EP1924751B1 - Corps d'armature realise en plastique renforce par fibres - Google Patents

Corps d'armature realise en plastique renforce par fibres Download PDFInfo

- Publication number

- EP1924751B1 EP1924751B1 EP06791978A EP06791978A EP1924751B1 EP 1924751 B1 EP1924751 B1 EP 1924751B1 EP 06791978 A EP06791978 A EP 06791978A EP 06791978 A EP06791978 A EP 06791978A EP 1924751 B1 EP1924751 B1 EP 1924751B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- reinforcing

- reinforcing body

- fibers

- rods

- reinforcing rods

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C5/00—Reinforcing elements, e.g. for concrete; Auxiliary elements therefor

- E04C5/07—Reinforcing elements of material other than metal, e.g. of glass, of plastics, or not exclusively made of metal

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C5/00—Reinforcing elements, e.g. for concrete; Auxiliary elements therefor

- E04C5/01—Reinforcing elements of metal, e.g. with non-structural coatings

- E04C5/02—Reinforcing elements of metal, e.g. with non-structural coatings of low bending resistance

- E04C5/04—Mats

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C5/00—Reinforcing elements, e.g. for concrete; Auxiliary elements therefor

- E04C5/01—Reinforcing elements of metal, e.g. with non-structural coatings

- E04C5/06—Reinforcing elements of metal, e.g. with non-structural coatings of high bending resistance, i.e. of essentially three-dimensional extent, e.g. lattice girders

- E04C5/0604—Prismatic or cylindrical reinforcement cages composed of longitudinal bars and open or closed stirrup rods

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C5/00—Reinforcing elements, e.g. for concrete; Auxiliary elements therefor

- E04C5/16—Auxiliary parts for reinforcements, e.g. connectors, spacers, stirrups

- E04C5/162—Connectors or means for connecting parts for reinforcements

- E04C5/166—Connectors or means for connecting parts for reinforcements the reinforcements running in different directions

Definitions

- the present invention relates to a reinforcing body for buildings, preferably for structures made of concrete materials or other hydraulically setting materials, which may in particular be mixed with other materials, such as soil materials, according to the preamble of claim 1. It comprises several, by connecting means at joints Reinforcing bars connected to each other and each made of fiber-reinforced plastics.

- the individual reinforcing rods can have any lengths and cross-sectional shapes as well as arbitrarily shaped end regions.

- the reinforcing rods have a round, in particular at least approximately circular cross-section and an at least substantially rectilinear longitudinal alignment.

- reinforcing bodies are well known. They are used to increase the mechanical strength, in particular to increase the tensile strength of concrete structures. Concrete is a major component of many structures, such as buildings or bridges. However, in order to be able to withstand the loads occurring during use, reinforcing struts that transmit tensile forces, in particular, must be embedded in the concrete as reinforcement or reinforcement. Reinforcing bars or reinforcing bodies made of steel have proved to be suitable reinforcement of concrete structures over many years.

- Steel reinforcements can corrode in situations where conditions of use are particularly severe, especially in humid or chemically aggressive environments.

- the corrosion of the steel reinforcement leads to a reduction of the adhesion forces or to a deterioration of the bedding between steel and concrete, which results in cracks and spalling of the concrete.

- This not only causes an ugly appearance of the affected buildings, sendern the corrosion of the steel reinforcements can eventually lead to weakening and eventually even to the final collapse of the building, which means a great threat.

- repair and maintenance costs are significantly increased to avoid further dangers.

- FRP-rebar Fiber Reinforced Plastic

- Fiber-reinforced plastics are fiber composites in which the plastics are combined with fibers made of a different material in order to obtain positive synergy effects and improved in the desired direction, in particular mechanically improved properties of the plastic.

- fibers for example, glass fibers can be used, which are preferably embedded in the longitudinal direction of a rod profile with so-called unidirectional fiber orientation in the plastic.

- a plurality of parallel oriented fibers which may for example have a diameter of 10 to 30 microns, is thus surrounded by a matrix of plastic resin.

- the fibers give the composite its high strength in the longitudinal direction, while the resin matrix serves to fix the fibers in their position while protecting them from harmful influences.

- reinforcing bodies of the type mentioned at the beginning are also known in particular from fiber-reinforced plastics.

- wires in particular conventional so-called Rödeldrähte, are often used, which in turn are susceptible to corrosion and can lead to the problems mentioned.

- these wire connections represent only a temporary transport and mounting backup, whereas they can no longer make a significant contribution to increasing the tensile, shear and shear forces of the concrete body after curing of the concrete.

