EP1811604B1 - Electrical terminal block - Google Patents

Electrical terminal block Download PDFInfo

- Publication number

- EP1811604B1 EP1811604B1 EP06024525A EP06024525A EP1811604B1 EP 1811604 B1 EP1811604 B1 EP 1811604B1 EP 06024525 A EP06024525 A EP 06024525A EP 06024525 A EP06024525 A EP 06024525A EP 1811604 B1 EP1811604 B1 EP 1811604B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- terminal

- fixing

- connector

- base

- connectors

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/26—Clip-on terminal blocks for side-by-side rail- or strip-mounting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/2491—Terminal blocks structurally associated with plugs or sockets

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

- H01R9/26—Clip-on terminal blocks for side-by-side rail- or strip-mounting

- H01R9/2616—End clamping members

Definitions

- the invention relates to an electrical terminal block, in particular for latching onto a mounting rail, consisting of a plurality of juxtaposed base terminals and a plurality of connector plugs, wherein the individual parent terminals each have a terminal housing, at least one conductor terminal arranged therein and at least one electrically connected to the conductor terminal element slot or at least two interconnected slots, wherein the individual connectors each have a connector housing, at least one conductor connection element arranged therein and an electrically connected to the conductor connection element plug contact and wherein the individual connectors are attachable to the individual terminal housing of the basic terminal.

- the invention also relates to an assembly of at least one connector for plugging onto one of the number of connectors corresponding number of parent terminals and two arranged on both sides of the connector or the mounting lids and a mounting cover for mounting on one side of the connector housing on the terminal housing of a basic terminal attachable connector.

- Electrical terminal blocks have been known for decades and are used millions of times in the wiring of electrical systems and equipment.

- the terminal blocks are usually snapped onto mounting rails, which in turn are often arranged in a plurality in a control cabinet.

- the terminal blocks are usually designed as connection terminals, so that they have at least two conductor connection elements which are electrically connected to one another via an electrically conductive connection rail, the busbar.

- connection terminals so that they have at least two conductor connection elements which are electrically connected to one another via an electrically conductive connection rail, the busbar.

- two-level or three-level terminals as well as three-wire or four-wire terminals may be mentioned, which then each have a correspondingly larger number of conductor connection elements.

- electrical terminal blocks in which at least one conductor connection element is replaced by a slot. On this slot then a connector can be plugged, which has a corresponding plug contact.

- the conductor connection element for connecting an electrical conductor is arranged in the connector housing of the connector.

- Such an electrical terminal is from the DE 295 14 711 U1

- the base clamp is usually snapped onto a mounting rail, so that the base clamp is the stationary part of the electrical terminal.

- the connector forms the ortsver Slichen part of the electrical terminal, since this can be plugged in a simple manner by means of its plug contact on the corresponding slots of the basic terminal or withdrawn from these again.

- the electrical supply lines are connected to the base terminal or to the arranged in the base terminal conductor connection elements, the electrical lines of the individual consumers are connected to the conductor connection element in the connector.

- the electrical terminal blocks are generally disc-shaped, they are usually plugged together with several other electrical terminal blocks to a terminal block. In such known electrical terminal blocks, it is then possible to reduce the wiring work and thus also the installation effort in that the electrical conductors of individual consumers are connected to a corresponding number of connection plugs. Subsequently, the connector, which can be assembled to form a connector block, only need to be plugged into a basic terminal block, wherein the basic terminal block has been assembled from a corresponding number of parent terminals.

- tension spring terminals As conductor connection elements in terminal blocks predominantly screw terminals or spring terminals, in particular tension spring terminals are used.

- the clamping principle with tension spring clamps is similar to that of screwdriving technology. While at the screw terminal a tension sleeve pulls the conductor against the current bar by the actuation of the clamping screw, is in the Tension spring clamp this task taken from the tension spring.

- the prestressed tension spring is opened with an actuating tool, such as a screwdriver, so that the conductor can be inserted through a window in the spring leg of the tension spring in the terminal compartment. After removal of the actuating tool, the conductor is pulled by the spring force of the tension spring against the current bar.

- the electrical conductor must first be stripped after cutting before the contact of the electrical conductor can take place. Since special tools are required for stripping the electrical conductor and since stripping takes time, electrical terminals have also been used for many years, to which electrical conductors can be connected without prior stripping. For this purpose, the insulated conductor is inserted into a conductor receptacle in the housing of the clamp and then pressed into a cutting element, whereby the insulation of the conductor is severed and the soul of the conductor is contacted by the cutting element.

- a fastener provided that is attached to the front side of the connector and engages behind a housing projection on the front side of the base terminal.

- the base terminal has two slots, but the connector can only be plugged onto the outer of the two slots, otherwise the connector can not be attached to the fastener to the base terminal.

- a terminal block which can be plugged together from a plurality of terminal blocks wherein in each case two conductor connection elements which are connected to each other in an electrically conductive manner and which are designed as spring-force terminals are arranged in the terminal housing of the terminal blocks.

- the terminal blocks or the terminal block are to be mounted on a mounting rail, the terminal blocks are each plugged onto a mounting foot, by means of which the individual terminal blocks can be snapped onto the mounting rail.

- the terminal blocks and the terminal block can be secured by the use of two end holders, each having a retaining clip and a support plate against lateral slippage on the mounting rail.

- the individual terminal blocks or the terminal block can also be screwed directly by means of two retaining clips on a housing wall.

- the DE 35 08 972 C1 discloses a terminal block of a plurality of side by side aufrastbaren on a mounting rail terminal blocks, which are limited at their ends by attachable to the support rail end angles.

- the end angle - and thus the terminal block - are held together via a outside of the area enclosed by the support rail area, secured to both end brackets locking pin.

- the present invention has for its object, an electrical terminal block, consisting of several basic terminals and a plurality of connectors designed and further develop such that a secure mechanical attachment of the connector can be ensured with the basic terminals.

- the number of interconnected basic terminals and the number of combined together to form a connector block connector should be freely selectable.

- a connector is to be provided, which can be fixed alone or together with other connectors securely on a base terminal or several basic terminals.

- each a mounting base terminal is arranged, which has a terminal housing with at least one fastening device, and that on both sides of the plurality of juxtaposed connectors each one Fastening cover is arranged, which has a fixing device corresponding to the fastening means, which is arranged eccentrically to the longitudinal direction of the mounting cover, so that the plurality of connector plugs on the mounting cover mechanically with the mounting base terminals - and thus with the basic terminals themselves - are connectable.

- the mechanical attachment of the terminal block to each other interconnected connector is no longer on the front side of the connector or the front side of the base sondem perpendicular thereto, namely by the arrangement of two mounting base clamps and the use of two mounting lids on the two longitudinal sides of the basic terminal block or of the connector plug block.

- the plurality of juxtaposed connector is thus enclosed or bounded laterally by the mounting lids, which can be mechanically fixed by means of the fastening device to the mounting base clamps, which are arranged laterally next to the plurality of side by side arranged parentheses.

- At least two fastening devices are formed in the terminal housing of the mounting base terminals, which are arranged one behind the other in the longitudinal direction of the mounting base terminal.

- the attachment means of the attachment cover is arranged eccentrically to the longitudinal direction of the attachment cover, so that two arranged by 180 ° to each other arranged attachment cover, d. H. two mounting lids, which are arranged with their backs opposite, are mechanically connected to a mounting base clamp together. Due to the eccentric arrangement of the fastening device and the arrangement of two fastening devices one behind the other, then in each case a fastening device cooperate with a fastening device.

- the mechanical connection between the fastening device formed in the fastening base clamp and the fastening device formed on the fastening cover can be designed as a latching connection.

