EP1522729B2 - Pompe à cavité progressive et stator pour une telle pompe - Google Patents

Pompe à cavité progressive et stator pour une telle pompe Download PDFInfo

- Publication number

- EP1522729B2 EP1522729B2 EP03022804A EP03022804A EP1522729B2 EP 1522729 B2 EP1522729 B2 EP 1522729B2 EP 03022804 A EP03022804 A EP 03022804A EP 03022804 A EP03022804 A EP 03022804A EP 1522729 B2 EP1522729 B2 EP 1522729B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- stator

- rotor

- casing

- axial

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C2/00—Rotary-piston machines or pumps

- F04C2/08—Rotary-piston machines or pumps of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing

- F04C2/10—Rotary-piston machines or pumps of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of internal-axis type with the outer member having more teeth or tooth-equivalents, e.g. rollers, than the inner member

- F04C2/107—Rotary-piston machines or pumps of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of internal-axis type with the outer member having more teeth or tooth-equivalents, e.g. rollers, than the inner member with helical teeth

- F04C2/1071—Rotary-piston machines or pumps of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of internal-axis type with the outer member having more teeth or tooth-equivalents, e.g. rollers, than the inner member with helical teeth the inner and outer member having a different number of threads and one of the two being made of elastic materials, e.g. Moineau type

- F04C2/1073—Rotary-piston machines or pumps of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of internal-axis type with the outer member having more teeth or tooth-equivalents, e.g. rollers, than the inner member with helical teeth the inner and outer member having a different number of threads and one of the two being made of elastic materials, e.g. Moineau type where one member is stationary while the other member rotates and orbits

- F04C2/1075—Construction of the stationary member

Definitions

- the invention relates to an elongated feed pump as an eccentric screw pump, consisting of a stator and a rotor.

- the stator may have a cylindrical outer sheath, preferably of metal, and a hollow sheath of a "rigid-elastic" material with a spiral-shaped inner surface and held or receivable by the same. He takes on a corresponding helical or helical rotor. Stator and rotor have the same direction slopes. Also of relevance is the stator itself, with "tight-elastic" lining or elastomeric jacket.

- Such pumps are known for various applications, for example as a feed pump for mortar mixtures or other abrasive conveying fluid, see. DE-B 33 04 751 (KTO) with "conical bias" between stator and rotor, becoming stronger to output MAS.

- a pump with elastomer stator is off DE-A 197 58 086 (Artemis) known. It corresponds to the preamble of claim 1. In her, a quick installation of the lining should be possible. An axially projecting elastomeric ring is provided for a sealing axial mounting.

- DE-A 198 01 021 Heunter

- a metallic, mostly hardened rotor is driven in rotation in operation in one of its pitch or helix opposite sense.

- a corresponding axial holding force must be applied by the input side drive shaft, possibly above the rotor upstream equipment parts, such as clutch, driver, mixing tool or the like .. become.

- the axial holding force arises as a "Reactio" by the “Actio” caused by the conveyance and forward movement of the conveyed material and the rotation of the rotor in the stator, after the rotor against the pitch of its helix and against the pitch of the helix of the inner lining of the stator (the inner shell) is driven in rotation by the drive means (on the input side).

- the jacket In order to facilitate the entry of the medium to be pumped ("conveying fluid") into the pump, the jacket (stator) is often widened funnel-shaped on the inlet side.

- the invention is based on the object to remedy the situation and to ensure greater service life, to prevent a change in the consistency of the medium to be conveyed and to avoid sudden losses of capacity at almost new replaced components.

- the described defect alleviated by the invention appeared to be a problem of the elastomer which prematurely worn out at the sealing points (the radially inwardly projecting ribs of the elastomeric helical coil) through an axially extending notch or groove thereby opening or closing a channel for backflow Achieved a poor seal between the helical rotor and the inner surface of the elastomeric lining of the outer shell.

- the cause was or was not in the elastomer compound or its processing or incorporation, but first had to be identified where the actual cause of this occurring and on a removed stator visible fault symptom was.

- To this described backflow channel in the interior of the stator a near the outlet end circumferentially into the stator or its elastomeric lining cut groove joined.

- the area which is (or would) be damaged by the sickle-shaped edge of the rotor is omitted without altering the actual length of the pump, that is to say without having to shorten the stator with its outer jacket or to make other modifications on site.

- the rotor moves with its crescent-shaped edge in a free space.

- the edge does not receive a compliant countermeasure where, upon displacement of its axial position, it could damage the stator with its elastomeric interior to trigger the chain of events that the user perceives as a "thick / thin" symptom.

- stator and rotor which is important for optimum delivery performance, is not more given.

- the creation of a clearance symbolizes avoiding a damaging contact of the crescent-shaped circumferential end edge (also called peripheral edge) in a rotating movement of the rotor with respect to the elastomeric, ie compliant and softer inner shell of the contrast, much stiffer outer shell of the stator.

