EP1533435A2 - Top covering for window - Google Patents

Top covering for window Download PDFInfo

- Publication number

- EP1533435A2 EP1533435A2 EP04388080A EP04388080A EP1533435A2 EP 1533435 A2 EP1533435 A2 EP 1533435A2 EP 04388080 A EP04388080 A EP 04388080A EP 04388080 A EP04388080 A EP 04388080A EP 1533435 A2 EP1533435 A2 EP 1533435A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- top covering

- window

- groove

- covering

- end portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000011521 glass Substances 0.000 claims description 8

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 claims description 3

- 229910052725 zinc Inorganic materials 0.000 claims description 3

- 239000011701 zinc Substances 0.000 claims description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 2

- 229910052782 aluminium Inorganic materials 0.000 claims description 2

- 238000007789 sealing Methods 0.000 abstract description 13

- 238000005452 bending Methods 0.000 abstract description 7

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 abstract description 4

- 239000000463 material Substances 0.000 description 6

- 239000000428 dust Substances 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- NMFHJNAPXOMSRX-PUPDPRJKSA-N [(1r)-3-(3,4-dimethoxyphenyl)-1-[3-(2-morpholin-4-ylethoxy)phenyl]propyl] (2s)-1-[(2s)-2-(3,4,5-trimethoxyphenyl)butanoyl]piperidine-2-carboxylate Chemical compound C([C@@H](OC(=O)[C@@H]1CCCCN1C(=O)[C@@H](CC)C=1C=C(OC)C(OC)=C(OC)C=1)C=1C=C(OCCN2CCOCC2)C=CC=1)CC1=CC=C(OC)C(OC)=C1 NMFHJNAPXOMSRX-PUPDPRJKSA-N 0.000 description 1

- 230000032683 aging Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000005357 flat glass Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D13/00—Special arrangements or devices in connection with roof coverings; Protection against birds; Roof drainage ; Sky-lights

- E04D13/03—Sky-lights; Domes; Ventilating sky-lights

- E04D13/0305—Supports or connecting means for sky-lights of flat or domed shape

- E04D13/031—Supports or connecting means for sky-lights of flat or domed shape characterised by a frame for connection to an inclined roof

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D13/00—Special arrangements or devices in connection with roof coverings; Protection against birds; Roof drainage ; Sky-lights

- E04D13/03—Sky-lights; Domes; Ventilating sky-lights

- E04D13/033—Sky-lights; Domes; Ventilating sky-lights provided with means for controlling the light-transmission or the heat-reflection, (e.g. shields, reflectors, cleaning devices)

Definitions

- the invention relates to a top covering for window, which is mounted on top of frame and sash, used to cover the horizontal gap at the section between the frame and the sash, thus prevents rain, snow, dust or other from entering the horizontal gap, ensures a wide open angle of the sash relative to the frame, such as 45°.

- a window top covering covers the gap to prevent rain from flowing to the position is a more effective and ideal choice.

- a Chinese Patent regarding a window top covering whose serial number is 02254262 discloses a window top covering, comprising a top covering mounted on the frame; a bending part below the top covering, one surface of which is facing outward, away from the frame and towards the opening of the window glass; a sealing pad mounted at the bending part below the top covering to seal the gap between the top covering and the sash glass pressing covering.

- the top covering is folded two times, and there is a certain distance from the opening at the bending position to its edge, so that the bending part won't block the sash when the sash is opened, thus the open angle is wide.

- a preferred open angle is usually set to 16°.

- the sealing pad seals the gap between the top covering and the glass fixture covering, protects the window from the weather effect.

- this type of the window top covering has the following problems, if a wider open angle is required, the edge of the top covering has to keep a certain height from the sash top surface such as the glass surface. While with the increasing of the height, the gap between the top covering and the glass pressing covering becomes wider, thus it needs to increase the width of the sealing strip. In this case, it is difficult to seal with the sealing strip only, because the sealing strip moves relative to the bottom covering when the window opens, thus the sealing strip needs to be soft, but when the window is strong, it is hard for the soft and wide sealing strip to stop the wind, and when it rains the rain will enter the window, then the covering fails. Also, since there is no covering in front of the sealing strip, air, sunshine and higher temperature tend to make the sealing strip aging too soon, which cause it losing flexibility thus fail the seal. And the wider gap between the top covering and the glass pressing covering affects the appearance of the window.

- the invention is to provide a window top covering for a wide angle or range of opening the window and has a better sealing performance.

