EP1908720A1 - Elevator pit barrier - Google Patents

Elevator pit barrier Download PDFInfo

- Publication number

- EP1908720A1 EP1908720A1 EP07117612A EP07117612A EP1908720A1 EP 1908720 A1 EP1908720 A1 EP 1908720A1 EP 07117612 A EP07117612 A EP 07117612A EP 07117612 A EP07117612 A EP 07117612A EP 1908720 A1 EP1908720 A1 EP 1908720A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- barrier

- pit

- car

- elevator installation

- installation according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000004888 barrier function Effects 0.000 title claims abstract description 56

- 238000009434 installation Methods 0.000 claims abstract description 18

- 239000000872 buffer Substances 0.000 claims abstract description 12

- 230000001105 regulatory effect Effects 0.000 claims abstract description 4

- 230000000717 retained effect Effects 0.000 claims 1

- 238000012423 maintenance Methods 0.000 description 8

- 230000006378 damage Effects 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 210000003127 knee Anatomy 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/28—Buffer-stops for cars, cages, or skips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/0043—Devices enhancing safety during maintenance

- B66B5/005—Safety of maintenance personnel

Definitions

- the present invention relates to elevators and, in particular, to a barrier located in the elevator pit to maintain the safety of personnel working in a pit of reduced depth.

- the ropes 4 are driven by a traction sheave (not shown) to move the car 1 along guide rails (not shown) mounted to opposing shaft walls 6.

- a buffer 16 is mounted in the pit 12 of the shaft 10 to arrest the car 1 should it travel beyond its normal travel limit (i.e. the lowest landing).

- a minimum free vertical clearance C exists between the pit floor 14 and the lowest part of the car 1, which in this instance is the pulley box 2.

- the toeguard 8 actually extends below the pulley box 2, as mentioned above, it can be explicitly excluded from consideration by the regulations.

- the objective of the present invention is to reduce the pit depth and thereby the minimum free vertical clearance between the pit floor and the lowest parts of the car while maintaining the safety of any personnel working in the pit.

- an elevator installation comprising a car within a shaft, a buffer mounted in a pit of the shaft and a barrier located in the pit surrounding or within an area wherein a vertical clearance between the pit floor and the car or equipment mounted thereon is less than a regulatory threshold value when the car fully compresses the buffer. Accordingly, the barrier acts to physically deterrent personnel within the pit from inadvertent presence in the area of reduced vertical clearance.

- the barrier is height-adjustable and biased to its highest position. Accordingly, the barrier can have a height greater than the reduced vertical clearance but will not be damaged if the car travels into it. Furthermore, even if a maintenance person were to get a hand for example trapped between the car and the barrier, the height-adjustability of barrier ensures that such entrapment will not cause personal injury.

- the barrier may be flexible and preferably elastically deformable. Such a barrier may take the form of an inflated balloon.

- the flexible and deformable barrier may comprise two flexible uprights interconnected by linkage means such as a net. Should the car descend into the barrier, the flexible uprights will automatically deform to a reduced height. Since this barrier contains no complicated moving parts it provides a relatively low cost solution.

- the flexible uprights are doubled-over so that if the car descends into the barrier each upright deforms outwards in mutually opposing directions. Accordingly, the greater the deformation of the uprights, the greater the area effectively protected by the barrier.

- the barrier may comprise a pair of channels each retaining at least one slider, and linkage means secured to and interconnecting the sliders of the opposing channels. Accordingly, if the car descends into the barrier, the linkage means and sliders moved downwards in the channels against the biasing force.

- the linkage means may have the form of rigid bars, wires, belts or a net.

