EP1642017B1 - Piston de moteur a combustion interne - Google Patents

Piston de moteur a combustion interne Download PDFInfo

- Publication number

- EP1642017B1 EP1642017B1 EP04738618A EP04738618A EP1642017B1 EP 1642017 B1 EP1642017 B1 EP 1642017B1 EP 04738618 A EP04738618 A EP 04738618A EP 04738618 A EP04738618 A EP 04738618A EP 1642017 B1 EP1642017 B1 EP 1642017B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- piston

- annular element

- piston base

- projection

- annular

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000002485 combustion reaction Methods 0.000 title claims abstract description 10

- 238000001816 cooling Methods 0.000 claims abstract description 12

- 229910000831 Steel Inorganic materials 0.000 claims description 2

- 239000010959 steel Substances 0.000 claims description 2

- 230000002093 peripheral effect Effects 0.000 claims 2

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000000919 ceramic Substances 0.000 description 1

- 239000000110 cooling liquid Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 239000000565 sealant Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/0015—Multi-part pistons

- F02F3/0023—Multi-part pistons the parts being bolted or screwed together

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/16—Pistons having cooling means

- F02F3/20—Pistons having cooling means the means being a fluid flowing through or along piston

- F02F3/22—Pistons having cooling means the means being a fluid flowing through or along piston the fluid being liquid

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F2003/0007—Monolithic pistons; One piece constructions; Casting of pistons

Definitions

- the invention relates to a piston for an internal combustion engine according to the preamble of claim 1.

- a piston for an internal combustion engine which consists of a piston body with pin bosses and with a box-shaped shaft.

- an annular member is welded, in the outside of which a part of the ring part is incorporated, and the upper part is designed as a firing bar.

- the component forms, together with the piston bottom side part of the piston main body an annular cooling channel, which is closed by a molded to the piston body, circumferential wall to the hub side.

- the annular member is welded via each of its two end faces with the piston body, which makes the production of the piston known from the prior art very time consuming and labor-intensive.

- the invention is based on the problem to simplify the manufacturing process of a piston equipped with a cooling channel to accelerate and thus cheaper.

- An expedient embodiment of the invention is the subject of the dependent claim. This results in a quick and easy to produce screw between a piston body and a ring member, which receives high strength by the mechanical stress under which an elastically formed projection sets the ring member.

- Fig. 1 shows a piston 1 for an internal combustion engine in a sectional view, which consists of two halves, of which the left half represents a section of the piston 1 along a longitudinal axis 2 of a hub bore 3 and the right half offset by 90 ° thereto longitudinal section of the piston 1.

- the piston 1 consists of a piston body 4, with a piston element on the bottom side 5, a ring member 6 is screwed, which carries a top land 7 and a ring portion 8 of the piston 1.

- the piston body 4 and the ring member 6 are made of steel.

- the piston main body 4 is formed in one piece and has a combustion bowl 10 in the region of the piston head 9.

- a respective hub support 11, 11 ' two pin bosses 12, 12' each having a hub bore 3, 3 'are integrally formed on the piston head 9, whose end faces 16 are set back relative to the ring member 6 in the direction of the piston longitudinal axis 17.

- the pin bosses 12, 12 ' are connected to each other via shaft elements 13, 13'.

- a carrier of the ring member 6 and a piston body 4 may be used, in which the end faces 16 of the pin bosses 12, 12 'are arranged not reset relative to the ring section 8.

- the recess 18 over the entire circumference of the piston partly between the Shaft members 13, 13 'and the ring member 6 and partly between the pin bosses 12, 12' and the ring member 6 circumferentially arranged.

- the piston body 4 forms in the region of the piston head 9 together with the ring member 6 an annular cooling channel 14, which is partly incorporated in the piston body 4 and partly in the ring member 6.

- the cooling channel 14 is covered by a projection 15 of the piston body 4, which is formed like a plate spring and is arranged starting from the piston body 4 in the direction of the piston head 9 inclined. It can be seen in Fig. 1 also a drain opening 20 of the cooling channel 14th

- Fig. 2 makes a section across the piston 1 along the line AA in Fig. 1 in which the pin bosses 12, 12 'facing side of the piston head 9 can be seen in a bottom view.