- the invention provides a top covering for a window, characterized in that it comprises a first top covering which is mounted to the window frame, and a second top covering which is mounted to the sash, wherein the first top covering has a front end portion provided with a downwardly bended front flap, the second top covering has a back end portion provided with an upwardly bended back flap, wherein the front end portion is disposed under the back end portion, with the front and back flaps inserted into the comers defined by each other.

- the second top covering has a flat base portion and a sloped portion provided with the back end portion and extended and angled from the base portion.

- the front and back flaps are flat.

- the front and back flaps are curved.

- a drainage groove is formed in the first top covering.

- the sides of the first top covering are closed by side pieces.

- the second top covering has a front portion provided with a curved front edge bended downwards therefrom.

- the second top covering having a stepped surface at the front edge in order to press upon the surface of the window sash glass.

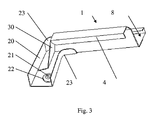

- the side pieces has a groove.

- the groove has a curved comer.

- the groove has a right angled comer.

- a hole is formed in the bottom of the groove.

- the bottom of the groove is formed with a collar surrounding a hole.

- the first top covering or/and the second top covering is/are made from aluminum or zinc or plastic.

- the first top covering and/or the second top covering is galvanized or painted.

- a preferred embodiment of the top covering according to the invention comprises a first top covering 1 and a second top covering 2.

- the first top covering 1 is fixed onto a window frame 12, while the second top covering is mounted on a sash 11 corresponding thereto, or on the fixture of glazing (not shown), as long as it is substantially fixed to the sash.

- the front end portion of the first top covering 1 is provided with a flat flap 4 bended downward.

- the back end portion of the second top covering 2 is inserted below the front end portion of the first top covering 1.

- the second top covering 2 is also provided with a flat flap 3 bended upward at the back end portion.

- the two flaps 3, 4 are inserted into the grooves formed by each other, and they can rotate relative to each other.

- the second top covering 2 bends down to form a sloped flat portion 5 as it approaches the flap 3, with a sharp angle is defined between the sloped portion 5 and the flat base portion 13.

- the sloped portion 5 is provided so that the second top covering can be swung to a wider angle of opening the sash relative to the first top covering, and the base portion 13 of the second top covering 2 partially shields the interface of the first and second shields at the flaps 3, 4. This decreases the height of the first shield 1 with the same angle of opening the sash, and hides the flaps 3, 4 from somewhere in front of the window.

- this arrangement provides a sort of seal for blocking winds from entering between the flaps.

- the flaps 3 and 4 may be curved instead of being flat.

- the first top covering is formed with a drainage groove 8 open upward, a side wall of the groove 8 is connected with an angled portion 14 so that the water on the first top covering can be discharged into the drainage groove 8, and the water flow to the flap 4 can be reduced.

- two side pieces 30 close the side ends of the first top covering 1 respectively to prevent wind or rain from entering through the two ends, and present a beautiful top covering appearance.

- a curved front edge 7 is formed with the second top covering bended downwards from the front end.

- the curved front edge 7 reduces the distance between the second shield 2 and the glazing fixture 9 or glazing 10 for a narrowed gap between the second shield 2 and the fixture 9 and a better seal.

- a winding curtain is hung up under the top covering, and has a curtain material 6 goes through the gap between the second top covering and the fixture, with the curved front edge 7 pressing the curtain material 6 downward and pushing the same towards the glass 10 for a desired tension thereof.

- the curved edge 7 is a sealing element, and a guide track for the curtain material 6, as the curved shape does not scratch the curtain material 6 and facilitates the smooth movement of the curtain.

- the ends of the first top covering 1 are connected to a U-shaped groove 20, and the drainage groove 8 and two end pieces 30 are embedded and fixed into the U-shaped groove 20.

- the U-shaped groove 20 is formed with a hole 21, through which a screw fastens the first top covering to the window frame.

- a collar 22 is placed at the bottom of the U-shaped groove and surrounding the hole 21, so as to prevent the water from flowing down from the U-shaped groove through the hole 21.

- the first top covering and the second top covering are made of an aluminum alloy plate, which is light, stainless and high-strength.

- the plate may be painted. PVC or zinc or other materials may be used to manufacturing the top covering, alternatively.

- the second shield 2 will rotate with the sash with the flap 3 moving down to the right of the flap 4 of the first top covering, while the sloped portion 5 moves to the flap 4 of the first top covering 1.

- the window is opened to the maximum extent.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

- Wing Frames And Configurations (AREA)

Abstract

Description

- The invention relates to a top covering for window, which is mounted on top of frame and sash, used to cover the horizontal gap at the section between the frame and the sash, thus prevents rain, snow, dust or other from entering the horizontal gap, ensures a wide open angle of the sash relative to the frame, such as 45°.