- the clearance symbolizes an axial extent and a radial extent for a reduction of the strength of the elastomeric lining (claim 3, claim 4), or vice versa, a widening of the worm gear in the radial direction on a predetermined axial piece near the exit on the pressure side of the stator.

- a circumferential sealing web (claim 16) may also be formed axially projecting and radially far outward on the elastomeric end face, but in its axial extent is substantially less than 2% of the axial length of a stator pitch (a screw stage or a stage on the other hand, he has a completely different task, that of the axial and radial sealing of the connection point of the stator to the further functional parts, without that he would be functionally related to the crescent-shaped end of the rotor or a geometry of the rotor.

- a stator pitch a screw stage or a stage on the other hand

- a reduction of the A-measure in the conveying direction in the continuing pressure-loaded section of the screw pump refers to a respective pitch stage in terms of their beginning and their end.

- the inside width of the inner shell is further reduced substantially uniformly per level.

- a combination of helical formation and conical expansion of the shell in the exit region provides a lightweight manufacturing technique (claim 8).

- the screw shell is no longer tapered conically to the pressure-side end, but slightly or more expanded, retains its basic snail shape and in addition receives a conically widening shape.

- the conicity in the direction of compression in this section which is endangered by the crescent-shaped engagement, runs as "counter-conicity", in the sense of an expansion and not a narrowing of the clear space formed by the helical inner surface of the elastomeric inner jacket.

- This "widened conicity” can be compared with such a “reducing conicity” or such a clear space, which lies axially further forward, ie opposite to the conveying direction (claim 8), or immediately before the beginning of the counterconceptivity ("widening" conicity) ,

- the expansion extends radially on an axial length such that both directions together achieve a reduction in the wall thickness of the elastomeric inner liner in this axially short piece on the exit side.

- a cylindrically shaped expansion, retraction or wall thickness reduction (claim 6, claim 16) can pass directly into a circumferentially extending sealing ridge at the front end.

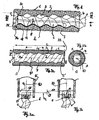

- the eccentric screw pump has in the example as out FIG. 1 can be seen, an outer cylindrical elongated housing 1 of a predetermined diameter and predetermined length.

- the housing may be made of steel, for example.

- a hollow cylindrical shell for example, made of high-wear rubber or the like.

- the inner surface 3 has a helical contour for the formation of a double-flighted screw channel with double pitch.

- the screw channel is conically widened, as shown at 4, to facilitate the entry of a medium to be conveyed to the exit side MAS as a fluid, eg a mixture of water and an additive.

- the stator can be axially slotted or multi-part, which is not shown separately.

- the pitch direction 7 is the same for stator and rotor.

- the longitudinal axis 11 of the coiled rotor portion is radially offset by 2 * e with respect to the central axis 10 of the screw flights of the stator (the axis of rotation of the rotor), whereby the Eccentricity 9 (or "e") yields.

- the rotor 6 On the inlet side MES, the rotor 6 is extended beyond the beginning of the stator at 8 in order in the axis 10 a screw head 17 (FIG. Fig. 3a ), over which the rotor can be driven in one of the pitch direction of stator and rotor opposite sense.

- the outlet opening 5 of the stator of the pump is specially designed on the outlet side MAS. Further details below.

- a conicity k is due to a black, increasing edge area of the helical worm in FIG. 1 represents, which is operated with an increasing contact pressure from the input side 4 to the output side 5, in order to take into account the increasing delivery pressure and better form the sealing lines to delimit the delivery chambers in the elastomeric stator shell 2.

- Such delivery chambers are in the upper section of the FIG. 1 between the screw channel (formed by the inner wall forming 3 of the elastomeric lining 2) and the outer wall of the elongate coil 6 illustrates.

- the sealing lines of the chambers are represented in cross section by the short black overlap strips which, even during operation, do not overlap, but by yielding the elastomeric material create a pressure sealing effect to the stator as well as the continuous zone k.

- the axial direction is denoted by z, also as a conveying direction, wherein the two axes 10, 11 are offset eccentrically and can be seen with the offset 9.

- the consequence of the wear is that the rotor has changed its position z1 relative to the stator by the offset 19, whereby it has migrated into the stator counter to the conveying direction.

- the measure .DELTA.z corresponds to the offset 19 and the widening of the provided with a recording screw head 17 in the coupling 18 on the driver 16 of the mixing tool 15, wherein in particular the in FIG. 3b Deposited with v points wear by an axial removal of the non-hardened driver tool against the hardened steel of the rotor subject.

- Figures 2 show the stator in a normal training.

- the inlet end 4 is flared, while the worm gear is unchanged as far as in the direction perpendicular to the axis 10 extending plane 22, in which the outlet-side opening 5 'of the shell 2 is located.