- Fig. 2 shows an inlet opening 19 and the discharge opening 20 of the not recognizable in the selected form of representation cooling channel 14 for cooling the piston 1 provided cooling liquid. Hatched are the shaft elements 13, 13 'and the associated pin bosses 12, 12' shown. To recognize are in Fig. 2

- the projection 15, which is visible in the region of the recessed end faces 16 of the pin bosses 12, 12 'in a bottom view, and the lower end face 21 of the ring element. 6

- the thread 5 can be provided with a ceramic sealant for the purpose of improved sealing of the screw first, before the ring member 6 is screwed via the thread 5 on the prefabricated piston body 4.

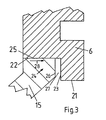

- the lower end face 21 of the ring member 6 comes into contact with the surface 25 of the projection 15, which in the present embodiment is flat, ie, plateau-like, but may also be roof, or dish-shaped or may have a spherical shape.

- the projection 15 is formed so thin-walled that it elastically yields when screwing the ring member 6 when it exerts a pressure on the projection 15. After screwing the ring element 6, the projection 15 thus sets the ring element 6 under mechanical stress, which improves the strength the screw connection between the ring element 6 and the bottom region of the piston main body 4 contributes.

- the lower end face 21 of the ring element 6 is provided with a recess 24 which has on its inside a radially oriented surface 22 and subsequently on its outside an axially aligned surface 23.

- the axially lying surface 23 is screwed into the lower end face 21 of the ring member 6 in the radial direction so far that, as in Fig.

- a radial clearance 27 results when screwing the ring member 6 on the piston 1, the radially oriented surface 22 of the lower end face 21 of Ring element 6 comes into first contact with the surface 25 of the projection 15.

- the radial width of this radial clearance is in this case between 0 .mu.m and 300 .mu.m.

- the elastic compliance of the projection 15 results in further screwing the ring member 6 to the fact that the upper portion of the projection 15 moves in the direction of arrow 28 until the outer boundary surface 26 of the projection 15 to the axially aligned surface 23 of the recess 24 in Stop comes. This contributes to an improvement in the strength of the screw connection and the rigidity of the upper piston area.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

Abstract

Claims (2)

- L'Invention concerne un piston (1) pour un moteur à explosion- doté d'un corps de base (4) en acier forgé, comprenant deux moyeux d'axe (12,12') qui sont reliés chacun avec la base de piston (9) par un support de moyeu (11,11') et qui sont reliés entre eux par deux éléments d'arbre (13, 13') disposés sur la base de piston (9), et- comprenant un élément annulaire (6) qui forme la partie radiale extérieure de la base de piston (9), la couronne de piston (7), au moins un élément de la partie annulaire (8) et un canal de refroidissement (14) annulaire avec le corps de base (4),

les bords extérieurs (16) des moyeux d'axe (12,12') sont reculés par rapport à la surface périphérique du cylindre de piston et des évidements (18) sont formés entre les éléments d'arbre (13, 13') et la partie supérieure du piston (1) portant l'élément annulaire (6) de telle façon qu'une partie saillante (15) périphérique est obtenue pour former conjointement avec l'élément annulaire (6) une délimitation radialement extérieure et axialement inférieure du canal de refroidissement (14),

caractérisée par le fait- que l'élément annulaire (6) est vissé avec le corps de base (4), et- que la partie saillante (15) est réalisée sous la forme d'un anneau de support élastique ou d'une rondelle conique qui ne se déforme pas lors du dévissage de l'élément annulaire (6). - Piston (1) pour un moteur à explosion selon la revendication 1, caractérisé par le fait que le bord (21) de l'élément annulaire (6) faisant face aux moyeux d'axe (12, 12') comporte un évidement (24) dirigé vers l'intérieur avec une surface (22) intérieure disposée radialement et une surface alignée (23) disposée axialement en direction des moyeux d'axe (12, 12'), et que les surfaces de délimitation (25, 26) de la partie saillante (15) faisant face à la base de piston (9) restent adjacentes aux surfaces (22, 23) de l'évidement (24) après le dévissage de l'élément annulaire (6).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10325914A DE10325914B4 (de) | 2003-06-07 | 2003-06-07 | Kolben für einen Verbrennungsmotor |