- this connection is designed as a screw connection, for which purpose the fastening device or the fastening devices in the terminal housing of the mounting base clamp is designed as a threaded insert and are and the fastening cover has a screw receptacle and a screw as a fastening device.

- the mounting base clamps and the mounting cover are formed as separate components, the number of connectable to a basic terminal block basic terminals or the number of connectable to a connector plug connector connector is arbitrary. In principle, it is possible to mechanically connect only one connector by means of two mounting lids on the two mounting base clamps with a basic terminal. In general, however, a plurality of connectors, for example, three, four, five or six connectors, be arranged between two mounting lids, which are then plugged and fixed to a consisting of a corresponding number of parent terminals basic terminal block, which has a mounting base clamp on both sides.

- the mechanical connection of the mounting cover with the plug housings of the connector takes place by latching, for which a plurality of locking pins arranged on the mounting lids and in the side wall of the connector housing corresponding recesses are formed.

- the terminal housing of the mounting base terminals with the terminal housings of the basic terminals can be mechanically connected to each other, in which case a locking preferably takes place by means of appropriately trained latching hook and corresponding locking grooves. This allows a connection of the mounting base terminals with the basic terminals when plugging or swinging up done on a mounting rail.

- the terminal housing of the mounting base terminal the same width, preferably also the same length and the same height as the terminal housing of a basic terminal.

- the mounting base clamp thus has the same pitch as the parent terminals themselves, so that only the width of the terminal block, but not its other dimensions changed by the use of the two mounting base terminals.

- the invention also relates to a unit of at least one connector for plugging on a number of connectors corresponding number of parent terminals and two arranged on both sides of the connector or the mounting lids.

- end holders for terminal blocks are known in the prior art, which can be plugged onto a mounting rail and fixed there by means of screws, whereby the terminal blocks arranged between two end holders are fixed in their position in the longitudinal direction of the mounting rail ( US 6,145,213 A ).

- Fastening cover for connector are not yet known.

- the attachment cover is characterized in that it has a fastening device by means of which the unit is fastened on a corresponding number of basic clamps can be.

- the fastening device of the fastening cover is - as previously described in connection with the electrical terminal block according to the invention - arranged eccentrically to the longitudinal direction of the fastening cover, wherein the fastening device preferably consists of a screw holder and a screw.

- the assembly according to the invention not only from a connector, but from several connectors, they are preferably mechanically connected to each other, including either locking pin and corresponding recesses or latching hooks and corresponding locking grooves are formed on the side walls of the connector.

- the individual connection plugs can thus be first plugged together to form a corresponding connection plug block, after which the two fastening covers are then plugged onto the free side walls of the outer connection plug of the connection plug block.

- the invention also relates to a fastening cover for fastening to a side wall of the plug housing of a connector plug, wherein the fastening cover is an off-center to the longitudinal direction having the fastening cover arranged fastening device.

- the fastening device is preferably formed by a screw receptacle into which a corresponding screw can be inserted or screwed.

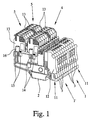

- the Fig. 1 and 2 each show two electrical terminal blocks 1, 1 ', which are snapped on side by side on a support rail 2.

- the two terminal blocks 1, 1 ' consist of three or five mutually adjacent basic terminals 3 and in each case a double number ie six or ten connectors 4, 5, wherein in each case two connectors 4, 5 are attached to a base terminal 3.

- a base terminal 3 For fixing the basic terminals 3 on the support rail 2 corresponding 3, known from the prior art, locking elements are formed in the foot of the base clamp.

- the basic terminals 3 each have a terminal housing 6 consisting of insulating material and two conductor connection elements arranged therein.

- the Conductor connection elements which are designed here as screw terminals, but can also be designed as tension spring terminals, leg spring terminals or as cutting terminals are - not shown here - busbars electrically connected to one slot, to which the connector 4, 5 are plugged.

- Fig. 2 are the individual clamping screws 7 of the screw terminals designed as conductor connection elements of the basic terminals shown.

- the individual basic terminals 3 in particular with regard to the configuration of the conductor connection elements and the slots, is on the Fig. 1 of the DE 295 14 711 U1 directed.

- the individual basic terminals 3 exclusively have slots, so that then the screw terminals formed as conductor connection elements are replaced by corresponding slots.

- the number of conductor connection elements and the slots is variable, so that the invention is not limited to the basic terminals 3 shown in the figures with two conductor connection elements and two slots.

- the conductor connection elements 9 of the connector 4, 5 are also designed as screw terminals and the plug contacts 10 as tulip-shaped sockets.

- the plug contact 10 of the connector 3, 4 may alternatively be designed as a plug socket as a plug pin to form the training, in which case the arranged in the base terminal 3 slot is formed as a corresponding connector socket.

- a fixing base terminal 11 is in each case the mounting rail 2 latched, which have a the dimensions of the terminal housing 6 corresponding terminal housing 12.

- the middle mounting base terminal 11 is assigned to both consisting of three basic terminals 3 (left) basic terminal block as well as consisting of five basic terminals 3 (right) basic terminal block or the associated connector plugs 4, 5.

- each connector block has two mounting cover 13.

- a total of four - threaded inserts 14, 15 are formed in the terminal housings 12 of the mounting base terminals 11 more - in the illustrated embodiments.

- the four threaded inserts 14, 15 are arranged in pairs in succession in the longitudinal direction of the mounting base clamp 11, wherein the first, inner pair of threaded inserts 14 is the inner connector plugs 4 and the second, outer pair of threaded inserts 15 associated with the outer connector plugs 5.

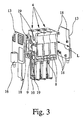

- the fastening cover 13 each have a screw receptacle 16 for a screw 17, which can be screwed into a corresponding threaded insert 14, 15 in the terminal housing 12 of the mounting base terminal 11.

- the screw receptacles 16 are arranged eccentrically to the longitudinal direction of the mounting cover 13 so that two 180 ° rotated to each other arranged attachment cover 13 of two Anschlußstekkerblöcke each in one of the two consecutively arranged threaded inserts 14 and 15 of the mounting base clamp 11 are screwed.

- two, each with their backs facing mounting cover 13 can be fixed together on a mounting base clamp 11.

- This particularly space-saving design is in the middle mounting base clamp 11 in Fig. 2 shown. Due to the off-center arrangement of the screw receptacle 16 on the mounting cover 13 and the formation of two consecutively arranged threaded inserts 14 and 15 in the mounting base 11 thus only three mounting base clamps 11 are required for secure mechanical fixation of two connector blocks with four Befest Trentsdekkeln. If three terminal blocks 1 are snapped together next to one another on a support rail, then only four fixing base clamps 11 are required for the mechanical fixation of likewise three connector blocks with six fixing lids 13.

- the mounting cover 13 with the plug housings 8 of the connector 4, 5 can be latched, for which purpose a plurality of locking pin 18 and in the side walls of the connector housing 8 corresponding locking recesses 19 are arranged or formed on the mounting lids.

- the terminal housing 12 of the mounting base terminal 11 has the same dimensions, in particular the same pitch as the terminal housing 6 of the basic terminals 3.

- the mounting cover 13 have substantially the same length L as the connector housing 8 of the connector 4, 5.

- one of the two mounting cover 13 also has the same height as the connector housing 8, so that the mounting cover 13 not only for mechanical fixation of the connector 4, 5 on the base terminals 3 but also for sealing arranged in the connector housings 8 conductor connection elements 9 and Plug contacts 10 are used.

