EP1726235B1 - Storing and applying device - Google Patents

Storing and applying device Download PDFInfo

- Publication number

- EP1726235B1 EP1726235B1 EP06300519.3A EP06300519A EP1726235B1 EP 1726235 B1 EP1726235 B1 EP 1726235B1 EP 06300519 A EP06300519 A EP 06300519A EP 1726235 B1 EP1726235 B1 EP 1726235B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- applicator element

- cavity

- applicator

- branches

- product

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D40/00—Casings or accessories specially adapted for storing or handling solid or pasty toiletry or cosmetic substances, e.g. shaving soaps or lipsticks

- A45D40/26—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball

- A45D40/262—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball using a brush or the like

- A45D40/265—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball using a brush or the like connected to the cap of the container

- A45D40/267—Appliances specially adapted for applying pasty paint, e.g. using roller, using a ball using a brush or the like connected to the cap of the container comprising a wiper

Definitions

- the present invention relates to the applicators of cosmetic products, including care products.

- the European patent application EP 0 875 169-A1 discloses an applicator having an applicator member having a flocked foam block at one end. The lateral surface of the applicator member is striated.

- the European patent EP 0 824 329-B1 discloses a packaging and application device comprising a wiper member consisting at least partially of a cellular material.

- the applicator member is in the form of a hollow body having a cavity adapted to house a reserve of product.

- the French patent application FR 2,771,077 also discloses a packaging device and application comprising a wiper member formed at least in part by a porous material elastically deformable.

- the applicator member has slots that are sufficiently narrow so that the wiper member can hardly reach them, making it possible to preserve a reserve of product inside the applicator member after spinning. .

- the European patent application EP 0 693 263-A1 discloses an applicator comprising a rod at the end of which is disposed a compound application member a loop whose two ends are connected separately to the rod. Such an applicator is more particularly intended for the application of nail polish and the rod has a flexibility close to that of the applicator member.

- the present invention aims to provide a new applicator to achieve a neat makeup, comfortable to use, and able to store a relatively large amount of product.

- the subject of the invention is a packaging and application device as defined in claim 1.

- the application element passes through a wiper member between the moment when it leaving the product and the moment when the composition is applied, the absence of deformation of the cavity can result from the use of a sufficient wiper member flexible to not unduly deform the application element, for example a wiper member having a corrugated lip, or may result from a particular setting of an adjustable wiper member.

- the absence of deformation of the cavity can result from a wiper member that is sufficiently flexible to not unduly stress the application element, for example a wiper member having a corrugated lip, or a particular setting of the wiper member when it is adjustable.

- At least one of the branches may have a flocking coating on at least half of its length, for example, better along its entire length.

- the cavity may be completely or not filled with product before application.

- the product present in the cavity can come directly into contact with the surface to be treated.

- the product may be liquid, being for example intended for application to the lips, skin, or integuments.

- the product may also be solid or powdery, being for example in the form of a loaf, to moisten or not to allow the removal of the product.

- the product is packaged in a container provided with a wiper member, which is for example made of a non-cellular material, for example an elastomer, which may allow to leave more product in the cavity.

- the wiper member comprises for example one or more slots.

- the cavity can provide a reserve of product providing additional autonomy to the application element or easier to deposit a larger amount of product, to enhance a makeup effect, for example the color or brightness of a product applied to the lips, for example the gloss of a lip gloss.

- the application can still take place on the integuments, in particular the eyelashes and / or the eyebrows, for the care or makeup of these.

- At least one of the branches may have, in cross section, an at least partially rounded shape. Such a shape can improve application comfort and reduce the risk that movement of the applicator element over the area to be removed removes previously applied product.

- At least one of the branches may for example have in cross section a circular, oval or elliptical shape.

- at least one of the branches may have a substantially triangular, square or rectangular cross-sectional shape.

- the branches may each have a substantially rectilinear longitudinal axis or curvilinear, possibly corrugated.

- At least one of the branches may have a dimension, in cross section, greater than the width of the cavity, for example a width or height greater than the width of the cavity.

- the cavity may have a maximum width greater than the diameter of the rod.

- the application element may be devoid of metal, which allows for example its passage in a microwave oven.

- the shape of the application element may depend in particular on the region of the body or face on which the product is to be applied.

- the cavity may advantageously extend substantially parallel to a plane forming a non-zero angle with the longitudinal axis of a rod to which the applicator element is connected. At least a portion of the applicator element can thus be elongated along a longitudinal axis that forms a non-zero angle with the longitudinal axis of the support rod.

- the longitudinal axis of the applicator element may be substantially coaxial with that of the rod which carries the applicator element.

- the application element may have a symmetrical envelope surface of revolution or not.

- the applicator element may have a symmetrical shape relative to a median plane, in particular a median plane containing the longitudinal axis of the support rod. The latter can be connected, at the end opposite to that carrying the applicator element, to a closing cap of the container.

- the width of the applicator element can grow and then decrease towards the distal end of the applicator element.

- the width of the applicator element can thus be greater, at least one point of its length, or even more than a quarter or half of its length, to the diameter of the rod.

- the applicator element may comprise at least one longitudinal side that is offset laterally outwardly relative to the rod. The applicator element thus protrudes laterally from the rod on at least one side.

- the applicator element may protrude laterally from the rod, either because of its width which exceeds that of the rod and / or the direction in which it extends.

- the distance from which the applicator element protrudes from the stem may for example correspond to the length of the flocking hairs or be greater.

- the thickness of material around the cavity, at least in the distal half of the applicator element, may be non-constant, for example because of a thicker region formed at the junction of the branches.

- the application element may have a single tip centered on a medial axis, giving more precision to the makeup.

- the applicator element may be devoid of elongated reliefs such as pins or teeth made by molding with the branches of the applicator element and connecting thereto.

- the container comprises, as mentioned above, an attached wiper member, which is for example fixed in the neck of the container.

- Fixation of the applicator element on the rod can be carried out in various ways and the application element can include a fastening tip engaged in the rod.

- the applicator element may comprise a tip crimped into the rod or snapped in or on it. Rather than being attached to the rod, the application element can be made at least partially in one piece with the rod.

- the rod may have an outer diameter greater than or equal to 2.5 mm, better than or equal to 3 mm, in particular of the order of about 4 mm, which gives it a certain rigidity and can increase the precision of the makeup.

- the cavity may extend over more than half the width of the applicator element.

- the cavity can be traversed over more than half the length of the cavity.

- the thickness of the membrane may be less than or equal to 1 mm, by example.

- the cavity may have a non-constant width and, for example, a generally triangular shape.

- the width of the cavity may be less than the width of the two branches together.

- the cavity may extend over more than half the length of the applicator element.

- the application element may have magnetic properties, in particular magnetic particles.

- the application element may comprise proximal and distal portions shaped to facilitate the crossing of the wiper member, when it is present.

- the distal portion may for example be tapered in a direction opposite to the stem.

- the application element may comprise more than two branches, including at least one branch of longitudinal axis not parallel to the longitudinal axis of the application element.

- the two branches of the element for example, have different shapes, for example. It may be the same when the product is intended for application to the lips, for the care or makeup thereof.

- One of the branches is for example thicker, which may allow to decenter the cavity. The latter can be unique.

- the cavity may have a relatively elongated shape, with an m / n ratio for example greater than or equal to 3, or 4, or 5 or 6, where m denotes the length of the cavity and n its widest width.

- a relatively narrow shape of the cavity may promote retention of the product, for example.

- the width of the cavity may pass through an extremum between its two free ends, this extremum being for example a maximum.

- the cavity may extend along a longitudinal axis that is not coincidental with that of the stem, for example parallel but offset or curvilinear.

- the branches may have a longitudinal outer edge convex outwardly, or concave outwards, or substantially rectilinear over a fraction at least of its length, for example about halfway length.

- the application element may comprise a first branch having an outer edge at least partially convex towards the outside and a second branch having an outer edge at least partially concave or rectilinear.

