EP1512904A2 - Vehicle headlamp - Google Patents

Vehicle headlamp Download PDFInfo

- Publication number

- EP1512904A2 EP1512904A2 EP04020697A EP04020697A EP1512904A2 EP 1512904 A2 EP1512904 A2 EP 1512904A2 EP 04020697 A EP04020697 A EP 04020697A EP 04020697 A EP04020697 A EP 04020697A EP 1512904 A2 EP1512904 A2 EP 1512904A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- reflector

- diaphragm shaft

- bearing shell

- bearing

- holder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000005096 rolling process Methods 0.000 claims description 10

- 230000003287 optical effect Effects 0.000 claims description 7

- 229910052751 metal Inorganic materials 0.000 claims description 6

- 239000002184 metal Substances 0.000 claims description 6

- 230000005540 biological transmission Effects 0.000 claims description 3

- 230000002452 interceptive effect Effects 0.000 claims description 3

- 230000001747 exhibiting effect Effects 0.000 claims description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 2

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 2

- 229910000861 Mg alloy Inorganic materials 0.000 description 2

- 238000004512 die casting Methods 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 230000001154 acute effect Effects 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21S—NON-PORTABLE LIGHTING DEVICES; SYSTEMS THEREOF; VEHICLE LIGHTING DEVICES SPECIALLY ADAPTED FOR VEHICLE EXTERIORS

- F21S41/00—Illuminating devices specially adapted for vehicle exteriors, e.g. headlamps

- F21S41/60—Illuminating devices specially adapted for vehicle exteriors, e.g. headlamps characterised by a variable light distribution

- F21S41/68—Illuminating devices specially adapted for vehicle exteriors, e.g. headlamps characterised by a variable light distribution by acting on screens

- F21S41/683—Illuminating devices specially adapted for vehicle exteriors, e.g. headlamps characterised by a variable light distribution by acting on screens by moving screens

- F21S41/698—Shaft-shaped screens rotating along its longitudinal axis

Definitions

- the invention relates to a headlamp for vehicles with a cast cup-shaped reflector having an inner and outer focal point, with a diaphragm shaft arranged between a lens and the reflector, the axis of rotation about a horizontal and transverse to the optical axis is adjustable in several rotational positions for different light functions, and with a holder attached to the front edge portion of the reflector for at least one storage means of the diaphragm shaft.

- From DE - A - 199 21 907 is a headlamp for vehicles with a two Known burner dish-shaped reflector, which is a lens and a diaphragm shaft are assigned.

- the aperture shaft extends transversely to the optical axis arranged in the apex region of the reflector Light source.

- the diaphragm shaft is rotatably supported about its axis of rotation and has encircling an outwardly curved lateral surface with several focal lines depending on the rotational position of the diaphragm shaft to the formation of light-dark boundaries serve different light figures.

- the aperture shaft points Burning lines for symmetrical and asymmetrical dipped beam and high beam on.

- the Aperture shaft is with its storage means at both end areas in Bearing openings of a holder mounted on the front edge of the area Reflector is attached. On the holder is the side with the aperture shaft coupled drive means attached.

- the drive means consists of a motor and a gearbox. The disadvantage here is that the location of storage and thus the diaphragm shaft is fixed exclusively by the holder.

- the tolerance chain to the reflection surface of the Reflectors should be so large that the aperture is not optimal to the Reflection surface is positioned and thus the below a cut-off line the dimmed light figures prescribed and desired high light values are not more than sufficiently large.

- the tolerance chain to the reflection surface of the Reflectors should be so large that the aperture is not optimal to the Reflection surface is positioned and thus the below a cut-off line the dimmed light figures prescribed and desired high light values are not more than sufficiently large.

- From DE - A - 100 47 207 is a headlamp for vehicles with a Aperture shaft known to be connected to the front edge of the area Reflektors in the application neither described nor clearly illustrated.