Landscapes

- Connections Arranged To Contact A Plurality Of Conductors (AREA)

Description

Die Erfindung betrifft einen elektrischen Reihenklemmenblock, insbesondere zum Aufrasten auf eine Tragschiene, bestehend aus einer Mehrzahl von nebeneinander angeordneten Grundklemmen und einer Mehrzahl von Anschlußsteckern, wobei die einzelnen Grundklemmen jeweils ein Klemmengehäuse, mindestens ein darin angeordnetes Leiteranschlußelement und mindestens einen mit dem Leiteranschlußelement elektrisch verbundenen Steckplatz oder mindestens zwei miteinander verbundene Steckplätze aufweisen, wobei die einzelnen Anschlußstecker jeweils ein Steckergehäuse, mindestens ein darin angeordnetes Leiteranschlußelement und einen mit dem Leiteranschlußelement elektrisch verbundenen Steckkontakt aufweisen und wobei die einzelnen Anschlußstecker auf die einzelnen Klemmengehäuse der Grundklemme aufsteckbar sind.The invention relates to an electrical terminal block, in particular for latching onto a mounting rail, consisting of a plurality of juxtaposed base terminals and a plurality of connector plugs, wherein the individual parent terminals each have a terminal housing, at least one conductor terminal arranged therein and at least one electrically connected to the conductor terminal element slot or at least two interconnected slots, wherein the individual connectors each have a connector housing, at least one conductor connection element arranged therein and an electrically connected to the conductor connection element plug contact and wherein the individual connectors are attachable to the individual terminal housing of the basic terminal.

Daneben betrifft die Erfindung noch eine Baueinheit aus mindestens einem Anschlußstecker zum Aufstecken auf eine der Anzahl der Anschlußstecker entsprechende Anzahl von Grundklemmen und zwei auf beiden Seiten des oder der Anschlußstecker angeordneten Befestigungsdeckeln sowie einen Befestigungsdeckel zum Befestigen an einer Seite des Steckergehäuses eines auf das Klemmengehäuse einer Grundklemme aufsteckbaren Anschlußsteckers.In addition, the invention also relates to an assembly of at least one connector for plugging onto one of the number of connectors corresponding number of parent terminals and two arranged on both sides of the connector or the mounting lids and a mounting cover for mounting on one side of the connector housing on the terminal housing of a basic terminal attachable connector.

Elektrische Reihenklemmen sind seit Jahrzehnten bekannt und werden millionenfach bei der Verdrahtung elektrischer Anlagen und Geräte verwendet. Die Reihenklemmen werden meist auf Tragschienen aufgerastet, welche ihrerseits häufig in einer Mehrzahl in einem Schaltschrank angeordnet sind. Die Reihenklemmen sind in der Regel als Verbindungsklemmen ausgebildet, so daß sie mindestens zwei Leiteranschlußelemente aufweisen, die über eine elektrisch leitende Verbindungsschiene, die Stromschiene, elektrisch miteinander verbunden sind. Neben diesem Grundtyp der Reihenklemmen gibt es darüber hinaus eine Vielzahl von unterschiedlichen Reihenklemmentypen, die speziell den jeweiligen Anwendungsfällen angepaßt sind. Als Beispiel seien hier Doppelstock- oder Dreistock-Klemmen sowie Dreileiter- oder Vierleiter-Klemmen genannt, die dann jeweils eine entsprechend größere Anzahl an Leiteranschlußelementen aufweisen.Electrical terminal blocks have been known for decades and are used millions of times in the wiring of electrical systems and equipment. The terminal blocks are usually snapped onto mounting rails, which in turn are often arranged in a plurality in a control cabinet. The terminal blocks are usually designed as connection terminals, so that they have at least two conductor connection elements which are electrically connected to one another via an electrically conductive connection rail, the busbar. In addition to this basic type of terminal blocks, there are also a variety of different types of terminal blocks that are specially adapted to the particular application. As an example, two-level or three-level terminals as well as three-wire or four-wire terminals may be mentioned, which then each have a correspondingly larger number of conductor connection elements.

Daneben gibt es auch elektrische Reihenklemmen, bei denen zumindest ein Leiteranschlußelement durch einen Steckplatz ersetzt ist. Auf diesen Steckplatz kann dann ein Anschlußstecker aufgesteckt werden, der einen entsprechenden Steckkontakt aufweist. Das Leiteranschlußelement zum Anschließen eines elektrischen Leiters ist dabei im Steckergehäuse des Anschlußsteckers angeordnet.In addition, there are also electrical terminal blocks, in which at least one conductor connection element is replaced by a slot. On this slot then a connector can be plugged, which has a corresponding plug contact. The conductor connection element for connecting an electrical conductor is arranged in the connector housing of the connector.

Eine derartige elektrische Reihenklemme ist aus der

Da die elektrischen Reihenklemmen in der Regel scheibenförmig ausgebildet sind, werden sie meist mit mehreren anderen elektrischen Reihenklemmen zu einem Reihenklemmenblock zusammengesteckt. Bei derartigen bekannten elektrischen Reihenklemmen ist es dann möglich, die Verdrahtungsarbeit und damit auch den Montageaufwand dadurch zu reduzieren, daß die elektrischen Leiter einzelner Verbraucher an eine entsprechende Anzahl von Anschlußsteckern angeschlossen werden. Anschließend müssen die Anschlußstecker, welche zu einem Anschlußsteckerblock zusammengesetzt werden können, nur noch in einen Grundklemmenblock eingesteckt werden, wobei der Grundklemmenblock aus einer entsprechenden Anzahl von Grundklemmen zusammengesetzt worden ist.Since the electrical terminal blocks are generally disc-shaped, they are usually plugged together with several other electrical terminal blocks to a terminal block. In such known electrical terminal blocks, it is then possible to reduce the wiring work and thus also the installation effort in that the electrical conductors of individual consumers are connected to a corresponding number of connection plugs. Subsequently, the connector, which can be assembled to form a connector block, only need to be plugged into a basic terminal block, wherein the basic terminal block has been assembled from a corresponding number of parent terminals.

Als Leiteranschlußelemente werden in Reihenklemmen überwiegend Schraubklemmen oder Federkraftklemmen, insbesondere Zugfederklemmen verwendet. Das Klemmprinzip bei Zugfederklemmen ist ähnlich dem der Schraubtechnik. Während bei der Schraubklemme eine Zughülse durch die Betätigung der Klemmenschraube den Leiter gegen den Strombalken zieht, wird bei der Zugfederklemme diese Aufgabe von der Zugfeder übernommen. Hierzu wird die vorgespannte Zugfeder mit einem Betätigungswerkzeug, beispielsweise einem Schraubendreher geöffnet, so daß der Leiter durch ein Fenster im Federschenkel der Zugfeder in den Anschlußraum eingeführt werden kann. Nach dem Entfernen des Betätigungswerkzeuges wird der Leiter durch die Federkraft der Zugfeder gegen den Strombalken gezogen.As conductor connection elements in terminal blocks predominantly screw terminals or spring terminals, in particular tension spring terminals are used. The clamping principle with tension spring clamps is similar to that of screwdriving technology. While at the screw terminal a tension sleeve pulls the conductor against the current bar by the actuation of the clamping screw, is in the Tension spring clamp this task taken from the tension spring. For this purpose, the prestressed tension spring is opened with an actuating tool, such as a screwdriver, so that the conductor can be inserted through a window in the spring leg of the tension spring in the terminal compartment. After removal of the actuating tool, the conductor is pulled by the spring force of the tension spring against the current bar.