- the application element may also comprise, in a variant, a first branch having an outer edge at least partially concave outwards and a second branch having an outer edge at least partially concave outwards or rectilinearly.

- the outer edge of at least one of the branches may be at least partially grooved.

- the branches can be molded together in a thermoplastic material and be flocked at least partially after molding.

- the branches meet, on the side of the stem, before reaching the latter, when one moves in the direction of the stem.

- the application element may comprise flocking hairs having different lengths and / or diameters, with for example longer hairs in the vicinity. of the distal end of the applicator element, which can make it possible to make up short eyelashes.

- the bristles can be of different materials.

- Such a device offers several possibilities of makeup or treatment of the eyelashes and / or eyebrows, for example an application of the product on the side using one of the branches of the applicator only or a product application flat using both branches.

- the branches can be two in number.

- the branches can be unstriated.

- Such an applicator is flocked with, for example, a mixture of bristles, in particular bristles of different diameter and / or lengths.

- the flocking may in particular extend over at least one of the branches, for example over substantially its entire length.

- the flocking hairs can still be made of different materials.

- a distal portion of the applicator element may thus comprise, for example, a flocking with longer hairs and / or a greater density of hair, in order to facilitate the makeup of short eyelashes.

- the distance between the first and second ends may be constant.

- the three branches define between them a cavity which can be filled with product.

- Such an applicator is used for example for makeup or care of the skin, mucous membranes or integuments.

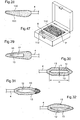

- the device 1 for packaging and application represented at figure 1 comprises a container 2 containing a product P to be applied and an applicator 3 comprising a rod 4 of longitudinal axis X, provided at one end with a gripping element 5 also constituting a sealing cap of the container 2 and at the other end of an application element 6.

- the axis X of the rod 4 is rectilinear but it could be curved, alternatively.

- the container 2 is provided in the upper part with a neck 7.

- the gripping element 5 is screwed on the neck 7 but could alternatively be fixed otherwise, snap-fastening for example.

- the application element 6 has, as can be seen on the figure 5 , a generally symmetrical shape with respect to a median plane of symmetry M and comprises a cavity 12 which is delimited laterally by two branches 13 and axially by distal portions 14 and proximal 15 joining the branches 13.

- the latter are elongated along longitudinal axes respective Y extend substantially parallel to a plane B, as can be seen on the figure 4 , which makes with the axis X of the rod 4 an angle ⁇ which is for example between about 20 ° and about 30 °.

- the angle ⁇ between each Y axis and the median plane of symmetry M is, for example, between 5 and 45 °, as can be seen on FIG. figure 2 .

- the branches 13 and the distal 14 and proximal portions 15 are made by plastic injection and covered with a flocking.

- the distal portion 14 defines a single tip centered on a median axis.

- the application element 6 protrudes laterally from the rod 4, when the latter is observed along its axis.

- the shape of the distal 14 and proximal portions 15 is advantageously chosen so as to facilitate the crossing of the opening 11 of the container 2.

- the proximal portion 15 may thus comprise edges 60, adjacent to the stem 4, extending obliquely relative to the X axis, and the distal portion 14 may have a generally tapered shape.

- the branches 13 converge towards each other towards the distal portion 14 and the cavity 12 has, when the application element 6 is observed in elevation, a substantially triangular shape.

- the cavity 12 extends for example, as can be seen on the Figures 2 and 5 in particular, over more than a quarter of the width b of the applicator element 6 as well as over more than a quarter of its length l .

- the dimensions of the cavity 12 may be chosen as a function of the quantity of product that it is desired to possibly retain, particularly by capillarity, in the cavity 12 after removal of the applicator from the container.

- a wiper member 8 is engaged in the neck 7.

- This wiper member 8 comprises a flange 9 resting on the upper edge of the neck 7 and a wiper lip 10 defining in the example considered an orifice of spinning 11 of circular section, of diameter a, for example substantially equal to that of the rod 4.

- the latter has a diameter generally greater than 2.5 mm, for example of the order of 4 mm.

- the wiper member 8 may be sufficiently flexible so that the application element 6 can be extracted without significant deformation of the cavity 12.

- the product P present in the cavity 12 increases the autonomy of the applicator and can also improve comfort on application, facilitating the sliding of the applicator on the treated surface.

- the product P is for example intended to be applied to the lips and the user can deposit it on them, for example by bringing the rear face 20 of the applicator element 6 to their contact, as illustrated in FIG. figure 7 .

- the rear face 20 corresponds to that which is situated on the rear side when the application element 6 is observed with the branches 13 extending towards the front.

- the deposited product thickness may be different, which may allow the user to vary, for example, the brightness of the makeup.

- the product P present in the cavity 12 can be deposited and the product-laden surface P coming into contact with the lips can be relatively large, so that the lips can be made up pretty quickly.

- the application can be made only with the end of the distal portion 15, to draw an outline for example.

- the wiper member 8 is constituted by a block of a cellular material, elastically compressible.

- the wiper member 8 may be traversed at its center by a recess 42 defining the opening 11 of the container, as can be seen on the figure 9 , with one or more slits.

- the diameter of the recess 42 may for example correspond substantially to that of the rod 4.

- the wiper member may still, regardless of its nature, alveolar or not, have one or more slots, which may be contiguous edges or not.

- FIG. 10 We have represented figure 10 an elastomer wiper member 8 having a central opening, for example circular, for the passage of the rod and the applicator element and several slots 100, which may be radial.

- Fixing the application element 6 on the rod 4 can be effected by various means.

- the proximal portion 15 is extended, as can be seen on the figure 5 , by a tip 18 engaged inside the rod 4.

- This tip 18 is for example glued, stapled or welded in the rod 4. The latter can be further crimped onto the tip, as shown in FIG. figure 11 .

- the figure 12 illustrates the possibility of securing the application element and the rod by snapping.

- the tip 18 is for example configured to snap onto a head 70 made at the end of the rod 4.

- the outer diameter of the tip 18 may then, for example, correspond substantially to that of the rod 4.

- the body of the applicator element can still be made in one piece with the rod 4, as illustrated in FIG. figure 13 .

- the applicator element 6 may have an edge 72 extending substantially in alignment with the rod 4.

- the applicator element 6 protrudes laterally from the rod 4 on the side opposite the edge 72.

- the application element 6 may also comprise more than one cavity 12, for example two cavities 12 as shown in FIG. figure 17 .

- the two cavities 12 are for example aligned along the longitudinal axis of the applicator element 6.

- the latter may have, for example, in front view, the general shape of an eight.

- the application element 6 extends obliquely relative to the longitudinal axis X of the rod 4.

- the applicator element 6 can be further extended, in a non-illustrated variant, along a curvilinear longitudinal axis.

- each branch 13 may for example extend with its longitudinal axis Y contained in a plane which is parallel to the longitudinal axis X of the rod 4.

- the cavity 12 opens at the front and at the back of the applicator element 6, when it is observed from the front, as on the figure 2 .

- the branches 13 may have, over at least a portion of their length, a solid cross section, of circular shape for example. We have illustrated on Figures 18 to 22 the possibility for the branches 13 to present a different shape in section. In a variant not shown, the branches 13 are hollow.

- the branches 13 may for example have a height h which is greater than the width w of the cavity 12 between the branches, as illustrated in FIG. figure 22 .

- the cavity 12 is filled with air before any contact of the application element 6 with the product contained in the container. It could be otherwise.

- the cavity 12 may for example be at least partially occupied by the flocking extending on the body of the applicator element 6, as is the case in the example illustrated in FIG. figure 23 .

- the flocking hairs covering the body of the application element 6 may for example be long enough for the bristles located on the facing faces of the branches 13 to meet.

- the application element 6 can, as illustrated in FIG. figure 24 , have two cavities 12 which are separated by a membrane 80 joining the branches 13 and located for example mid-thickness thereof.