- the object of the invention is the, in the preamble of claim 1 described headlights for vehicles to improve such that at a simply constructed headlight after the assembly of the diaphragm shaft their exact positioning to the reflection surface of the reflector is safe.

- the object is achieved according to the invention in that the front Edge portion of the reflector fastened holder with a section one Bearing shell of the front edge area spans and the storage means the diaphragm shaft holds radially in the bearing shell without clearance radially to the axis of rotation.

- the cast reflector is made in one piece and diecasting for Example of a magnesium or aluminum alloy or by means Injection molding made of plastic.

- the aperture is exactly to Reflection surface of the reflector positioned as the bearing shell of the reflector and its reflection surface together by an adjustable tool part are demoldable and the holder holds the diaphragm shaft to the bearing shell.

- the Aperture also exactly to the adjacent outer focal point of the reflector arranged and below the cut-off line of each generated light figure reaches optimal light levels.

- the exact positioning of the aperture shaft to the outer focal point the reflector no disturbing color fringing at the cut-off of the Light figure.

- the bearing shell of the reflector spanning portion of the holder under pretension on the Storing means of the diaphragm shaft and presses the storage means against the Bearing shell, wherein the bearing shell of the reflector a two-point system defining positioning surfaces for the storage means of the diaphragm shaft has and a plant side of the bearing shell of the reflector spanning section of the holder together with the Positioning surfaces of the bearing shell of the reflector a three-point system for defines the storage means of the diaphragm shaft.

- This is the aperture shaft arranged very precisely to the outer focal point of the elliptical reflector and safe in all directions transverse to the axis of rotation backlash on the bearing shell held.

- a the Storage means adjacent to the axis of rotation fixing abutment surface adjacent is arranged. It can also be on both sides of the two Positioning surfaces are each arranged a contact surface, the together form a groove and the storage means of the diaphragm shaft between to record oneself.

- the diaphragm shaft is rotatable smoothly when the storage means of Aperture shaft placed on a journal of the diaphragm shaft Rolling bearing has.

- the shielding means of the shutter shaft is protected against damage is arranged and securely held when the holder forms a bearing shell, the together with the bearing shell of the reflector, a bearing opening for the Storage means of the diaphragm shaft is and the bearing shell of the holder a radial inward and the contact surface for the three-point system having exhibiting contact element.

- the holder can cost-effectively from a Be punched sheet metal blank, wherein the contact element from the holder bent sheet metal section is.

- the diaphragm shaft is provided with a Storage means at a free end portion by the holder and the Bearing shell of the reflector radially and axially supported while the Shield shaft with the other free end section in one on the reflector salaried drive means of the diaphragm shaft supported radially to the axis of rotation and is mounted axially floating. This allows between the aperture shaft and the drive means no tensions occur.

- the aperture is held by the drive means exactly to the outer focal point of the reflector, when the drive means between the front and back of the reflector on a reflector side are attached to holding elements of the reflector, wherein Positioning means of reflector parallel to the rotation axis of the shutter shaft and drive means are inserted into each other, which holds the diaphragm shaft holder Position the drive unit towards the reflecting surface of the reflector.

- the diaphragm shaft each arranged with one at its two end portions Storage means supported by the holder in a bearing shell of the reflector is, wherein an end portion of the diaphragm shaft with one on the reflector arranged drive means is coupled via a transmission.

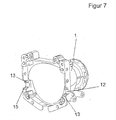

- Another particular advantage of the invention is that the holder the Light exit opening of the reflector surrounds and both for holding the Headlamps as well as a Abschatters, which adjacent to Aperture shaft extends and at least in a rotational position of the diaphragm shaft shields interfering light rays together with the aperture. This is for the holder of the diaphragm shaft no separate part necessary.

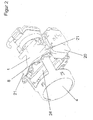

- a headlight for vehicles shown in FIGS. 1 and 2 is designed as a projection module that has an elliptical reflector 1, a light source 28 arranged in the apex region of the reflector 1, a lens 4 and a diaphragm shaft 5 arranged between the reflector 1 and the lens 2.

