EP1538645B1 - Hybrid-Leistungsschalter - Google Patents

Hybrid-Leistungsschalter Download PDFInfo

- Publication number

- EP1538645B1 EP1538645B1 EP03293050A EP03293050A EP1538645B1 EP 1538645 B1 EP1538645 B1 EP 1538645B1 EP 03293050 A EP03293050 A EP 03293050A EP 03293050 A EP03293050 A EP 03293050A EP 1538645 B1 EP1538645 B1 EP 1538645B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- circuit breaker

- breaker device

- parallel

- series

- breaking cell

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004065 semiconductor Substances 0.000 claims abstract description 74

- 239000003990 capacitor Substances 0.000 claims abstract description 26

- 238000000034 method Methods 0.000 claims abstract description 3

- 230000000712 assembly Effects 0.000 claims description 2

- 238000000429 assembly Methods 0.000 claims description 2

- 230000003213 activating effect Effects 0.000 abstract 1

- 238000010891 electric arc Methods 0.000 description 15

- 230000002457 bidirectional effect Effects 0.000 description 6

- 230000003068 static effect Effects 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 238000012423 maintenance Methods 0.000 description 4

- 230000002159 abnormal effect Effects 0.000 description 2

- 230000015556 catabolic process Effects 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000006731 degradation reaction Methods 0.000 description 2

- 230000003111 delayed effect Effects 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000005291 magnetic effect Effects 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 229910018503 SF6 Inorganic materials 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000008033 biological extinction Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 230000000593 degrading effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000001066 destructive effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 239000003302 ferromagnetic material Substances 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 230000009931 harmful effect Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 230000010355 oscillation Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- SFZCNBIFKDRMGX-UHFFFAOYSA-N sulfur hexafluoride Chemical compound FS(F)(F)(F)(F)F SFZCNBIFKDRMGX-UHFFFAOYSA-N 0.000 description 1

- 229960000909 sulfur hexafluoride Drugs 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000013519 translation Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/22—Power arrangements internal to the switch for operating the driving mechanism

- H01H3/222—Power arrangements internal to the switch for operating the driving mechanism using electrodynamic repulsion

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H9/00—Details of switching devices, not covered by groups H01H1/00 - H01H7/00

- H01H9/54—Circuit arrangements not adapted to a particular application of the switching device and for which no provision exists elsewhere

- H01H9/541—Contacts shunted by semiconductor devices

- H01H9/542—Contacts shunted by static switch means

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/22—Power arrangements internal to the switch for operating the driving mechanism

- H01H3/222—Power arrangements internal to the switch for operating the driving mechanism using electrodynamic repulsion

- H01H2003/225—Power arrangements internal to the switch for operating the driving mechanism using electrodynamic repulsion with coil contact, i.e. the movable contact itself forms a secondary coil in which the repulsing current is induced by an operating current in a stationary coil

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H9/00—Details of switching devices, not covered by groups H01H1/00 - H01H7/00

- H01H9/54—Circuit arrangements not adapted to a particular application of the switching device and for which no provision exists elsewhere

- H01H9/548—Electromechanical and static switch connected in series

Definitions

- the present invention relates to the field of circuit breaker devices in particular for alternative or continuous electrical networks and electrical systems or equipment in general.

- circuit breaker devices which are inserted into an electrical circuit to be protected have a switch element which cuts off the current flowing in the circuit to be protected under abnormal operating conditions, for example in the event of a short circuit occurring in the circuit to be protected.

- the circuit breaker devices are mechanical, that is to say that the breaking of the current is obtained only by the opening of a mechanical switch element.

- a mechanical switch element comprises two contacting conductive parts which are in mechanical contact when the switch element is closed (normal operation) and which mechanically separate when the switch element is open (abnormal operation in case of overcurrent).

- the mechanical cutoff results in the establishment of an electric arc because of the large energy accumulated in the circuit in which the circuit breaker device is mounted and protects.

- This electric arc degrades firstly by erosion conductive parts making contact and secondly the environment surrounding the ionization switch element. Thus the current takes some time to stop because of this ionization.

- This electric arc by degrading the conductive parts making contact requires maintenance operations which are restrictive and expensive.

- the conductive parts making contact are placed in an interrupting chamber, it is a chamber filled with a specific medium that can be air, the vacuum, a particular gas for example sulfur hexafluoride SF 6 but which in the future will probably be banned for environmental reasons.

- This specific medium is able to withstand the overpressure created by the formation of the electric arc and is intended to promote its extinction.

- Such circuit breaker devices with a mechanical switch element have a high breaking time.

- the time for the mechanical switch element to open is of the order of a millisecond or even several milliseconds.

- Another disadvantage is that they are bulky, the dimensions of the breaking chamber are all the more important as the tension is high.

- the first systems using power thyristors were born at LV low voltage ( ⁇ 1kV).

- IGBT Insulated Gate Bipolar Transistor bipolar transistor insulated gate

- the circuit breaker devices have Joule losses in the on state and a cooling device must be provided. It is also necessary to integrate a system of dissipation of the energy present at the moment of the cut.

- This circuit breaker device 10 is intended to protect an electric circuit materialized by an electric line L.

- the circuit breaker device 10 is connected in series. with the circuit to be protected L.

- the circuit breaker device 10 comprises a main branch 1 in which there is a mechanical switch element 2 and an auxiliary branch 3 connected in parallel with the main branch 1.

- the auxiliary branch 3 comprises a half-cut cell

- This cut-off cell 4 comprises a Graetz bridge 40 with four diodes D and connected to the terminals of a diagonal. of the Graetz bridge 40 at least one semiconductor breaking element 41 connected in parallel with a varistor 42.

- This breaking element can be a thyristor.

- This element can be open-controlled, for example an IGCT thyristor.

- commandable at opening is that the semiconductor breakout element opens as soon as an appropriate command is applied to it.

- a simple thyristor is not "controllable at the opening". It opens after a command, only a zero current.

- the semiconductor cut-off element 41 is therefore either in a conducting state (closed) or in a non-conducting state (open), which makes the semiconductor breaking cell active (open) or non-conducting (closed). ).

- connection of the semiconductor breaking cell 4 to the main branch 1 is at the ends of the other diagonal of the Graetz bridge 40.