- the cavity 12 can only lead to one face of the application element 6, as illustrated in FIG. figure 25 , the application element may comprise a membrane 82 defining for example at least partially the application surface by its outer face 83.

- This membrane 82 may for example be flocked externally.

- at least one orifice allows the product contained in the cavity 12 to gain the outer face 83, through the membrane 82.

- This membrane 80 may be flocked or not.

- the membrane 80 may be replaced by a grid 81, as shown in FIG. figure 26 .

- the membranes 80 or 82 may be molded in one piece with the branches 13.

- the membrane 82 may be replaced by an attached membrane 34, as illustrated in FIG. figure 27 .

- the membrane 34 may for example comprise a woven or a nonwoven, a foam, a perforated film, a grid, a felt, among others, and may be fixed by welding or gluing, for example.

- the membrane 34 may be permeable or not to the product P contained in the cavity 12.

- the body of the application element 6 is for example made at least partially by injection molding in a thermoplastic material, for example PVC, PU, EVA, SIS-SEB, nitrile, silicone, EPDM, Hytrel®, Pebax® , Santoprene®, or other thermoplastics, for example elastomers.

- a thermoplastic material for example PVC, PU, EVA, SIS-SEB, nitrile, silicone, EPDM, Hytrel®, Pebax® , Santoprene®, or other thermoplastics, for example elastomers.

- the applicator element 6 can also be made of non-thermoplastic materials, for example resins, in particular flexible resins, or be produced otherwise than by molding, for example by cutting.

- Figures 28 and 29 an applicator element 6 having upper and lower faces 131 which converge towards the distal end of the applicator element, at least along a portion of the cavity 12.

- the longitudinal axis X of the rod 4 is for example substantially parallel to one of these faces, for example the upper face 130.

- the application element 6 also has, when viewed from above as shown in FIG. figure 29 , substantially rectilinear longitudinal edges that converge towards the distal end.

- the application elements represented on the Figures 30 to 45 can advantageously be used for the application of a product, makeup or care, on keratin fibers, for example eyelashes or eyebrows.

- the single cavity 12 has an elongated shape, the ratio of the length m of the cavity to the greatest width n thereof being, for example, greater than or equal to 3, or 4, or 5 or 6. For example, there is 3 ⁇ m / n ⁇ 6.

- the figure 30 represents an application element whose cavity 12 has a substantially constant width over at least half of its length.

- the longitudinal edges of the branches 13 are rectilinear and parallel to each other, on either side of a median portion located mid-length of the cavity.

- the applicator element 6 is flocked and its distal portion is covered by bristles longer than those covering the branches 13. This distal portion serves for example to make up the corner of the eye.

- the branches 13 have unequal widths and the cavity 12 is off-center.

- the longitudinal edges of the branches 13 appear grooved, when the applicator element is observed from above.

- the figure 34 illustrates the possibility for the branches 13 of the application element to have concave longitudinal edges outwardly.

- the cavity may then have a width passing through a minimum between its two axial ends.

- the longitudinal edges of the branches are convex outwards, and the cavity 12 presents when viewed from above a lenticular shape.

- the application element represented in figure 36 has a curvilinear longitudinal axis Y and the free end of the applicator element is not on the longitudinal axis X of the rod.

- One of the branches has an outwardly convex outer edge and the other branches an outwardly concave outer edge.

- the application element of the figure 37 has a branch having an outer edge convex outward and another branch having a straight outer edge.

- the cavity 12 can be relatively narrow and form a capillary slot.

- the cavity 12 is wider than in the example of the figure 37 and has a variable width, passing through an extremum.

- the figure 39 illustrates the possibility for the applicator element to comprise two branches, one of which has a rectilinear outer edge and the other a concave outer edge outwards.

- the applicator element has a curvilinear longitudinal axis, as in the example of the figure 36 and the free end of the applicator element is located on the same side, relative to the longitudinal axis X of the rod, as practically all the rest of the applicator element.

- the figure 41 illustrates the possibility for one of the branches of the application element to have grooves while the other branch is devoid of it. These grooves extend for example transversely to the branch.

- the Figures 42 and 43 represent application members having a third limb 16 which joins the distal and proximal portions of the applicator element.

- the third branch is situated on one side of the plane defined by the longitudinal axes of the two branches 13, as can be seen on the figure 44 .

- the branch 16 has for example an arcuate shape.

- the two branches 13 and the third limb 16 are arranged in a regular manner around the longitudinal axis Y of the applicator element, the proximal portion of the applicator element having a section cross-section generally in the shape of a triangle or three-pointed star, as can be seen on figure 45 .

- the application elements of the Figures 30 to 45 are for example made at least partially by molding material, including a thermoplastic material.

- the application elements of the Figures 30 to 45 may allow to load the eyelashes with a relatively large amount of product. Two branches of the application element can be used simultaneously or successively to apply the product on the eyelashes.

- the application of the product may optionally be carried out in various ways depending on the desired result, the application element being for example used flat, on the edge or with various inclinations , the chosen orientation allowing the user to control, for example, the intensity of the makeup and possibly the combing of the eyelashes.

- the application element may have shapes other than those illustrated, for example diamond, circle or ellipse when the application element is observed from the front.

- the application elements may comprise magnetic particles, in order to be able for example to attract magnetic fibers contained in the product.

- an application element having a clearly elongated shape is advantageously made so as to allow this deformation.

- the rod of the applicator may optionally be devoid of the gripping element 5.

- the product P is for example contained, in the form of a paste, a compacted powder or a loose powder or otherwise, in a cup of a housing 110, as illustrated in FIG. figure 47 in an example which does not form part of the invention.

- the applicator is for example received in a corresponding housing 112 of the housing.

- the application element can be loaded into product by being brought into contact with it. Deformation of the application element may or may not occur at the moment the product is taken.

- the application element of Figures 48 to 51 has a more tapered shape when viewed from the side, as on the figure 50 .

- the angles i 1 , i 2 , i 3 are for example respectively between 6 and 16 °, i 1 being for example close to 11 °, 17.7 and 27.7, i 2 being for example close to 20.7 ° and 25.4 and 35.4, i 3 being for example close to 30.4 °.

- the front faces 200 and rear 20 converge towards the distal end 201 of the application element, being for example substantially planar.

- the sides of the applicator element may be rounded both in section in a plane perpendicular to the Y axis and when viewed from above or below on the Figures 48 and 49 .

- the height of the cavity 12, measured perpendicularly to the Y axis, may vary over at least half the length of the cavity.

- the length of the cavity 12, measured along the Y axis, may be less than or equal to 20 mm or greater than 20 mm.

- the cavity 12 may have a width that varies over more than half the length of the cavity 12.

- the container 2 is made with minus two parts 2a and 2b which are movable relative to each other so as to exert a constraint on the wiper member 8 and for example vary the section for the passage of the applicator element.

- the container has an extension 210 under the neck which presses on the wiper member so as to expand more or less thereof.

- the opening thereof may be sufficiently small to exert a stress on the applicator element, which may be deformed as it passes through the wiper member.

- the diameter of the opening of the wiper member is sufficiently large so that the applicator element undergoes no stress during the crossing of the wiper member. spin, or even undergoes a stress that does not cause a significant deformation of the cavity 12.

- the invention is not limited to a way of producing the means for varying the opening of the wiper member.

- the wiper member 8 may include a wavy wringing lip having corrugations 220 which allows it to deploy to the passage of the applicator element. This may make it possible not to exert on the applicator element a stress causing a substantial deformation of the cavity 12.

- the corrugations may for example be in the form of an alternation of hollows and bumps in the circumferential direction around the opening of the wiper member.

Landscapes

- Coating Apparatus (AREA)

- Cosmetics (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Brushes (AREA)

- Closures For Containers (AREA)

Description

La présente invention concerne les applicateurs de produits cosmétiques, y compris de soin.The present invention relates to the applicators of cosmetic products, including care products.