| PCT/DE2004/001164 WO2004111420A1 (fr) | 2003-06-07 | 2004-06-07 | Piston de moteur a combustion interne |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1642017A1 EP1642017A1 (fr) | 2006-04-05 |

| EP1642017B1 true EP1642017B1 (fr) | 2011-05-11 |

Family

ID=33482690

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04738618A Expired - Lifetime EP1642017B1 (fr) | 2003-06-07 | 2004-06-07 | Piston de moteur a combustion interne |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US6938537B2 (fr) |

| EP (1) | EP1642017B1 (fr) |

| JP (1) | JP4365409B2 (fr) |

| KR (1) | KR101142238B1 (fr) |

| CN (1) | CN100412345C (fr) |

| BR (1) | BRPI0411090B1 (fr) |

| DE (1) | DE10325914B4 (fr) |

| HK (1) | HK1088941A1 (fr) |

| WO (1) | WO2004111420A1 (fr) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10340292A1 (de) * | 2003-09-02 | 2005-04-14 | Mahle Gmbh | Kolben für einen Verbrennungsmotor |

| DE102005044597A1 (de) * | 2005-09-17 | 2007-03-29 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor |

| US20070295299A1 (en) * | 2006-06-12 | 2007-12-27 | Mahle Technology, Inc. | Piston for a combustion engine |

| US20070283917A1 (en) * | 2006-06-12 | 2007-12-13 | Lapp Michael T | Piston for a combustion engine |

| DE102007027162A1 (de) * | 2007-06-13 | 2008-12-18 | Mahle International Gmbh | Zweiteiliger Kolben für einen Verbrennungsmotor |

| DE102007036236A1 (de) * | 2007-08-02 | 2009-02-05 | Mahle International Gmbh | Gebauter Kolben |

| DE102008038325A1 (de) | 2007-12-20 | 2009-06-25 | Mahle International Gmbh | Verfahren zum Befestigen eines Ringelementes auf einem Kolben für einen Verbrennungsmotor |

| DE102008045456A1 (de) * | 2008-09-02 | 2010-03-04 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor |

| WO2011064853A1 (fr) * | 2009-11-25 | 2011-06-03 | トヨタ自動車株式会社 | Piston pour moteur à combustion interne et moteur à combustion interne |

| US8776670B2 (en) * | 2010-02-17 | 2014-07-15 | Mahle International Gmbh | Piston assembly |

| BR112015005723A2 (pt) * | 2012-09-27 | 2017-07-04 | Ks Kolbenschmidt Gmbh | pistão construído em duas peças de uma máquina de combustão interna |

| DE102014000253A1 (de) * | 2014-01-08 | 2015-07-09 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor und Verfahren zu seiner Herstellung |

| EP3452712A1 (fr) | 2016-05-04 | 2019-03-13 | KS Kolbenschmidt GmbH | Piston |

Family Cites Families (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE278074C (fr) * | ||||

| GB186060A (en) * | 1921-09-17 | 1923-02-22 | Christian Bergh Backer | Improvements in or relating to pistons |

| US1723823A (en) * | 1926-03-15 | 1929-08-06 | Perfect Circle Co | Piston |

| DE589409C (de) * | 1930-11-02 | 1933-12-14 | Elektronmetall G M B H | Kolben fuer Brennkraftmaschinen |

| US2244008A (en) * | 1939-06-16 | 1941-06-03 | Gen Motors Corp | Piston construction |