- a rotor like the rotor 6 after FIG. 1 is in its working position z1 and is driven in rotation, he makes at the surrounding elastomeric sheath 2 a considerable flexing work.

- a crescent-shaped edge 24 is correspondingly involved in the output-side end face 25 of the rotor 6, since in the case according to FIG. 2a the worm threads run unchanged to the mantle end face in the plane 22.

- the crescent-shaped end edge 24 works thereby, when the offset .DELTA.z becomes larger, in the material of the shell, and causes a corresponding notch or even a cut. These can have a radial depth of up to 3 mm and more.

- the jacket elastomer becomes hot, up to 60 ° to 70 ° Celsius and bulges, folds a little way inwards, and reduces the outlet cross-section of the opening 5 for the conveyed medium (conveying fluid).

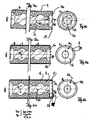

- FIGS. 1 and 4 to 6 show the occurrence of this damage can be effectively avoided.

- the outlet opening 5 of the shell 2 is widened compared to an assumed regular screw surface course and thus precludes a pressure-exerted touch the crescent-shaped end edge 24 of the rotor with the jacket 2 during operation, preferably even if the rotor due to wear of parts in the drive path (s , Figures 3 ) changes its predetermined regular axial position z1 relative to the stator counter to the conveying direction (by offset 19 or ⁇ z in FIG Figures 3 ).

- the crescent-shaped edge 24 shown in section as a sharp, less than 180 ° having cutting edge, does not touch the elastomeric sheath 2, but a distance is provided.

- FIG. 1 Another axial shift back by more than ⁇ z FIG. 3b would in FIG. 1 lead to an even further shifted to the right axial position of the rotor 2, connected to a possibly pending (burdening) Contact, despite a widened design of the outlet opening 5.

- a mere touch itself is not harmful, only one that leads to additional compressive stress to a cutting action in the elastomer, which then the axially further to the pressure side portion of the elastomer jacket to undesirable radial displacements would cause in.

- the area of reduction of the shell wall thickness 2 near the end face at the outlet MAS is not a large axial distance, but a substantial radial expansion of the outlet opening 5.

- the lengths can after a step L1 after FIG. 2a as a comparative object, several of which are provided along the entire length L of the stator by the elastomeric inner liner.

- a change in the internal dimension of the interior may be indicated by indicating the percentage reduction corresponding to a percentage reinforcement or thickening of the elastomeric jacket 2.

- This indication can also extend to the A measure and the C measure after FIG. 2b as changing in the course of the z-direction.

- the two dimensions A and C define the largest and smallest dimension of the interior, wherein the largest and the smallest distance of the inner surface of the elastomeric lining 2 in section after FIG. 2a correspond.

- the shape of the widening 5 of the end MAS of the stator can be different.

- FIGS. 6 A similar plan view results in the training after FIGS. 6 in which the widening 5b is stepped. This corresponds to a substantially cylindrical retraction of the elastomer wall 2 '.

- FIGS. 4 corresponds with the expansion 5c substantially the in FIG. 1 shown form, with an additional screw share in the z5 section.

- FIG. 4b shows the corresponding plan view.

- FIG. 5b a slope at the widening or enlargement 5a

- the FIG. 6b a cylindrical recess 5b, or a plan view of an end-face, radially directed surface

- the FIG. 4b a combination of a conical expansion connected to a helical lug 5c with a conicity other than that which led to the widening portion of the length z5 (in the previously stored area and the preceding stages).

- Such a helical formation connected to a conical or cylindrical configuration can also be described as a conical shape is maintained, with inverted conicity, so one that relaxes a compressive load, or does not arise and is directed outwards to a thinner wall thickness 2 'of the elastomeric jacket 2, or but significantly and more so conically widened that the gap distances between a crescent-shaped edge 24 after FIG. 1 and the inner surface of the expansion 5 can be seen even with a built-rotor.

- All embodiments have in addition a frontally arranged circumferential web-shaped seal 21, for sealing attachment to further intermediate sections (receiving) in the transition section to the delivery hose on the pressure side.

- This circumferential ridge 21 is disposed radially far outward on the elastomeric inner jacket, near the rigid housing or outer jacket 1. It extends in the axial direction by far less than 2% of a step length L1, and has no influence on the protection of the inner wall of the elastomer liner 2 against damage caused by the rotor. When installed, this bridge is almost completely compressed.

- FIG. 6a To illustrate the axial extent and the radial expansion is in FIG. 6a a group of reference numerals are shown, so the residual wall thickness 2 ', which results from the introduction of a cylindrical recess 5b or a cylindrical expansion 5b, preferably matching a radial thickness of the just described circumferential web 21.

- the axial extent z5 of the relocation or expansion generally as "Clearance G" after FIG. 1 to describe is related to the length L1 of a step (a thread).