- For an open able window, in particular a sloped roof window, in order to prevent the leakage, wind or dust in the gap at the top connecting surface between the frame and the sash, other than sealing the gap between the frame and the sash with seal pad or other material, using a window top covering covers the gap to prevent rain from flowing to the position is a more effective and ideal choice.

- A Chinese Patent regarding a window top covering whose serial number is 02254262 discloses a window top covering, comprising a top covering mounted on the frame; a bending part below the top covering, one surface of which is facing outward, away from the frame and towards the opening of the window glass; a sealing pad mounted at the bending part below the top covering to seal the gap between the top covering and the sash glass pressing covering. The top covering is folded two times, and there is a certain distance from the opening at the bending position to its edge, so that the bending part won't block the sash when the sash is opened, thus the open angle is wide. A preferred open angle is usually set to 16°. And the bending part is hard to be seen, the sealing pad seals the gap between the top covering and the glass fixture covering, protects the window from the weather effect.

- However, this type of the window top covering has the following problems, if a wider open angle is required, the edge of the top covering has to keep a certain height from the sash top surface such as the glass surface. While with the increasing of the height, the gap between the top covering and the glass pressing covering becomes wider, thus it needs to increase the width of the sealing strip. In this case, it is difficult to seal with the sealing strip only, because the sealing strip moves relative to the bottom covering when the window opens, thus the sealing strip needs to be soft, but when the window is strong, it is hard for the soft and wide sealing strip to stop the wind, and when it rains the rain will enter the window, then the covering fails. Also, since there is no covering in front of the sealing strip, air, sunshine and higher temperature tend to make the sealing strip aging too soon, which cause it losing flexibility thus fail the seal. And the wider gap between the top covering and the glass pressing covering affects the appearance of the window.

- The invention is to provide a window top covering for a wide angle or range of opening the window and has a better sealing performance.

- Therefore, the invention provides a top covering for a window, characterized in that it comprises a first top covering which is mounted to the window frame, and a second top covering which is mounted to the sash, wherein the first top covering has a front end portion provided with a downwardly bended front flap, the second top covering has a back end portion provided with an upwardly bended back flap, wherein the front end portion is disposed under the back end portion, with the front and back flaps inserted into the comers defined by each other.

Preferably, the second top covering has a flat base portion and a sloped portion provided with the back end portion and extended and angled from the base portion.

Preferably, the front and back flaps are flat.

Preferably, the front and back flaps are curved.

Preferably, a drainage groove is formed in the first top covering.

Preferably,the sides of the first top covering are closed by side pieces.

Preferably, the second top covering has a front portion provided with a curved front edge bended downwards therefrom.

Preferably, the second top covering having a stepped surface at the front edge in order to press upon the surface of the window sash glass.

Preferably, the side pieces has a groove.

Preferably, the groove has a curved comer.

Preferably, the groove has a right angled comer.

Preferably, a hole is formed in the bottom of the groove.

Preferably, the bottom of the groove is formed with a collar surrounding a hole.

Preferably, the first top covering or/and the second top covering is/are made from aluminum or zinc or plastic.

Preferably, the first top covering and/or the second top covering is galvanized or painted. -

- Fig.1 is a cross section of a preferred window top covering embodiment structure according to the invention;

- Fig.2 is a cross section of a window top covering in Fig.1 when being opened;

- Fig.3 is a groove shaped side piece attached to the left end of the first top covering.

-

- A window top covering according to the invention will be hereafter described in detail with reference to the drawings and the preferred embodiment.

- As shown in Fig.1 and 2, a preferred embodiment of the top covering according to the invention comprises a first top covering 1 and a second top covering 2. The first

top covering 1 is fixed onto awindow frame 12, while the second top covering is mounted on asash 11 corresponding thereto, or on the fixture of glazing (not shown), as long as it is substantially fixed to the sash. - The front end portion of the first top covering 1 is provided with a

flat flap 4 bended downward. The back end portion of the second top covering 2 is inserted below the front end portion of the first top covering 1. The second top covering 2 is also provided with aflat flap 3 bended upward at the back end portion. The twoflaps flat portion 5 as it approaches theflap 3, with a sharp angle is defined between thesloped portion 5 and theflat base portion 13. Thesloped portion 5 is provided so that the second top covering can be swung to a wider angle of opening the sash relative to the first top covering, and thebase portion 13 of the second top covering 2 partially shields the interface of the first and second shields at theflaps first shield 1 with the same angle of opening the sash, and hides theflaps flaps - The first top covering is formed with a

