs or single hobs with a heating surface of glass ceramic for gas-fired appliances, wherein the burner plate (1, 10) a first combustion region (2) and a second combustion region (4, 11), which are controlled separately , having,

characterized in that

the first combustion region (2) has an at least partially non-uniform shape in the circumferential direction.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200710008895 DE102007008895A1 (en) | 2007-02-23 | 2007-02-23 | burner plate |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1962016A2 true EP1962016A2 (en) | 2008-08-27 |

| EP1962016A3 EP1962016A3 (en) | 2015-05-27 |

Family

ID=39427712

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08101726.1A Withdrawn EP1962016A3 (en) | 2007-02-23 | 2008-02-19 | Burner plate |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1962016A3 (en) |

| DE (1) | DE102007008895A1 (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202014101097U1 (en) * | 2014-03-11 | 2015-06-12 | Ulrich Dreizler | Burner with a surface combustion |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0718551A2 (en) | 1994-12-20 | 1996-06-26 | Schott Glaswerke | Radiant burner with a gas-permeable burner plate |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US434258A (en) * | 1890-08-12 | Burner for gas or vapor stoves | ||

| US3606612A (en) * | 1969-10-20 | 1971-09-20 | Columbia Gas Syst | Gas burner and control |

| NL176301C (en) * | 1974-08-24 | Schwank Gmbh | APPLIANCE WITH AT LEAST ONE GAS BURNER FOR A HOB. | |

| AT378845B (en) * | 1979-06-06 | 1985-10-10 | Nibelle Pierre Dkfm | COOKING AREA FOR A GAS STOVE |

| DE3728466A1 (en) * | 1987-08-26 | 1989-03-09 | Ego Elektro Blanc & Fischer | COOKER |

| DE4130337C2 (en) * | 1991-09-12 | 2002-05-02 | Ego Elektro Blanc & Fischer | Method for operating an electric heating unit and electric heating unit |

| JP3624310B2 (en) * | 2000-07-25 | 2005-03-02 | アタム技研株式会社 | Gas combustion equipment |

| DE10251548A1 (en) * | 2002-11-05 | 2004-05-19 | Cramer Sr, S.R.O. | Performance-optimized radiation burner |

-

2007

- 2007-02-23 DE DE200710008895 patent/DE102007008895A1/en not_active Withdrawn

-

2008

- 2008-02-19 EP EP08101726.1A patent/EP1962016A3/en not_active Withdrawn

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0718551A2 (en) | 1994-12-20 | 1996-06-26 | Schott Glaswerke | Radiant burner with a gas-permeable burner plate |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1962016A3 (en) | 2015-05-27 |

| DE102007008895A1 (en) | 2008-08-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19813691C1 (en) | Hob for gas cooker | |

| DE10012578C2 (en) | hob | |

| DE10315343A1 (en) | Gas burner used for cooking, includes burner main body arranged in interior chamber formed by cover and burner ring such that outer diameter of cover is larger than inner diameter of burner ring | |

| DE102005032980A1 (en) | Combustion chamber assembly for an evaporator burner | |

| EP0718551A2 (en) | Radiant burner with a gas-permeable burner plate | |

| DE3433880A1 (en) | Cooking hob | |

| EP1962016A2 (en) | Burner plate | |

| DE69206501T2 (en) | Infrared radiation burner for ceramic hob. | |

| DE29805620U1 (en) | Hob with a gas burner | |

| WO2014166807A1 (en) | Pot/pan support, pot/pan support arrangement and gas cooking point | |

| DE3018794C2 (en) | Gas stove with a heat transferring plate and a radiant burner | |

| DE19861078A1 (en) | Gas cooker with glass plate uses subplate blower to promote secondary air to burner flame area plus collector trough formed between raised plate rim and plate flat as pan tip-over guard. | |

| DE19505470A1 (en) | Arrangement for fixing and centring pot support on atmospheric gas burner, esp. on a glass ceramic cooking zone | |

| DE102011017683B4 (en) | Pan supports and gas hob | |

| DE69518939T2 (en) | Cooking hob with positionable gas burner | |

| DE102007021939A1 (en) | hob | |

| DE19844551C2 (en) | Gas cooker | |

| DE102014208409A1 (en) | Radiator for a cooking appliance and cooking appliance with a radiator | |

| DE102018205970A1 (en) | Radiator for a cooking appliance and cooking appliance | |

| EP2473784B1 (en) | Gas-burner arrangement and gas cooking point | |

| CH691756A5 (en) | Means for supporting vaulted cooking pans. | |

| DE202011003179U1 (en) | kiln | |

| EP1833281B1 (en) | Hob with ceramic cooking plates | |

| AT396173B (en) | COOKING POINT | |

| WO2002016831A1 (en) | Gas radiant burner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: OBERHOMBURG, MARTIN Inventor name: HACOHEN, JOSEPH Inventor name: MASTIO, EMMANUEL Inventor name: CLAUSS, STEPHANE Inventor name: CONRAT, JUAN-IGNACIO |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BSH HAUSGERAETE GMBH |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F24C 3/06 20060101ALI20150420BHEP Ipc: F23D 14/56 20060101ALI20150420BHEP Ipc: F23D 14/08 20060101ALI20150420BHEP Ipc: F23D 14/58 20060101ALI20150420BHEP Ipc: F23D 14/16 20060101AFI20150420BHEP |

|

| 17P | Request for examination filed |

Effective date: 20151127 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: RS Extension state: BA Extension state: MK Extension state: AL |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20170901 |