- the size of the radial expansion r5 corresponds to a shape along the axial distance z5 on which the expansion r5 takes place. It does not have to be constant, but it can be like that FIGS. 5a and 4a show, vary circumferentially and take different values in the longitudinal direction z.

- the widening or widening for the release of the jacket from the end edge of the rotor should be at least 2%, preferably above 3%, or 5% to 10% of a stage L1 of the stator worm 3.

- a stage L1 of the stator worm 3 For better understanding is in FIG. 2 such a stage is drawn.

- the lower limit of the extension is about 2 mm to 4 mm, but may also be 5 mm to 11 mm or more, up to half a step.

- the occurring reduction of the pump-effective length of the stator is compensated by a corresponding increase in the bias voltage k between the rotor and stator.

- the conicity is in the sectional view through inclined connecting lines 21 in FIGS. 5a, 6a seen. They correspond to the illustrated conicity k, which ensures an increased bias to the pressure side.

- the change in taper takes place in an advantageous manner by continuous change of the A-measure.

- the percentage reduction of this level per level should be at least 0.4%.

- the number of stages of the stator is equal to the stator length divided by the pitch of its flights.

- the conicity of the stator screw results from the difference between the C and A dimensions of inlet MES and outlet MAS, where the reduction is evenly distributed over the number of slopes (steps).

- the mean of the A measure per step is the A measure at the entrance of the step less the A measure at the exit of the step. In this sense, here the percentage reduction of the A measure per step is understood to mean the A measure difference per step multiplied by 100 and divided by the A measure at the input of the step.

- a segregation, ie a consistency change of the pumped medium, as well as early wear of the pump parts can be avoided in a very simple manner and with the possibility to compensate for a reduction in the purchase of pump power.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Rotary Pumps (AREA)

- Details And Applications Of Rotary Liquid Pumps (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Claims (18)

- Pompe à vis sans fin excentrique comprenant une enveloppe interne (2), constituée d'un matériau résistant à l'usure et élastique, dans une enveloppe de boîtier cylindrique (1) en une ou plusieurs pièces; une surface interne (3) de l'enveloppe (2), ou de l'enveloppe interne (2), présentant, sur sa face (3) tournée vers l'intérieur, la forme d'un pas de vis avec un sens et une longueur prédéterminés du pas de vis;

un rotor spiralé ou hélicoïdal (6, 8), inséré sous précontrainte dans l'enveloppe dans une première position axiale (z1) et avec une excentricité radiale (9) et maintenu du côté de l'entraînement dans cette position (15, 16), avec le même sens de pas de vis (7) que celui du stator (2); caractérisée en ce qu'une ouverture de sortie (5) du stator (2) est élargie depuis son extrémité frontale sur une partie de la longueur axiale de transport radialement vers l'extérieur sur toute la circonférence, de sorte qu'une arête frontale (24), tournant lors du fonctionnement de la pompe, de l'extrémité (23) du rotor située près de l'ouverture de sortie - de préférence lors d'un décalage axial (19; Δz) du rotor dû à l'usure - puisse tourner sans contact ou librement (G) par rapport à la surface interne (3) du stator. - Pompe à vis sans fin excentrique selon la revendication 1, comportant un stator constitué d'un boîtier cylindrique (1) d'une seule pièce et de l'enveloppe interne (2) en matériau élastomère qui y est agencée fixement, dont la surface interne (3) s'étend en spirale ou en hélice autour de l'axe longitudinal (10; z), et un rotor hélicoïdal allongé (6), qui est agencé, de manière décalée radialement dans une mesure prédéterminée (9, e) avec son axe central (11) par rapport à l'axe longitudinal (10) du stator, dans une position axiale donnée (z) par rapport au stator dans celui-ci, qui présente la même direction de pas de vis que celle de l'enveloppe interne, qui peut être entraîné en rotation - à l'opposé du sens du pas de vis de la surface interne (3) de l'enveloppe interne - et qui est maintenu d'un côté entraînement (8) dans la position axiale donnée (z); dans laquelle- l'enveloppe interne (2) est évidée ou élargie, à partir de sa face avant côté sortie (22) tant dans la direction radiale que dans la direction axiale dans une mesure telle qu'une arête frontale côté sortie (24) du rotor (6) tourne de manière excentrique en périphérie lors d'un fonctionnement de la pompe - ne sollicitant pas la face interne (3) de l'enveloppe (2);- on prévoit, pour compenser une perte de performances, une diminution, distribuée sur le restant de la longueur du stator, d'une plus grande largeur intérieure (mesure A) des canaux à vis formés par la surface interne (3) dans le stator (2), pour obtenir une conicité plus forte.

