EP1516544B1 - Dispositif et procédé de séchage pour tabac - Google Patents

Dispositif et procédé de séchage pour tabac Download PDFInfo

- Publication number

- EP1516544B1 EP1516544B1 EP04090361A EP04090361A EP1516544B1 EP 1516544 B1 EP1516544 B1 EP 1516544B1 EP 04090361 A EP04090361 A EP 04090361A EP 04090361 A EP04090361 A EP 04090361A EP 1516544 B1 EP1516544 B1 EP 1516544B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- drying

- product

- moisture

- drying unit

- drying device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000001035 drying Methods 0.000 title claims description 118

- 241000208125 Nicotiana Species 0.000 title description 9

- 235000002637 Nicotiana tabacum Nutrition 0.000 title description 9

- 241000196324 Embryophyta Species 0.000 title description 6

- 238000000034 method Methods 0.000 title description 2

- 235000019505 tobacco product Nutrition 0.000 claims description 4

- 238000005303 weighing Methods 0.000 claims 3

- 238000004519 manufacturing process Methods 0.000 claims 1

- 239000000463 material Substances 0.000 description 21

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 18

- 230000008020 evaporation Effects 0.000 description 16

- 238000001704 evaporation Methods 0.000 description 16

- 230000001276 controlling effect Effects 0.000 description 8

- 238000005259 measurement Methods 0.000 description 6

- 238000011088 calibration curve Methods 0.000 description 2

- 238000012937 correction Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000013072 incoming material Substances 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B3/00—Preparing tobacco in the factory

- A24B3/04—Humidifying or drying tobacco bunches or cut tobacco

Definitions

- the invention relates to a drying system for drying a tobacco material, comprising a drying device for drying the guided through the drying device Good and a measuring device for generating a measuring signal, which is related to the input moisture of Guts before its delivery to the drying device comprises.

- the invention further relates to a corresponding drying method.

- the DE 33 36 632 C2 discloses a device for drying tobacco leaves in which the speed at which the sheets are fed is adjustable by manually varying the width of a feeder.

- a drum vaporizing apparatus in which a conveyor belt arranged in the drum is displaceable, wherein, depending on the final moisture of the product, the conveyor belt is displaced so far into the drum that the desired product moisture is achieved.

- the changed Dwell time of the tobacco in the dryer is the changed Dwell time of the tobacco in the dryer.

- the displacement of the conveyor belt requires a complex mechanism.

- a humidification and Sossierstrom for a tobacco stream known.

- the plant comprises a sump station, an input moisture meter and a belt scale. From the corresponding signals, a computer determines the dry matter of the tobacco. The speed of the belt weigher is controlled so that the dry matter of the tobacco fed to the sorter station has a preset value. In order to achieve a constant outlet humidity, humidification nozzles are activated within the skip station.

- the object of the present invention is to provide a drying plant, in which a simple means a reliable constant maintenance of the initial moisture is achieved.

- the drying system comprises a control device for controlling the guided through the drying device Gutsmassenstroms depending on the measured signal, wherein a variable control of the Gutsmassenstroms takes place such that at higher input moisture lower Gutsmassenstrom is passed through the drying device and vice versa.

- the drying device supplied amount of water is controlled in a simple manner. At higher input moisture, a lower Gutsmassenstrom is performed by the drying device for constant maintenance of the outlet moisture and vice versa. In this case, the amount of water evaporated per unit time and in particular the evaporation temperature can be kept constant in the drying device.

- mass flow refers to the mass transported per unit time, which is given in kg / h, for example.

- control device is not limited to control in the strict sense, but may also include control, for example, the preferred control in response to a Congressfeuchtemeßsignals. "Control device” is therefore representative of "control and / or regulating device”.

- the control can preferably take place by controlling the mass flow of material supplied to the drying device. This allows the use of known evaporation devices with a constant transport speed.

- the control of the Gutsmassenstroms passed through the drying device can be done in a simple manner, for example by controlling an optionally provided conveyor belt. This may be, for example, a feed belt of a feed unit for feeding the Gutsmasse to the drying device. But it is also possible that the control device acts on a transport device for transporting the material through the drying device, so that the supplied Gutsmassenstrom does not necessarily have to be changed.

- the measuring device is a moisture measuring device.

- it may be a moisture measuring device for measuring the input moisture of the material before it is fed to the drying device.

- this is not mandatory.

- m e (dry matter) denotes the input mass of the dry matter.