Sowohl bei der Schraubklemme als auch bei der Zugfederklemme muß der elektrische Leiter nach dem Ablängen zunächst abisoliert werden, bevor die Kontaktierung des elektrischen Leiters erfolgen kann. Da für das Abisolieren des elektrischen Leiters Spezialwerkzeug erforderlich ist und da das Abisolieren Zeit in Anspruch nimmt, werden seit vielen Jahren auch elektrische Klemmen verwendet, an die elektrische Leiter ohne vorheriges Abisolieren angeschlossen werden können. Dazu wird der isolierte Leiter in eine Leiteraufnahme im Gehäuse der Klemme eingeführt und anschließend in ein Schneidelement gedrückt, wodurch die Isolierung des Leiters durchtrennt und die Seele des Leiters von dem Schneidelement kontaktiert wird.Both in the screw and the tension spring clamp, the electrical conductor must first be stripped after cutting before the contact of the electrical conductor can take place. Since special tools are required for stripping the electrical conductor and since stripping takes time, electrical terminals have also been used for many years, to which electrical conductors can be connected without prior stripping. For this purpose, the insulated conductor is inserted into a conductor receptacle in the housing of the clamp and then pressed into a cutting element, whereby the insulation of the conductor is severed and the soul of the conductor is contacted by the cutting element.

Zur sicheren mechanischen Verbindung von Anschlußstecker und Grundklemme ist bei der aus der

Aus der

Auch bei dieser elektrischen Reihenklemme ist jedoch ein separates Befestigungselement erforderlich, welches den Anschlußstecker stirnseitig mit der Grundklemme verbindet. Geht das Befestigungselement verloren, so kann es vorkommen, daß ein Anschlußstecker ungewollt von einer Grundklemme abgezogen wird. Insbesondere dann, wenn mehrere Anschlußstecker zu einem Anschlußsteckerblock zusammengesetzt werden sollen, sind darüber hinaus eine Mehrzahl von Befestigungselementen erforderlich, um eine sichere und dauerhafte mechanische Befestigung der Anschlußstecker an den Grundklemmen zu gewährleisten.However, in this electrical terminal, a separate fastener is required, which connects the connector frontally with the base terminal. If the fastener is lost, it may happen that a connector is unintentionally removed from a base terminal. In particular, when multiple connectors are to be assembled into a connector block, moreover, a plurality of fasteners are required to ensure a secure and permanent mechanical attachment of the connector to the parent terminals.

Aus der

Die

Der vorliegenden Erfindung liegt die Aufgabe zugrunde, einen elektrischen Reihenklemmenblock, bestehend aus mehreren Grundklemmen und mehreren Anschlußsteckern derart auszugestalten und weiterzubilden, daß eine sichere mechanische Befestigung der Anschlußstecker mit den Grundklemmen gewährleistet werden kann. Darüber hinaus soll die Anzahl der miteinander verbundenen Grundklemmen sowie die Anzahl der miteinander zu einem Anschlußsteckerblock zusammengefaßten Anschlußstecker frei wählbar seien. Außerdem soll ein Anschlußstecker zur Verfügung gestellt werden, der alleine oder zusammen mit weiteren Anschlußsteckern sicher auf einer Grundklemme bzw. mehreren Grundklemmen befestigt werden kann.The present invention has for its object, an electrical terminal block, consisting of several basic terminals and a plurality of connectors designed and further develop such that a secure mechanical attachment of the connector can be ensured with the basic terminals. In addition, the number of interconnected basic terminals and the number of combined together to form a connector block connector should be freely selectable. In addition, a connector is to be provided, which can be fixed alone or together with other connectors securely on a base terminal or several basic terminals.

Diese Aufgabe ist bei dem eingangs beschriebenen elektrischen Reihenklemmenblock dadurch gelöst, daß auf beiden Seiten der Mehrzahl von nebeneinander angeordneten Grundklemmen je eine Befestigungsgrundklemme angeordnet ist, die ein Klemmengehäuse mit mindestens einer Befestigungsvorrichtung aufweist, und daß auf beiden Seiten der Mehrzahl von nebeneinander angeordneten Anschlußsteckern je ein Befestigungsdeckel angeordnet ist, der eine zur Befestigungsvorrichtung korrespondierende Befestigungseinrichtung aufweist, die außermittig zur Längsrichtung des Befestigungsdeckels angeordnet ist, so daß die Mehrzahl von Anschlußsteckern über die Befestigungsdeckel mechanisch mit den Befestigungsgrundklemmen - und damit auch mit den Grundklemmen selber - verbindbar sind.This object is achieved in the electrical terminal block described above in that on both sides of the plurality of juxtaposed parent terminals each a mounting base terminal is arranged, which has a terminal housing with at least one fastening device, and that on both sides of the plurality of juxtaposed connectors each one Fastening cover is arranged, which has a fixing device corresponding to the fastening means, which is arranged eccentrically to the longitudinal direction of the mounting cover, so that the plurality of connector plugs on the mounting cover mechanically with the mounting base terminals - and thus with the basic terminals themselves - are connectable.

Erfindungsgemäß erfolgt die mechanische Befestigung der zu einem Anschlußsteckerblock miteinander verbundenen Anschlußstecker nicht mehr an der Stirnseite der Anschlußstecker bzw. der Stirnseite der Grundklemme sondem senkrecht dazu, nämlich durch die Anordnung von zwei Befestigungsgrundklemmen und die Verwendung von zwei Befestigungsdeckeln an den beiden Längsseiten des Grundklemmenblocks bzw. des Anschlußsteckerblocks. Die Mehrzahl der nebeneinander angeordneten Anschlußstecker wird somit seitlich von den Befestigungsdeckeln umschlossen bzw. begrenzt, welche mit Hilfe der Befestigungseinrichtung an den Befestigungsgrundklemmen mechanisch fixiert werden können, die seitlich neben der Mehrzahl von nebeneinander angeordneten Grundklemmen angeordnet sind.According to the mechanical attachment of the terminal block to each other interconnected connector is no longer on the front side of the connector or the front side of the base sondem perpendicular thereto, namely by the arrangement of two mounting base clamps and the use of two mounting lids on the two longitudinal sides of the basic terminal block or of the connector plug block. The plurality of juxtaposed connector is thus enclosed or bounded laterally by the mounting lids, which can be mechanically fixed by means of the fastening device to the mounting base clamps, which are arranged laterally next to the plurality of side by side arranged parentheses.

Gemäß einer besonders bevorzugten Ausgestaltung der Erfindung sind im Klemmengehäuse der Befestigungsgrundklemmen mindestens zwei Befestigungsvorrichtungen ausgebildet, die in Längsrichtung der Befestigungsgrundklemme hintereinander angeordnet sind. Außerdem ist die Befestigungseinrichtung der Befestigungsdeckel außermittig zur Längsrichtung der Befestigungsdeckel angeordnet, so daß zwei um 180° zueinander gedreht angeordnete Befestigungsdeckel, d. h. zwei Befestigungsdeckel, die mit ihren Rückseiten gegenüberliegend angeordnet sind, gemeinsam mechanisch mit einer Befestigungsgrundklemme verbindbar sind. Durch die außermittige Anordnung der Befestigungseinrichtung und die Anordnung von zwei Befestigungsvorrichtungen hintereinander, kann dann jeweils eine Befestigungseinrichtung mit einer Befestigungsvorrichtung zusammenwirken.According to a particularly preferred embodiment of the invention, at least two fastening devices are formed in the terminal housing of the mounting base terminals, which are arranged one behind the other in the longitudinal direction of the mounting base terminal. In addition, the attachment means of the attachment cover is arranged eccentrically to the longitudinal direction of the attachment cover, so that two arranged by 180 ° to each other arranged attachment cover, d. H. two mounting lids, which are arranged with their backs opposite, are mechanically connected to a mounting base clamp together. Due to the eccentric arrangement of the fastening device and the arrangement of two fastening devices one behind the other, then in each case a fastening device cooperate with a fastening device.