On connaît par le brevet européen

On connaît par le brevet

La demande de brevet européen

Le brevet européen

La demande de brevet français

On connaît par ailleurs par le brevet européen

La demande de brevet européen

On connaît par la demande de brevet

Le brevet

La présente invention vise à proposer un nouvel applicateur permettant de réaliser un maquillage soigné, confortable à utiliser, et capable d'emmagasiner une quantité relativement importante de produit.The present invention aims to provide a new applicator to achieve a neat makeup, comfortable to use, and able to store a relatively large amount of product.

Selon l'un de ses aspects, l'invention a pour objet un dispositif de conditionnement et d'application tel que défini dans la revendication 1. Quand l'élément d'application passe à travers un organe d'essorage entre le moment où il quitte le produit et le moment où la composition est appliquée, l'absence de déformation de la cavité peut résulter de l'utilisation d'un organe d'essorage suffisamment flexible pour ne pas déformer outre mesure l'élément d'application, par exemple un organe d'essorage comportant une lèvre ondulée, ou peut 'résulter d'un réglage particulier d'un organe d'essorage réglable.According to one of its aspects, the subject of the invention is a packaging and application device as defined in

Lorsque l'élément d'application traverse un organe d'essorage entre le moment où il quitte le produit et celui où le produit est appliqué, l'absence de déformation de la cavité peut résulter d'un organe d'essorage suffisamment souple pour ne pas contraindre outre mesure l'élément d'application, par exemple un organe d'essorage comportant une lèvre ondulée, ou un réglage particulier de l'organe d'essorage lorsque celui-ci est réglable.When the applicator element passes through a wiper member between the moment when it leaves the product and that where the product is applied, the absence of deformation of the cavity can result from a wiper member that is sufficiently flexible to not unduly stress the application element, for example a wiper member having a corrugated lip, or a particular setting of the wiper member when it is adjustable.

L'une au moins des branches peut comporter un revêtement de flocage sur au moins la moitié de sa longueur, par exemple, mieux sur toute sa longueur.At least one of the branches may have a flocking coating on at least half of its length, for example, better along its entire length.

La cavité peut être complètement ou non remplie de produit, avant l'application. Le produit présent dans la cavité peut venir directement au contact de la surface à traiter.The cavity may be completely or not filled with product before application. The product present in the cavity can come directly into contact with the surface to be treated.

Le produit peut être liquide, étant par exemple destiné à l'application sur les lèvres, la peau, ou les phanères. Le produit peut encore être solide ou pulvérulent, étant par exemple sous la forme d'un pain, à humidifier ou non pour permettre le prélèvement du produit.The product may be liquid, being for example intended for application to the lips, skin, or integuments. The product may also be solid or powdery, being for example in the form of a loaf, to moisten or not to allow the removal of the product.

Le produit est conditionné dans un récipient pourvu d'un organe d'essorage, lequel est par exemple réalisé dans un matériau non alvéolaire, par exemple un élastomère, ce qui peut permettre de laisser davantage de produit dans la cavité. L'organe d'essorage comporte par exemple une ou plusieurs fentes.The product is packaged in a container provided with a wiper member, which is for example made of a non-cellular material, for example an elastomer, which may allow to leave more product in the cavity. The wiper member comprises for example one or more slots.

La cavité peut permettre de constituer une réserve de produit procurant une autonomie supplémentaire à l'élément d'application ou permettant de déposer plus facilement une quantité plus importante de produit, afin de renforcer un effet du maquillage, par exemple la couleur ou la brillance d'un produit appliqué sur les lèvres, par exemple la brillance d'un brillant à lèvres. L'application peut encore avoir lieu sur les phanères, notamment les cils et/ou les sourcils, pour le soin ou le maquillage de ceux-ci.The cavity can provide a reserve of product providing additional autonomy to the application element or easier to deposit a larger amount of product, to enhance a makeup effect, for example the color or brightness of a product applied to the lips, for example the gloss of a lip gloss. The application can still take place on the integuments, in particular the eyelashes and / or the eyebrows, for the care or makeup of these.

Lorsque seule une portion de l'élément d'application est floquée, cela peut permettre par exemple à l'utilisateur de sélectionner la branche, l'extrémité, le côté ou la face de l'élément d'application qui est floqué ou non en fonction du résultat de maquillage souhaité.When only a portion of the application element is flocked, this may allow for example the user to select the branch, the end, the side or the face of the application element which is flocked or not depending on the desired makeup result.

L'une des branches au moins peut présenter, en section transversale, une forme au moins partiellement arrondie. Une telle forme peut améliorer le confort à l'application et réduire le risque que le déplacement de l'élément d'application sur la région à maquiller n'enlève du produit préalablement appliqué. L'une au moins des branches peut par exemple présenter en section transversale une forme circulaire, ovale ou elliptique. En variante, l'une au moins des branches peut présenter en section transversale une forme sensiblement triangulaire, carrée ou rectangulaire.At least one of the branches may have, in cross section, an at least partially rounded shape. Such a shape can improve application comfort and reduce the risk that movement of the applicator element over the area to be removed removes previously applied product. At least one of the branches may for example have in cross section a circular, oval or elliptical shape. As a variant, at least one of the branches may have a substantially triangular, square or rectangular cross-sectional shape.

Les branches peuvent présenter chacune un axe longitudinal sensiblement rectiligne ou curviligne, éventuellement ondulé.The branches may each have a substantially rectilinear longitudinal axis or curvilinear, possibly corrugated.

Au moins l'une des branches peut présenter une dimension, en section transversale, supérieure à la largeur de la cavité, par exemple une largeur ou une hauteur supérieure à la largeur de la cavité.At least one of the branches may have a dimension, in cross section, greater than the width of the cavity, for example a width or height greater than the width of the cavity.

La cavité peut présenter une largeur maximale supérieure au diamètre de la tige.The cavity may have a maximum width greater than the diameter of the rod.

L'élément d'application, voire l'applicateur tout entier, peut être dépourvu de métal, ce qui autorise par exemple son passage dans un four à micro-ondes.The application element, or even the entire applicator, may be devoid of metal, which allows for example its passage in a microwave oven.

La forme de l'élément d'application pourra dépendre notamment de la région du corps ou du visage sur laquelle le produit doit être appliqué.The shape of the application element may depend in particular on the region of the body or face on which the product is to be applied.

Pour les lèvres par exemple, la cavité peut avantageusement s'étendre sensiblement parallèlement à un plan formant un angle non nul avec l'axe longitudinal d'une tige à laquelle l'élément d'application se raccorde. Une portion au moins de l'élément d'application peut ainsi être allongée selon un axe longitudinal qui forme un angle non nul avec l'axe longitudinal de la tige de support. L'axe longitudinal de l'élément d'application peut encore être sensiblement coaxial à celui de la tige qui porte l'élément d'application.For lips for example, the cavity may advantageously extend substantially parallel to a plane forming a non-zero angle with the longitudinal axis of a rod to which the applicator element is connected. At least a portion of the applicator element can thus be elongated along a longitudinal axis that forms a non-zero angle with the longitudinal axis of the support rod. The longitudinal axis of the applicator element may be substantially coaxial with that of the rod which carries the applicator element.

L'élément d'application peut présenter une surface enveloppe symétrique de révolution ou non. L'élément d'application peut présenter une forme symétrique relativement à un plan médian, notamment un plan médian contenant l'axe longitudinal de la tige de support. Cette dernière peut être reliée, à l'extrémité opposée à celle portant l'élément d'application, à un capuchon de fermeture du récipient.The application element may have a symmetrical envelope surface of revolution or not. The applicator element may have a symmetrical shape relative to a median plane, in particular a median plane containing the longitudinal axis of the support rod. The latter can be connected, at the end opposite to that carrying the applicator element, to a closing cap of the container.

En partant de la tige à laquelle l'élément d'application se raccorde, la largeur de l'élément d'application peut croître puis décroître en direction de l'extrémité distale de l'élément d'application.Starting from the rod to which the applicator element is connected, the width of the applicator element can grow and then decrease towards the distal end of the applicator element.