- Pompe à vis sans fin excentrique selon la revendication 1 ou 2, caractérisée en ce qu'il y a un passage libre (G) de l'arête périphérique (24) côté sortie du rotor (6), généré par un décalage radial et axial d'une face frontale (22) côté sortie de l'enveloppe de stator (2) axialement à l'opposé du sens de transport sur une section de longueur (z5) qui correspond au moins à 2 % d'une longueur axiale d'un pas de stator (spire de vis sans fin L1), en particulier à plus de 3 %, entre 5 % et 10 % ou jusqu'à une demi-spire.

- Pompe à vis sans fin excentrique selon la revendication 3, caractérisée en ce que l'on dimensionne le décalage en particulier sous la forme d'un évidement ou d'un élargissement de sorte que le passage libre (G) soit conservé même lors d'un décalage axial du rotor (6) dû à l'usure (19, Δz).

- Pompe à vis sans fin excentrique selon l'une quelconque des revendications précédentes, dans laquelle, pour compenser la perte de performances apparaissant du fait du décalage d'une section (z5) de la face frontale (22) côté sortie du stator (2) et la réduction consécutive de son au moins un pas de vis efficace en transport,(i) on prévoit une réduction de la largeur intérieure du canal de vis sous la forme d'une réduction de la mesure A dans le sens de transport par spire de vis sans fin (L1) de l'enveloppe de stator (2) d'au moins 0,4%; ou(ii) on diminue une largeur intérieure de l'enveloppe interne par spire (L1) de plus de sensiblement 0,4 %, la largeur intérieure de l'ouverture d'entrée (4) se réduisant sensiblement en permanence par rapport à l'ouverture de sortie (5).

- Pompe à vis sans fin excentrique selon la revendication 1 ou 2, dans laquelle l'élargissement possède une section de forme sensiblement cylindrique (5b).

- Pompe à vis sans fin excentrique selon la revendication 1 ou 2 ou 6, dans laquelle l'élargissement (5) de l'ouverture côté pression possède une section de forme sensiblement conique (5a), en particulier même avec un élargissement sensiblement conique sous la forme d'un cône d'entrée (4) sur la face d'entrée (MES) du stator ou de la pompe.

- Pompe à vis sans fin excentrique selon la revendication 1 ou 2 ou 7, dans laquelle, sur une partie (z5) de la longueur axiale proche de la face de sortie (MAS), la surface interne hélicoïdale (3) s'étend radialement vers l'extérieur et axialement vers l'avant du côté de pression (5c), en particulier à l'encontre d'une réduction, s'étendant sensiblement en permanence, de la dimension radiale de la surface interne (3) avant la partie axiale mentionnée (z5), en commençant près de la face d'entrée du stator ou de la pompe.

- Pompe à vis sans fin excentrique selon la revendication 1 ou 2, dans laquelle une extrémité frontale côté pression du stator porte une nervure élastomère annulaire (21) pour assurer l'étanchéité lors d'un montage du stator, à l'encontre d'un logement côté pression.

- Procédé pour faire fonctionner une pompe à vis sans fin excentrique comprenant une enveloppe (2) en matériau élastomère qui peut être insérée dans un boîtier sensiblement cylindrique (1) ou y être agencée, dont la surface interne (3) se présente sous la forme d'un pas de vis pour recevoir un rotor spiralé (6) insérable sous précontrainte dans l'enveloppe élastomère dans une position axiale prédéterminée et avec une excentricité radiale (9) prédéterminée et soutenu du côté entraînement dans cette position; caractérisé en ce qu'une ouverture de sortie (5; 5a, 5b, 5c) du stator (2) est élargie depuis son extrémité frontale et à l'encontre d'un sens de transport axial ou s'étend radialement de sorte que, lors du fonctionnement de la pompe, une arête frontale (24) tournant en périphérie à l'extrémité (23) du rotor (6) - de préférence avec un décalage axial (19; Δz) du rotor, par rapport au stator - tourne sans contact ou sans contact de pression sensible avec la surface interne (3) de l'enveloppe élastomère (2).

- Procédé selon la revendication 10, dans lequel le boîtier cylindrique est formé d'une seule pièce sous la forme d'une enveloppe périphérique continue ou est doté d'au moins une fente axiale ou est formé de plusieurs pièces avec plusieurs fentes axiales.

- Procédé selon la revendication 10, dans lequel l'extension ou l'élargissement (5a, 5b; 5) à l'extrémité frontale côté pression du stator a une forme sensiblement cylindrique, conique ou en pas de vis, ou présente une combinaison de ces sections.

- Procédé selon la revendication 10, dans lequel le stator sur sa face d'entrée frontale possède un élargissement (4) se présentant en particulier sous une forme conique.

- Procédé selon la revendication 10, dans lequel la longueur (z5) remontant axialement de l'élargissement (5) est supérieure à 2 %, de préférence à 5 % et inférieure à 50 % de la longueur axiale (L1) d'une spire du pas de vis du stator par rapport au pas de vis de celui-ci.