Grundsätzlich kann die mechanische Verbindung zwischen der in der Befestigungsgrundklemme ausgebildeten Befestigungsvorrichtung und der am Befestigungsdeckel ausgebildeten Befestigungseinrichtung als Rastverbindung ausgebildet sein. Vorzugsweise ist diese Verbindung jedoch als Schraubverbindung ausgebildet, wozu die Befestigungsvorrichtung bzw. die Befestigungsvorrichtungen im Klemmengehäuse der Befestigungsgrundklemme als Gewindeeinsatz ausgebildet ist bzw. sind und die Befestigungsdeckel eine Schraubenaufnahme und eine Schraube als Befestigungseinrichtung aufweisen. Hierdurch ist eine sichere und dauerhafte mechanische Befestigung der Befestigungsdeckel und damit der Anschlußstecker auf der Befestigungsgrundklemme sichergestellt, indem eine entsprechende Schraube in die Schraubenaufnahme am Befestigungsdeckel eingesteckt und dann in den Gewindeeinsatz in der Befestigungsgrundklemme eingeschraubt wird.In principle, the mechanical connection between the fastening device formed in the fastening base clamp and the fastening device formed on the fastening cover can be designed as a latching connection. Preferably, however, this connection is designed as a screw connection, for which purpose the fastening device or the fastening devices in the terminal housing of the mounting base clamp is designed as a threaded insert and are and the fastening cover has a screw receptacle and a screw as a fastening device. This ensures a secure and permanent mechanical attachment of the mounting cover and thus the connector on the mounting base clamp by a corresponding screw in the Insert the screw holder on the mounting cover and then screw it into the threaded insert in the mounting base clamp.

Dadurch, daß die Befestigungsgrundklemmen und die Befestigungsdeckel als separate Bauteile ausgebildet sind, ist die Anzahl der zu einem Grundklemmenblock verbindbaren Grundklemmen bzw. die Anzahl der zu einem Anschlußsteckerblock verbindbaren Anschlußstecker frei wählbar. Grundsätzlich ist es möglich, lediglich einen Anschlußstecker mittels zweier Befestigungsdeckel mechanisch über die beiden Befestigungsgrundklemmen mit einer Grundklemme zu verbinden. In der Regel werden jedoch mehrere Anschlußstecker, beispielsweise drei, vier, fünf oder sechs Anschlußstecker, zwischen zwei Befestigungsdeckeln angeordnet sein, die dann auf einen aus einer entsprechenden Anzahl an Grundklemmen bestehenden Grundklemmenblock, der an beiden Seiten eine Befestigungsgrundklemme aufweist, aufgesteckt und fixiert werden.The fact that the mounting base clamps and the mounting cover are formed as separate components, the number of connectable to a basic terminal block basic terminals or the number of connectable to a connector plug connector connector is arbitrary. In principle, it is possible to mechanically connect only one connector by means of two mounting lids on the two mounting base clamps with a basic terminal. In general, however, a plurality of connectors, for example, three, four, five or six connectors, be arranged between two mounting lids, which are then plugged and fixed to a consisting of a corresponding number of parent terminals basic terminal block, which has a mounting base clamp on both sides.

Vorzugsweise erfolgt die mechanische Verbindung der Befestigungsdeckel mit den Steckergehäusen der Anschlußstecker durch Verrasten, wozu an den Befestigungsdeckeln mehrere Rastzapfen angeordnet und in der Seitenwand der Steckergehäuse korrespondierende Rastausnehmungen ausgebildet sind. Entsprechend können auch die Klemmengehäuse der Befestigungsgrundklemmen mit den Klemmengehäusen der Grundklemmen mechanisch miteinander verbunden werden, wobei hier eine Verrastung vorzugsweise mittels entsprechend ausgebildeter Rasthaken und korrespondierenden Rastnuten erfolgt. Dadurch kann eine Verbindung der Befestigungsgrundklemmen mit den Grundklemmen beim Aufstecken bzw. Aufschwenken auf eine Tragschiene erfolgen.Preferably, the mechanical connection of the mounting cover with the plug housings of the connector takes place by latching, for which a plurality of locking pins arranged on the mounting lids and in the side wall of the connector housing corresponding recesses are formed. Accordingly, the terminal housing of the mounting base terminals with the terminal housings of the basic terminals can be mechanically connected to each other, in which case a locking preferably takes place by means of appropriately trained latching hook and corresponding locking grooves. This allows a connection of the mounting base terminals with the basic terminals when plugging or swinging up done on a mounting rail.

Gemäß einer letzten vorteilhaften Ausgestaltung des erfindungsgemäßen elektrischen Reihenklemmenblocks weist das Klemmengehäuse der Befestigungsgrundklemme dieselbe Breite, vorzugsweise auch dieselbe Länge und dieselbe Höhe wie das Klemmengehäuse einer Grundklemme auf. Die Befestigungsgrundklemme weist somit dasselbe Rastermaß wie die Grundklemmen selber auf, so daß sich durch die Verwendung der beiden Befestigungsgrundklemmen lediglich die Breite des Reihenklemmenblocks, nicht jedoch seine sonstigen Abmaße, verändert.According to a last advantageous embodiment of the electrical terminal block according to the invention, the terminal housing of the mounting base terminal the same width, preferably also the same length and the same height as the terminal housing of a basic terminal. The mounting base clamp thus has the same pitch as the parent terminals themselves, so that only the width of the terminal block, but not its other dimensions changed by the use of the two mounting base terminals.

Neben dem zuvor beschriebenen elektrischen Reihenklemmenblock betrifft die Erfindung auch eine Baueinheit aus mindestens einem Anschlußstecker zum Aufstecken auf eine der Anzahl der Anschlußstecker entsprechende Anzahl von Grundklemmen und zwei auf beiden Seiten des oder der Anschlußstecker angeordneten Befestigungsdeckeln. Zwar sind im Stand der Technik Endhalter für Reihenklemmen bekannt, welche auf eine Tragschiene aufgesteckt und dort mittels Schrauben fixiert werden können, wodurch die zwischen zwei Endhaltern angeordneten Reihenklemmen in ihrer Position in Längsrichtung der Tragschiene fixiert werden (

Die Befestigungseinrichtung des Befestigungsdeckels ist dabei - wie zuvor bereits im Zusammenhang mit dem erfindungsgemäßen elektrischen Reihenklemmenblock beschrieben - außermittig zur Längsrichtung des Befestigungsdeckels angeordnet, wobei die Befestigungseinrichtung vorzugsweise aus einer Schraubenaufnahme und einer Schraube besteht.The fastening device of the fastening cover is - as previously described in connection with the electrical terminal block according to the invention - arranged eccentrically to the longitudinal direction of the fastening cover, wherein the fastening device preferably consists of a screw holder and a screw.

Besteht die erfindungsgemäße Baueinheit nicht lediglich aus einem Anschlußstecker, sondern aus mehreren Anschlußsteckern, so sind diese vorzugsweise mechanisch miteinander verbindbar, wozu an den Seitenwänden der Anschlußstecker entweder Rastzapfen und korrespondierende Rastausnehmungen oder Rasthaken und korrespondierende Rastnuten ausgebildet sind. Die einzelnen Anschlußstecker können somit zunächst zu einem entsprechenden Anschlußsteckerblock zusammengesteckt werden, wonach dann die beiden Befestigungsdeckel auf die freien Seitenwände der außenliegenden Anschlußstecker des Anschlußsteckerblocks aufgesteckt werden.If the assembly according to the invention not only from a connector, but from several connectors, they are preferably mechanically connected to each other, including either locking pin and corresponding recesses or latching hooks and corresponding locking grooves are formed on the side walls of the connector. The individual connection plugs can thus be first plugged together to form a corresponding connection plug block, after which the two fastening covers are then plugged onto the free side walls of the outer connection plug of the connection plug block.