- Figs. 4 and 5 illustrate an elevator installation according to a first embodiment of the present invention. While the arrangements of the car 1 within the shaft 10 are identical to those previously described with respect to the prior art of Figs. 1 and 2 respectively, areas on the pit floor 14 directly beneath the underslung pulley box 2 or other components mounted under the car are clearly marked with a tape 18 of diagonal stripes of contrasting colours (e.g. yellow and black or red and white). Preferably, words such as "DANGER LOW CLEARANCE" can be printed in the tape 18. Furthermore, a barrier 20 is also erected in the pit 12 directly beneath the underslung pulley box 2. The barrier 20 comprises a pair of opposing flexible uprights 22 mounted to the pit floor 14 with an interconnecting net 24.

- the tape 18 and the barrier 20 both act as visible warnings that the area under the pulley box 2 could potentially have a reduced vertical clearance.

- the barrier 20 acts to physically deterrent personnel within the pit 12 from inadvertently working in the area of reduced vertical clearance.

- the barrier 20 will be deflected due to the flexible nature of the uprights 22. Hence, even if a maintenance person were to get a hand for example trapped between the pulley box 2 and the barrier 20, the barrier is sufficiently flexible to accommodate the body part without causing damage.

- the maintenance personnel Given the central location of the barrier 20 and the fact that it essentially spans the entire width of the pit 12, the maintenance personnel will inherently need to cross the barrier 20 occasionally; the barrier 20 is easily deformable to enable them to do so. However, these transitions across the barrier 20 make up only a small amount of the total time the maintenance personnel spend in the pit 12.

- the large majority of maintenance operations carried out in the pit 12 will actually require the person to face away from the barrier 20 which in turn generally means that their arms will also be projecting away from the barrier 20. In which case the person will only come into contact with the barrier if he backs into it and the normal reaction to that is to step slightly away and out of the reduced clearance area. Even the majority of work on the pulley box 2 is carried out from the side rather than underneath. Hence, a relatively low barrier, perhaps at knee height ( ⁇ 500mm), would be sufficient to effectively deter personnel from inadvertent presence in the area under the pulley box 2.

- Figs. 6 to 8 illustrate an alternative barrier 30 which is similar to the barrier 20 of the first embodiment but, in this instance, each of the uprights 32 is doubled-over with both ends secured to the pit floor 14.

- the doubled-over uprights 32 and the interconnected net 24 are deflected outwards. Accordingly, any person standing adjacent to the barrier 30 is also thrust away from the reduced clearance area under the pulley box 2. The car may continue to descend, and thereby further deform the barrier 30, until it rests on the fully compressed buffer 16, as shown in Fig. 8.

- the regulatory minimum free vertical clearance C may now be determined as existing between the pit floor 14 and the car 1, rather then between the pit floor 14 and the underslung pulley box 2 (as in the prior art of Fig. 3), enabling a space saving within the elevator installation corresponding to the height S of the pulley box 2.

- the barrier 40 comprises a pair of opposing uprights in the form of U-shaped channels 42.

- the channels 42 may be secured at their bases to the pit floor 14 as in the previously described embodiments, or, alternatively, they can be mounted on opposing side walls 6 of the shaft 10.

- Each channel 42 retains a plurality of sliders 46 connected to a net 44.

- the uppermost slider 46 in each channel 42 is biased upwards by a spring 48.

- Fig. 11 shows an alternative embodiment of the invention, wherein the upward bias of the net 44 is provided by a counterweight 50.

- the uppermost slider 46 within each channel 42 is attached by a wire or rope 54 which passes over a pulley 52 to the counterweight 50.

- the area under the pulley box 2 is a relatively low maintenance intensive area. If, on the other hand, the reduced clearance area is within a high maintenance intensive sector of the pit 12, then a relatively high barrier, perhaps at shoulder height ( ⁇ 1500mm), should be employed in or surrounding the reduced clearance area to positively prevent personnel from inadvertent presence in that area.

Landscapes

- Maintenance And Inspection Apparatuses For Elevators (AREA)

- Types And Forms Of Lifts (AREA)

Abstract

Description

- The present invention relates to elevators and, in particular, to a barrier located in the elevator pit to maintain the safety of personnel working in a pit of reduced depth.