- Utilisation d'un stator d'élastomère, comprenant une enveloppe externe sensiblement rigide et une enveloppe interne (2), qui y est agencée, en matériau élastomère plus mou par rapport à l'enveloppe externe, dont la surface interne (3) est réalisée en s'étendant de manière hélicoïdale autour d'un axe longitudinal (10), convenant pour le logement d'un rotor hélicoïdal excentrique (6), qui peut être introduit dans une position axiale prédéterminée (z1) par rapport à l'enveloppe du stator, dans ce dernier, et qui est maintenu du côté entraînement dans sa position axiale (18,16,17), dans lequel l'enveloppe interne d'élastomère (2) se présente avec une réduction depuis son front côté sortie (z5)(i) dans la direction axiale(ii) par rapport à une surface interne hélicoïdale (3) axialement plus en avant par rapport à la face de sortie MES dans la direction radiale (r5),

et le stator d'élastomère fournit un passage libre (G) près d'une arête frontale (24) côté sortie du rotor (6) lors du fonctionnement de la pompe, et dans lequel la surface interne hélicoïdale (3) diminue sensiblement en permanence à partir de la face d'entrée frontale dans sa mesure interne jusqu'avant d'atteindre l'épaisseur de paroi de l'enveloppe élastomère (2) se présentant sous forme réduite (r5, z5), convenant pour une pompe à vis sans fin excentrique selon la revendication 1. - Utilisation selon la revendication 15, dans laquelle, côté sortie (MAS), une nervure périphérique (21) est constituée d'un matériau élastomère qui dépasse axialement, en particulier, il y a une réduction sensiblement cylindrique de l'épaisseur de paroi de l'enveloppe élastomère (2) entre la nervure (21) et le début du premier élargissement radial (r5,5b) s'étendant axialement sur une partie (z5).

- Utilisation selon la revendication 16, dans laquelle une épaisseur de paroi restante (2') de l'enveloppe interne élastomère dans la zone de l'élargissement radial (5b) possède sensiblement la même épaisseur radiale que celle de la nervure périphérique (21) dépassant côté sortie (MAS).

- Utilisation selon la revendication 15, dans laquelle la mesure intérieure de l'enveloppe interne hélicoïdale (3) diminue par spire d'au moins 0,4 %, jusqu'avant l'élargissement radial (5, 5a, 5b, 5c).

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03022804A EP1522729B2 (fr) | 2003-10-07 | 2003-10-07 | Pompe à cavité progressive et stator pour une telle pompe |

| AT03022804T ATE349617T1 (de) | 2003-10-07 | 2003-10-07 | Exzenterschnecken-pumpe und stator für eine solche pumpe |

| DE50306120T DE50306120D1 (de) | 2003-10-07 | 2003-10-07 | Exzenterschnecken-Pumpe und Stator für eine solche Pumpe |

| ES03022804T ES2279917T5 (es) | 2003-10-07 | 2003-10-07 | Bomba de tornillo sin fin excéntrico y estator para una bomba semejante |

| CY20071100401T CY1106407T1 (el) | 2003-10-07 | 2007-03-22 | Αντλια με εκκεντρο κοχλια και επαγωγεας για τετοια αντλια |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03022804A EP1522729B2 (fr) | 2003-10-07 | 2003-10-07 | Pompe à cavité progressive et stator pour une telle pompe |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1522729A1 EP1522729A1 (fr) | 2005-04-13 |

| EP1522729B1 EP1522729B1 (fr) | 2006-12-27 |

| EP1522729B2 true EP1522729B2 (fr) | 2013-03-27 |

Family

ID=34306881

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03022804A Expired - Lifetime EP1522729B2 (fr) | 2003-10-07 | 2003-10-07 | Pompe à cavité progressive et stator pour une telle pompe |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP1522729B2 (fr) |

| AT (1) | ATE349617T1 (fr) |

| CY (1) | CY1106407T1 (fr) |

| DE (1) | DE50306120D1 (fr) |

| ES (1) | ES2279917T5 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3767105A1 (fr) | 2019-07-16 | 2021-01-20 | Arnold Jäger Holding GmbH | Stator pour une pompe à vis sans fin excentrique |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008175199A (ja) * | 2006-12-20 | 2008-07-31 | Heishin Engineering & Equipment Co Ltd | 一軸偏心ねじポンプ |

| CA3153581C (fr) | 2014-02-18 | 2024-02-06 | Vert Rotors Uk Limited | Machine volumetrique rotative |

| DE102016009028A1 (de) | 2016-07-26 | 2018-02-01 | Netzsch Pumpen & Systeme Gmbh | Rotor-Stator-System mit einem Einlauftrichter für eine Exzenterschneckenpumpe |

| DE102022100652A1 (de) | 2022-01-12 | 2023-07-13 | Knauf Pft Gmbh & Co. Kg | Stator für eine Exzenterschneckenpumpe |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1303705C2 (de) † | 1966-07-06 | 1973-10-11 | Axial foerdernde verdraengerpumpe mit rotierendem pumpelement | |