Schließlich betrifft die Erfindung noch einen Befestigungsdeckel zum Befestigen an einer Seitenwand des Steckergehäuses eines Anschlußsteckers, wobei der Befestigungsdeckel eine außermittig zur Längsrichtung des Befestigungsdeckels angeordnete Befestigungsvorrichtung aufweist. Die Befestigungseinrichtung wird dabei vorzugsweise von einer Schraubenaufnahme gebildet, in die eine entsprechende Schraube einsteckbar bzw. einschraubbar ist.Finally, the invention also relates to a fastening cover for fastening to a side wall of the plug housing of a connector plug, wherein the fastening cover is an off-center to the longitudinal direction having the fastening cover arranged fastening device. The fastening device is preferably formed by a screw receptacle into which a corresponding screw can be inserted or screwed.

Im einzelnen gibt es nun eine Vielzahl von Möglichkeiten, den erfindungsgemäßen elektrischen Reihenklemmenblock bzw. die erfindungsgemäße Baueinheit und den erfindungsgemäßen Befestigungsdeckel auszugestalten und weiterzubilden. Dazu wird verwiesen einerseits auf die den Patentansprüchen 1, 10 und 15 nachgeordneten Patentansprüche, andererseits auf die nachfolgende Beschreibung bevorzugter Ausfiihrungsbeispiele in Verbindung mit der Zeichnung. In der Zeichnung zeigen

- Fig. 1

- eine perspektivische Darstellung zweier nebeneinander auf einer Tragschiene angeordneter elektrischer Reihenklemmenblöcke,

- Fig. 2

- eine Draufsicht auf die beiden Reihenklemmenblöcke gemäß

Fig. 1 , - Fig. 3

- eine erste perspektivische Darstellung einer Baueinheit aus drei Anschlußsteckern und zwei Befestigungsdeckeln, und

- Fig. 4

- eine zweite perspektivische Darstellung der Baueinheit gemäß

Fig. 3 .

- Fig. 1

- a perspective view of two juxtaposed on a support rail electrical terminal blocks,

- Fig. 2

- a plan view of the two terminal blocks according to

Fig. 1 . - Fig. 3

- a first perspective view of an assembly of three connector plugs and two mounting lids, and

- Fig. 4

- a second perspective view of the assembly according to

Fig. 3 ,

Die

Die Grundklemmen 3 weisen jeweils ein aus Isolierstoff bestehendes Klemmengehäuse 6 und zwei darin angeordnete Leiteranschlußelemente auf. Die Leiteranschlußelemente, welche hier als Schraubklemmen ausgebildet sind, ebenso jedoch auch als Zugfederklemmen, Schenkelfederklemmen oder als Schneidanschlußklemmen ausgebildet sein können, sind über - hier nicht dargestellte - Stromschienen elektrisch mit je einem Steckplatz verbunden, auf den die Anschlußstecker 4, 5 aufgesteckt sind. In

Bezüglich einer alternativen Ausgestaltung der einzelnen Grundklemmen 3, insbesondere im Hinblick auf die Ausgestaltung der Leiteranschlußelemente und der Steckplätze, wird auf die

Die insbesondere in den

Auf beiden Seiten der miteinander verbundenen Grundklemmenblöcke, die aus einer Mehrzahl von - drei bzw. fünf - nebeneinander angeordneten Grundklemme 3 bestehen, ist jeweils eine Befestigungsgrundklemme 11 auf der Tragschiene 2 aufgerastet, die eine den Abmessungen der Klemmengehäuse 6 entsprechendes Klemmengehäuse 12 aufweisen. Wie insbesondere aus

Aus den

Die Befestigungsdeckel 13 weisen jeweils eine Schraubenaufnahme 16 für eine Schraube 17 auf, die in einen entsprechenden Gewindeeinsatz 14, 15 im Klemmengehäuse 12 der Befestigungsgrundklemme 11 eingeschraubt werden kann. Dadurch kann der Befestigungsdeckel 13 - und damit auch die Anschlußstecker 4, 5 - an der Befestigungsgrundklemme 11 bzw. den Grundklemmen 3 befestigt werden. Die Schraubenaufnahmen 16 sind dabei außermittig zur Längsrichtung der Befestigungsdeckel 13 angeordnet, so daß zwei um 180° zueinander gedreht angeordnete Befestigungsdeckel 13 zweier Anschlußstekkerblöcke jeweils in eine der beiden hintereinander angeordneten Gewindeeinsätzen 14 bzw. 15 der Befestigungsgrundklemme 11 einschraubbar sind. Somit können zwei, einander mit ihren Rückseiten zugewandte Befestigungsdeckel 13 gemeinsam auf einer Befestigungsgrundklemme 11 fixiert werden.The

Diese besonders platzsparende Ausführung ist bei der mittleren Befestigungsgrundklemme 11 in

Anhand der

Ebenso weisen auch die Befestigungsdeckel 13 im wesentlichen die gleiche Länge L wie die Steckergehäuse 8 der Anschlußstecker 4, 5 auf. Darüber hinaus weist einer der beiden Befestigungsdeckel 13 auch noch dieselbe Höhe wie das Steckergehäuse 8 auf, so daß die Befestigungsdeckel 13 nicht nur zur mechanischen Fixierung der Anschlußstecker 4, 5 auf den Grundklemmen 3 sondern auch zur Abdichtung der in den Steckergehäusen 8 angeordneten Leiteranschlußelemente 9 und Steckkontakte 10 dienen.Likewise, the mounting

Claims (17)

- Electrical terminal block (1, 1'), especially for latching onto a mounting rail (2), consisting of a plurality of base terminals (3) arranged side by side and a plurality of connectors (4, 5), wherein the individual base terminals (3) each have a terminal housing (6), at least one conductor terminal element arranged therein and at least one receptacle electrically connected to the conductor terminal element or at least two receptacles connected to one another, wherein each connector (4, 5) has a connector housing (8), at least one conductor terminal element (9) arranged therein and one plug-in contact (10) electrically connected to the conductor terminal element (9) and wherein the individual connectors (4, 5) can be plugged onto individual terminal housings (6) of the base terminal (3)

characterized in

that one fixing base terminal (11) is arranged on each side of the plurality of adjacently arranged base terminals (3), which has a terminal housing (12) with at least one fixing device (14, 15), and

that one fixing cover (13) is arranged on each side of the plurality of adjacently arranged connectors (4, 5), which has a fixing means corresponding to the fixing device (14, 15), which is disposed off-center to the longitudinal direction of the fixing cover (13),

so that the plurality of connectors (4, 5) can be mechanically connected via the fixing covers (13) to the fixing base terminal (11). - Electrical terminal block (1, 1') according to claim 1, characterized in that at least two fixing devices (14, 15) are formed in the terminal housing (12) of the fixing base terminal (11), which are arranged in succession in the longitudinal direction of the fixing base terminal (11), so that two fixing covers (13) mutually rotated by 180° can be commonly mechanically connected to a fixing base terminal (11), wherein, in each case, a fixing means (16) interacts with a fixing device (14, 15).