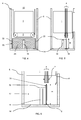

- There are increasing pressures on the elevator industry to reduce the space occupied by elevator installations within buildings. One solution would be to reduce the depth of the pit of the elevator shaft, however, regulations such as European Standard EN81-1:1998 specify that when an elevator car rests on its fully compressed buffers, there shall be a minimum free vertical clearance between the pit floor and the lowest parts of the car. There are exceptions to these rules such as for toeguards, roller guides, guide shoes and safety gear all of which are generally mounted on the outside periphery of the car. The situation is depicted in Figs. 1 to 3. In this example, the

elevator car 1 is supported by means of anunderslung pulley box 2 onropes 4. Theropes 4 are driven by a traction sheave (not shown) to move thecar 1 along guide rails (not shown) mounted to opposingshaft walls 6. Abuffer 16 is mounted in thepit 12 of theshaft 10 to arrest thecar 1 should it travel beyond its normal travel limit (i.e. the lowest landing). When thecar 1 rests on the fullycompressed buffer 16, as shown specifically in Fig. 3, a minimum free vertical clearance C exists between thepit floor 14 and the lowest part of thecar 1, which in this instance is thepulley box 2. Although thetoeguard 8 actually extends below thepulley box 2, as mentioned above, it can be explicitly excluded from consideration by the regulations. - The objective of the present invention is to reduce the pit depth and thereby the minimum free vertical clearance between the pit floor and the lowest parts of the car while maintaining the safety of any personnel working in the pit.

- This objective is achieved by providing an elevator installation comprising a car within a shaft, a buffer mounted in a pit of the shaft and a barrier located in the pit surrounding or within an area wherein a vertical clearance between the pit floor and the car or equipment mounted thereon is less than a regulatory threshold value when the car fully compresses the buffer. Accordingly, the barrier acts to physically deterrent personnel within the pit from inadvertent presence in the area of reduced vertical clearance.

- Preferably, the barrier is height-adjustable and biased to its highest position. Accordingly, the barrier can have a height greater than the reduced vertical clearance but will not be damaged if the car travels into it. Furthermore, even if a maintenance person were to get a hand for example trapped between the car and the barrier, the height-adjustability of barrier ensures that such entrapment will not cause personal injury.

- The barrier may be flexible and preferably elastically deformable. Such a barrier may take the form of an inflated balloon.

- Alternatively, the flexible and deformable barrier may comprise two flexible uprights interconnected by linkage means such as a net. Should the car descend into the barrier, the flexible uprights will automatically deform to a reduced height. Since this barrier contains no complicated moving parts it provides a relatively low cost solution.

- Preferably, the flexible uprights are doubled-over so that if the car descends into the barrier each upright deforms outwards in mutually opposing directions. Accordingly, the greater the deformation of the uprights, the greater the area effectively protected by the barrier.

- Alternatively, the barrier may comprise a pair of channels each retaining at least one slider, and linkage means secured to and interconnecting the sliders of the opposing channels. Accordingly, if the car descends into the barrier, the linkage means and sliders moved downwards in the channels against the biasing force.

- The linkage means may have the form of rigid bars, wires, belts or a net.

- The present invention is hereinafter described by way of specific examples with reference to the accompanying drawings in which:

- Figure 1 is a partial, rear plan view of a pit of an elevator installation according to the prior art:

- Figure 2 is a partial, side plan view of the pit of Fig. 1;

- Figure 3 corresponds with Fig. 2 illustrating the elevator car compressing the buffer;

- Figure 4 is a partial, rear plan view of a pit of an elevator installation in accordance with a first embodiment of the present invention;

- Figure 5 is a partial, side plan view of the pit of Fig. 4;

- Figure 6 is a partial, side plan view of a pit of an elevator installation in accordance with a second embodiment of the present invention;

- Figure 7 corresponds with Fig. 6 illustrating the elevator car engaging the barrier;

- Figure 8 corresponds with Fig. 6 illustrating the elevator car compressing the buffer:

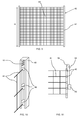

- Figure 9 is a plan view of a barrier according to a third embodiment of the invention;

- Figure 10 is an exploded perspective view of the barrier of Fig. 9; and

- Figure 11 is a sectional view of a barrier according to a fourth embodiment of the invention.