- Such reinforcing bodies with reinforcing bars connected by wire are known, for example, from the document WO 01/26974 A2 known.

- Object of the present invention is therefore to provide a structurally simple reinforcing body of the type mentioned, in which the individual reinforcing bars in a simple and efficient manner are joined together, so that a very high strength and at the same time a cost-effective production is made possible.

- the connecting fibers embedded in a plastic matrix are wound several times around the reinforcing rods at the connecting points, the connecting fibers being wound around the reinforcing rods in such a way that a tensile or compressive load exerted transversely to the longitudinal axis of a first reinforcing rod

- a joining force S is achieved longitudinally of a second reinforcing bar for a single joint, satisfying the formula S> 0.3 * A S * R B , where A S is the cross-sectional area of the second reinforcing bar and R B is the allowable operating stress of the second reinforcing bar.

- the main advantage lies in the fact that in a surprisingly simple manner, a high-strength, in particular immovable or positionally stable connection of the individual reinforcing bars is obtained with each other, which can be produced with relatively low manufacturing complexity and therefore at low cost.

- the reinforcing bars are connected to each other at the junctions by the multiple wrapping and subsequent curing particularly strong, so that a high-strength reinforcing body is obtained, which ensures an optimal increase in the mechanical strength of a concrete structure provided therewith.

- Extremely high connection forces which are up to 5000 N for reinforcing bars with a diameter of 6 mm, are already achieved at each individual connection point.

- Such high-strength and at the same time exceedingly compact connections of the reinforcing bars thus basically fulfill the same requirements as welding in reinforcing bodies made of steel.

- connection of the reinforcing bars to each other becomes considerably stronger than is possible with the use of cable ties or wires.

- the connecting means used according to the invention are in turn formed by fiber-reinforced plastic, which may have connection fibers of any type, any length, any diameter and any arrangement.

- the connecting fibers are wound in different directions or in different orientations about one connection point.

- the connecting fibers are at a cross-shaped joint both 45 ° to the left and 45 ° to the right inclined around the intersection. In this way, a particularly stable connection is obtained.

- the connecting fibers on a reinforcing bar or on both reinforcing bars cross each other at one point or at two points.

- the strength of the connection can be increased again.

- the connecting fibers comprise only fibers of the same kind.

- the connecting fibers and / or the plastic of the plastic matrix at the connecting points in each case consist of the same material as the fibers or the plastic in the reinforcing rods.

- the production engineering effort can be kept particularly low.

- the reinforcing bars have an outside surface profiling, which may preferably be formed in the form of ribs or a screw or a thread.

- non-uniform profilings for example roughened surfaces, may also be provided by resin-embedded sand grains in the form of a breading in order to increase the bond forces or to improve the bedding.

- the connecting means can be attached particularly easily.

- the reinforcing bars can also be arranged in any other orientations and / or at different angles.

- the reinforcing rods are arranged at least substantially two-dimensionally in the form of a mat.

- the individual reinforcing bars can lie one above the other in two planes and thus form a grid which is in particular rectangular.

- the reinforcing body according to the invention can be used in the desired size particularly well in flat building elements, for example in ceilings or walls. It is particularly advantageous in this case that all reinforcing bars can be embodied in a straight line, with a first group of reinforcing bars extending flat in a first plane and a second group of reinforcing bars likewise extending flat in a second plane parallel to the first plane runs. A deformation of individual reinforcing bars is not required, so that even fully hardened reinforcing bars can be particularly easily, quickly and connected to one another with the desired high strength.

- the grout bars may also form a three-dimensional reinforcing body, in particular a reinforcing cage, a reinforcing pile or a trellis or in particular three-legged or administratgurtigen lattice girder.

- additional stiffening rods can be provided, which extend at an angle oblique to the preferably rectangularly arranged reinforcing bars.

- a particularly versatile usability of the reinforcing body according to the invention can be achieved in that at least individual reinforcing bars are executed in sections or completely bent.

- the bends can also be designed so narrow or with such a small bending radius that the thus partially bent reinforcing bars are quasi angled.

- a plurality of reinforcing rods are formed completely bent into a circle, which are connected inside and / or outside with a plurality of preferably at a right angle thereto and at least approximately rectilinearly extending reinforcing bars are connected to a tubular reinforcing body, for example, used as a pile reinforcement can be.

- a tubular reinforcing body for example, used as a pile reinforcement

- a plurality of reinforcing bars are only bent angularly in sections and formed in the shape of a quadrilateral, in particular a rectangle, the inside and / or outside with a plurality of preferably at a right angle thereto arranged and at least approximately rectilinearly extending reinforcing bars to a cuboid reinforcing body are connected. Also, it is possible to perform the inside and / or outside extending reinforcing bars bent, so that a reinforcing body with a total curved. Course, in particular in the form of a grid arc is obtained.