- the lens 2 is inserted into a table-shaped frame 25 which is fixed to the front edge region 8 of the reflector 1.

- the reflector 1 has an inner and outer focal point 2 and 3.

- the inner focal point, the light source 28 and the outer focal point 3, the middle upper portion of the diaphragm shaft 5 is assigned.

- the light source 28 is a high-pressure gas discharge lamp, which carries an ignition device 27 at its base.

- the diaphragm shaft 5 is by die casting for example of a magnesium or Aluminum alloy produced. It can also be made from an elongated one Hollow body made of sheet metal, wherein the contour of the lateral surface of the Hollow body is produced by generating an internal high pressure (not ) Shown. At its free end portions, the diaphragm shaft 5 respectively Storage means 10, with which the diaphragm shaft 5 at the front Edge region 8 of the reflector 1 is mounted.

- the diaphragm shaft 5 is perpendicular to the optical axis 6 of the headlight in stored horizontally.

- An end portion of the diaphragm shaft 5 is with a motor (not shown) serving as drive means 20, by means of which the diaphragm shaft 5 can be brought into predetermined rotational positions is.

- a control electronics for the motor is integrated in the drive means 20.

- the drive means 20 has a housing which on holding elements 21 of the Reflektors 1 is attached.

- the holding element 21 are connected to the reflector 1 molded-on approaches to which by means of screws or rivets Drive means 20 on the reflector 1 can be fixed.

- the drive means 20 and thus the holding elements 21 are between the front and rear side of the Reflectors 1 arranged.

- the reflector 1 has two opposite each other Side holding elements 21, so that the drive means 20 optionally on both Side of the reflector 1 can be attached.

- the lateral surfaces of the diaphragm shaft 5 is formed such that in different adjusted about the axis of rotation 7 of the diaphragm shaft 5 Turning positions focal lines 8 of the optical light system are formed, by means of their light-dark borders differentiated dimmed light figures such as symmetrical and asymmetrical low beam for Right and left traffic are generated.

- the lateral surface of the diaphragm shaft. 5 is curved at least in the area having the focal lines formed and has at least one two focal lines running Surface portion formed differently from a cylindrical surface is.

- the lateral surface of the diaphragm shaft 5 thus extends in the surface section irregular (not shown). Furthermore, the lateral surface of the Aperture 5 a flattening for high beam on (not shown).

- a frame-like holder 9 is arranged, the on the side facing the lens 4 of the front edge region 8 abuts.

- the frame-like holder 9 is punched out of a sheet metal blank and has in Area of the diaphragm shaft 5 a shading 24, which together with the Shutter wave 5 interfering light rays shields.

- the shader 24 is executed strip-shaped and runs in its longitudinal extent parallel to Rotation axis 7 of the diaphragm shaft 5.

- the axis of rotation 7 is defined by the Storage means 10 of the diaphragm shaft 5, the two free end portions the diaphragm shaft 5 are arranged.

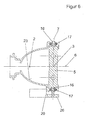

- the two storage means 10 each have a bearing pin 16, whose central axis is the axis of rotation 7.

- the Storage means 10, which is further away from the drive means 20 points a pushed onto the bearing pin 16 in a press fit rolling bearing 17.

- the rolling bearing 17 engages in a bearing shell 12 of the reflector 1 and is applied two positioning surfaces 13 of the bearing shell 12 at.

- the Positioning surfaces 13 are at an acute angle to each other and fix the diaphragm shaft very precisely to the reflection surface 23 of the reflector 1.

- Each on both sides of the positioning surfaces 13, the Bearing shell 12 of the reflector 1 contact surfaces 15, which together with the Positioning surfaces 13 form a receiving groove for the rolling bearing 17.

- the Contact surfaces 15 fix the diaphragm shaft 5 in their longitudinal extent.