| DE2937403A1 (de) † | 1979-09-15 | 1981-04-02 | Gummi-Jäger KG GmbH & Cie, 3000 Hannover | Nachstellbarer stator fuer exzenterschneckenpumpen |

| DE3304751A1 (de) † | 1983-02-11 | 1984-08-23 | Kunststofftechnik Obernkirchen GmbH & Co KG, 3063 Obernkirchen | Exzenterschneckenpumpe |

| DE19531318A1 (de) † | 1995-08-25 | 1997-02-27 | Artemis Kautschuk Kunststoff | Stator für Exzenterschneckenpumpen |

| DE10026694A1 (de) † | 1999-06-07 | 2000-12-21 | Inst Francais Du Petrole | Pumpe mit progressiven Kammern mit Verbundstator und Verfahern zu ihrer Herstellung |

| US6170572B1 (en) † | 1999-05-25 | 2001-01-09 | Delaware Capital Formation, Inc. | Progressing cavity pump production tubing having permanent rotor bearings/core centering bearings |

| US6183226B1 (en) † | 1986-04-24 | 2001-02-06 | Steven M. Wood | Progressive cavity motors using composite materials |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1215569A (en) * | 1969-08-29 | 1970-12-09 | Paul Gerhard Langer | Rotary positive-displacement pumps |

| DE4442060C1 (de) * | 1994-11-25 | 1996-03-14 | Netzsch Mohnopumpen Gmbh | Exzenterschneckenpumpe, insbesondere zum Fördern von Medien mit hoher Viskosität oder hohem Feststoffgehalt |

| DE19758086A1 (de) * | 1997-12-30 | 1999-07-01 | Artemis Kautschuk Kunststoff | Elastomerstator für Exzenterschneckenpumpen |

| DE19801021A1 (de) * | 1998-01-14 | 1999-07-22 | Sebastian Jaeger | Elastomerstator für Exzenterschneckenpumpen |

-

2003

- 2003-10-07 AT AT03022804T patent/ATE349617T1/de active

- 2003-10-07 ES ES03022804T patent/ES2279917T5/es not_active Expired - Lifetime

- 2003-10-07 EP EP03022804A patent/EP1522729B2/fr not_active Expired - Lifetime

- 2003-10-07 DE DE50306120T patent/DE50306120D1/de not_active Expired - Lifetime

-

2007

- 2007-03-22 CY CY20071100401T patent/CY1106407T1/el unknown

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1303705C2 (de) † | 1966-07-06 | 1973-10-11 | Axial foerdernde verdraengerpumpe mit rotierendem pumpelement | |

| DE2937403A1 (de) † | 1979-09-15 | 1981-04-02 | Gummi-Jäger KG GmbH & Cie, 3000 Hannover | Nachstellbarer stator fuer exzenterschneckenpumpen |

| DE3304751A1 (de) † | 1983-02-11 | 1984-08-23 | Kunststofftechnik Obernkirchen GmbH & Co KG, 3063 Obernkirchen | Exzenterschneckenpumpe |

| US6183226B1 (en) † | 1986-04-24 | 2001-02-06 | Steven M. Wood | Progressive cavity motors using composite materials |

| DE19531318A1 (de) † | 1995-08-25 | 1997-02-27 | Artemis Kautschuk Kunststoff | Stator für Exzenterschneckenpumpen |

| US6170572B1 (en) † | 1999-05-25 | 2001-01-09 | Delaware Capital Formation, Inc. | Progressing cavity pump production tubing having permanent rotor bearings/core centering bearings |

| DE10026694A1 (de) † | 1999-06-07 | 2000-12-21 | Inst Francais Du Petrole | Pumpe mit progressiven Kammern mit Verbundstator und Verfahern zu ihrer Herstellung |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3767105A1 (fr) | 2019-07-16 | 2021-01-20 | Arnold Jäger Holding GmbH | Stator pour une pompe à vis sans fin excentrique |

| WO2021009275A1 (fr) | 2019-07-16 | 2021-01-21 | Arnold Jäger Holding GmbH | Stator pour pompe à vis sans fin excentrique |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2279917T5 (es) | 2013-06-24 |

| ES2279917T3 (es) | 2007-09-01 |

| ATE349617T1 (de) | 2007-01-15 |

| CY1106407T1 (el) | 2011-10-12 |

| DE50306120D1 (de) | 2007-02-08 |

| EP1522729B1 (fr) | 2006-12-27 |

| EP1522729A1 (fr) | 2005-04-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2720130C3 (de) | Meißeldirektantrieb für Tiefbohrwerkzeuge | |

| EP1762726B1 (fr) | Système de stator d'une pompe de type Moineau | |

| EP3250829B1 (fr) | Pompe à vis excentrée munie d'un système de réglage automatique et procédé d'ajustement | |