- the load input weight increases at the same volume.

- the Gutsausgangsfeuchte is related to the Gutseingangsfeuchte and can serve as a measure in the context of the invention. Other measures such as the Gutseingangs admire are conceivable. Measuring a variable other than the input good moisture may require appropriate calibration.

- a Popeuchtemeßsensor is provided for measuring the initial moisture of Guts after leaving the drying device. This allows a control of the desired target size and a control of the Gutsmassenstroms guided by the drying device in response to a output from the Ninfeuchtemeß worn

- Trustfeuchtemeßsignals whereby a higher accuracy with respect to the desired constant output moisture is achieved.

- a balance is provided for measuring the input mass of the material before it is fed to the drying device. This can facilitate the adjustment or control of the desired mass flow of incoming material, but is not absolutely necessary for this.

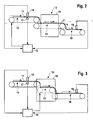

- the tobacco product 11 to be dried is fed in the direction of the arrow by means of a feed unit, which comprises the feed belt 10.

- a feed unit which comprises the feed belt 10.

- the material 11 of the drying device 13 is supplied.

- heaters not shown, cause heating of the by the Drying device 13 guided Good 11 to cause evaporation of water contained in the Good 11 and thus drying of the Guts 11.

- the dried product is fed to subsequent processing stages by means of the further conveyor belt 18.

- the drying device 13 from FIG. 1 may be, for example, a current dryer, a drum dryer, a fluidized-bed dryer or another dryer familiar to the person skilled in the art.

- the drying device 13 comprises an evaporation chamber 19, wherein the material 11 is guided through the evaporation chamber 19 by means of a transport device, which is designed here as a conveyor belt 12.

- the material may be swirled and / or transported by an energy transmitting medium, such as hot gas. Separate conveyors in the drying device 13 are therefore not mandatory.

- the input moisture of the product 11 is determined by means of the input moisture sensor 14, and a corresponding good input moisture signal f e is transmitted to the control device 15.

- the output moisture sensor 16 the initial moisture content f a of the product 11 is determined and a corresponding Gutsausgangsfeuchtesignal transmitted to the control device 15.

- the input ground m e of the material 11 is determined and a corresponding Gutseingangsmassesignal transmitted to the control device 15.

- the control device 15 controls the Gutsmassenstrom passed through the drying device 13 in response to at least one of the measured signals f e , f a , m e with the aim of keeping the Gutsausgangsfeuchte f a constant.

- the supply device is controlled in order to regulate the material input flow fed to the drying device 13. This can be done, for example, by controlling the conveying speed of the feed belt 10, as shown in FIGS. 1 and 2.

- m V (H 2 O) / ⁇ t denotes the mass of water evaporated per unit time in the drying device 13 and f a * the desired initial moisture (set value). If expediently the evaporation parameters, ie the evaporation temperature and the heat output are kept constant, the amount of water evaporated per unit time in the drying device 13 m V (H 2 O) / ⁇ t is approximately constant and approximately not guided by the amount or transport speed of the evaporation chamber Good dependent. By inserting the measured variable f e into the above formula, the mass flow m / ⁇ t to be set can then be determined by the drying device 13 by means of the above formula. The control is carried out in the examples of FIGS.

- the scale 17 for measuring the input ground signal may, for example, be a belt scale, for example as a unit with the feed belt 10. Other embodiments, such as an impact plate scale, are possible.

- the integration path of the scale 17, i. the detected in the measuring process measuring path to improve the accuracy as low as possible.

- the balance 17 and / or the input humidity sensor 14 as close as possible to the drying device 13 to allow the most timely control and thus changes on the route between the respective meter and the drying device 13 and other comparable sources of error as possible have little influence.

- the measurement of, for example, the input moisture f e is basically sufficient to control the mass flow of material through the drying device 13 Dependence of the corresponding measurement signal to achieve a constant output moisture to make.

- the initial moisture content f a (actual value) is determined by measurement, in order to be able to carry out a correction or an adjustment of this target variable with the desired value f a * .

- This can be achieved, for example, by inserting a correction factor f a * / f a into the above formula.

- the energy required for heating the tobacco energy can be compensated.

- the input moisture f e it is also possible to use another measured variable, such as, for example, the starting moisture f a or the input earth mass m e as the basis for the control; the measurement of the input moisture is then not mandatory.

- another measured variable such as, for example, the starting moisture f a or the input earth mass m e

- Figs. 1 to 3 can be dispensed with a metrological determination of the Gutseingangsmasse m e .