- the mechanical switch element 2 In normal operation, the mechanical switch element 2 is closed. Its two conducting parts making contact are in mechanical contact.

- the semiconductor breaking element 41 is in a non-conducting state.

- the circuit L to be protected can be traversed by an electric current via the main branch 1 of the circuit breaker device, ie via the mechanical switch element 2 and practically without losses by Joule effect. If an overcurrent occurs in the circuit L to be protected and therefore in the main branch 1 of the circuit breaker device, means (not shown) control the opening of the mechanical switch element 2 and simultaneously the setting-in state of the semiconductor breaking element 41.

- a low electric arc appears at the level of the conductive parts making contact with the mechanical switch element 2 during their separation. The voltage corresponding to this electric arc allows the current flowing in the circuit to be protected L to switch rapidly in the auxiliary branch 3 in which the semiconductor breaking cell 4 is conducting.

- the semiconductor breaking element 41 of the breaking cell 4 is set to non-conducting state, which allows the final cut of the current in the circuit L to be protected.

- the opening speed of the mechanical switch element 2 is as fast as possible so that the electric arc generated between the conductive parts making contact with the mechanical switch element 2 has an energy of weaker possible and is therefore no longer likely to degrade the said parts.

- this electric arc plays an important role because it is the low arc voltage (about ten volts) that polarizes the semiconductor breaking element 41 above its threshold voltage thus causing it to pass passing state and deflects the current in the branch auxiliary.

- the control signal is conventionally a pulse applied on the gate of the thyristor 41 at the moment of opening of the mechanical switch element 2.

- This hybrid circuit breaker device 10 therefore solves some of the technical difficulties of purely static circuit breaker devices, but its performance is mainly dependent on the opening speed of the mechanical switch element 2.

- circuit breaker devices whether static or hybrid, are unsatisfactory especially in the case of high voltage applications of high power.

- EP-A-1 014 403 discloses a circuit breaker device corresponding to the preamble of claim 1.

- the present invention is precisely intended to provide a hybrid circuit breaker device that does not have the disadvantages mentioned above.

- an object of the invention is to provide a hybrid circuit breaker device comprising a mechanical switch element and a semiconductor breaking element capable of driving a direct or alternating current and in which there is no electric arc when the opening of the mechanical switch element even if the current is important.

- Another object of the invention is to provide a hybrid circuit breaker device with reduced maintenance.

- the invention relates more precisely to a circuit breaker device comprising a main branch containing a mechanical switch element and an auxiliary branch containing a semiconductor breaking cell, this auxiliary branch being connected in parallel with the main branch.

- the main branch comprises in series with the mechanical switch element a series switching assistance module comprising a semiconductor breaking cell controllable at the opening in parallel with an impedance.

- the auxiliary branch comprises a parallel module for switching assistance comprising an impedance, this impedance including at least one element of the capacitor type.

- the impedance of the switching aid serial module is preferably a varistor.

- the semiconductor cutoff cell controllable at the opening may comprise at least one series assembly with a diode and an IGCT type thyristor.

- the open-ended semiconductor breaking cell may have two series assemblies mounted in parallel to each other.

- the semiconductor breaking cell of the auxiliary branch may comprise at least one thyristor.

- the semiconductor breaking cell of the auxiliary branch may comprise two thyristors connected in parallel head to tail.

- the auxiliary branch breaking cell comprises a thyristor and a Graetz bridge having two diagonals, the thyristor forming a diagonal of the Graetz bridge, the main branch forming the other diagonal of the Graetz bridge.

- the impedance of the parallel switching assistance module may comprise a capacitor in series with the thyristor.

- a series inductor can be connected in series with the capacitor.

- the impedance of the parallel module for switching assistance may comprise an assembly formed of a capacitor and a first resistor connected in parallel, this assembly being in series with a second resistor and with the semiconductor breaking cell of the auxiliary branch.

- a series inductor can be connected in series with the assembly and the second resistor.

- the parallel module for switching assistance may comprise a Graetz bridge having two diagonals, a set parallel to the capacitor and a resistor being connected across a first diagonal of the Graetz bridge, an inductor auxiliary being connected to the terminals of the other diagonal, one of the terminals of the second diagonal is connected to the semiconductor breaking cell of the auxiliary branch.

- a series inductor can be connected between the Graetz bridge and the semiconductor break cell of the auxiliary branch.

- the mechanical switch element may comprise a Thomson type electromagnetic drive moving contact.

- the present invention also relates to a method for tripping a circuit breaker device thus characterized. It consists, in the presence of an overcurrent in the main branch, switching from an on state to a non-on state the controllable semiconductor breaking cell to the opening of the switching aid serial module, to switch from a non-on state to a passing state the semiconductor break cell of the auxiliary branch, then to open the mechanical switch element which was initially closed, and finally to switch, from the appearance of a current zero, the state in the non-passing state the semiconductor breaking cell of the auxiliary branch.

- FIG. 2 shows schematically a circuit breaker device according to the invention.

- This device comprises, as in the prior art, a main branch 1 containing a mechanical switch element 2 and an auxiliary branch 3 connected in parallel with the main branch 1 and containing a semiconductor breaking cell 4.

- This semi-cutoff cell -conductor is either in an on state or in a non-passing state.

- the circuit breaker device according to the invention comprises in the main branch 1 a series module for switching assistance M2 formed of another semiconductor breaking cell controllable at the opening 5 mounted in parallel with an impedance Z1.

- the term "serial module" is used to indicate that this module is in the main branch 1.

- This semiconductor breaking cell controllable at the opening 5 is in either a passing state or a non-passing state.

- the series switching assistance module M2 is connected in series with the mechanical switch element 2.

- the auxiliary branch 3 comprises in addition to the semiconductor breaking cell 4 a parallel module for assisting the switching.

- switching M4 formed of an impedance Z2 with at least one capacitor type element C.

- parallel module is used to indicate that the module is in the auxiliary branch 3 in parallel.

- impedance used in this context refers to a portion of circuit exhibiting an opposition to the passage of any current (DC or AC), such a circuit portion is made based on inductance coil type components and / or capacitor and / or resistance.

- circuit breaker device will be bidirectional to operate in AC but it is not an obligation, it can be monodirectional.