- the reinforcing bodies are factory-prefabricated such that the plastic matrix is completely cured with the connecting fibers embedded therein.

- the reinforcing bodies according to the invention come in a completely rigid state to the construction site where they are integrated into the structure or in the concrete.

- the connections of the reinforcing bars are performed by means of pliers-like machines, which are arranged in large numbers, preferably in a common production area and at the same time produce a correspondingly large number, preferably all, of a reinforcing body.

- the reinforcing bodies may also be designed as a prepreg, the plastic matrix having the connecting fibers embedded therein being pre-cured only to a certain extent in such a way that a certain, relatively low mobility is still present in the connecting points, the plastic matrix is completely curable by supplying heat at a later time.

- prepregs are known per se.

- a significant advantage consists in the fact that the reinforcing body is particularly flexible and still can be formed according to the current requirements at the site and then finally fixed by brief heating.

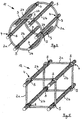

- the in the FIGS. 1 and 2 illustrated reinforcing body 1 consists of four individual, each rectilinear reinforcing bars 2a and 2b, which are arranged at right angles to each other in the manner of a double cross.

- the two reinforcing bars 2a parallel to each other in a first plane 3a and the other two Bewebungsstäbe 2b are also arranged parallel to each other in a second plane 3b on the reinforcing bars 2a.

- the reinforcing body 1 similar to FIG. 3 also include a much larger number of reinforcing bars 2a and 2b, so that the FIG. 1 then only a section of the entire reinforcement body 1 would represent.

- the rebars 2a and 2b which are designed as so-called FRP rebars, each consist of fiber-reinforced plastic, in which case glass fibers are embedded in a proportion of about 60% to 85% in a matrix of polyester resin.

- aramid fibers or carbon fibers may as well be embedded in a matrix of epoxy resin or vinyl ester resin.

- the reinforcing rods 2a and 2b formed with a substantially circular cross-section here here all have the same length and the same diameter, which may preferably be in the range of 5 mm to 25 mm, but also above.

- the surfaces of the Bewehungsstäbe 2a and 2b are profiled by a light thread structure.

- the wandering rods 2a and 2b can also have different diameters and / or different lengths or shapes.

- the four reinforcing bars 2a and 2b are connected to each other at the four connection points 4 by connecting means 5 in pairs.

- the connecting means 5 each comprise connecting fibers 6, which are embedded in a plastic matrix 7 and wound around the reinforcing bars 2a and 2b several times.

- the resin 7 is previously applied to the fiber material 6, so that the fibers 6 are "wet" wound and applied.

- glass fibers 6 are surrounded by a matrix 7 of polyester resin.

- the connecting means 5 can also act after the complete curing of the resin 7 cohesively.

- the connecting fibers 6 are here wound on the reinforcing bars 2b at angles of + 45 ° and -45 ° obliquely to the longitudinal direction of the reinforcing bars 2b.

- the connecting fibers 6 are guided so that they (based on the plane of drawing of FIG. 2 ) both in front of and behind the reinforcing bars 2a.

- FIG. 3 shown also essentially two-dimensionally constructed reinforcing body 10 consists of eighteen rectangularly arranged reinforcing bars 2a and 2b, which are connected in grid form as a reinforcing mat to a total of eighty-four joints 4. Again, the reinforcing bars 2a are in a first plane 3a, on which the reinforcing bars 2b are arranged in a second plane 3b.

- the connecting means 5 comprise in each case, as in the example described above, connecting fibers 6 which are embedded in a plastic matrix 7 and are wound around the reinforcing rods 2a and 2b several times.

- a high-strength connection of individual reinforcing rods 2a, 2b with each other resulting in a stable, lightweight and completely corrosion resistant insulator body 1, which can be advantageously used in concrete cover or concrete walls.

- the reinforcing body 1 can be used on bridges or buildings, but also in tunneling for reinforcement of concrete or similar building materials.

- reinforcing bodies 11 and 12 which have a three-dimensional shape in the form of a tube ( FIG. 4 ) or a cuboid ( FIG. 5 ) to have.

- the in FIG. 4 shown reinforcing body 11 consists of two circularly bent reinforcing bars 2a, which are interconnected by six mutually parallel reinforcing bars 2b, which are each attached to the inner circumference of the circular reinforcing bars 2a at a right angle to the inventive way.

- the in FIG. 4 shown reinforcing body 11 consists of two circularly bent reinforcing bars 2a, which are interconnected by six mutually parallel reinforcing bars 2b, which are each attached to the inner circumference of the circular reinforcing bars 2a at a right angle to the inventive way.