- the feed rate to be set can either be calculated or in particular determined by means of a stored calibration curve. It may therefore be necessary to calibrate the feed rate for different values of the corresponding measurement signal.

- unmeasured magnitudes can be calculated, for example, or determined using stored calibration curves. For example, it may be necessary to calibrate the bulk mass flow to be conducted by the drying device 13 for different values of the corresponding measuring signal.

- the conveyor belt speed of the conveyor belt 12 for controlling the funded by the drying device 13 Gutsmassenstroms be controlled.

- a single continuous conveyor belt may also be provided.

- FIG. 4A the material 11 supplied to the drying device 13 has an input moisture of 50%.

- a dry matter mass unit an empty box

- a water mass unit a hatched box

- a box corresponds to a mass of 1 kg.

- the evaporation temperature, the evaporation rate and other evaporation parameters of the drying device 13 are set and are kept constant so that 2 kg of water are evaporated in the drying device 13 per second. It is a property of the drying device 13 regardless of the humidity and transport speed of the guided through the drying device 13 Good.

- the wet material is fed with an input mass flow of 6 kg / s and passed through the drying device 13, where it may stay due to the set transport speed 1 s in the drying device 13; this leads to an evaporation of 2 kg of water, so that the initial moisture content of the goods is 25% (1 kg of water to 3 kg of dry material, see Fig. 4A). It is assumed that this corresponds to the desired initial moisture content.

- the input mass flow can be doubled from 5 kg / s to 10 kg / s.

- This can be achieved, for example, as in the example of FIG. 4C, by doubling the feed rate, as indicated by the double arrow.

- the transport speed through the drying device 13 remains unchanged in comparison with the previous state shown in FIG. 4B. Since the material therefore remains unchanged in the drying device 13 for 1 s and 2 kg of water are evaporated, the material leaves the drying device 13 at 8 kg / s and the desired moisture content of 25% (see Fig. 4C).

- the input mass flow remains unchanged, but the transport speed is doubled by the drying device 13. Now the material remains only 1/2 second in the drying device 13; During this period, only 1 kg of water is evaporated in the drying device 13. As a result, the material leaves the drying apparatus 13 at 4 kg / s and the desired humidity of 25% (see Fig. 4D).

- the material could be conveyed at 8 kg / s and conveyed through the drying device 13 at a speed increased by 25%.

- the embodiments in which the transport speed through the drying device 13 at all times remains constant (for example, Fig. 4C, 4E), preferably over the embodiments, for which this is not true (for example, Fig. 4D), as this, the use of known evaporators with constant Transport speed allowed.

Landscapes

- Drying Of Solid Materials (AREA)

Claims (12)

- Installation de séchage pour le séchage d'un produit de tabac (11), qui comporte un dispositif de séchage (13) pour le séchage du produit (11) guidé à travers le dispositif de séchage (13) et un dispositif de mesure pour générer un signal de mesure qui est corrélé à l'humidité initiale du produit (11) avant son introduction vers le dispositif de séchage (13), caractérisée en ce que l'installation de séchage comprend un dispositif de commande (15) pour la commande du flux massique de produit, guidé à travers le dispositif de séchage (13), en fonction du signal de mesure, une commande variable du flux massique de produit étant réalisée de telle sorte que, dans le cas d'une humidité initiale supérieure, un flux massique plus faible de produit est guidé à travers le dispositif de séchage et inversement.

- Installation de séchage selon la revendication 1, caractérisée en ce que l'installation de séchage est conçue pour la commande du flux massique de produit introduit vers le dispositif de séchage (13).

- Installation de séchage selon la revendication 1 ou 2, caractérisée en ce que l'installation de séchage est conçue pour la commande de la vitesse de transport d'une bande transporteuse du produit.

- Installation de séchage selon l'une des revendications 1 à 3, caractérisée en ce que le dispositif de mesure est un dispositif de mesure de l'humidité.

- Installation de séchage selon l'une des revendications 1 à 4, caractérisée en ce que l'installation de séchage comprend un dispositif (14) de mesure de l'humidité pour la mesure de l'humidité initiale du produit (11) avant son introduction vers le dispositif de séchage (13).

- Installation de séchage selon l'une des revendications 1 à 5, caractérisée en ce que l'installation de séchage comprend une balance (17) destinée à la mesure de la masse entrante de produit (11) avant son introduction vers le dispositif de séchage (13).