- FIG. 3A shows in detail a first embodiment of a circuit breaker device according to the invention.

- This circuit breaker device is bidirectional, it is suitable for a phase of an alternating electric network but also for a continuous electrical network.

- the dotted parts are superfluous in a one-way circuit breaker device.

- the semiconductor breaking cell controllable at the opening 5 comprises at least one series assembly formed of a diode D1 and a semiconductor component controllable at the opening IG2.

- a component may be a thyristor type IGCT, a conventional thyristor would not be suitable because it opens only zero current.

- Two series sets are used when the circuit-breaker device has to be bidirectional and in this case the two sets are connected in parallel to each other.

- the connection of the second set IG'2, D'1 is shown in dashed lines to show that the second set is optional.

- This semiconductor breaking cell controllable at the opening 5 is connected in parallel with an impedance Z1 which is of varistor type V1.

- This varistor which may be of MOV (metal oxide varistor) type, is dimensioned to dissipate energy which in the past was dissipated during the establishment of the electric arc.

- the assembly of the opening-controllable semiconductor breaking cell 5 and the impedance Z1 is connected in series with the mechanical switch element 2.

- the varistor V1 can withstand a voltage representing only a fraction of the network voltage, for example half.

- the mechanical switch element 2 may be based on the use of forces. electromagnetic devices for moving a movable contact 2.1, the object being to obtain the establishment of a force index jump.

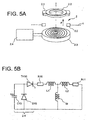

- An example of a mechanical switch element 2 is illustrated in FIG. 5A. This mechanical switch element is Thomson type without ferromagnetic material. The known principle is based on Lenz's law.

- the movable contact 2.1 is secured to a moving part 2.2 of non-magnetic conductive material.

- This piece 2.2 cooperates with a propulsion circuit comprising a preferably flat coil 2.3 and a supply circuit 2.4.

- the choice of the flat coil 2.3 makes it possible to obtain a vertical magnetic field near the moving part 2.2.

- a counter-current in the opposite direction originates in the moving part 2.2 and because of the interaction between these two currents, a force of repulsion F appears between the flat coil 2.3 and the moving part 2.2.

- This repulsive force F causes a displacement of the moving part 2.2 which was in an initial position of rest.

- the movable contact 2.1 In this initial rest position, the movable contact 2.1 is in electrical contact with at least one fixed contact 2.0 (connected to the circuit L to be protected) and the mechanical switch element 2 is closed.

- the repulsion force F which applies to the moving part 2.2 is intended to separate the movable contact 2.1 from the fixed contact 2.0 and thus to open the mechanical switch element 2. Thanks to its ring-shaped recessed shape, the moving part 2.2, is propelled vertically in a translation. In this way, the moving mass is reduced with respect to a solid part, as is the energy required for propulsion and / or the speed of displacement is increased. Other moving part geometries are possible for example a solid disk.

- the moving part 2.2 and the movable contact 2.1 are merged.

- the moving part would be for example silver-coated aluminum to also perform the function of electrical contact.

- L1 represents the inductance of the flat coil 2.3

- R10 is its resistance

- L2 represents the inductance of the moving part 2.2

- R11 is its resistance

- M represents the mutual inductance between the flat coil 2.3 and the moving part 2.2.

- This equivalent circuit is connected to the supply circuit 2.4 which is formed of at least one capacitor C10 intended to be charged at a voltage Uo before a discharge, a diode D10 connected in parallel with the capacitor C10 and a thyristor TH10 inserted between the parallel set C10, D10 and the equivalent circuit.

- the semiconductor breaking cell 4 which is in the auxiliary branch 3 is formed of two thyristors TH1, TH'1 mounted head to tail.

- One of the TH'1 thyristors can be omitted in a directional mono assembly.

- the M4 parallel switching aid module is connected in series with the switchgear semiconductor 4 of the auxiliary branch 3. It comprises a resistor R2 connected in series with a parallel assembly formed of a resistor R1 in parallel with a capacitor C1.

- the parallel switching assistance module M4 may also comprise in series with the resistor R2 and the parallel assembly R1, C1, a series inductance LS1. This series inductance LS1 serves to limit the rise rate of the current during the conduction of the semiconductor breaking cell 4 to obtain a proper engagement even DC.

- Impedance Z2 comprises capacitor C1, resistors R1 and R2 and series inductance LS1.

- FIG. 3B illustrates another embodiment of a circuit breaker device according to the invention derived from that of FIG. 3A.

- This parallel module M4 comprises a Graetz Pb bridge with four diodes D21 to D24.

- a first diagonal of the Graetz bridge Pb is mounted a parallel assembly with a capacitor C11 and a resistor R11.

- An auxiliary inductor LA1 is connected in parallel across the other diagonal of the Graetz Pb bridge.

- One of the ends of the second diagonal is connected to the main branch 1.

- the other end of the second diagonal is connected to the semiconductor breaking cell 4 via series LS1 inductance (if present).

- the impedance Z2 comprises the capacitor C11, the resistor R11, the auxiliary inductance LA1 and the series inductance LS1.

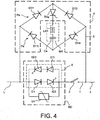

- FIG. 4 illustrates another embodiment of a circuit breaker device according to the invention. Compared with FIGS. 3A, 3B, the same configuration is found in the main branch 1, ie the mechanical switch element 2 in series with the series switching assistance module M2.

- the semiconductor breaking cell 4 comprises a Graetz Pa bridge with four diodes D11 to D14 and mounted in a diagonal of the Graetz bridge, a thyristor THa.

- This Graetz Pa bridge is connected to the terminals of the series assembly formed by the series switching assistance module M2 and the mechanical switch element 2. This connection is made at the ends of the other diagonal of the bridge.

- the parallel switching assistance module M4 comprises a capacitor Ca which is connected diagonally in series with the thyristor THa.

- a series inductance LS1 can be inserted between the thyristor THa and the capacitor Ca.

- the impedance Z2 comprises the capacitor Ca and the series inductance LS1.

- the semiconductor components controllable at the opening of the main branch 1 may be thyristors of IGCT type, the Single thyristors are not suitable because it is necessary to control the opening without waiting for a zero crossing of the current.

- the semiconductor breaking cell controllable at the opening 5 of the series module for switching assistance M2 switches to a non-passing state.