- reinforcing body 12 in contrast, consists of two substantially square reinforcing bars 2a, which are interconnected by four mutually parallel reinforcing bars 2b, which are also attached inside the four corners of the square reinforcing bars 2a at a right angle also on the inventive way.

- the connecting means 5 each comprise, at the connecting points 4 around the reinforcing bars 2a and 2b, multiply wound connecting fibers 6 which are embedded in a plastic matrix 7.

- the resulting highly stable and completely insensitive to corrosion reinforcement body 11 and 12 can be advantageously used as a pile reinforcement.

- the present invention is not limited to the embodiment shown here.

- the reinforcing bodies 1, 10, 11 and 12 may vary in particular in number and / or shape and / or size and / or orientation of the reinforcing bars.

- fibers and / or Plastics made of other materials can be used.

- the connecting fibers 6 can be arranged differently.

- rebars of different types, in particular different size and / or shape, can be joined together to form a reinforcing body.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Reinforcement Elements For Buildings (AREA)

- Laminated Bodies (AREA)

- Reinforced Plastic Materials (AREA)

- Working Measures On Existing Buildindgs (AREA)

Claims (15)

- Corps d'armature (1) pour des édifices, en particulier pour des édifices à base de matériaux de béton, comprenant plusieurs barres d'armature (2a, 2b) reliées entre elles par des moyens liaison (5) en des points de liaison (4) et à base de plastique renforcé de fibre, les moyens de liaison (5) comprenant des fibres de liaison (6) qui sont intégrées dans une matrice de plastique (7),

caractérisé en ce que

les fibres de liaison (6) sont enroulées aux points de liaison (4) plusieurs fois autour des barres d'armature (2a, 2b) de telle sorte que, dans le cas d'une charge de traction ou de pression exercée transversalement à l'axe longitudinal d'une première barre d'armature (2a, 2b), dans le sens longitudinal d'une seconde barre d'armature (2b, 2a) pour un point de liaison (4) individuel, on obtient une force de liaison S qui répond à la formule S > 0,3 * AS * RB, AS décrivant la surface de section de la seconde barre d'armature (2b, 2a) et RB la tension d'utilisation autorisée de la seconde barre d'armature (2b, 2a). - Corps d'armature selon la revendication 1, caractérisé en ce que les fibres de liaison (6) sont enroulées dans différentes directions autour de respectivement un point de liaison (4).

- Corps d'armature selon la revendication 1 ou 2, caractérisé en ce que les fibres de liaison (6) se croisent à chaque fois en au moins un point sur une barre d'armature (2a, 2b) ou sur les deux barres d'armature (2a, 2b).

- Corps d'armature selon l'une quelconque des revendications 1 à 3, caractérisé en ce que les fibres de liaison (6) comportent des fibres de verre et/ou des fibres d'aramide et/ou des fibres de carbone.

- Corps d'armature selon l'une quelconque des revendications précédentes, caractérisé en ce que les fibres de liaison (6) et/ou le plastique de la matrice de plastique (7) aux points de liaison (4) sont à base du même matériau que les fibres ou le plastique dans les barres d'armature (2a, 2b).

- Corps d'armature selon l'une quelconque des revendications précédentes, caractérisé en ce que les barres d'armature (2a, 2b) présentent un profilage côté extérieur, qui est conçu en particulier sous la forme d'un profil vissable ou de préférence sous la forme d'un filetage.

- Corps d'armature selon l'une quelconque des revendications précédentes, caractérisé en ce que les barres d'armature (2a, 2b) sont disposées au moins essentiellement à angle droit les unes par rapport aux autres.

- Corps d'armature selon l'une quelconque des revendications précédentes, caractérisé en ce que les barres d'armature (2a, 2b) sont disposées au moins essentiellement en deux dimensions sous la forme d'un treillis (1, 10).

- Corps d'armature selon la revendication 8, caractérisé en ce que toutes les barres d'armature (2a, 2b) sont étirées en ligne droite, un premier groupe de barres d'armature (2a) s'étendant dans un premier plan (3a) et un second groupe de barres d'armature (2b) s'étendant dans un second plan (3b), qui est agencé parallèlement au premier plan (3a).

- Corps d'armature selon l'une quelconque des revendications précédentes, caractérisé en ce que les barres d'armature (2a, 2b) forment un corps d'armature (11, 12) en trois dimensions, en particulier un pieu d'armature (11) ou une cage d'armature (12).