La largeur de l'élément d'application peut ainsi être supérieure, en au moins un point de sa longueur, voire sur plus du quart ou de la moitié de sa longueur, au diamètre de la tige. L'élément d'application peut comporter au moins un côté longitudinal qui est décalé latéralement vers l'extérieur relativement à la tige. L'élément d'application déborde ainsi latéralement de la tige sur au moins un côté.The width of the applicator element can thus be greater, at least one point of its length, or even more than a quarter or half of its length, to the diameter of the rod. The applicator element may comprise at least one longitudinal side that is offset laterally outwardly relative to the rod. The applicator element thus protrudes laterally from the rod on at least one side.

L'élément d'application peut déborder latéralement de la tige, que ce soit en raison de sa largeur qui excède celle de la tige et/ou de la direction dans laquelle il s'étend.The applicator element may protrude laterally from the rod, either because of its width which exceeds that of the rod and / or the direction in which it extends.

La distance de laquelle l'élément d'application déborde de la tige peut correspondre par exemple à la longueur des poils de flocage ou être plus importante.The distance from which the applicator element protrudes from the stem may for example correspond to the length of the flocking hairs or be greater.

L'épaisseur de matière, autour de la cavité, au moins dans la moitié distale de l'élément d'application, peut être non constante, en raison par exemple d'une région plus épaisse formée à la jonction des branches.The thickness of material around the cavity, at least in the distal half of the applicator element, may be non-constant, for example because of a thicker region formed at the junction of the branches.

L'élément d'application peut présenter une pointe unique centrée sur un axe médian, conférant plus de précision au maquillage.The application element may have a single tip centered on a medial axis, giving more precision to the makeup.

L'élément d'application peut être dépourvu de reliefs de forme allongée tels que des picots ou dents réalisés par moulage avec les branches de l'élément d'application et se raccordant à celles-ci.The applicator element may be devoid of elongated reliefs such as pins or teeth made by molding with the branches of the applicator element and connecting thereto.

Le récipient comporte, comme mentionné plus haut, un organe d'essorage rapporté, lequel est par exemple fixé dans le col du récipient.The container comprises, as mentioned above, an attached wiper member, which is for example fixed in the neck of the container.

La fixation de l'élément d'application sur la tige peut s'effectuer de diverses manières et l'élément d'application peut notamment comporter un embout de fixation engagé dans la tige. L'élément d'application peut comporter un embout serti dans la tige ou encliqueté dans ou sur celle-ci. Plutôt que d'être rapporté sur la tige, l'élément d'application peut encore être réalisé au moins partiellement d'un seul tenant avec la tige.Fixation of the applicator element on the rod can be carried out in various ways and the application element can include a fastening tip engaged in the rod. The applicator element may comprise a tip crimped into the rod or snapped in or on it. Rather than being attached to the rod, the application element can be made at least partially in one piece with the rod.

La tige peut présenter un diamètre extérieur supérieur ou égal à 2,5 mm, mieux supérieur ou égal à 3 mm, notamment de l'ordre de 4 mm environ, ce qui lui confère une certaine rigidité et peut accroître la précision du maquillage.The rod may have an outer diameter greater than or equal to 2.5 mm, better than or equal to 3 mm, in particular of the order of about 4 mm, which gives it a certain rigidity and can increase the precision of the makeup.

La cavité peut s'étendre sur plus de la moitié de la largeur de l'élément d'application.The cavity may extend over more than half the width of the applicator element.

La cavité peut être traversante sur plus de la moitié de la longueur de la cavité. Lorsque la cavité n'est pas traversante et que l'élément d'application comporte une membrane moulée d'un seul tenant avec les branches ou rapportée sur ces dernières, l'épaisseur de la membrane peut être inférieure ou égale à 1 mm, par exemple.The cavity can be traversed over more than half the length of the cavity. When the cavity is not through and the application element comprises a diaphragm molded integrally with the branches or attached thereto, the thickness of the membrane may be less than or equal to 1 mm, by example.

La cavité peut présenter une largeur non constante et, par exemple, une forme générale triangulaire.The cavity may have a non-constant width and, for example, a generally triangular shape.

La largeur de la cavité peut être inférieure à la largeur des deux branches réunies.The width of the cavity may be less than the width of the two branches together.

La cavité peut s'étendre sur plus de la moitié de la longueur de l'élément d'application.The cavity may extend over more than half the length of the applicator element.

L'élément d'application peut présenter des propriétés magnétiques, notamment comporter des particules magnétiques.The application element may have magnetic properties, in particular magnetic particles.

L'élément d'application peut comporter des portions proximale et distale conformées pour faciliter la traversée de l'organe d'essorage, lorsque celui-ci est présent. La portion distale peut par exemple être effilée dans une direction opposée à la tige.The application element may comprise proximal and distal portions shaped to facilitate the crossing of the wiper member, when it is present. The distal portion may for example be tapered in a direction opposite to the stem.

L'élément d'application peut comporter plus de deux branches, dont au moins une branche d'axe longitudinal non parallèle à l'axe longitudinal de l'élément d'application.The application element may comprise more than two branches, including at least one branch of longitudinal axis not parallel to the longitudinal axis of the application element.

Notamment lorsque le produit est destiné à l'application sur les fibres kératiniques, par exemple les cils ou les sourcils, les deux branches de l'élément d'application présentent par exemple des formes différentes. Il peut en être de même lorsque le produit est destiné à l'application sur les lèvres, pour le soin ou le maquillage de celles-ci.In particular when the product is intended for application to keratin fibers, for example eyelashes or eyebrows, the two branches of the element for example, have different shapes, for example. It may be the same when the product is intended for application to the lips, for the care or makeup thereof.

L'une des branches est par exemple plus épaisse, ce qui peut permettre de décentrer la cavité. Cette dernière peut être unique.One of the branches is for example thicker, which may allow to decenter the cavity. The latter can be unique.

La cavité peut présenter une forme relativement allongée, avec un rapport m/n par exemple supérieur ou égal à 3, ou 4, ou 5 ou 6, où m désigne la longueur de la cavité et n sa plus grande largeur. Une forme relativement étroite de la cavité peut favoriser une rétention du produit, par exemple.The cavity may have a relatively elongated shape, with an m / n ratio for example greater than or equal to 3, or 4, or 5 or 6, where m denotes the length of the cavity and n its widest width. A relatively narrow shape of the cavity may promote retention of the product, for example.

La largeur de la cavité peut passer par un extremum entre ses deux extrémités libres, cet extremum étant par exemple un maximum. La cavité peut s'étendre selon un axe longitudinal non confondu avec celui de la tige, par exemple parallèle mais décalé ou curviligne.The width of the cavity may pass through an extremum between its two free ends, this extremum being for example a maximum. The cavity may extend along a longitudinal axis that is not coincidental with that of the stem, for example parallel but offset or curvilinear.

Les branches peuvent présenter un bord extérieur longitudinal convexe vers l'extérieur, ou concave vers l'extérieur, ou sensiblement rectiligne sur une fraction au moins de sa longueur, par exemple à mi-longueur environ.The branches may have a longitudinal outer edge convex outwardly, or concave outwards, or substantially rectilinear over a fraction at least of its length, for example about halfway length.

L'élément d'application peut comporter une première branche ayant un bord extérieur au moins partiellement convexe vers l'extérieur et une deuxième branche ayant un bord extérieur au moins partiellement concave ou rectiligne.The application element may comprise a first branch having an outer edge at least partially convex towards the outside and a second branch having an outer edge at least partially concave or rectilinear.

L'élément d'application peut encore comporter, en variante, une première branche ayant un bord extérieur au moins partiellement concave vers l'extérieur et une deuxième branche ayant un bord extérieur au moins partiellement concave vers l'extérieur ou rectiligne.The application element may also comprise, in a variant, a first branch having an outer edge at least partially concave outwards and a second branch having an outer edge at least partially concave outwards or rectilinearly.