| US2772933A (en) | 1955-06-22 | 1956-12-04 | Alco Products Inc | Pistons |

| DE1049174B (de) * | 1956-10-25 | 1959-01-22 | Mahle Kg | OElgekuehlter Kolben, insbesondere fuer Brennkraftmaschinen |

| US3190273A (en) * | 1964-01-03 | 1965-06-22 | Continental Aviat & Eng Corp | Piston for internal combustion engine |

| DE1245640B (de) * | 1964-11-25 | 1967-07-27 | Mahle Kg | Kolben fuer Brennkraftmaschinen |

| DK112141B (da) * | 1966-07-12 | 1968-11-11 | Burmeister & Wains Mot Mask | Stempel, navnlig til forbrændingsmotorer. |

| DE2140824C2 (de) * | 1971-08-14 | 1983-06-01 | M.A.N. Maschinenfabrik Augsburg-Nürnberg AG, 8900 Augsburg | Ölgekühlter Kolben für Brennkraftmaschinen |

| DE2348870A1 (de) | 1973-09-28 | 1975-04-10 | Maschf Augsburg Nuernberg Ag | Mehrteiliger kolben fuer brennkraftmaschinen, insbesondere grossdieselmotoren |

| DD123962A1 (fr) * | 1975-12-24 | 1977-01-26 | ||

| GB1588515A (en) * | 1976-09-02 | 1981-04-23 | Ass Eng Ltd | Pistons |

| DE2914456A1 (de) * | 1979-04-10 | 1980-10-23 | Schmidt Gmbh Karl | Gebauter kolben fuer brennkraftmaschinen |

| US4286505A (en) * | 1979-04-23 | 1981-09-01 | Caterpillar Tractor Co. | Oil cooled piston |

| DE3338419A1 (de) * | 1983-10-22 | 1985-05-02 | Mtu Motoren- Und Turbinen-Union Friedrichshafen Gmbh, 7990 Friedrichshafen | Kolben fuer eine hubkolbenbrennkraftmaschine |

| IT1240526B (it) * | 1990-07-31 | 1993-12-17 | Borgo Nova S.P.A. | Perfezionamento relativo a pistoni, in genere. |

| DE4208037C2 (de) * | 1992-03-13 | 1998-03-26 | Mahle Gmbh | Mehrteiliger, gekühlter Kolben für Verbrennungsmotoren |

| US6003479A (en) * | 1997-05-12 | 1999-12-21 | Evans; Mark M. | Piston construction |

| DE19846152A1 (de) * | 1998-10-07 | 2000-04-13 | Mahle Gmbh | Kolben mit Kolbengrundkörper aus geschmiedetem Stahl und einem Kühlkanal |

| US6286414B1 (en) * | 1999-08-16 | 2001-09-11 | Caterpillar Inc. | Compact one piece cooled piston and method |

| US6327962B1 (en) * | 1999-08-16 | 2001-12-11 | Caterpillar Inc. | One piece piston with supporting piston skirt |

| DE10047258C2 (de) * | 2000-09-23 | 2003-02-06 | Ks Kolbenschmidt Gmbh | Kolben mit sich am Basisteil abstützenden und angeschweißtem Ringabschnitt |

| JP3714170B2 (ja) * | 2001-02-05 | 2005-11-09 | 日本電気株式会社 | オンラインショッピング決済方法及びそのシステム並びにオンラインショッピング決済プログラム |

-

2003

- 2003-06-07 DE DE10325914A patent/DE10325914B4/de not_active Expired - Fee Related

- 2003-12-30 US US10/749,176 patent/US6938537B2/en not_active Expired - Fee Related

-

2004

- 2004-06-07 KR KR1020057024014A patent/KR101142238B1/ko not_active IP Right Cessation

- 2004-06-07 JP JP2006515670A patent/JP4365409B2/ja not_active Expired - Fee Related

- 2004-06-07 EP EP04738618A patent/EP1642017B1/fr not_active Expired - Lifetime

- 2004-06-07 WO PCT/DE2004/001164 patent/WO2004111420A1/fr active Application Filing