- Corps d'armature selon la revendication 10, caractérisé en ce qu'au moins des barres d'armature (2a, 2b) individuelles sont pliées de façon partielle ou complètement.

- Corps d'armature selon la revendication 11, caractérisé en ce que plusieurs barres d'armature (2a) sont conçues avec une forme circulaire, qui sont reliées côté intérieur et/ou côté extérieur à plusieurs barres d'armature (2b) agencées au moins approximativement en ligne droite pour former un corps d'armature (11) de forme tubulaire.

- Corps d'armature selon la revendication 11, caractérisé en ce que plusieurs barres d'armature (2a) sont pliées en partie à angle droit et sont réalisées sous la forme d'un rectangle, qui sont reliées côté intérieur et/ou côté extérieur à plusieurs barres d'armature (2b) agencées au moins approximativement en ligne droite pour former un corps d'armature (12) en forme de parallélépipède.

- Corps d'armature selon l'une quelconque des revendications précédentes, caractérisé en ce que la matrice de plastique (7) est durcie complètement avec les fibres de liaison (6) intégrées à l'intérieur.

- Corps d'armature selon l'une quelconque des revendications 1 à 13, caractérisé en ce qu'il est réalisé sous forme de préimprégné, la matrice de plastique (7) étant prédurcie avec les fibres de liaison (6) intégrées à l'intérieur jusqu'à un certain degré de telle sorte qu'une certaine mobilité est obtenue aux points de liaison (4), la matrice de plastique (7) pouvant être durcie complètement par l'arrivée de chaleur.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL06791978T PL1924751T3 (pl) | 2005-09-10 | 2006-09-11 | Korpus zbrojeniowy z tworzywa sztucznego wzmocnionego włóknami |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102005043386A DE102005043386A1 (de) | 2005-09-10 | 2005-09-10 | Bewehrungskörper aus faserverstärktem Kunststoff |

| PCT/EP2006/008830 WO2007028652A1 (fr) | 2005-09-10 | 2006-09-11 | Corps d'armature realise en plastique renforce par fibres |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1924751A1 EP1924751A1 (fr) | 2008-05-28 |

| EP1924751B1 true EP1924751B1 (fr) | 2010-04-07 |

Family

ID=37651058

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06791978A Active EP1924751B1 (fr) | 2005-09-10 | 2006-09-11 | Corps d'armature realise en plastique renforce par fibres |

Country Status (18)

| Country | Link |

|---|---|

| US (1) | US20090145074A1 (fr) |

| EP (1) | EP1924751B1 (fr) |

| JP (1) | JP4796143B2 (fr) |

| KR (1) | KR101327118B1 (fr) |

| CN (1) | CN101263270B (fr) |

| AT (1) | ATE463631T1 (fr) |

| AU (1) | AU2006289279B2 (fr) |

| BR (1) | BRPI0615640A2 (fr) |

| CA (1) | CA2619816C (fr) |

| DE (2) | DE102005043386A1 (fr) |

| ES (1) | ES2344155T3 (fr) |

| IL (1) | IL190035A0 (fr) |

| NO (1) | NO20080949L (fr) |

| NZ (1) | NZ566212A (fr) |

| PL (1) | PL1924751T3 (fr) |

| RU (1) | RU2008113914A (fr) |

| WO (1) | WO2007028652A1 (fr) |

| ZA (1) | ZA200803068B (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014102861A1 (de) * | 2014-03-04 | 2015-09-10 | Technische Universität Dresden | Bewehrungsgitter für den Betonbau, Hochleistungsfilamentgarn für den Betonbau und Verfahren zu deren Herstellung |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2937352B1 (fr) * | 2008-10-16 | 2010-11-26 | Kp1 | Insert de brochage pour poutre en beton arme ou precontraint |

| CN101560816B (zh) * | 2009-05-15 | 2011-03-09 | 同济大学 | Frp筋纤维布缠接同轴连接方法 |

| US8381479B1 (en) * | 2009-09-28 | 2013-02-26 | Felix E. Ferrer | Pre-fabricated modular reinforcement cages for concrete structures |

| DE102012108132B4 (de) * | 2012-08-31 | 2015-01-22 | Firep Rebar Technology Gmbh | Verfahren zur Herstellung von Bewehrungselementen aus faserverstärktem Kunststoff |

| US8973322B2 (en) * | 2013-01-16 | 2015-03-10 | Rupert Heron | Masonry units and structures formed therefrom |

| US9267287B1 (en) * | 2014-01-22 | 2016-02-23 | Steven James Bongiorno | Pre-fabricated threaded bar assemblies |