- Installation de séchage selon la revendication 6, caractérisée en ce que l'installation de séchage est conçue pour la commande du flux massique de produit guidé à travers le dispositif de séchage (13) en fonction d'un signal de mesure émis par la balance (17).

- Installation de séchage selon la revendication 6 ou 7, caractérisée en ce que la balance (17) est réalisée en tant que balance à courroie.

- Installation de séchage selon l'une des revendications 1 à 8, caractérisée en ce que l'installation de séchage comprend un dispositif (16) de mesure de l'humidité de sortie pour la mesure de l'humidité de sortie du produit (11) après qu'il a quitté le dispositif de séchage (13).

- Installation de séchage selon la revendication 9, caractérisée en ce que l'installation de séchage est conçue pour le réglage du flux massique de produit guidé à travers le dispositif de séchage (13) en fonction d'un signal de mesure émis par le dispositif (16) de mesure de l'humidité de sortie.

- Installation de séchage selon l'une des revendications 1 à 10, caractérisée en ce que le flux massique de produit guidé à travers le dispositif de séchage (13) est réglé de façon indirectement proportionnelle à la différence entre l'humidité initiale et la valeur de consigne de l'humidité de sortie.

- Procédé de séchage pour le séchage d'un produit de tabac, comportant l'amenée du produit à un dispositif de séchage et le séchage du produit guidé à travers le dispositif de séchage, caractérisé par la génération d'un signal de mesure qui est corrélé à l'humidité initiale du produit avant son introduction vers le dispositif de séchage, et par la commande variable du flux massique de produit amené au dispositif de séchage en fonction du signal de mesure de telle sorte que, dans le cas d'une humidité initiale supérieure, un flux massique plus faible de produit est guidé à travers le dispositif de séchage et inversement.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04090361A EP1516544B1 (fr) | 2003-09-19 | 2004-09-17 | Dispositif et procédé de séchage pour tabac |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03090308 | 2003-09-19 | ||

| EP03090308 | 2003-09-19 | ||

| EP04090361A EP1516544B1 (fr) | 2003-09-19 | 2004-09-17 | Dispositif et procédé de séchage pour tabac |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1516544A1 EP1516544A1 (fr) | 2005-03-23 |

| EP1516544B1 true EP1516544B1 (fr) | 2007-06-27 |

Family

ID=34196151

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04090361A Expired - Lifetime EP1516544B1 (fr) | 2003-09-19 | 2004-09-17 | Dispositif et procédé de séchage pour tabac |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1516544B1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106403563A (zh) * | 2016-09-28 | 2017-02-15 | 青岛科技大学 | 一种根据出口温度智能控制给煤量的干燥系统 |

| CN106403502A (zh) * | 2016-09-28 | 2017-02-15 | 青岛科技大学 | 一种根据入口温度智能控制电机转速的干燥系统 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005062857A1 (de) * | 2005-12-23 | 2007-06-28 | Hauni Maschinenbau Ag | Verfahren und Vorrichtung zum Trocknen eines Faserprodukt-Massenstroms |

| CN106403501B (zh) * | 2016-09-28 | 2019-03-26 | 青岛科技大学 | 一种根据给煤量智能控制给进风量的干燥系统 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1206771B (de) * | 1963-11-18 | 1965-12-09 | Hauni Werke Koerber & Co Kg | Verfahren und Vorrichtung zum Trocknen von Tabak oder aehnlichem Gut |

| DE1532063A1 (de) * | 1965-07-06 | 1970-01-08 | Hauni Werke Koerber & Co Kg | Verfahren und Anlage zum Verballen von Gruenballen |

| DE2019369C3 (de) * | 1970-04-22 | 1980-08-28 | Hauni-Werke Koerber & Co Kg, 2050 Hamburg | Verfahren zum Trocknen von Tabak und Trocknungsförderer |

| SE373488B (sv) * | 1973-06-07 | 1975-02-10 | Svenska Tobaks Ab | Sett att mojliggora noggrann bestemning eller reglering av en behandling av en godsmassa och anordning for utovning av settet |

| JPS619275A (ja) * | 1984-06-21 | 1986-01-16 | 日本たばこ産業株式会社 | たばこ葉刻乾燥機の温度制御方法 |

-

2004

- 2004-09-17 EP EP04090361A patent/EP1516544B1/fr not_active Expired - Lifetime

Non-Patent Citations (1)