drainage groove 8 open upward, a side wall of thegroove 8 is connected with anangled portion 14 so that the water on the first top covering can be discharged into thedrainage groove 8, and the water flow to theflap 4 can be reduced. There is an angled flap 15 bended into thegroove 8, by means of which a flashing part (not shown) can easily installed to the window. As shown in Fig. 3, twoside pieces 30 close the side ends of the first top covering 1 respectively to prevent wind or rain from entering through the two ends, and present a beautiful top covering appearance. - A curved

front edge 7 is formed with the second top covering bended downwards from the front end. The curvedfront edge 7 reduces the distance between thesecond shield 2 and theglazing fixture 9 or glazing 10 for a narrowed gap between thesecond shield 2 and thefixture 9 and a better seal. Meanwhile, a winding curtain is hung up under the top covering, and has acurtain material 6 goes through the gap between the second top covering and the fixture, with the curvedfront edge 7 pressing thecurtain material 6 downward and pushing the same towards theglass 10 for a desired tension thereof. Thus, thecurved edge 7 is a sealing element, and a guide track for thecurtain material 6, as the curved shape does not scratch thecurtain material 6 and facilitates the smooth movement of the curtain. - Referring to Fig.3, the ends of the first top covering 1 are connected to a

U-shaped groove 20, and thedrainage groove 8 and twoend pieces 30 are embedded and fixed into theU-shaped groove 20. The U-shapedgroove 20 is formed with ahole 21, through which a screw fastens the first top covering to the window frame. Acollar 22 is placed at the bottom of the U-shaped groove and surrounding thehole 21, so as to prevent the water from flowing down from the U-shaped groove through thehole 21. - The first top covering and the second top covering are made of an aluminum alloy plate, which is light, stainless and high-strength. The plate may be painted. PVC or zinc or other materials may be used to manufacturing the top covering, alternatively.

- Referring to Fig.2, as the sloped roof window is opened, the

second shield 2 will rotate with the sash with theflap 3 moving down to the right of theflap 4 of the first top covering, while thesloped portion 5 moves to theflap 4 of the first top covering 1. When the slopedportion 5 and theflap 4 of the first top covering abut each other, the window is opened to the maximum extent.

Claims (9)

- A top covering for a window, characterized in that it comprises a first top covering which is mounted to the window frame, and a second top covering which is mounted to the sash, wherein the first top covering has a front end portion provided with a downwardly bended front flap, the second top covering has a back end portion provided with an upwardly bended back flap, wherein the front end portion is disposed under the back end portion, with the front and back flaps inserted into the comers defined by each other.

- A top covering according to claim 1, wherein the second top covering has a flat base portion and a sloped portion provided with the back end portion and extended and angled from the base portion.

- A top covering according to claim 1 or 2, wherein the front and back flaps can be flat or, wherein the front and back flaps can be curved.

- A top covering according to any of the preceding claims, wherein a drainage groove is formed in the first top covering.

- A top covering according to any of the preceding claims, wherein the sides of the first top covering can be closed by side pieces.

- A top covering according to any of the preceding claims, wherein the sides of the second top covering can be closed by side pieces.

- A top covering according to any of the preceding claims, wherein the second top covering can have a front portion provided with a curved front edge bended downwards there from or, wherein the second top covering can have a stepped surface at the front edge in order to press upon the surface of the window sash glass.

- A top covering according to any of the preceding claims, wherein the side pieces has a groove, wherein the groove can have a curved comer or, wherein the groove can have a right angled comer and/or, wherein a hole can be formed in the bottom of the groove and/or, wherein the bottom of the groove can be formed with a collar surrounding a hole.

- A top covering according to any of the preceding claims, wherein the first top covering or/and the second top covering can be made from aluminum or zinc or plastic or, wherein the first top covering and/or the second top covering can be galvanized or painted.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU200320121962XU CN2714760Y (en) | 2003-11-21 | 2003-11-21 | Window top cover plate |

| CN200320121962 | 2003-11-21 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1533435A2 true EP1533435A2 (en) | 2005-05-25 |

| EP1533435A3 EP1533435A3 (en) | 2007-10-24 |

Family

ID=34427795

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04388080A Withdrawn EP1533435A3 (en) | 2003-11-21 | 2004-11-20 | Top covering for window |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1533435A3 (en) |

| CN (1) | CN2714760Y (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009033938A1 (en) * | 2009-07-14 | 2011-01-20 | Roto Frank Ag | Roof window and method for fixing a cover plate |