- the voltage across the impedance Z1 (varistor V1) increases to its threshold value.

- the voltage at the terminals of the series switching assistance module M2 increases, the impedance Z1 opposing the passage of current in the main branch 1.

- the semiconductor breaking cell 4 of the auxiliary branch 3 becomes conducting.

- the current flowing in the circuit to be protected L is deflected in the auxiliary branch 3, which diverts the energy which otherwise would have been dissipated in the semiconductor breaking cell controllable at the opening 5 of the main branch 1 at the risk of destroying it.

- the current in the mechanical switch element 2 tends to zero and the voltage across it is zero.

- the mechanical switch element 2 is then open without causing the establishment of an electric arc.

- the voltage at its terminals After the opening of the mechanical switch element 2, the voltage at its terminals immediately becomes equal to the voltage that was present across the impedance Z2 because the current being canceled in the impedance Z1, the voltage at its terminals becomes null. All the voltage of the auxiliary branch 3 is applied to the mechanical switch element 2 which is open.

- the current flowing in the auxiliary branch 3 is limited by the presence of the impedance Z2 which opposes its passage and the maximum value of this current is significantly reduced.

- the capacitor type element C charges.

- the semiconductor breaking cell 4 of the auxiliary branch 3 is rendered non-conducting.

- the transition to the off state is caused by the zero crossing of the current in the semiconductor breaking cell 4 of the auxiliary branch 3.

- the mechanical switch element 2 is open, the semiconductor breaking cell 4 of the auxiliary branch 3 is in the off state as well as the semiconductor breaking cell controllable at the opening 5 of the series switching assistance module M2. No more current flows in the circuit to be protected L and the circuit breaker device has played its role of protection.

- the advantage of the variant of Figure 3B is to perform the current limiting function in part by the impedance of the auxiliary inductance LA1. After the tripping in the main branch 1 and the branching of the current in the parallel branch 3 a portion of the current passes into the auxiliary inductance LA1 before the final cut by thyristors TH1, TH'1 of the semiconductor breaking cell. 4. This makes it possible to reduce the design constraints on the capacitor C11 which is used in this case, essentially in its role of deflecting the current from the main branch 1 to the parallel branch 3.

- the current B in the mechanical switch element 2 goes to zero. This zero crossing takes a certain time when there is LS1 series inductance in the M4 parallel switching aid module.

- the current D passing through the semiconductor breaking cell 4 of the auxiliary branch 3 is the current from the circuit L diverted from the main branch 1.

- This current D reaches a maximum (about 5000 A) then decreases due to the presence in the impedance Z2 of the capacitor type element C which is charged.

- the current D ends up canceling at a time t1 and the semiconductor breaking cell 4 of the auxiliary branch 3 is forced to the off state.

- the time interval between t0 and t1 is about 450 microseconds.

- FIG. 6B which is a zoom of FIG. 6A around time t0, further represents the shape of voltage E at the terminals of mechanical switch element 2.

- This voltage E is zero at the same time as current B after t0, which allows to open the mechanical switch element 2 without generating an electric arc. This opening is done at a time t2.

- the time interval between t0 and t2 is about 20 microseconds. Then the voltage E across the mechanical switch element 2 begins to grow and reaches the voltage that was present across the impedance Z2.

- Such a circuit breaker device is capable of operating both low voltage A or B and high voltage A or B. These voltages may be DC or AC voltages.

- Such a circuit breaker device has a mechanical switch element that can operate in a normal environment. This means that it can operate without being confined to a breaking chamber in an appropriate gaseous or vacuum atmosphere.

- a passive cooling device can be used.

- Such a circuit breaker device is compact. Its footprint is much smaller than that of configurations with interrupting chamber.

- a delay is possible in bidirectional mode because it is possible for the hybrid circuit breaker device to operate for a certain time with its auxiliary branch 3 in conduction while leaving the LC circuit (formed of the capacitor C, of the series inductance LS1 of the parallel module). switching assistance M4 and circuit inductance to be protected L) oscillating before being cut by the semiconductor breaking cell 4. During this period the current is limited by the impedances of the auxiliary branch 3.

Landscapes

- Driving Mechanisms And Operating Circuits Of Arc-Extinguishing High-Tension Switches (AREA)

- Arc-Extinguishing Devices That Are Switches (AREA)

- Electronic Switches (AREA)

- Keying Circuit Devices (AREA)

- Control Of Eletrric Generators (AREA)

Claims (15)

- Leistungsschutzschalter mit einem Hauptzweig (1), der ein mechanisches Unterbrecherelement (2) enthält, und einem Nebenzweig (3), der eine Halbleiterschaltzelle (4) enthält, wobei dieser Nebenzweig (3) mit dem Hauptzweig (1) parallel geschaltet ist, dadurch gekennzeichnet, dass der Hauptzweig (1) in Reihe mit dem mechanischen Unterbrecherelement (2) ein in Reihe geschaltetes Umschalthilfsmodul (M2) enthält, das eine mit einer Impedanz (Z1) parallel geschaltete aufsteuerbare Halbleiterschaltzelle (5) aufweist, und dass der Nebenzweig (3) ein parallel geschaltetes Umschalthilfsmodul (M4) mit einer Impedanz (Z2) enthält, wobei diese Impedanz (Z2) zumindest ein Kondensatorelement (C) umfasst.

- Leistungsschutzschalter nach Anspruch 1, dadurch gekennzeichnet, dass die Impedanz (Z1) des in Reihe geschalteten Umschalthilfsmodul (M2) ein Varistor (V1) ist.

- Leistungsschutzschalter nach einem der Ansprüche 1 oder 2, dadurch gekennzeichnet, dass die aufsteuerbare (M2) Halbleiterschaltzelle (5) zumindest eine in Reihe geschaltete Einheit (D1, IG2) mit einer Diode und einem Thyristor vom Typ IGCT enthält.

- Leistungsschutzschalter nach Anspruch 3, dadurch gekennzeichnet, dass er zwei in Reihe geschaltete Einheiten (D1, IG2, D'1, IG'2) enthält, die antiparallel geschaltet sind.

- Leistungsschutzschalter nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, dass die Halbleiterschaltzelle (4) des Nebenzweigs (3) zumindest einen Thyristor (THa) enthält.