| CN104563522A (zh) * | 2014-11-25 | 2015-04-29 | 中冶建筑研究总院有限公司 | Frp筋的固定连接方法 |

| US10280621B2 (en) | 2015-04-08 | 2019-05-07 | A New Twist Llc | Method of tying a rebar tie |

| CN106639477B (zh) * | 2017-01-22 | 2018-09-21 | 武汉大学 | 一种具有抗震和自愈合性能的内置阻尼梁构件 |

| DE102017107948A1 (de) * | 2017-04-12 | 2018-10-18 | Technische Universität Dresden | Bewehrungsstab zum Einbringen in eine Betonmatrix sowie dessen Herstellungsverfahren, ein Bewehrungssystem aus mehreren Bewehrungsstäben sowie ein Betonbauteil |

| EP3424690B1 (fr) | 2017-07-03 | 2023-09-13 | Solidian GmbH | Procédé et dispositif de fabrication d'une grille d'armature |

| CN108824702B (zh) * | 2018-07-25 | 2023-10-03 | 广东工业大学 | 一种大直径frp筋材端部连接结构和连接方法及其应用 |

| RU2725981C1 (ru) * | 2019-05-13 | 2020-07-08 | Общество с ограниченной ответственностью "ГАЛЕН" | Арматурная сетка из композитного материала |

| DE102019126609A1 (de) * | 2019-10-02 | 2021-04-08 | Technische Universität Dresden | Rohrförmiges Bewehrungselement, Verfahren zu dessen Herstellung, Verwendung, Globalbewehrung, Druckerbeschreibungsdatei und Betonbauteil |

| JP7317314B2 (ja) * | 2019-10-08 | 2023-07-31 | 国立大学法人東海国立大学機構 | 構造物、構造体、構造体の製造方法、及び構造物の製造方法 |

| US11149397B2 (en) * | 2019-12-09 | 2021-10-19 | Basalt World Corp. | Side loaded remediation method and apparatus for reinforced concrete pilings |

| US20220412082A1 (en) * | 2021-06-23 | 2022-12-29 | 9443-3638 Québec inc. | Composite ceiling and method of construction |

| US11578493B2 (en) * | 2021-06-29 | 2023-02-14 | Saudi Arabian Oil Company | Mechanical couplings for reinforcing bars |

| IT202100026576A1 (it) * | 2021-10-18 | 2023-04-18 | Pre Sac S R L | Reticolato di barre e sfere cave in plastica dura per l’armamento di conglomerato cementizio |

| US20230407636A1 (en) * | 2022-06-16 | 2023-12-21 | ICF Building Systems LLC | Concrete form systems, devices, and related methods |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1688957A (en) * | 1928-10-23 | Structural reeneorce element | ||

| US1950343A (en) * | 1930-09-06 | 1934-03-06 | Kalman Steel Co | Reenforcement for headers and stretchers |

| DE1484984C2 (de) * | 1962-03-08 | 1975-12-04 | Ferrotest Gmbh, Basel (Schweiz) | Gitterartiges vorgefertigtes Bewehrungselement für Stahlbetonbauteile |

| US3473285A (en) * | 1967-09-29 | 1969-10-21 | Gateway Erectors Inc | Method of erection of concrete reinforcing structures |

| GB8322645D0 (en) * | 1983-08-23 | 1983-09-28 | Lambeg Ind Research Assn | Textile reinforced cement structure |

| CA1238205A (fr) * | 1985-04-26 | 1988-06-21 | Cerminco Inc. | Tige de renfort pour structures en beton arme |

| US4910076A (en) * | 1986-03-11 | 1990-03-20 | Mitsubishi Kasei Corporation | Fiber reinforced cement mortar product |

| US5110656A (en) * | 1989-03-15 | 1992-05-05 | Kanebo Ltd. | Impregnated leno fabric and reinforced inorganic matrix article |

| JPH0718206B2 (ja) * | 1989-09-14 | 1995-03-01 | 帝人株式会社 | 構造用ロッドの製造方法 |

| US5763043A (en) * | 1990-07-05 | 1998-06-09 | Bay Mills Limited | Open grid fabric for reinforcing wall systems, wall segment product and methods of making same |

| EP0532140A1 (fr) * | 1991-09-13 | 1993-03-17 | Board of Regents of the University of Nebraska | Panneaux-sandwich préfabriqués en béton |

| JPH0587115U (ja) * | 1992-04-30 | 1993-11-22 | 株式会社有沢製作所 | コンクリート補強材 |

| US5542785A (en) * | 1993-09-28 | 1996-08-06 | Lowtech Corporation, Inc. | Rebar cage wheel spacer centralizer system for drilled shafts |