- Electrical terminal block (1, 1') according to claim 1 or 2, characterized in that the fixing device or the fixing devices (14, 15) is/are designed in the terminal housing (12) of the fixing base terminal (11) as a threaded insert (14, 15) and in that the fixing cover (13) has a screw receiver (16) and a screw (17) as fixing means.

- Electrical terminal block (1, 1') according to any one of claims 1 to 3, characterized in that the fixing covers (13) can be mechanically connected, in particular latched, to the connector housings (8) of the connectors (4, 5).

- Electrical terminal block (1, 1') according to claim 4, characterized in that a plurality of locking pins (18) are arranged on the fixing covers (13) and corresponding recesses (19) are formed in the side wall of the connector housings (8).

- Electrical terminal block (1, 1') according to any one of claims 1 to 5, characterized in that the terminal housings (12) of the fixing base terminals (11) can be mechanically connected to the terminal housings (6) of the base terminals (3).

- Electrical terminal block (1, 1') according to any one of claims 1 to 6, characterized in that the terminal housings (6) of the base terminals (3) can be mechanically connected to one another.

- Electrical terminal block (1, 1') according to one of claims 1 to 7, characterized in that the terminal housing (12) of the fixing base terminal (11) has the same width and preferably also has the same length and the same height as the terminal housing (6) of the base terminal (3).

- Electrical terminal block (1, 1') according to one of claims 1 to 8, characterized in that the individual base terminals (3) each have two conductor terminal elements and two receptacles electrically connected to the conductor terminal elements, and that two connectors (4, 5) can each be attached in succession in the longitudinal direction of the base terminals (3) to the individual terminal housings (6) of the base terminal (3).

- Modular unit comprising at least one connector (4) for plugging onto a number of base terminals (3) corresponding to the number of connectors (4) and two fixing covers (13) arranged on both sides of the connector (4) or the connectors (4), wherein each connector (4) has a connector housing (8), at least one conductor terminal element (9) arranged therein and one plug-in contact (10) electrically connected to the conductor terminal element (9) and wherein each fixing cover (13) has a fixing mechanism disposed off-center to the longitudinal direction of the fixing cover (13).

- Modular unit according to claim 10, characterized in that the fixing mechanism of the fixing cover (13) consists of a screw receiver (16) and of a screw (17).

- Modular unit according to claim 10 or 11, characterized in that the fixing covers (13) can be mechanically connected to the connector housings (8) of the connector (4), particularly can be latched by means of the locking pins (18) arranged on the fixing covers (13) and the recesses (19) formed in the side wall of the connector housings (8).

- Modular unit according to any one of claims 10 to 12, characterized in that the connector housings (8) of the connectors (4) can be mechanically connected to one another.

- Modular unit according to any one of claims 10 to 13, characterized in that at least one fixing cover (13) has essentially the same length (L) and the same height (H), preferably the same outer circumference as the connector housing (8).

- Fixing cover (13) for attachment to a side wall of the connector housing (8) of a connector (4) that can be plugged onto the terminal housing (6) of a base terminal (3), wherein the fixing cover (13) has a fixing means (16, 17), which is disposed off-center to the longitudinal direction of the fixing cover (13).

- Fixing cover (13) according to claim 15, characterized in that the fixing mechanism consists of a screw receiver (16) and a screw (17).

- Fixing cover (13) according to claim 15 or 16, characterized in that a plurality of locking pins (18) are arranged on the fixing covers (13) for mechanical connection with the connector housings (8) of the connectors (4).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006003064A DE102006003064B4 (en) | 2006-01-20 | 2006-01-20 | Electrical terminal block |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1811604A2 EP1811604A2 (en) | 2007-07-25 |

| EP1811604A3 EP1811604A3 (en) | 2008-06-18 |

| EP1811604B1 true EP1811604B1 (en) | 2013-03-20 |

Family

ID=37909682

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06024525A Not-in-force EP1811604B1 (en) | 2006-01-20 | 2006-11-27 | Electrical terminal block |

Country Status (6)

| Country | Link |

|---|---|

| US (2) | US7537496B2 (en) |

| EP (1) | EP1811604B1 (en) |

| JP (1) | JP4843509B2 (en) |

| CN (1) | CN101030675B (en) |

| DE (1) | DE102006003064B4 (en) |

| ES (1) | ES2409204T3 (en) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101160274B1 (en) * | 2007-10-23 | 2012-06-28 | 아베베 아게 | Terminal block having a connector |

| DE102008014177A1 (en) * | 2008-03-14 | 2009-09-17 | Phoenix Contact Gmbh & Co. Kg | Terminal block and terminal block |

| DE202008015307U1 (en) * | 2008-11-19 | 2010-04-08 | Weidmüller Interface GmbH & Co. KG | Connection system for the realization of branches on continuous conductors |

| DE102009021461A1 (en) * | 2009-05-15 | 2010-11-18 | Moeller Gmbh | Transverse connector for switching devices connected to a supporting element |

| DE102009032147B3 (en) | 2009-07-07 | 2011-07-28 | Phoenix Contact GmbH & Co. KG, 32825 | safety device |

| WO2012018371A1 (en) * | 2010-07-26 | 2012-02-09 | Omega Engineering, Inc. | Terminal block |

| DE102012206600A1 (en) * | 2012-04-20 | 2013-10-24 | Wöhner GmbH & Co. KG Elektrotechnische Systeme | DIN rail adapter |

| DE102012011676B4 (en) * | 2012-05-14 | 2022-02-03 | Phoenix Contact Gmbh & Co. Kg | Fastening clamp and assembly with two fastening clamps and several terminal blocks arranged side by side |

| USD732477S1 (en) * | 2012-06-13 | 2015-06-23 | Phoenix Contact Gmbh & Co. Kg | Plug block comprising a plurality of modular plugs |

| USD731977S1 (en) * | 2012-06-13 | 2015-06-16 | Phoenix Contact Gmbh & Co. Kg | Test plug block comprising a plurality of modular test plugs |

| DE102012107264A1 (en) * | 2012-08-08 | 2014-02-13 | Phoenix Contact Gmbh & Co. Kg | connection module |

| DE102013004666A1 (en) * | 2013-03-19 | 2014-09-25 | Phoenix Contact Gmbh & Co. Kg | Terminal block arrangement |

| DE102013112115A1 (en) * | 2013-11-04 | 2015-05-07 | Phoenix Contact Gmbh & Co. Kg | Bridge module for a component assembly system |

| US9306351B2 (en) * | 2014-02-14 | 2016-04-05 | Huawei Technologies Co., Ltd. | Power distribution connection apparatus |

| FR3025947B1 (en) | 2014-09-16 | 2016-11-11 | Abb France | INSULATING BODY FOR DETACHABLE CONNECTOR |

| EP3076486B1 (en) | 2015-03-30 | 2020-04-22 | TE Connectivity Services GmbH | Row of releasable connectors for junction block |

| CN107636903B (en) * | 2015-04-09 | 2019-07-02 | 菲尼克斯电气开发及制造股份有限公司 | Modularization PCB shell with earth clip |

| DE102015105546A1 (en) * | 2015-04-10 | 2016-10-13 | Phoenix Contact Gmbh & Co. Kg | honeycomb block |

| DE102016109426B4 (en) * | 2016-05-23 | 2019-03-28 | Wago Verwaltungsgesellschaft Mbh | electronic device |

| LU93126B1 (en) * | 2016-06-28 | 2018-01-24 | Phoenix Contact Gmbh & Co Kg Intellectual Property Licenses & Standards | Through terminal |

| DE102017124143A1 (en) * | 2017-10-17 | 2019-04-18 | Phoenix Contact Gmbh & Co. Kg | mounting clamp |