- Leistungsschutzschalter nach Anspruch 5, dadurch gekennzeichnet, dass die Halbleiterschaltzelle (4) zwei Thyristoren (TH1, TH'1) enthält, die antiparallel geschaltet sind.

- Leistungsschutzschalter nach Anspruch 5, dadurch gekennzeichnet, dass die Halbleiterschaltzelle (4) des Nebenzweigs (3) einen Thyristor (THa) und eine Graetz-Brücke (D11, D12, D13, D14) mit zwei Diagonalen enthält, wobei der Thyristor (THa) eine Diagonale der Graetz-Brücke bildet und wobei der Hauptzweig (1) die andere Diagonale der Graetz-Brücke ist.

- Leistungsschutzschalter nach Anspruch 7, dadurch gekennzeichnet, dass die Impedanz (Z2) des parallel geschalteten Umschalthilfsmoduls (M4) einen Kondensator (Ca) in Reihe mit dem Thyristor (THa) enthält.

- Leistungsschutzschalter nach Anspruch 8, dadurch gekennzeichnet, dass eine in Reihe geschaltete Induktivität zwischen Kondensator (Ca) und Thyristor (THa) geschaltet ist.

- Leistungsschutzschalter nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, dass die Impedanz (Z2) des parallel geschalteten Umschalthilfsmoduls (M4) eine Einheit enthält, die aus einem Kondensator (C12) und einem ersten Widerstand (R1) gebildet ist, die parallel geschaltet sind, wobei diese Einheit in Reihe mit einem zweiten Widerstand (R2) und mit der Halbleiterschaltzelle (4) des Nebenzweigs (3) geschaltet ist.

- Leistungsschutzschalter nach Anspruch 10, dadurch gekennzeichnet, dass eine in Reihe geschaltete Induktivität (LS1) in Reihe mit der Einheit und dem zweiten Widerstand (R2) geschaltet ist.

- Leistungsschutzschalter nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, dass das parallel geschaltete Umschalthilfsmodul (M4) eine Graetz-Brücke (Pb) mit zwei Diagonalen enthält, wobei eine parallel geschaltete Einheit mit dem Kondensator (C11) und einem Widerstand (R11) an die Anschlussklemmen einer ersten Diagonalen der Graetz-Brücke angeschlossen ist, wobei eine Nebeninduktivität (La1) an die Anschlussklemmen der zweiten Diagonale angeschlossen ist, wobei eine der Anschlussklemmen der zweiten Diagonale mit der Halbleiterschaltzelle (4) des Nebenzweigs (3) verbunden ist.

- Leistungsschutzschalter nach Anspruch 12, dadurch gekennzeichnet, dass eine in Reihe geschaltete Induktivität (LS1) zwischen der Graetz-Brücke (Pb) und der Halbleiterschaltzelle (4) des Nebenzweigs geschaltet ist.

- Leistungsschutzschalter nach einem der Ansprüche 1 bis 13, dadurch gekennzeichnet, dass das mechanische Unterbrecherelement (2) einen elektromagnetisch angetriebenen beweglichen Kontakt (2.1) vom Typ Thomson enthält.

- Verfahren zum Auslösen eines Leistungsschutzschalters nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, dass es darin besteht, bei einer vorhandenen Überlast im Hauptzweig (1)- die aufsteuerbare Halbleiterschaltzelle (5) von einem durchgängigen Zustand in einen nicht durchgängigen Zustand umzuschalten,- die Halbleiterschaltzelle (4) des Nebenzweigs (3) von einem nicht durchgängigen Zustand in einen durchgängigen Zustand umzuschalten,- das ursprünglich geschlossene mechanische Unterbrecherelement dann zu öffnen,- und schließlich bei Auftreten eines Nulldurchgangs die Halbleiterschaltzelle (4) des Nebenzweigs (3) von dem durchgängigen Zustand in den nicht durchgängigen Zustand umzuschalten.

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE60303773T DE60303773T2 (de) | 2003-12-05 | 2003-12-05 | Hybrid-Leistungsschalter |

| ES03293050T ES2259409T3 (es) | 2003-12-05 | 2003-12-05 | Dispositivo disyuntor hibrido. |

| EP03293050A EP1538645B1 (de) | 2003-12-05 | 2003-12-05 | Hybrid-Leistungsschalter |

| AT03293050T ATE319177T1 (de) | 2003-12-05 | 2003-12-05 | Hybrid-leistungsschalter |

| US10/895,456 US7508636B2 (en) | 2003-12-05 | 2004-02-26 | Hybrid circuit breaker device |

| RU2004135408/09A RU2338287C2 (ru) | 2003-12-05 | 2004-12-03 | Гибридное выключающее устройство |

| CNB2004100979348A CN100339925C (zh) | 2003-12-05 | 2004-12-06 | 混合式电路断路器装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03293050A EP1538645B1 (de) | 2003-12-05 | 2003-12-05 | Hybrid-Leistungsschalter |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1538645A1 EP1538645A1 (de) | 2005-06-08 |

| EP1538645B1 true EP1538645B1 (de) | 2006-03-01 |

Family

ID=34443123

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03293050A Expired - Lifetime EP1538645B1 (de) | 2003-12-05 | 2003-12-05 | Hybrid-Leistungsschalter |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7508636B2 (de) |

| EP (1) | EP1538645B1 (de) |

| CN (1) | CN100339925C (de) |

| AT (1) | ATE319177T1 (de) |

| DE (1) | DE60303773T2 (de) |

| ES (1) | ES2259409T3 (de) |

| RU (1) | RU2338287C2 (de) |

Families Citing this family (72)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005040432A1 (de) * | 2005-08-25 | 2007-03-01 | Rwth Aachen | Strombegrenzender Schalter |

| EP2369709B1 (de) | 2005-10-24 | 2016-05-04 | Robert Bosch GmbH | Lastschalter mit Sicherungen mit Steuerungsmanagement für Solarzellen |

| US7876538B2 (en) * | 2005-12-20 | 2011-01-25 | General Electric Company | Micro-electromechanical system based arc-less switching with circuitry for absorbing electrical energy during a fault condition |

| US7633725B2 (en) * | 2005-12-20 | 2009-12-15 | General Electric Company | Micro-electromechanical system based soft switching |