| US5609806A (en) * | 1994-06-28 | 1997-03-11 | Reichhold Chemicals, Inc. | Method of making prepreg |

| CH691608A5 (de) * | 1996-08-28 | 2001-08-31 | Sacac Hergiswil Ag | Rohr- und/oder stabförmige faserverstärkte Konstruktionen. |

| DE19730393C2 (de) * | 1997-07-16 | 2001-02-08 | Niels Wendland | Gittergewebe |

| US6263629B1 (en) * | 1998-08-04 | 2001-07-24 | Clark Schwebel Tech-Fab Company | Structural reinforcement member and method of utilizing the same to reinforce a product |

| SG109413A1 (en) * | 1999-10-14 | 2005-03-30 | Natsteel Asia Pte Ltd | Collapsible cage |

| US6612085B2 (en) * | 2000-01-13 | 2003-09-02 | Dow Global Technologies Inc. | Reinforcing bars for concrete structures |

| CH694375A5 (fr) * | 2000-08-08 | 2004-12-15 | Sc Tech Philippe Menetrey Dr | Armature flexible de connexion reliant les armatures d'une structure en béton. |

| GB0212687D0 (en) * | 2002-05-31 | 2002-07-10 | Composhield As | Reinforced composite panel |

| US20050108980A1 (en) * | 2002-10-22 | 2005-05-26 | Andrew Barmakian | Rod-reinforced cushion beam |

| CN2622288Y (zh) * | 2003-04-29 | 2004-06-30 | 南京奥沃科技发展有限公司 | 纤维增强塑料筋 |

| GB0314538D0 (en) * | 2003-06-21 | 2003-07-30 | Composhield As | Reinforcement assembly for matrix materials |

-

2005

- 2005-09-10 DE DE102005043386A patent/DE102005043386A1/de not_active Withdrawn

-

2006

- 2006-09-11 NZ NZ566212A patent/NZ566212A/en not_active IP Right Cessation

- 2006-09-11 AT AT06791978T patent/ATE463631T1/de active

- 2006-09-11 KR KR1020087005881A patent/KR101327118B1/ko not_active IP Right Cessation

- 2006-09-11 DE DE502006006652T patent/DE502006006652D1/de active Active

- 2006-09-11 JP JP2008529562A patent/JP4796143B2/ja not_active Expired - Fee Related

- 2006-09-11 US US12/066,135 patent/US20090145074A1/en not_active Abandoned

- 2006-09-11 CN CN2006800330984A patent/CN101263270B/zh not_active Expired - Fee Related

- 2006-09-11 BR BRPI0615640-1A patent/BRPI0615640A2/pt not_active IP Right Cessation

- 2006-09-11 WO PCT/EP2006/008830 patent/WO2007028652A1/fr active Application Filing

- 2006-09-11 AU AU2006289279A patent/AU2006289279B2/en not_active Ceased

- 2006-09-11 CA CA2619816A patent/CA2619816C/fr not_active Expired - Fee Related

- 2006-09-11 ES ES06791978T patent/ES2344155T3/es active Active

- 2006-09-11 PL PL06791978T patent/PL1924751T3/pl unknown

- 2006-09-11 EP EP06791978A patent/EP1924751B1/fr active Active

- 2006-09-11 RU RU2008113914/03A patent/RU2008113914A/ru not_active Application Discontinuation

-

2008

- 2008-02-26 NO NO20080949A patent/NO20080949L/no not_active Application Discontinuation

- 2008-03-09 IL IL190035A patent/IL190035A0/en unknown

- 2008-04-08 ZA ZA200803068A patent/ZA200803068B/xx unknown

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014102861A1 (de) * | 2014-03-04 | 2015-09-10 | Technische Universität Dresden | Bewehrungsgitter für den Betonbau, Hochleistungsfilamentgarn für den Betonbau und Verfahren zu deren Herstellung |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2619816A1 (fr) | 2007-03-15 |