- In the following description, for the avoidance of unnecessary repetition, features of the invention which are common to more than one embodiment have been assigned a common reference numeral and where appropriate share a common description.

- Figs. 4 and 5 illustrate an elevator installation according to a first embodiment of the present invention. While the arrangements of the

car 1 within theshaft 10 are identical to those previously described with respect to the prior art of Figs. 1 and 2 respectively, areas on thepit floor 14 directly beneath theunderslung pulley box 2 or other components mounted under the car are clearly marked with atape 18 of diagonal stripes of contrasting colours (e.g. yellow and black or red and white). Preferably, words such as "DANGER LOW CLEARANCE" can be printed in thetape 18. Furthermore, abarrier 20 is also erected in thepit 12 directly beneath theunderslung pulley box 2. Thebarrier 20 comprises a pair of opposingflexible uprights 22 mounted to thepit floor 14 with an interconnectingnet 24. Accordingly, when maintenance personnel are in thepit 12, thetape 18 and thebarrier 20 both act as visible warnings that the area under thepulley box 2 could potentially have a reduced vertical clearance. Moreover, thebarrier 20 acts to physically deterrent personnel within thepit 12 from inadvertently working in the area of reduced vertical clearance. - If at any time the

pulley box 2 should come into engagement with thebarrier 20, thebarrier 20 will be deflected due to the flexible nature of theuprights 22. Hence, even if a maintenance person were to get a hand for example trapped between thepulley box 2 and thebarrier 20, the barrier is sufficiently flexible to accommodate the body part without causing damage. - Given the central location of the

barrier 20 and the fact that it essentially spans the entire width of thepit 12, the maintenance personnel will inherently need to cross thebarrier 20 occasionally; thebarrier 20 is easily deformable to enable them to do so. However, these transitions across thebarrier 20 make up only a small amount of the total time the maintenance personnel spend in thepit 12. The large majority of maintenance operations carried out in thepit 12 will actually require the person to face away from thebarrier 20 which in turn generally means that their arms will also be projecting away from thebarrier 20. In which case the person will only come into contact with the barrier if he backs into it and the normal reaction to that is to step slightly away and out of the reduced clearance area. Even the majority of work on thepulley box 2 is carried out from the side rather than underneath. Hence, a relatively low barrier, perhaps at knee height (≈500mm), would be sufficient to effectively deter personnel from inadvertent presence in the area under thepulley box 2. - Figs. 6 to 8 illustrate an

alternative barrier 30 which is similar to thebarrier 20 of the first embodiment but, in this instance, each of theuprights 32 is doubled-over with both ends secured to thepit floor 14. As shown specifically in Fig. 7, as thepulley box 2 descends upon thebarrier 30, the doubled-overuprights 32 and the interconnectednet 24 are deflected outwards. Accordingly, any person standing adjacent to thebarrier 30 is also thrust away from the reduced clearance area under thepulley box 2. The car may continue to descend, and thereby further deform thebarrier 30, until it rests on the fullycompressed buffer 16, as shown in Fig. 8. - Since the

barriers pulley box 2, the regulatory minimum free vertical clearance C may now be determined as existing between thepit floor 14 and thecar 1, rather then between thepit floor 14 and the underslung pulley box 2 (as in the prior art of Fig. 3), enabling a space saving within the elevator installation corresponding to the height S of thepulley box 2. - A further embodiment of the invention is illustrated in Figs. 9 and 10. In this embodiment, the

barrier 40 comprises a pair of opposing uprights in the form ofU-shaped channels 42. Thechannels 42 may be secured at their bases to thepit floor 14 as in the previously described embodiments, or, alternatively, they can be mounted onopposing side walls 6 of theshaft 10. Eachchannel 42 retains a plurality ofsliders 46 connected to a net 44. Theuppermost slider 46 in eachchannel 42 is biased upwards by aspring 48. - If at any time the