| US20070139829A1 (en) * | 2005-12-20 | 2007-06-21 | General Electric Company | Micro-electromechanical system based arc-less switching |

| US7643256B2 (en) | 2006-12-06 | 2010-01-05 | General Electric Company | Electromechanical switching circuitry in parallel with solid state switching circuitry selectively switchable to carry a load appropriate to such circuitry |

| US7542250B2 (en) * | 2007-01-10 | 2009-06-02 | General Electric Company | Micro-electromechanical system based electric motor starter |

| US9076607B2 (en) * | 2007-01-10 | 2015-07-07 | General Electric Company | System with circuitry for suppressing arc formation in micro-electromechanical system based switch |

| US8358488B2 (en) * | 2007-06-15 | 2013-01-22 | General Electric Company | Micro-electromechanical system based switching |

| DE102007042903A1 (de) | 2007-07-02 | 2009-01-08 | Bammert, Jörg | Elektrische Schaltung |

| US7808764B2 (en) * | 2007-10-31 | 2010-10-05 | General Electric Company | System and method for avoiding contact stiction in micro-electromechanical system based switch |

| WO2011044928A1 (en) | 2009-10-13 | 2011-04-21 | Abb Research Ltd. | A hybrid circuit breaker |

| CA2780946C (en) * | 2009-11-16 | 2016-05-10 | Abb Technology Ag | Device and method to break the current of a power transmission or distribution line and current limiting arrangement |

| EP2339599A1 (de) * | 2009-12-22 | 2011-06-29 | ABB Research Ltd. | Schalter und Verwendung dafür |

| CA2798652C (en) * | 2010-05-11 | 2015-07-21 | Abb Technology Ag | A high voltage dc breaker apparatus |

| DE102010052136A1 (de) * | 2010-11-22 | 2012-05-24 | Siemens Aktiengesellschaft | Schaltungsanordnungen für elektronisch gesteuerte DC-Netze |

| GB2486408A (en) | 2010-12-09 | 2012-06-20 | Solaredge Technologies Ltd | Disconnection of a string carrying direct current |

| FR2968829B1 (fr) * | 2010-12-10 | 2012-12-21 | Schneider Electric Ind Sas | Disjonteur limiteur de courant |

| EP2469552B1 (de) | 2010-12-23 | 2014-02-26 | ABB Technology AG | Verfahren, Schutzschalter und Schalteinheit zum Abschalten von Hochspannungsgleichströmen |

| GB2493911A (en) * | 2011-08-18 | 2013-02-27 | Univ Manchester | Conduction path of direct current circuit breaker |

| EP2777115B1 (de) * | 2011-11-11 | 2016-01-27 | ABB Technology AG | Verwendung des transferschalters eines hybridleistungsschalters als wahlschalter |

| CN104137211B (zh) * | 2011-11-18 | 2016-01-13 | Abb技术有限公司 | 具有缓冲电路的高压直流混合电路断路器 |

| WO2013091700A1 (en) * | 2011-12-21 | 2013-06-27 | Abb Technology Ltd | An arrangement for controlling the electric power transmission in a hvdc power transmission system |

| ES2911756T3 (es) * | 2011-12-22 | 2022-05-20 | Siemens Energy Global Gmbh & Co Kg | Dispositivo disyuntor híbrido de cd |

| FR2985082B1 (fr) | 2011-12-23 | 2014-02-21 | Alstom Technology Ltd | Dispositif disjoncteur mecatronique et procede de declenchement associe et application a la coupure de courant continu eleve |

| WO2014032692A1 (en) * | 2012-08-27 | 2014-03-06 | Abb Technology Ltd | Apparatus arranged to break an electrical current |

| EP2722859B2 (de) | 2012-10-16 | 2019-08-28 | ABB Schweiz AG | Mehrfachblock-Hybridvakuumschalter mit in Reihe geschalteten Vakuumunterbrechern |

| FR2998705B1 (fr) | 2012-11-28 | 2015-02-13 | Alstom Technology Ltd | Dispositif de commande de type a ressort en particulier pour disjoncteur ou interrupteur a haute ou moyenne tension |

| CN103021739B (zh) * | 2012-11-30 | 2014-10-15 | 西安交通大学 | 混合式直流断路器 |

| DK2907152T3 (en) * | 2012-12-19 | 2016-12-05 | Siemens Ag | Device for switching a direct current into a pole of a DC voltage network |

| WO2014117807A1 (de) * | 2013-01-29 | 2014-08-07 | Siemens Aktiengesellschaft | Gleichspannungsschalter zum schalten einer kurzunterbrechung |

| CN103972875B (zh) * | 2013-01-31 | 2016-07-06 | 南京南瑞继保电气有限公司 | 限制线路电流或使电流分断的装置及其控制方法 |

| CN103346531B (zh) * | 2013-02-06 | 2014-11-26 | 西安交通大学 | 一种双向分断的混合式断路器 |

| EP2768102B1 (de) * | 2013-02-13 | 2016-02-10 | General Electric Technology GmbH | Stromkreisunterbrechungsvorrichtung |

| CN103280763B (zh) * | 2013-02-27 | 2016-12-28 | 国网智能电网研究院 | 一种直流断路器及其实现方法 |

| US9198255B2 (en) | 2013-03-14 | 2015-11-24 | Nxp B.V. | Voltage to current architecture to improve PWM performance of output drivers |

| EP2787520B1 (de) | 2013-04-02 | 2015-11-04 | ABB Technology AG | Vakuumkammer mit einteiliger metallischer Abdeckung zur Selbstzentrierung |

| US9054530B2 (en) | 2013-04-25 | 2015-06-09 | General Atomics | Pulsed interrupter and method of operation |

| EP3031062B1 (de) * | 2013-08-05 | 2018-12-12 | Innolith Assets AG | Wechselschalter mit blockierendem halbleiter |

| KR101506581B1 (ko) * | 2013-08-14 | 2015-03-27 | 주식회사 효성 | 고전압 dc 차단기 |

| US9947496B2 (en) | 2013-08-30 | 2018-04-17 | Eaton Industries (Netherlands) B.V. | Circuit breaker with hybrid switch |