Le bord extérieur d'au moins l'une des branches peut être au moins partiellement rainuré.The outer edge of at least one of the branches may be at least partially grooved.

Les branches peuvent être moulées ensemble dans une matière thermoplastique et être floquées au moins partiellement après leur moulage.The branches can be molded together in a thermoplastic material and be flocked at least partially after molding.

Les branches se rejoignent, du côté de la tige, avant d'atteindre cette dernière, lorsque l'on se déplace en direction de la tige.The branches meet, on the side of the stem, before reaching the latter, when one moves in the direction of the stem.

L'élément d'application peut comporter des poils de flocage présentant des longueurs et/ou des diamètres différents, avec par exemple des poils plus longs à proximité de l'extrémité distale de l'élément d'application, ce qui peut permettre de maquiller des cils courts. Les poils peuvent être en des matériaux différents.The application element may comprise flocking hairs having different lengths and / or diameters, with for example longer hairs in the vicinity. of the distal end of the applicator element, which can make it possible to make up short eyelashes. The bristles can be of different materials.

Un tel dispositif offre plusieurs possibilités de maquillage ou de traitement des cils et/ou sourcils, par exemple une application du produit sur le côté en utilisant l'une des branches de l'applicateur seulement ou une application du produit à plat en utilisant les deux branches. Les branches peuvent être au nombre de deux seulement. Les branches peuvent être non striées.Such a device offers several possibilities of makeup or treatment of the eyelashes and / or eyebrows, for example an application of the product on the side using one of the branches of the applicator only or a product application flat using both branches. The branches can be two in number. The branches can be unstriated.

Un tel applicateur est floqué, avec par exemple un mélange de poils, notamment des poils de diamètre et/ou de longueurs différents. Le flocage peut notamment s'étendre sur l'une des branches au moins, par exemple sur sensiblement toute sa longueur. Les poils de flocage peuvent encore être réalisés en des matériaux différents. Une portion distale de l'élément d'application peut ainsi comporter, par exemple, un flocage avec des poils plus longs et/ou une densité de poils plus grande, afin de faciliter le maquillage des cils courts.Such an applicator is flocked with, for example, a mixture of bristles, in particular bristles of different diameter and / or lengths. The flocking may in particular extend over at least one of the branches, for example over substantially its entire length. The flocking hairs can still be made of different materials. A distal portion of the applicator element may thus comprise, for example, a flocking with longer hairs and / or a greater density of hair, in order to facilitate the makeup of short eyelashes.

La distance entre les première et deuxième extrémités peut être constante. Les trois branches définissent entre elles une cavité qui peut se remplir de produit.The distance between the first and second ends may be constant. The three branches define between them a cavity which can be filled with product.

Un tel applicateur est utilisé par exemple pour le maquillage ou le soin de la peau, des muqueuses ou des phanères.Such an applicator is used for example for makeup or care of the skin, mucous membranes or integuments.

L'invention a encore pour objet, selon un autre de ses aspects, un procédé de maquillage de la peau ou des lèvres tel que défini dans la revendication 43. L'invention pourra être mieux comprise à la lecture de la description détaillée qui va suivre, d'exemples non limitatifs de mise en oeuvre de celle-ci, et à l'examen du dessin annexé, sur lequel :

- la

figure 1 est une coupe longitudinale, schématique et partielle, d'un dispositif de conditionnement et d'application réalisé conformément à l'invention, - la

figure 2 représente isolément l'élément d'application de lafigure 1 , - la

figure 3 est une section transversale selon III-III de lafigure 2 , - la

figure 4 est une vue de côté dans la direction de la flèche IV de lafigure 2 , - la

figure 5 est une coupe longitudinale de l'élément d'application, selon V-V de lafigure 4 , - la

figure 6 représente isolément la partie supérieure d'une variante de réalisation du récipient de lafigure 1 , - la

figure 7 illustre l'utilisation de l'applicateur pour appliquer un produit sur les lèvres, - la

figure 8 illustre la possibilité d'utiliser un organe d'essorage réalisé au moins partiellement dans un matériau alvéolaire, - la

figure 9 est une section transversale selon IX-IX de lafigure 8 , de l'organe d'essorage représenté isolément, - la

figure 10 représente partiellement et en vue de face une variante de réalisation de l'organe d'essorage, - les

figures 11 à 13 sont des vues analogues à lafigure 5 illustrant différents modes de fixation de l'élément d'application sur la tige, - les

figures 14 à 17 sont des vues analogues à lafigure 2 de variantes de réalisation de l'élément d'application, - les

figures 18 à 25 et 27 sont des sections analogues à lafigure 3 de variantes de réalisation, - la

figure 26 est une vue analogue à lafigure 2 d'une variante de réalisation, - la

figure 28 représente en vue de côté un élément d'application conforme à une variante de mise en oeuvre de l'invention, - la

figure 29 représente l'élément d'application de lafigure 28 en vue de dessus, - les

figures 30 à 41 représentent en vue de dessus d'autres exemples d'éléments d'application, - les

figures 42 et 43 représentent de manière schématique, en perspective, des éléments d'application à trois branches, - les

figures 44 et 45 sont des sections transversales respectivement selon XLIV et XLV desfigures 42 et 43 , - la

figure 46 est une coupe longitudinale d'une variante de réalisation de l'applicateur, - la

figure 47 représente un exemple illustratif d'un ensemble qui ne fait pas partie de l'invention, - la

figure 48 est une vue de dessus de variante de réalisation d'un élément d'application, - la

figure 49 est une vue de dessous de l'élément d'application de lafigure 48 , - la

figure 50 représente l'élément d'application en élévation, - la

figure 51 est une coupe selon LI-LI de lafigure 48 , - la

figure 52 représente, de manière schématique, en coupe longitudinale, une variante de réalisation du récipient, et - la

figure 53 représente, de manière schématique et en coupe longitudinale, une variante de réalisation de l'organe d'essorage.

- the

figure 1 is a longitudinal section, schematic and partial, of a packaging and application device produced according to the invention, - the

figure 2 represents in isolation the application element of thefigure 1 , - the

figure 3 is a cross section along III-III of thefigure 2 , - the

figure 4 is a side view in the direction of arrow IV of thefigure 2 , - the

figure 5 is a longitudinal section of the application element, according to VV of thefigure 4 , - the

figure 6 represents in isolation the upper part of an embodiment variant of the container of thefigure 1 , - the

figure 7 illustrates the use of the applicator to apply a product on the lips, - the

figure 8 illustrates the possibility of using a wiper member made at least partially of a cellular material, - the

figure 9 is a cross section along IX-IX of thefigure 8 , the wring member shown in isolation, - the

figure 10 represents partially and in front view an alternative embodiment of the wiper member, - the

Figures 11 to 13 are similar views to thefigure 5 illustrating different modes of attachment of the application element on the rod, - the

Figures 14 to 17 are similar views to thefigure 2 variant embodiments of the application element, - the

Figures 18 to 25 and 27 are sections analogous to thefigure 3 variants of embodiment, - the

figure 26 is a view similar to thefigure 2 an alternative embodiment, - the

figure 28 represents in side view an application element according to an alternative embodiment of the invention, - the

figure 29 represents the application element of thefigure 28 in top view, - the

Figures 30 to 41 represent in top view other examples of application elements, - the

Figures 42 and 43 schematically represent, in perspective, application elements with three branches, - the

Figures 44 and 45 are cross-sections respectively according to XLIV and XLVFigures 42 and 43 , - the

figure 46 is a longitudinal section of an embodiment variant of the applicator, - the

figure 47 represents an illustrative example of a set which does not form part of the invention, - the

figure 48 is a top view of an alternative embodiment of an application element, - the

figure 49 is a bottom view of the application element of thefigure 48 , - the

figure 50 represents the elevation application element, - the

figure 51 is a section according to LI-LI of thefigure 48 , - the

figure 52 represents, schematically, in longitudinal section, an alternative embodiment of the container, and - the

figure 53 represents, schematically and in longitudinal section, an alternative embodiment of the wiper member.