pulley box 2 descends into the net 44, the net 44 will descend therewith against the biasing force of thespring 48. - Fig. 11 shows an alternative embodiment of the invention, wherein the upward bias of the net 44 is provided by a

counterweight 50. Theuppermost slider 46 within eachchannel 42 is attached by a wire orrope 54 which passes over apulley 52 to thecounterweight 50. - Although all of embodiments above describe the use of a barrier under the

underslung pulley box 2, it will be appreciated that the barrier can be used to deter personnel from inadvertent presence in any area of thepit 12 which has the possibility of reduced clearance. - As previously described the area under the

pulley box 2 is a relatively low maintenance intensive area. If, on the other hand, the reduced clearance area is within a high maintenance intensive sector of thepit 12, then a relatively high barrier, perhaps at shoulder height (≈1500mm), should be employed in or surrounding the reduced clearance area to positively prevent personnel from inadvertent presence in that area. - If the person needs to specifically work in a designated reduced clearance area, he can easily collapse the barrier to do so.

- Although a net 24,44 has been used in the preferred embodiments to interconnect the

uprights channels 48, will be readily appreciated that this can easily be replaced by other linkage means such as wires or rods.

Claims (10)

- An elevator installation comprising a car (1) within a shaft (10) and a buffer (16) mounted in a pit (12) of the shaft (10)

CHARACTERISED BY

a barrier (20;30;40) located in the pit (12) surrounding or within an area wherein a vertical clearance between the pit floor (14) and the car (1) or equipment mounted thereon is less than a regulatory threshold value (C) when the car (1) fully compresses the buffer (16). - An elevator installation according to claim 1, wherein the barrier (20;30;40) is height-adjustable and biased to its highest position.

- An elevator installation according to claim 2, wherein the barrier (20;30) comprises linkage means (24) interconnecting two flexible uprights (22;32).

- An elevator installation according to claim 3, wherein the flexible uprights (32) are doubled-over.

- An elevator installation according to claim 2, wherein the barrier (40) comprises linkage means (44) interconnecting sliders (46) retained in channels (42).

- An elevator installation according to claim 5, wherein the uppermost slider (46) of each channel (42) is biased by a spring (48).

- An elevator installation according to claim 5, wherein the uppermost slider (46) of each channel (42) is biased by a counterweight (50).

- An elevator installation according to any of claims 5 to 7, wherein each channel is mounted to a shaft wall (6).

- An elevator installation according to any preceding claim, wherein the barrier (20;30;40) has a height (H) of 500mm or greater.

- An elevator installation according to claim 9, wherein the barrier height (H) is 1500mm or greater.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20070117612 EP1908720B1 (en) | 2006-10-06 | 2007-10-01 | Elevator pit barrier |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP06121879 | 2006-10-06 | ||

| EP20070117612 EP1908720B1 (en) | 2006-10-06 | 2007-10-01 | Elevator pit barrier |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1908720A1 true EP1908720A1 (en) | 2008-04-09 |

| EP1908720B1 EP1908720B1 (en) | 2012-04-25 |

Family

ID=39148391

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20070117612 Active EP1908720B1 (en) | 2006-10-06 | 2007-10-01 | Elevator pit barrier |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1908720B1 (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10052459A1 (en) * | 2000-10-23 | 2002-05-02 | Mueller Wolfgang T | Devices for formation of protection space for lifts without machine space with reduced shaft has retractable apron designed as stable frame open upwards which is slid in guides mounted on cabin or in shaft head |

| EP1479636A1 (en) | 2003-05-21 | 2004-11-24 | Inventio Ag | Buffer that can create a safety inspection zone for elevators |

| WO2005058739A2 (en) * | 2003-12-10 | 2005-06-30 | Otis Elevator Company | Elevator pit safety apparatus |

| US20060042883A1 (en) * | 2004-09-02 | 2006-03-02 | Gary Scott | Elevator pit safety device |