| EP3082208B1 (de) * | 2013-12-11 | 2018-09-05 | Mitsubishi Electric Corporation | Dc-schutzschalter |

| WO2015113120A1 (ru) * | 2014-01-31 | 2015-08-06 | Любомир СЕКУЛОВ | Быстродействующий выключатель постоянного и переменного тока |

| CN103986138B (zh) * | 2014-05-14 | 2017-01-25 | 国家电网公司 | 一种模块化限流断路器功率模块 |

| EP3251189B1 (de) * | 2015-01-30 | 2018-10-10 | ABB Schweiz AG | Skalierbare schaltanlage zur verbindung von gleichstromleistungsnetzwerken |

| US9742185B2 (en) | 2015-04-28 | 2017-08-22 | General Electric Company | DC circuit breaker and method of use |

| EP4012738A1 (de) * | 2015-05-05 | 2022-06-15 | Siemens Aktiengesellschaft | Schalteinrichtung |

| DE102015226475A1 (de) * | 2015-05-05 | 2016-11-10 | Siemens Aktiengesellschaft | Schalteinrichtung |

| US9660439B2 (en) * | 2015-06-05 | 2017-05-23 | General Electric Company | Direct current power distribution and protection system |

| EP3332412A4 (de) * | 2015-08-05 | 2019-03-13 | ABB Schweiz AG | Bidirektionales angetriebenes ventil und steuerungsverfahren dafür und hybrides hgü-system mit mehreren anschlüssen damit |

| KR101794945B1 (ko) | 2015-08-24 | 2017-12-01 | 주식회사 효성 | Dc 차단기 |

| CN106558865B (zh) * | 2015-09-25 | 2019-03-15 | 全球能源互联网研究院 | 一种改进型级联全桥高压直流断路器及其快速重合方法 |

| US9998117B2 (en) | 2015-12-10 | 2018-06-12 | Abb Schweiz Ag | Solid state resettable fuses |

| GB2560887A (en) * | 2017-03-21 | 2018-10-03 | Gridon Ltd | AC switching arrangement |

| EP3389069B1 (de) * | 2017-04-11 | 2019-12-11 | Microelettrica Scientifica S.p.A. | Verbesserter schalter für anwendungen mit hohem gleichstrom oder hochspannung wie zum beispiel industrie- und/oder eisenbahnanwendungen |

| DE102017122218A1 (de) * | 2017-09-26 | 2019-03-28 | Eaton Industries (Austria) Gmbh | Niederspannungs-Schutzschaltgerät |

| GB2574038A (en) * | 2018-05-24 | 2019-11-27 | Entrust Microgrid Llp | Two-stage switching mechanism for use in a DC circuit |

| DE102018114641B4 (de) * | 2018-06-19 | 2025-06-12 | Vacon Oy | Schaltung, Vorrichtung und Frequenzumrichter sowie Verfahren zum Betreiben einer elektronischen Schaltung |

| US11646575B2 (en) | 2018-10-24 | 2023-05-09 | The Florida State University Research Foundation, Inc. | Direct current hybrid circuit breaker with reverse biased voltage source |

| US11424093B2 (en) | 2018-10-24 | 2022-08-23 | The Florida State University Research Foundation, Inc. | Direct current hybrid circuit breaker with reverse biased voltage source |

| KR102164975B1 (ko) * | 2019-01-29 | 2020-10-13 | 전남대학교산학협력단 | 양방향 dc 차단기 |

| GB2585838A (en) * | 2019-07-16 | 2021-01-27 | Eaton Intelligent Power Ltd | Hybrid circuit breaker with improved current capacity per device size |

| EP3879548B1 (de) * | 2020-03-10 | 2022-12-21 | ABB Schweiz AG | Fehlerstrombegrenzerschutzschalter |

| US11394199B2 (en) * | 2020-09-11 | 2022-07-19 | Abb Schweiz Ag | Intelligent current limiting for solid-state switching |

| CN112713050A (zh) * | 2020-12-11 | 2021-04-27 | 平高集团有限公司 | 一种电磁快速机构及快速机械开关 |

| WO2022204996A1 (zh) * | 2021-03-30 | 2022-10-06 | 华为数字能源技术有限公司 | 断路器和供电系统 |

| CN113078621B (zh) * | 2021-04-21 | 2025-07-01 | 辰硕电子(九江)有限公司 | 一种嵌入式mov组件 |

| GB202115513D0 (en) | 2021-10-28 | 2021-12-15 | Rolls Royce Plc | Electrical power system |

| US11901140B2 (en) * | 2022-05-16 | 2024-02-13 | Rockwell Automation Technologies, Inc. | Hybrid circuit breaker with solid state devices |

| EP4456358A1 (de) * | 2023-04-27 | 2024-10-30 | Airbus SAS | Schutz in einem elektrischen gleichstrom-hochspannungssystem |

| US20250079101A1 (en) * | 2023-08-31 | 2025-03-06 | Siemens Industry, Inc. | Magnetic switch for hybrid circuit breaker applications |

| CN119132886B (zh) * | 2024-09-19 | 2025-12-09 | 哈尔滨工业大学 | 混合式直流继电器拓扑电路及其控制方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH609182A5 (de) * | 1975-12-01 | 1979-02-15 | Asea Ab | |

| SU843017A1 (ru) * | 1979-05-22 | 1981-06-30 | Предприятие П/Я А-7147 | Способ защиты мощных цепей токоограничи-ВАющиМи ВыКлючАТЕл Ми |

| SU943881A1 (ru) * | 1980-12-16 | 1982-07-15 | Всесоюзный научно-исследовательский проектно-конструкторский и технологический институт низковольтного аппаратостроения | Гибридный выключатель посто нного тока |

| US4631621A (en) * | 1985-07-11 | 1986-12-23 | General Electric Company | Gate turn-off control circuit for a solid state circuit interrupter |

| US4644309A (en) * | 1985-12-30 | 1987-02-17 | General Electric Company | High speed contact driver for circuit interruption device |

| US4723187A (en) * | 1986-11-10 | 1988-02-02 | General Electric Company | Current commutation circuit |

| US4862313A (en) * | 1987-12-11 | 1989-08-29 | Hitachi, Ltd. | Driving apparatus for DC circuit breakers |

| US5164872A (en) * | 1991-06-17 | 1992-11-17 | General Electric Company | Load circuit commutation circuit |

| CA2275616A1 (en) * | 1996-12-17 | 1998-06-25 | Dan Windmar | Device and method relating to protection of an object against over-currents comprising over-current reduction |

| EP1014403A1 (de) * | 1998-12-21 | 2000-06-28 | Asea Brown Boveri AG | Strombegrenzender Schalter |

| SE9900852D0 (sv) * | 1999-03-08 | 1999-03-08 | Secheron Sa | An electrical coil module, an electrical coil comprising such modules, an actuation mechanism including such a coil and a circuit breaker comprising such an actuation mechanism |

| DE10002870A1 (de) * | 2000-01-24 | 2001-08-23 | Abb Research Ltd | Vorrichtung zum Begrenzen eines Stromes |