| Title |

|---|

| None * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106403563A (zh) * | 2016-09-28 | 2017-02-15 | 青岛科技大学 | 一种根据出口温度智能控制给煤量的干燥系统 |

| CN106403502A (zh) * | 2016-09-28 | 2017-02-15 | 青岛科技大学 | 一种根据入口温度智能控制电机转速的干燥系统 |

| CN106403502B (zh) * | 2016-09-28 | 2019-03-26 | 青岛科技大学 | 一种根据入口温度智能控制电机转速的干燥系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1516544A1 (fr) | 2005-03-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69417163T2 (de) | Verfahren und Vorrichtung zur Quantifizierung eines Teigproduktes | |

| EP0421165B1 (fr) | Procédé de tarage d'une bascule à bande transporteuse de dosage | |

| EP0140213B1 (fr) | Procédé et dispositif pour mesurer le débit de matériaux susceptibles de couler | |

| DE2504902C2 (de) | Verfahren und Vorrichtung zum Steuern der Schnittleistung eines Tabakschneiders | |

| CH668641A5 (de) | Verfahren und vorrichtung zur automatischen erfassung des durchsatzes eines schuettgutstromes, z.b. getreide. | |

| DE2904308A1 (de) | Verfahren und anordnung zum trocknen von tabak | |

| DE2019369C3 (de) | Verfahren zum Trocknen von Tabak und Trocknungsförderer | |

| DE2432848C2 (de) | Verfahren und Vorrichtung zum Trocknen von Tabak | |

| DE3037025C2 (fr) | ||

| DE2747232A1 (de) | Verfahren und vorrichtung zur durchfuehrung von behandlungsvorgaengen fuer schuettgueter u.dgl. | |

| EP0043137B1 (fr) | Procédé et appareil pour la détermination continue de l'humidité de produits alimentaires granuleux | |

| WO1986004417A1 (fr) | Procede et dispositif de determination de valeurs caracteristiques, en particulier de cereales | |

| DE1532066C3 (de) | Anordnung zum fortlaufenden Zusammenführen von verschiedenen Tabakkomponenten | |

| DE1299237C2 (de) | Verfahren und vorrichtung zum trocknen von tabak | |

| EP1516544B1 (fr) | Dispositif et procédé de séchage pour tabac | |

| DE2427229C3 (de) | Verfahren zur Regelung der Behandlung einer Tabakblattmasse und Vorrichtung zum Ausüben des Verfahrens | |

| DE2461579C3 (de) | Verfahren und Vorrichtung zur kontinuierlichen Zuführung pulverförmigen Gutes von einem Vorratsbehälter zu einem Verbraucher | |

| DE2841470C2 (fr) | ||

| DE2807691B1 (de) | Verfahren und Vorrichtung zur Regelung der Feinheit von Fertiggut aus einer Mahlanlage | |

| EP1129019B1 (fr) | Procede et dispositif pour le transport pneumatique de produits en vrac | |

| EP0121599A2 (fr) | Procédé et dispositif pour le transport pneumatique des particules fines | |

| DE1206771B (de) | Verfahren und Vorrichtung zum Trocknen von Tabak oder aehnlichem Gut | |

| DE1914466B2 (de) | Verfahren zum abnehmen von tabak von einem vorrat sowie vorrichtung zum ausueben des verfahrens | |

| DE3212423A1 (de) | Verfahren zum pneumatischen austrag von gut aus einem vorratsbehaelter | |

| DE19723218A1 (de) | Verfahren und Vorrichtung zum Abwägen eines schüttfähigen Gutes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050922 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004004177 Country of ref document: DE Date of ref document: 20070809 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070927 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20071004 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071008 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070927 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071127 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| BERE | Be: lapsed |

Owner name: HAUNI MASCHINENBAU A.G. Effective date: 20070930 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: PHILIP MORRIS PRODUCTS S.A. Effective date: 20080320 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070928 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: PHILIP MORRIS PRODUCTS S.A. |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070917 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080924 Year of fee payment: 5 Ref country code: NL Payment date: 20080930 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080924 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080930 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070917 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070627 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090917 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20100401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090917 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090917 |

|

| PLBD | Termination of opposition procedure: decision despatched |

Free format text: ORIGINAL CODE: EPIDOSNOPC1 |

|

| PLBM | Termination of opposition procedure: date of legal effect published |

Free format text: ORIGINAL CODE: 0009276 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION PROCEDURE CLOSED |

|

| 27C | Opposition proceedings terminated |

Effective date: 20110527 |