-

2007

- 2007-10-01 EP EP20070117612 patent/EP1908720B1/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10052459A1 (en) * | 2000-10-23 | 2002-05-02 | Mueller Wolfgang T | Devices for formation of protection space for lifts without machine space with reduced shaft has retractable apron designed as stable frame open upwards which is slid in guides mounted on cabin or in shaft head |

| EP1479636A1 (en) | 2003-05-21 | 2004-11-24 | Inventio Ag | Buffer that can create a safety inspection zone for elevators |

| WO2005058739A2 (en) * | 2003-12-10 | 2005-06-30 | Otis Elevator Company | Elevator pit safety apparatus |

| US20060042883A1 (en) * | 2004-09-02 | 2006-03-02 | Gary Scott | Elevator pit safety device |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1908720B1 (en) | 2012-04-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8807289B2 (en) | Elevator pit barrier | |

| JP6263650B2 (en) | Train platform safety equipment | |

| US11198594B2 (en) | Elevator car apron | |

| KR20110114190A (en) | An apparatus for falling prevent of elevator | |

| KR100789706B1 (en) | Safety equipment of train platform | |

| US20040195047A1 (en) | Elevator | |

| EP1908720B1 (en) | Elevator pit barrier | |

| JP4276941B2 (en) | Safety device used for maintenance of elevator system on elevator car | |

| CN110775779B (en) | Apron board of elevator car | |

| CN110650912B (en) | Pit ladder for elevator | |

| JP3406173B2 (en) | Ladder for elevator pit | |

| EP1760028B1 (en) | Room-less lifting equipment for persons and goods | |

| KR101593499B1 (en) | Drying apparatus for fire hose with safety blocking equipment | |

| JP3076858B2 (en) | Elevator safety net device | |

| JP4406273B2 (en) | Elevator work protection device | |

| US10407934B2 (en) | Safety barrier for automated vehicle parking facility | |

| KR102629387B1 (en) | Inclined elevator capable of changing direction of entrance doors and location of machine room without restriction | |

| KR102021842B1 (en) | Protecting device falling person of elevator using wire rope | |

| CN210715715U (en) | Elevator shock attenuation backing plate | |

| CN215248890U (en) | Safety protection device for preventing human body from falling into elevator shaft | |

| US20240336456A1 (en) | Apron device, elevator car and method for protecting from falling into elevator shaft | |

| JP2007290832A (en) | Elevator installation method and installation device | |

| JP2006036531A (en) | Elevator exclusively for ascent and descent | |

| ITUA20164672A1 (en) | LIFT | |

| US162535A (en) | Improvement in safety apparatus for lifts or hoists |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20081001 |

|

| 17Q | First examination report despatched |

Effective date: 20081104 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 555048 Country of ref document: AT Kind code of ref document: T Effective date: 20120515 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602007022214 Country of ref document: DE Effective date: 20120621 Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20120611 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2384187 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120702 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20120425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120825 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120726 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20130128 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602007022214 Country of ref document: DE Effective date: 20130128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120725 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20171020 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 555048 Country of ref document: AT Kind code of ref document: T Effective date: 20181001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181001 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20211026 Year of fee payment: 15 Ref country code: PT Payment date: 20210917 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20211119 Year of fee payment: 15 Ref country code: SE Payment date: 20211022 Year of fee payment: 15 Ref country code: CZ Payment date: 20211001 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20211020 Year of fee payment: 15 Ref country code: BE Payment date: 20211026 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221001 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20221101 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20221031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230403 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221101 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R084 Ref document number: 602007022214 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221001 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20231124 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231024 Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221002 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20231026 Year of fee payment: 17 Ref country code: DE Payment date: 20231027 Year of fee payment: 17 Ref country code: CH Payment date: 20231102 Year of fee payment: 17 |