-

2003

- 2003-12-05 ES ES03293050T patent/ES2259409T3/es not_active Expired - Lifetime

- 2003-12-05 EP EP03293050A patent/EP1538645B1/de not_active Expired - Lifetime

- 2003-12-05 DE DE60303773T patent/DE60303773T2/de not_active Expired - Lifetime

- 2003-12-05 AT AT03293050T patent/ATE319177T1/de active

-

2004

- 2004-02-26 US US10/895,456 patent/US7508636B2/en not_active Expired - Fee Related

- 2004-12-03 RU RU2004135408/09A patent/RU2338287C2/ru not_active IP Right Cessation

- 2004-12-06 CN CNB2004100979348A patent/CN100339925C/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN1617281A (zh) | 2005-05-18 |

| CN100339925C (zh) | 2007-09-26 |

| RU2004135408A (ru) | 2006-05-10 |

| US7508636B2 (en) | 2009-03-24 |

| ATE319177T1 (de) | 2006-03-15 |

| DE60303773T2 (de) | 2006-09-21 |

| DE60303773D1 (de) | 2006-04-27 |

| EP1538645A1 (de) | 2005-06-08 |

| RU2338287C2 (ru) | 2008-11-10 |

| ES2259409T3 (es) | 2006-10-01 |

| US20050146814A1 (en) | 2005-07-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1538645B1 (de) | Hybrid-Leistungsschalter | |

| EP2795645B1 (de) | Mechatronische schutzschaltvorrichtung und verfahren zur auslösung und verwendung für untebrechung des hochgleichstroms | |

| EP3942585B1 (de) | Stromabschaltvorrichtung für hochspannungsgleichstrom mit resonator und schaltung | |

| FR2738664A1 (fr) | Dispositif hybride utilisant l'effet miller pour la protection des contacts electriques contre la formation d'arcs | |

| EP3903333B1 (de) | Stromschutzschalter für hochspannungsgleichstrom mit kapazitiver pufferschaltung und steuerungsverfahren | |

| EP4167261A1 (de) | Elektrische schaltvorrichtung, entsprechendes schaltsystem und verfahren | |

| EP3903334B1 (de) | Stromunterbrechervorrichtung für hochspannungsgleichstrom mit adaptivem schwingkreis und steuerungsverfahren | |

| EP1870977B1 (de) | Vorrichtung zum Schutz gegen Überspannungen, die mit mehreren, in Reihe geschalteten Funkenstrecken mit simultaner Auslösung verbunden ist, und entsprechende Verfahren | |

| EP3437115B1 (de) | Hybridisierungsystem für hochspannungsgleichstrom | |

| WO2004042762A1 (fr) | Dispositif de protection contre les surtensions a electrode mobile | |

| EP0517618B1 (de) | Lasttrenngerät für elektrische Schaltung | |

| FR2676587A1 (fr) | Disjoncteur a grand pouvoir de coupure. | |

| EP4385107B1 (de) | Vorrichtung und verfahren zum trennen eines hochspannungsgleichstroms mit einer sicherung und schwingstromüberlastungssystem | |

| EP2631927B1 (de) | Verfahren zum Unterbrechen eines Lichtbogens, Verfahren und Vorrichtung zum Schutz einer Anlage vor Überspannungen | |

| FR2595865A1 (fr) | Interrupteur electrique, plus particulierement son actionneur magnetique de contact a haute vitesse | |

| EP4315381B1 (de) | Abschaltvorrichtung für elektrischen hochspannungsstrom mit plasmaröhre | |

| EP3699942B1 (de) | Einschaltsystem einer vakuumschaltröhre | |

| WO2013160217A1 (fr) | Circuit actionneur de commande de disjoncteur | |

| EP3523817A1 (de) | Co2:schalter für ein hochspannungsgleichstromnetz | |

| EP4104195B1 (de) | Mechanische stromabschaltvorrichtung für hochspannungsgleichstrom mit einem kondensator in einer sekundären bahn, einrichtung und verfahren mit einer solchen vorrichtung | |

| EP4485496A1 (de) | Elektrische schutzvorrichtung | |

| EP2546851B1 (de) | Hochspannungsunterbrechungsvorrichtung in einem Stromnetz | |

| FR2699729A1 (fr) | Disjoncteur à extinction d'arc par fractionnement d'arc à la source. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20041022 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 60303773 Country of ref document: DE Date of ref document: 20060427 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060601 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060601 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060801 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2259409 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061231 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20061204 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060602 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061205 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060301 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20121211 Year of fee payment: 10 Ref country code: CZ Payment date: 20121122 Year of fee payment: 10 Ref country code: DE Payment date: 20121207 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20121219 Year of fee payment: 10 Ref country code: TR Payment date: 20121127 Year of fee payment: 10 Ref country code: GB Payment date: 20121219 Year of fee payment: 10 Ref country code: SE Payment date: 20121214 Year of fee payment: 10 Ref country code: IT Payment date: 20121214 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20121123 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20121219 Year of fee payment: 10 |

|

| BERE | Be: lapsed |

Owner name: SOC. TECHNIQUE POUR L'ENERGIE ATOMIQUE TECHNICATO Effective date: 20131231 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60303773 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 319177 Country of ref document: AT Kind code of ref document: T Effective date: 20131205 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20131205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131206 Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131205 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60303773 Country of ref document: DE Effective date: 20140701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131231 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131231 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131205 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131205 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20150709 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131205 |