- the Bearing shell 12 of the reflector 1 and the reflection surface 23 of the reflector first are demolded together from a tool part.

- the bearing shell 12 of Reflektors 1 In the bearing shell 12 of Reflektors 1 is the rolling bearing 17 through a bearing shell 12th spanning portion 11 of the holder 9 held.

- the section 11 forms also a bearing shell 18, which together with the bearing shell 12 of the Reflektors 1 form a bearing opening for the rolling bearing 17.

- the section 11 has an investment element 19 pushed out of its central area on, the biased with an abutment side 14 on the roller bearing 17th abuts and together with the positioning surfaces 13 a three-point system for the rolling bearing 17 forms.

- the diaphragm shaft 5 is in the range of Drive means 20 with its bearing journal 16 axially floating in one Bearing of the drive means 20 stored.

- the drive means 20 and the Reflector 1 have interlocking positioning means 22 through which the diaphragm shaft 5 is fixed exactly to the reflection surface 23 of the reflector 1 is held.

- the positioning means 22 consist of pins of the Drive means 20, the backlash in corresponding holes of the reflector 1 intervention.

- the plugging direction of the positioning means 22 runs parallel to The axis of rotation 7 of the diaphragm shaft 5.

- the reflector 1 and the holder 9 have the side of the drive means 20 and an unused bearing shell 12 and 18 on. This and because the reflector on the other side Holding elements 21 and positioning means 22 for the drive means 20th can, the drive means 20 and the rolling bearing 17 optionally on the one or the other side of the reflector 1 are mounted.

- both Storage means 10 of the diaphragm shaft 5 each have a rolling bearing 17, which in each held a Lagerschlager 12 of the reflector 1 by the holder 9 are.

- the drive means 21 of the reflector 1 mounted drive means 20th is coupled via a gear 26 with the diaphragm shaft 5.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Non-Portable Lighting Devices Or Systems Thereof (AREA)

- Lighting Device Outwards From Vehicle And Optical Signal (AREA)

Abstract

Description

Die Erfindung betrifft einen Scheinwerfer für Fahrzeuge mit einem gegossenen schalenförmigen Reflektor, der einen inneren und äußeren Brennort aufweist, mit einer zwischen einer Linse und dem Reflektor angeordneten Blendenwelle, die um eine horizontale und quer zur optischen Achse verlaufenden Drehachse in mehrere Drehstellungen für unterschiedliche Lichtfunktionen verstellbar ist, und mit einem an dem vorderen Randbereich des Reflektors befestigten Halter für mindestens ein Lagerungsmittel der Blendenwelle.The invention relates to a headlamp for vehicles with a cast cup-shaped reflector having an inner and outer focal point, with a diaphragm shaft arranged between a lens and the reflector, the axis of rotation about a horizontal and transverse to the optical axis is adjustable in several rotational positions for different light functions, and with a holder attached to the front edge portion of the reflector for at least one storage means of the diaphragm shaft.