Le dispositif 1 de conditionnement et d'application représenté à la

Dans l'exemple illustré, l'axe X de la tige 4 est rectiligne mais il pourrait être courbe, en variante.In the illustrated example, the axis X of the

Le récipient 2 est pourvu en partie supérieure d'un col 7. L'élément de préhension 5 se visse sur le col 7 mais pourrait en variante se fixer autrement, par encliquetage par exemple.The

Dans l'exemple illustré, l'élément d'application 6 présente, comme on peut le voir sur la

Les branches 13 et les portions distale 14 et proximale 15 sont réalisées par injection de matière plastique et recouvertes d'un flocage. La portion distale 14 définit une pointe unique centrée sur un axe médian.The

L'élément d'application 6 déborde latéralement de la tige 4, lorsque que celle-ci est observée selon son axe. La forme des portions distale 14 et proximale 15 est avantageusement choisie de manière à faciliter le franchissement de l'ouverture 11 du récipient 2. La portion proximale 15 peut ainsi comporter des bords 60, adjacents à la tige 4, s'étendant obliquement relativement à l'axe X, et la portion distale 14 peut présenter une forme générale effilée.The

Dans l'exemple considéré, les branches 13 convergent l'une vers l'autre en direction de la portion distale 14 et la cavité 12 présente, lorsque l'élément d'application 6 est observé en élévation, une forme sensiblement triangulaire.In the example considered, the

La cavité 12 s'étend par exemple, comme on peut le voir sur les

Dans la variante illustrée à la

L'organe d'essorage 8 peut être suffisamment souple pour que l'élément d'application 6 puisse être extrait sans déformation sensible de la cavité 12.The

Le produit P présent dans la cavité 12 accroît l'autonomie de l'applicateur et peut améliorer également le confort à l'application, en facilitant le glissement de l'applicateur sur la surface traitée.The product P present in the

Le produit P est par exemple destiné à être appliqué sur les lèvres et l'utilisateur peut le déposer sur celles-ci en amenant par exemple la face arrière 20 de l'élément d'application 6 à leur contact, comme illustré à la

Lors de l'application, suivant la surface de l'élément d'application 6 en contact avec la zone traitée, l'épaisseur de produit déposée pourra être différente, ce qui peut permettre à l'utilisateur de faire varier par exemple la brillance du maquillage.During the application, depending on the surface of the

Lorsque l'élément d'application 6 est appliqué à plat, le produit P présent dans la cavité 12 peut se déposer et la surface chargée de produit P venant au contact des lèvres peut être relativement importante, de sorte que les lèvres peuvent être maquillées assez rapidement.When the

Le cas échéant, l'application peut se faire seulement avec le bout de la portion distale 15, pour dessiner un contour par exemple.If necessary, the application can be made only with the end of the

On a illustré à la

Sur la

L'organe d'essorage 8 peut être traversé en son centre par un évidement 42 définissant l'ouverture 11 du récipient, comme on peut le voir sur la

Le diamètre de l'évidement 42 peut par exemple correspondre sensiblement à celui de la tige 4.The diameter of the

L'organe d'essorage peut encore, quelle que soit sa nature, alvéolaire ou non, avoir une ou plusieurs fentes, lesquelles peuvent être à bords jointifs ou non.The wiper member may still, regardless of its nature, alveolar or not, have one or more slots, which may be contiguous edges or not.

On a représentée à la

La fixation de l'élément d'application 6 sur la tige 4 peut s'effectuer par divers moyens.Fixing the

Dans l'exemple de la

Cet embout 18 est par exemple collé, agrafé ou soudé dans la tige 4. Cette dernière peut encore être sertie sur l'embout, comme illustré sur la

La

Dans une variante non illustrée, c'est la tige 4 qui est encliquetée sur l'embout 18.In a variant not shown, it is the

Le corps de l'élément d'application peut encore être réalisé d'une seule pièce avec la tige 4, comme illustré sur la

On a illustré à la

On a illustré sur la

L'élément d'application 6 peut encore comporter plus d'une cavité 12, par exemple deux cavités 12 ainsi que représenté à la

Les deux cavités 12 sont par exemple alignées selon l'axe longitudinal de l'élément d'application 6. Ce dernier peut présenter par exemple, en vue de face, la forme générale d'un huit.The two

Dans l'exemple de la

L'élément d'application 6 peut encore être allongé, dans une variante non illustrée, selon un axe longitudinal curviligne.The

L'élément d'application 6 peut être réalisé autrement et chaque branche 13 peut par exemple s'étendre avec son axe longitudinal Y contenu dans un plan qui est parallèle à l'axe longitudinal X de la tige 4.The

Dans l'exemple de la

Les branches 13 peuvent présenter, sur au moins une portion de leur longueur, une section transversale pleine, de forme circulaire par exemple. On a illustré sur les

Les branches 13 peuvent par exemple présenter une hauteur h qui est supérieure à la largeur w de la cavité 12 entre les branches, comme illustré à la

Dans les exemples qui viennent d'être décrits, la cavité 12 est remplie d'air avant tout contact de l'élément d'application 6 avec le produit contenu dans le récipient. Il pourrait en être autrement.In the examples which have just been described, the

Ainsi, la cavité 12 peut par exemple être au moins partiellement occupée par le flocage s'étendant sur le corps de l'élément d'application 6, comme c'est le cas dans l'exemple illustré à la

L'élément d'application 6 peut, comme illustré à la

La cavité 12 peut ne déboucher que sur une face de l'élément d'application 6, comme illustré à la

Cette membrane 80 peut être floquée ou non. La membrane 80 peut être remplacée par une grille 81, comme illustré à la

Les membranes 80 ou 82 peuvent être moulées d'un seul tenant avec les branches 13.The

La membrane 82 peut être remplacée par une membrane 34 rapportée, comme illustré sur la

La membrane 34 peut être perméable ou non au produit P contenu dans la cavité 12.The

Le corps de l'élément d'application 6 est par exemple réalisé au moins partiellement par moulage par injection dans une matière thermoplastique, par exemple du PVC, PU, EVA, SIS-SEB, nitrile, silicone, EPDM, Hytrel®, Pebax®, Santoprene®, ou d'autres thermoplastiques, par exemple élastomères.The body of the

L'élément d'application 6 peut encore être réalisé dans des matières non thermoplastiques, par exemple des résines, notamment des résines souples, ou être réalisé autrement que par moulage, par exemple par découpage.The

On a représenté aux

L'axe longitudinal X de la tige 4 est par exemple sensiblement parallèle à l'une de ces faces, par exemple la face supérieure 130.The longitudinal axis X of the

Dans cet exemple, l'élément d'application 6 présente également, lorsqu'observé de dessus comme représenté à la

Les éléments d'application représentés sur les

Dans ces éléments d'application, la cavité 12, unique, présente une forme allongée, le rapport de la longueur m de la cavité à la plus grande largeur n de celle-ci étant par exemple supérieur ou égal à 3, ou 4, ou 5 ou 6. On a par exemple 3 ≤ m/n ≤ 6.In these application elements, the

La

Dans l'exemple de la

Dans l'exemple de la

Dans l'exemple de la

La

Dans l'exemple de la

L'élément d'application représenté à la

L'élément d'application de la

Dans l'exemple de réalisation de la

La

Dans l'exemple de la

La

Les

Dans l'exemple de la

Dans l'exemple de la

On a illustré à la

Les éléments d'application des

Les éléments d'application des

Pour tous les éléments d'application précédemment décrits, l'application du produit pourra le cas échéant s'effectuer de diverses manières selon le résultat recherché, l'élément d'application étant par exemple utilisé à plat, sur la tranche ou avec diverses inclinaisons, l'orientation choisie permettant à l'utilisateur de contrôler par exemple l'intensité du maquillage et éventuellement le peignage des cils.For all the application elements described above, the application of the product may optionally be carried out in various ways depending on the desired result, the application element being for example used flat, on the edge or with various inclinations , the chosen orientation allowing the user to control, for example, the intensity of the makeup and possibly the combing of the eyelashes.