| EP3187736A1 (fr) | Pompe centrifuge horizontale multi-etagée destinée au transport d'un fluide et son procédé de réparation | |

| DE202009002823U1 (de) | Exzenterschneckenpumpe | |

| EP2994640B1 (fr) | Stator de pompe d'alimentation | |

| EP3610154B1 (fr) | Pompe à vis excentrique | |

| EP1738078B1 (fr) | Stator pour pompe a vis sans fin excentrique ou moteur a vis sans fin excentrique selon le principe de moineau | |

| EP1828611A1 (fr) | Pompe a palettes coulissantes | |

| EP1522729B2 (fr) | Pompe à cavité progressive et stator pour une telle pompe | |

| DE102011101648A1 (de) | Schraubenmaschine, insbesondere Schraubenspindelpumpe | |

| DE102014112391A1 (de) | Pumpe zur Förderung einer Flüssigkeit, insbesondere zur Förderung eines Abgasreinigungsadditivs | |

| EP2505335A2 (fr) | Dispositif d'extrusion pour la production d'un profil en forme de bande ou tube en matière plastique ou de caoutchouc | |

| DE102005028818B3 (de) | Stator für eine Exzenterschneckenpumpe und Verfahren zu seiner Herstellung | |

| EP3767105B1 (fr) | Stator pour une pompe à vis sans fin excentrique | |

| DE2848514A1 (de) | Kraftsparendes pumpenrad | |

| WO2017194508A1 (fr) | Pompe à broches hélicoïdales | |

| DE102013100451B4 (de) | Rotor für Schnecken- und / oder Exzenterschneckenpumpen und Schnecken- oder Exzenterschneckenpumpe | |

| DE102009019418A1 (de) | Umlaufverdrängerpumpe mit verbesserter Lagerschmierung | |

| DE102019005367B4 (de) | Verfahren zur Herstellung eines Statorbauteil für eine Exzenterschneckenpumpe, Statorbauteil und Exzenterschneckenpumpe | |

| WO1990003521A1 (fr) | Pompe a vis excentrique | |

| EP1338796A2 (fr) | Pompe Moineau | |

| EP1282777B1 (fr) | Pompe a piston rotatif | |

| DE102016225196A1 (de) | Elektromotorische Ölpumpe | |

| DE102017104768A1 (de) | Exzenterschneckenpumpe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050427 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50306120 Country of ref document: DE Date of ref document: 20070208 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070327 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KELLER & PARTNER PATENTANWAELTE AG |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070403 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20070400881 Country of ref document: GR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070528 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2279917 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: NETZSCH-MOHNOPUMPEN GMBH Effective date: 20070925 |

|

| 26 | Opposition filed |

Opponent name: KUNSTSTOFFTECHNIK RODENBERG GMBH Effective date: 20070927 Opponent name: NETZSCH-MOHNOPUMPEN GMBH Effective date: 20070925 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| BERE | Be: lapsed |

Owner name: JOHANN HEINRICH BORNEMANN G.M.B.H. - KUNSTSTOFFTEC Effective date: 20071031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071031 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071031 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071007 |

|

| R26 | Opposition filed (corrected) |

Opponent name: KUNSTSTOFFTECHNIK RODENBERG GMBH Effective date: 20070927 Opponent name: NETZSCH-MOHNOPUMPEN GMBH Effective date: 20070925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070628 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061227 |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091007 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20110317 Year of fee payment: 8 Ref country code: CZ Payment date: 20110224 Year of fee payment: 8 Ref country code: CH Payment date: 20110317 Year of fee payment: 8 Ref country code: SE Payment date: 20110223 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20110225 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110224 Year of fee payment: 8 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CY Payment date: 20110302 Year of fee payment: 8 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: NETZSCH-MOHNOPUMPEN GMBH Effective date: 20070925 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: NETZSCH-MOHNOPUMPEN GMBH Effective date: 20070925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111007 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: ML Ref document number: 20070400881 Country of ref document: GR Effective date: 20120503 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20111007 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120629 |

|

| R26 | Opposition filed (corrected) |

Opponent name: NETZSCH-MOHNOPUMPEN GMBH Effective date: 20070925 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111102 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111008 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20121023 Year of fee payment: 10 Ref country code: IT Payment date: 20121025 Year of fee payment: 10 |

|

| 27A | Patent maintained in amended form |

Effective date: 20130327 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20121029 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20121221 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 50306120 Country of ref document: DE Effective date: 20130327 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2279917 Country of ref document: ES Kind code of ref document: T5 Effective date: 20130624 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130628 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50306120 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 349617 Country of ref document: AT Kind code of ref document: T Effective date: 20131007 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50306120 Country of ref document: DE Effective date: 20140501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140501 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131007 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131007 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20141107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131008 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120503 |