Aus der DE - A - 199 21 907 ist ein Scheinwerfer für Fahrzeuge mit einem zwei Brennorte aufweisenden schalenförmigen Reflektor bekannt, dem eine Linse und eine Blendenwelle zugeordnet sind. Die Blendenwelle erstreckt sich quer zur optischen Achse der im Scheitelbereich des Reflektors angeordneten Lichtquelle. Die Blendenwelle ist drehbar um ihre Drehachse gelagert und weist umlaufend eine nach außen gekrümmte Mantelfläche mit mehreren Brennlinien auf, die je nach Drehstellung der Blendenwelle zur Bildung von Hell-Dunkel-Grenzen unterschiedlicher Lichtfiguren dienen. Die Blendenwelle weist Brennlinien für symmetrisches und asymmetrisches Abblendlicht und Fernlicht auf. An den gegenüberliegenden Endbereichen der Blendenwelle ist ein Antriebsmittel bzw. Lagerungsmittel angeordnet, so dass die Blendenwelle in die vorgegebenen Drehstellungen positioniert und verstellt werden kann. Die Blendenwelle ist mit ihren Lagerungsmitteln an beiden Endbereichen in Lageröffnungen eines Halters gelagert, der an dem vorderen Randbereich des Reflektors befestigt ist. An dem Halter ist seitlich das mit der Blendenwelle gekoppelte Antriebsmittel befestigt. Das Antriebsmittel besteht aus einem Motor und einem Getriebe. Nachteilig hierbei ist, dass die Lage der Lagerung und somit der Blendenwelle ausschließlich durch den Halter festgelegt ist. Da dieser ein separates Teil ist kann die Toleranzkette zu der Reflexionsfläche des Reflektors so groß sein, dass die Blendenwelle nicht optimal zu der Reflexionsfläche positioniert ist und somit die unterhalb einer Hell-Dunkel-Grenze der abgeblendeten Lichtfiguren vorgeschrieben und gewünschten hohen Lichtwerte nicht mehr als ausreichend groß sind. Darüber hinaus kann durch eine ungenaue Lage der Blendenwelle zur Reflexionsfläche des Reflektors die Lichtfigur im Bereich der Hell-Dunkel-Grenze einen störenden Farbsaum aufweisen.From DE - A - 199 21 907 is a headlamp for vehicles with a two Known burner dish-shaped reflector, which is a lens and a diaphragm shaft are assigned. The aperture shaft extends transversely to the optical axis arranged in the apex region of the reflector Light source. The diaphragm shaft is rotatably supported about its axis of rotation and has encircling an outwardly curved lateral surface with several focal lines depending on the rotational position of the diaphragm shaft to the formation of light-dark boundaries serve different light figures. The aperture shaft points Burning lines for symmetrical and asymmetrical dipped beam and high beam on. At the opposite end portions of the shutter shaft is a Drive means or storage means arranged so that the diaphragm shaft in the predetermined rotational positions can be positioned and adjusted. The Aperture shaft is with its storage means at both end areas in Bearing openings of a holder mounted on the front edge of the area Reflector is attached. On the holder is the side with the aperture shaft coupled drive means attached. The drive means consists of a motor and a gearbox. The disadvantage here is that the location of storage and thus the diaphragm shaft is fixed exclusively by the holder. Because of this a separate part is can the tolerance chain to the reflection surface of the Reflectors should be so large that the aperture is not optimal to the Reflection surface is positioned and thus the below a cut-off line the dimmed light figures prescribed and desired high light values are not more than sufficiently large. In addition, can by an inaccurate position of the diaphragm shaft to the reflection surface of the Reflektors the light figure in the range of the light-dark border a disturbing Have color fringing.

Aus der DE - A - 100 47 207 ist ein Scheinwerfer für Fahrzeuge mit einer Blendenwelle bekannt, deren Verbindung mit dem vorderen Randbereich des Reflektors in der Anmeldung weder beschrieben noch klar dargestellt ist.From DE - A - 100 47 207 is a headlamp for vehicles with a Aperture shaft known to be connected to the front edge of the area Reflektors in the application neither described nor clearly illustrated.