| CN109787019A (en) * | 2017-11-10 | 2019-05-21 | 许继电气股份有限公司 | Connection terminal module, connecting terminal and connecting terminal mounting base |

| US10194553B1 (en) | 2017-11-11 | 2019-01-29 | Rockwell Automation Asia Pacific Business Center Pte. Ltd. | Selectively installable and removable auxiliary wiring device for I/O module |

| US10498053B1 (en) * | 2019-02-19 | 2019-12-03 | Stephen Sawzin | Electrical wiring junction box |

| JP7148155B2 (en) | 2020-01-09 | 2022-10-05 | 宏和 清水 | Handle for strength training device and strength training device provided with the same |

| CN113437570B (en) * | 2021-07-08 | 2022-12-23 | 吉林工程技术师范学院 | Spliced track wiring mechanism for track traffic |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3201747A (en) * | 1965-08-17 | Method for crimping wet spun cellulose triacetate | ||

| US3710301A (en) * | 1971-05-24 | 1973-01-09 | Westinghouse Electric Corp | Bus duct with improved means for connecting housing structures |

| DE3038833A1 (en) * | 1980-10-15 | 1982-05-27 | Robert Bosch Gmbh, 7000 Stuttgart | Fixing bracket for wall mounting of elements - has interlocking brackets to allow elements to be secured to vertical wall |

| US4516189A (en) | 1984-02-29 | 1985-05-07 | Johnson Service Company | Control apparatus having modular construction |

| DE3508972C1 (en) * | 1985-03-13 | 1986-08-07 | C.A. Weidmüller GmbH & Co, 4930 Detmold | Terminal block |

| JPH0359728U (en) * | 1989-10-12 | 1991-06-12 | ||

| DE4438805C1 (en) * | 1994-10-31 | 1996-03-07 | Weidmueller Interface | Field bus connection module for coupling of local bus conductor of machine and plant control systems |

| DE29514711U1 (en) * | 1995-09-13 | 1995-11-02 | Weidmüller Interface GmbH & Co, 32760 Detmold | Terminal block arrangement |

| DE19635821C1 (en) * | 1996-09-04 | 1997-11-27 | Weidmueller Interface | Connector block which can be attached to carrier rail |

| GB2327158B (en) * | 1997-07-08 | 1999-09-22 | Weidmuller Limited | Fuseholder |

| JP4174096B2 (en) | 1998-03-31 | 2008-10-29 | ソニーマニュファクチュアリングシステムズ株式会社 | Position detection device |

| US6146213A (en) * | 1998-12-10 | 2000-11-14 | Yoon; Heung-Sik | Wire connection with exchangeable securing member for electric connection terminal assembly |

| US6425770B1 (en) * | 2000-04-14 | 2002-07-30 | Rockwell Automation Technologies, Inc. | Input/output device having removable module |

| US6452770B1 (en) * | 2000-05-31 | 2002-09-17 | Lucent Technologies Inc. | Power buss inhibit through data input/output lines |

| DE10045498C5 (en) * | 2000-09-13 | 2006-06-08 | Phoenix Contact Gmbh & Co. Kg | Electrical terminal block |

| US6521837B2 (en) * | 2001-02-23 | 2003-02-18 | Universal Electric Corporation | Electrical busway housing system and connection means therefor |

| FR2822015B1 (en) * | 2001-03-09 | 2003-04-25 | Valeo Electronique | ELECTRONIC BOX WITHOUT OPENING COVER |

-

2006

- 2006-01-20 DE DE102006003064A patent/DE102006003064B4/en active Active

- 2006-11-27 ES ES06024525T patent/ES2409204T3/en active Active

- 2006-11-27 EP EP06024525A patent/EP1811604B1/en not_active Not-in-force

-

2007

- 2007-01-12 US US11/622,656 patent/US7537496B2/en not_active Expired - Fee Related

- 2007-01-18 JP JP2007009276A patent/JP4843509B2/en not_active Expired - Fee Related

- 2007-01-22 CN CN2007100044334A patent/CN101030675B/en not_active Expired - Fee Related

-

2009

- 2009-05-14 US US12/465,790 patent/US7753739B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2007194218A (en) | 2007-08-02 |

| JP4843509B2 (en) | 2011-12-21 |

| ES2409204T3 (en) | 2013-06-25 |

| DE102006003064A1 (en) | 2007-08-09 |

| CN101030675B (en) | 2010-06-23 |

| US20070173136A1 (en) | 2007-07-26 |

| DE102006003064B4 (en) | 2010-04-15 |

| US7753739B2 (en) | 2010-07-13 |

| EP1811604A3 (en) | 2008-06-18 |

| CN101030675A (en) | 2007-09-05 |

| EP1811604A2 (en) | 2007-07-25 |

| US20090221191A1 (en) | 2009-09-03 |

| US7537496B2 (en) | 2009-05-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1811604B1 (en) | Electrical terminal block | |

| EP2255410B1 (en) | Modular terminal, and modular terminal block | |

| EP1189307B1 (en) | Electrical terminal block | |

| EP2839544B1 (en) | Test terminal block | |

| EP2965389B1 (en) | Connection terminal | |

| EP1753087B1 (en) | ELECTRICAL terminal | |

| EP3342005B1 (en) | Electric terminal block | |

| EP2255409A1 (en) | Jumper, and structural unit comprising at least two modular electric terminals and a jumper | |

| EP1760834A2 (en) | Electrical terminal assembly | |

| EP3259807B1 (en) | Electric terminal block | |

| WO2012163716A1 (en) | Test and connection apparatus arrangement, and test apparatus | |

| EP2650983A1 (en) | Coupling for a busbar | |

| DE102008025433B4 (en) | Clamp terminal block | |

| DE102004040859B4 (en) | Electrical terminal block and test plug for use with an electrical terminal | |

| EP2429037B1 (en) | Frame clamp element for electromechanical switching devices with integrated connection piece | |

| DE102017124143A1 (en) | mounting clamp | |

| WO2016206932A1 (en) | Assembly of a terminal device for connecting electric conductors | |

| EP3625854A1 (en) | Connection device for connecting at least one electrical conductor to a stud terminal | |

| DE69904504T2 (en) | BUSSCHIENENVERBINDUNGSSTRUKTUR | |

| DE102008011217B4 (en) | Operating tool for connecting an insulated conductor | |

| DE102019125746A1 (en) | Terminal block arrangement with pick-off terminal | |

| EP3499668A1 (en) | Modular holding element for fastening an electrical bus bar and holding device comprising a plurality of such holding elements | |

| DE19714742A1 (en) | Connecting terminal block for multiple wire connections | |

| DE20214875U1 (en) | Rail mounted switches latch into position and are formed for a connecting plug to engage the switch |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20081216 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20090203 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 602572 Country of ref document: AT Kind code of ref document: T Effective date: 20130415 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502006012622 Country of ref document: DE Effective date: 20130516 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2409204 Country of ref document: ES Kind code of ref document: T3 Effective date: 20130625 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130620 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130621 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20130320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130720 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| 26N | No opposition filed |

Effective date: 20140102 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20131113 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502006012622 Country of ref document: DE Effective date: 20140102 |

|

| BERE | Be: lapsed |

Owner name: PHOENIX CONTACT G.M.B.H. & CO. KG Effective date: 20131130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20131127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131130 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131127 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 602572 Country of ref document: AT Kind code of ref document: T Effective date: 20131127 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20141107 Year of fee payment: 9 Ref country code: TR Payment date: 20141124 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131127 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20141120 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20061127 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131127 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20151229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141128 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502006012622 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130320 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20160729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151127 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20181122 Year of fee payment: 13 |

|