- 2004-06-07 CN CNB2004800158221A patent/CN100412345C/zh not_active Expired - Fee Related

- 2004-06-07 BR BRPI0411090-0A patent/BRPI0411090B1/pt not_active IP Right Cessation

-

2006

- 2006-08-23 HK HK06109370A patent/HK1088941A1/xx not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| EP1642017A1 (fr) | 2006-04-05 |

| JP2006527326A (ja) | 2006-11-30 |

| US20040244581A1 (en) | 2004-12-09 |

| JP4365409B2 (ja) | 2009-11-18 |

| BRPI0411090B1 (pt) | 2015-05-12 |

| DE10325914B4 (de) | 2012-08-02 |

| HK1088941A1 (en) | 2006-11-17 |

| DE10325914A1 (de) | 2004-12-23 |

| BRPI0411090A (pt) | 2006-07-25 |

| CN1802498A (zh) | 2006-07-12 |

| US6938537B2 (en) | 2005-09-06 |

| CN100412345C (zh) | 2008-08-20 |

| KR20060014443A (ko) | 2006-02-15 |

| WO2004111420A1 (fr) | 2004-12-23 |

| KR101142238B1 (ko) | 2012-05-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1960653B1 (fr) | Piston en deux pieces pour moteur a combustion interne | |

| EP1828587B1 (fr) | Piston refroidi et en plusieurs parties destine a un moteur a combustion interne | |

| EP1920152B1 (fr) | Piston en deux parties pour moteur a combustion interne | |

| EP1642017B1 (fr) | Piston de moteur a combustion interne | |

| WO2005124136A1 (fr) | Piston compose conçu pour un moteur a combustion interne | |

| EP1913250B1 (fr) | Piston pour un moteur a combustion interne et bague de fermeture pour le canal de refroidissement dudit piston | |

| WO2006058525A1 (fr) | Piston en deux parties d'un moteur a combustion interne | |

| EP2342441B1 (fr) | Piston avec canal de refroidissement pour un moteur à combustion interne, avec un élément de fermeture qui ferme le canal de refroidissement | |

| WO2008074277A1 (fr) | Insert pour une chemise de cylindre ou un cylindre de moteur à combustion | |

| DE102011013067A1 (de) | Verfahren zur Herstellung eines Kolbens für einen Verbrennungsmotor | |

| EP1636475B1 (fr) | Piston de moteur a combustion interne | |

| EP1636474B1 (fr) | Procede de production d'un piston monobloc pour un moteur a combustion | |

| DE4418284B4 (de) | Drehschwingungsdämpfer-Doppelschwungrad, insbesondere für Kraftfahrzeuge | |

| DE10209168B4 (de) | Stahlkolben mit Kühlkanal | |

| EP1819921B1 (fr) | Piston d'un moteur a combustion interne | |

| WO2005024217A1 (fr) | Piston pour moteur a combustion | |

| WO2007031472A1 (fr) | Pompe a piston | |

| DE102014015947A1 (de) | Kühlkanalabdeckung sowie mit einer Kühlkanalabdeckung versehener Kolben | |

| DE102005044597A1 (de) | Kolben für einen Verbrennungsmotor | |

| EP2893177B1 (fr) | Piston pour moteur à combustion interne | |

| DE10205179A1 (de) | Kühlwasserabdichtung zwischen einem Motorblock und einer Zylinderlaufbuchse | |

| WO2007115525A1 (fr) | Piston pour moteur à combustion interne | |

| DE102006007161A1 (de) | Elastisches Lager, insbesondere für den Nutzfahrzeugbau | |

| WO2015062718A1 (fr) | Piston destiné à un moteur à combustion interne et procédé de fabrication dudit piston |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20051217 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RBV | Designated contracting states (corrected) |

Designated state(s): DE FR GB IT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502004012505 Country of ref document: DE Effective date: 20110622 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120214 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502004012505 Country of ref document: DE Effective date: 20120214 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20150622 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20150622 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150630 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20150630 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004012505 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160607 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20170228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170103 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160607 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160607 |