L'élément d'application peut présenter des formes autres que celles illustrées, par exemple en losange, en cercle ou en ellipse lorsque l'élément d'application est observé de face.The application element may have shapes other than those illustrated, for example diamond, circle or ellipse when the application element is observed from the front.

Les éléments d'application peuvent comporter des particules magnétiques, afin d'être capables par exemple d'attirer des fibres magnétiques contenues dans le produit.The application elements may comprise magnetic particles, in order to be able for example to attract magnetic fibers contained in the product.

Lorsque l'élément d'application est déformable, sa déformabilité peut être mise à profit pour récupérer du produit qui adhère à la surface intérieure du récipient. Un élément d'application présentant une forme nettement allongée, comme c'est le cas par exemple des éléments d'application des

Bien entendu, l'invention n'est pas limitée aux exemples de réalisation qui viennent d'être décrits. On peut notamment combiner entre elles les caractéristiques des différents exemples de réalisation.Of course, the invention is not limited to the embodiments which have just been described. In particular, the characteristics of the different exemplary embodiments can be combined with one another.

Tous les éléments d'application décrits plus haut, notamment ceux décrits en référence au dessin, peuvent être utilisés sans qu'une déformation de l'élément d'application n'intervienne entre le chargement en produit et l'application, ce qui peut être le cas par exemple lorsque ces éléments d'application sont utilisés en association avec une réserve de produit contenue ailleurs que dans un récipient pourvu d'un col.All the application elements described above, especially those described with reference to the drawing, can be used without deformation of the application element between the product loading and the application, which can be the case for example when these application elements are used in combination with a reserve of product contained elsewhere than in a container provided with a neck.

Dans de tels exemples de mise en oeuvre de l'invention, la tige de l'applicateur peut éventuellement être dépourvue de l'élément de préhension 5.In such exemplary embodiments of the invention, the rod of the applicator may optionally be devoid of the

Le produit P est par exemple contenu, sous la forme d'une pâte, d'une poudre compactée ou d'une poudre libre ou autrement, dans une coupelle d'un boîtier 110, comme illustré à la

L'élément d'application peut être chargé en produit en étant amené au contact de celui-ci. Une déformation de l'élément d'application peut avoir lieu ou non au moment où le produit est prélevé.The application element can be loaded into product by being brought into contact with it. Deformation of the application element may or may not occur at the moment the product is taken.

On a représenté aux

Par rapport à l'exemple de réalisation de la

Les faces avant 200 et arrière 20 convergent vers l'extrémité distale 201 de l'élément d'application, étant par exemple sensiblement planes. Les côtés de l'élément d'application peuvent être arrondis à la fois en coupe dans un plan perpendiculaire à l'axe Y et lorsqu'observé de dessus ou de dessous sur les

La longueur de la cavité 12, mesurée le long de l'axe Y, peut être inférieure ou égale à 20 mm ou supérieur à 20 mm.The length of the

La cavité 12 peut présenter une largeur qui varie sur plus de la moitié de la longueur de la cavité 12.The

Lorsqu'un élément d'application, tel que par exemple l'un de ceux décrits plus haut, est utilisé en association avec un organe d'essorage 8, celui-ci peut éventuellement être réglable comme illustré à la

Dans l'exemple de la

Pour un réglage donné de l'organe d'essorage, l'ouverture de celui-ci peut être suffisamment faible pour exercer une contrainte sur l'élément d'application, lequel peut se déformer à la traversée de l'organe d'essorage. Pour un autre réglage de l'organe d'essorage 8, le diamètre de l'ouverture de l'organe d'essorage est suffisamment grand pour que l'élément d'application ne subisse aucune contrainte lors de la traversée de l'organe d'essorage, voire ne subisse qu'une contrainte qui n'entraîne pas une déformation sensible de la cavité 12.For a given setting of the wiper member, the opening thereof may be sufficiently small to exert a stress on the applicator element, which may be deformed as it passes through the wiper member. For another adjustment of the

Bien entendu, l'invention n'est pas limitée à une façon de réaliser les moyens permettant de faire varier l'ouverture de l'organe d'essorage.Of course, the invention is not limited to a way of producing the means for varying the opening of the wiper member.

On a illustré à la

L'expression « comportant un » doit être comprise comme étant synonyme de l'expression « comportant au moins un », sauf si le contraire est spécifié.The expression "having one" shall be understood as being synonymous with the expression "having at least one" unless the contrary is specified.

Claims (43)

- A packaging and applicator device comprising:- a receptacle containing the product (P) for application and including a wiper member (8),- an applicator for applying the product contained in the receptacle, the applicator comprising a stem and an applicator element (6) at one end of the stem projecting laterally therefrom, the applicator element having at least two branches (13) of plastic material, in particular injected plastic material, with at least one of the branches being flocked at least in part, the branches meeting at their ends and defining between them a cavity (12) that is open to the outside via at least one face of the applicator element for use in applying the product, the cavity being elongate in shape and extending along the branches, the branches being sufficiently rigid to prevent the cavity from deforming substantially when the applicator element passes through the wiper member between the moment when the applicator element leaves the product and the moment when the product is applied.

- The device according to claim 1, wherein the cavity (12) opens out via two opposite faces of the applicator element.

- The device according to claim 1, wherein the cavity (12) presents an outline that is closed, in at least one plane.

- The device according to any one of the preceding claims, wherein the cavity (12) extends substantially parallel to a plane forming a non-zero angle (α) with the longitudinal axis (X) of a stem (4) to which the applicator element is connected.

- The device according to any one of the preceding claims, wherein at least a portion (13) of the applicator element (6) is elongate along a longitudinal axis (Y) that forms a non-zero angle (α) with the longitudinal axis of a stem (4) to which the applicator element (6) is connected.

- The device according to any one of the preceding claims, wherein the wiper member is made from elastomer.

- The device according to the preceding claim, wherein the wiper member (8) is secured in a neck (7) of the receptacle.

- The device according to any one of the preceding claims, wherein the applicator element (6) is symmetrical in shape about a midplane, in particular a midplane (M) containing the longitudinal axis (X) of a stem (4) to which the applicator element is connected.

- The device according to any one of the preceding claims, wherein the applicator comprises a stem (4) carrying the applicator element (6) and connected at its other end to a cap (5) for closing the receptacle.

- The device according to claim 9, wherein the applicator element (6) includes a fastener endpiece (18) engaged in the stem (4).

- The device according to claim 9, wherein the stem (4) presents an outside diameter that is greater than or equal to 2.5 mm, better greater than or equal to 3 mm, in particular approximately 4 mm.

- The device according to claim 9, wherein the applicator element is fitted to the stem.

- The device according to claim 9, wherein the applicator element is molded with the stem.

- The device according to any one of the preceding claims, wherein the cavity (12) extends over more than half the width (b) of the applicator element.

- The device according to any one of claims 1 to 13, wherein the width of the cavity is less than the width of the two branches together.

- The device according to any one of the preceding claims, wherein the cavity (12) extends over more than half the length (1) of the applicator element (6).

- The device according to any one of the preceding claims, wherein, prior to any contact with the product, the cavity (12) is filled with air.

- The device according to any one of the preceding claims, wherein the cavity (12) in plan view presents a shape that is substantially triangular.

- The device according to any one of the preceding claims, wherein at least a distal end portion (14) of the applicator element is flocked.

- The device according to any one of claims 1 to 18, wherein the entire surface of the applicator element for applying the product is flocked.

- The device according to any one of the preceding claims, wherein the applicator element presents a cross-section of generally flat shape.