| ZA200803068B (en) | 2009-02-25 |

| US20090145074A1 (en) | 2009-06-11 |

| NO20080949L (no) | 2008-04-09 |

| JP2009508021A (ja) | 2009-02-26 |

| AU2006289279A1 (en) | 2007-03-15 |

| DE502006006652D1 (de) | 2010-05-20 |

| BRPI0615640A2 (pt) | 2011-05-24 |

| CN101263270A (zh) | 2008-09-10 |

| KR20080036144A (ko) | 2008-04-24 |

| AU2006289279B2 (en) | 2011-08-04 |

| WO2007028652A1 (fr) | 2007-03-15 |

| NZ566212A (en) | 2010-04-30 |

| ES2344155T3 (es) | 2010-08-19 |

| ATE463631T1 (de) | 2010-04-15 |

| EP1924751A1 (fr) | 2008-05-28 |

| PL1924751T3 (pl) | 2010-09-30 |

| RU2008113914A (ru) | 2009-10-20 |

| IL190035A0 (en) | 2008-08-07 |

| KR101327118B1 (ko) | 2013-11-07 |

| CA2619816C (fr) | 2013-06-25 |

| JP4796143B2 (ja) | 2011-10-19 |

| AU2006289279A2 (en) | 2008-04-03 |

| CN101263270B (zh) | 2010-12-15 |

| DE102005043386A1 (de) | 2007-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1924751B1 (fr) | Corps d'armature realise en plastique renforce par fibres | |

| EP2894272B1 (fr) | Béton armé haute performance | |

| EP3272958B1 (fr) | Élément de construction destiné a l'isolation thermique | |

| EP0815329B1 (fr) | Element de traction en forme de boucle a plusieurs couches | |

| DE102007037951A1 (de) | Betonverbundstütze | |

| EP1795667A2 (fr) | Elément d'armature pour structures en béton armé, béton précontraint ou similaires | |

| WO2013113442A1 (fr) | Système de renforcement pour bâtiments | |

| WO2008003426A1 (fr) | Pièce de transmission de force renforcée | |

| DE102006021781B4 (de) | Elementwand | |

| EP3819431B1 (fr) | Agencement de renfort au moyen d'une construction existante et d'un dispositif de renfort appliqué à celle-ci ainsi que procédé de renforcement d'une construction existante | |

| WO2021063453A1 (fr) | Élément d'armature tubulaire, procédé de fabrication d'un élément d'armature, armature globale, utilisation d'un élément d'armature, élément en béton et fichier de programme | |

| WO2016198270A1 (fr) | Structure de pylône en treillis ainsi que procédé servant à améliorer la stabilité sur une structure de pylône en treillis | |

| EP3705657B1 (fr) | Structure de renfort textile pour un composant, procédé de fabrication pour une structure de renfort, composant et pièce semi-finie | |

| EP3656937B1 (fr) | Composant destiné à l'isolation thermique | |

| EP2276898B1 (fr) | Pièce de montage préfabriquée possédant un dispositif de stabilisation | |

| DE102016211176B4 (de) | Verfahren und Verwendung einer Vorrichtung zur Durchführung des Verfahrens zur Herstellung von Betonbauteilen | |

| DE102005030409A1 (de) | Wendelförmiges Bewährungselement | |

| DE29900172U1 (de) | Hochzugfester und korrosionsbeständiger Kunststoff-Zuganker mit integriertem Gewinde und seine Verwendung | |

| EP3556960B1 (fr) | Dispositif d'armature et procédé de fabrication d'un corps de matériau de construction au moyen dudit dispositif d'armature | |

| EP0566539A1 (fr) | Armature pour maçonnerie | |

| DE102019105493A1 (de) | Textile Bewehrungsstruktur für ein Bauteil, Herstellungsverfahren für eine Bewehrungsstruktur, Bauteil und Halbfertigteil | |

| EP3845354A2 (fr) | Procédé de fabrication de segments pour une tour, segment précontraint, anneau de tour, tour, éolienne ainsi que dispositif de précontrainte | |

| WO2001086089A1 (fr) | Elements de construction stabilises par precontrainte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20080407 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: BA HR RS |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: FIREP REBAR TECHNOLOGY GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAX | Requested extension states of the european patent have changed |

Extension state: RS Payment date: 20080407 Extension state: BA Payment date: 20080407 Extension state: HR Payment date: 20080407 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: BA HR RS |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502006006652 Country of ref document: DE Date of ref document: 20100520 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2344155 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20100407 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100807 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100526 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100708 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100809 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 |

|

| 26N | No opposition filed |

Effective date: 20110110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100911 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101008 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100707 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20150923 Year of fee payment: 10 Ref country code: GB Payment date: 20150922 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20150921 Year of fee payment: 10 Ref country code: PL Payment date: 20150903 Year of fee payment: 10 Ref country code: SE Payment date: 20150922 Year of fee payment: 10 Ref country code: AT Payment date: 20150921 Year of fee payment: 10 Ref country code: FR Payment date: 20150923 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20150925 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20150923 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160912 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20161001 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 463631 Country of ref document: AT Kind code of ref document: T Effective date: 20160911 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160911 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160911 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160911 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160911 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170921 Year of fee payment: 12 Ref country code: CH Payment date: 20170925 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20160930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160911 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160912 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20181129 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502006006652 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180930 |