| DE102009033939A1 (en) * | 2009-07-14 | 2011-02-10 | Roto Frank Ag | Roof window and method for fixing a cover plate |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2269628A1 (en) * | 1974-05-02 | 1975-11-28 | Hoeganaes Ab | Hinged type skylight cladding - has U-shaped section on fixed frame with flange held by roof hatch collar |

| DE2946514A1 (en) * | 1979-11-17 | 1981-05-27 | Blefa AG, 9510 Kreuztal | COVER COLLAR FOR ROOF WINDOWS O.AE. ROOF INSTALLATION |

| DE9016725U1 (en) * | 1990-12-11 | 1991-03-28 | Roto Frank AG, 7022 Leinfelden-Echterdingen | Cover for a sash frame of a roof window |

| DE29924667U1 (en) * | 1998-04-07 | 2004-10-14 | Vkr Holding A/S | Frame structure in skylight mounted in buildings |

| EP1533440A2 (en) * | 2003-11-21 | 2005-05-25 | VKR Holding A/S | Sealing sash frame and roof window equipped therewith |

-

2003

- 2003-11-21 CN CNU200320121962XU patent/CN2714760Y/en not_active Expired - Fee Related

-

2004

- 2004-11-20 EP EP04388080A patent/EP1533435A3/en not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2269628A1 (en) * | 1974-05-02 | 1975-11-28 | Hoeganaes Ab | Hinged type skylight cladding - has U-shaped section on fixed frame with flange held by roof hatch collar |

| DE2946514A1 (en) * | 1979-11-17 | 1981-05-27 | Blefa AG, 9510 Kreuztal | COVER COLLAR FOR ROOF WINDOWS O.AE. ROOF INSTALLATION |

| DE9016725U1 (en) * | 1990-12-11 | 1991-03-28 | Roto Frank AG, 7022 Leinfelden-Echterdingen | Cover for a sash frame of a roof window |

| DE29924667U1 (en) * | 1998-04-07 | 2004-10-14 | Vkr Holding A/S | Frame structure in skylight mounted in buildings |

| EP1533440A2 (en) * | 2003-11-21 | 2005-05-25 | VKR Holding A/S | Sealing sash frame and roof window equipped therewith |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009033938A1 (en) * | 2009-07-14 | 2011-01-20 | Roto Frank Ag | Roof window and method for fixing a cover plate |

| DE102009033939A1 (en) * | 2009-07-14 | 2011-02-10 | Roto Frank Ag | Roof window and method for fixing a cover plate |

| DE102009033939B4 (en) * | 2009-07-14 | 2011-07-21 | Roto Frank Ag, 70771 | Roof window and method for fixing a cover plate |

| DE102009033938B4 (en) * | 2009-07-14 | 2018-01-18 | Roto Frank Ag | Roof window and method for fixing a cover plate |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1533435A3 (en) | 2007-10-24 |

| CN2714760Y (en) | 2005-08-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4831779A (en) | Self-draining panel threshold combination | |

| US6334283B1 (en) | Water resistant window frame | |

| US20080034677A1 (en) | Rooflight | |

| US20130326973A1 (en) | Window rain guard & wind deflector | |

| US7647735B2 (en) | Roofwindow having drainage system | |

| EP1533435A2 (en) | Top covering for window | |

| US20060064937A1 (en) | Weather strip assembly and method of application of same | |

| GB2039028A (en) | Window ventilator | |

| US4389816A (en) | Sheet metal protective cover for awning windows | |

| US7409981B2 (en) | Shutter device with guideways | |

| EP1533440A2 (en) | Sealing sash frame and roof window equipped therewith | |

| CN100501101C (en) | Sealed window sash frame and pitched roof sky-light containing the same | |

| JP2004217152A (en) | Raindrop preventing structure of back door | |

| JP4670636B2 (en) | Vehicle rear lamp | |

| CN213175296U (en) | High-water-tightness built-in hidden screen casement window | |

| CN210977121U (en) | Sliding window lower sliding channel sealing structure | |

| US20230167674A1 (en) | Replacement Weather Seal for A Garage Door | |

| CN221481732U (en) | Aluminum alloy outer window | |

| CN111155726B (en) | Waterproof window body | |

| JP2000136607A (en) | Cover member for eaves gutter | |

| JPH1071860A (en) | Mold forming part of weather strip | |

| AU714252B2 (en) | Improvements to louvre windows | |

| JPS6321674Y2 (en) | ||

| CN1229563C (en) | Bottom covering piece for window | |

| KR19990053343A (en) | Structure of weather strip on the upper door of rainwater intrusion prevention |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: VKR HOLDING A/S |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20071208 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20081111 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20100601 |