Aufgabe der Erfindung ist es, den im Oberbegriff des Anspruchs 1

beschriebenen Scheinwerfer für Fahrzeuge derart zu verbessern, dass bei

einem einfach aufgebauten Scheinwerfer nach der Montage der Blendenwelle

ihre genaue Positionierung zur Reflexionsfläche des Reflektors sicher ist. Diese

Aufgabe wird nach der Erfindung dadurch gelöst, dass der an dem vorderen

Randbereich des Reflektors befestigte Halter mit einem Abschnitt eine

Lagerschale des vorderen Randbereichs überspannt und das Lagerungsmittel

der Blendenwelle radial zur Drehachse spielfrei in der Lagerschale haltert. Der

gegossene Reflektor ist einteilig ausgeführt und mittels Druckgießen zum

Beispiel aus einer Magnesium- oder Aluminiumlegierung oder mittels

Spritzgießen aus Kunststoff herstellbar. Die Blendenwelle ist genau zur

Reflexionsfläche des Reflektors positioniert, da die Lagerschale des Reflektors

und seine Reflexionsfläche zusammen durch ein verstellbares Werkzeugteil

entformbar sind und der Halter die Blendenwelle an der Lagerschale hält. Durch

die genaue Positionierung der Blendenwelle zur Reflexionsfläche ist die

Blendenwelle auch genau zum benachbarten äußeren Brennort des Reflektors

angeordnet und werden unterhalb der Hell-Dunkel-Grenze der jeweils

erzeugten Lichtfigur optimale Lichtwerte erreicht. Darüber hinaus entsteht

wegen der genauen Positionierung der Blendenwelle zum äußeren Brennort

des Reflektors kein störender Farbsaum an der Hell-Dunkel-Grenze der

Lichtfigur.The object of the invention is the, in the preamble of

Nach einer Weiterbildung der Erfindung liegt der die Lagerschale des Reflektors überspannende Abschnitt des Halters unter Vorspannung an dem Lagerungsmittel der Blendenwelle an und drückt das Lagerungsmittel gegen die Lagerschale, wobei die Lagerschale des Reflektors eine Zweipunktanlage definierende Positionierungsflächen für das Lagerungsmittel der Blendenwelle aufweist und eine Anlageseite des die Lagerschale des Reflektors überspannenden Abschnitts des Halters zusammen mit den Positionierungsflächen der Lagerschale des Reflektors eine Dreipunktanlage für das Lagerungsmittel der Blendenwelle definiert. Dadurch ist die Blendenwelle sehr genau zum äußeren Brennort des elliptischen Reflektors angeordnet und sicher in allen Richtungen quer zur Drehachse spielfrei an der Lagerschale gehalten. In diesem Zusammenhang ist es vorteilhaft, wenn mindestens zu einer der beiden Positionierungsflächen der Zweipunktanlage eine das Lagerungsmittel parallel zur Drehachse fixierende Anlagefläche benachbart angeordnet ist. Es kann auch auf beiden Seiten der beiden Positionierungsflächen jeweils eine Anlagefläche angeordnet sein, die zusammen ein Nut bilden und das Lagerungsmittel der Blendenwelle zwischen sich aufnehmen.According to a development of the invention is the bearing shell of the reflector spanning portion of the holder under pretension on the Storing means of the diaphragm shaft and presses the storage means against the Bearing shell, wherein the bearing shell of the reflector a two-point system defining positioning surfaces for the storage means of the diaphragm shaft has and a plant side of the bearing shell of the reflector spanning section of the holder together with the Positioning surfaces of the bearing shell of the reflector a three-point system for defines the storage means of the diaphragm shaft. This is the aperture shaft arranged very precisely to the outer focal point of the elliptical reflector and safe in all directions transverse to the axis of rotation backlash on the bearing shell held. In this context, it is advantageous if at least to one of the two positioning surfaces of the two-point system a the Storage means adjacent to the axis of rotation fixing abutment surface adjacent is arranged. It can also be on both sides of the two Positioning surfaces are each arranged a contact surface, the together form a groove and the storage means of the diaphragm shaft between to record oneself.

Die Blendenwelle ist leichtgängig drehbar, wenn das Lagerungsmittel der Blendenwelle ein auf einen Lagerzapfen der Blendenwelle aufgesetztes Wälzlager aufweist.The diaphragm shaft is rotatable smoothly when the storage means of Aperture shaft placed on a journal of the diaphragm shaft Rolling bearing has.

Das Lagerungsmittel der Blendenwelle ist geschützt vor Beschädigung angeordnet und sicher gehalten ist, wenn der Halter eine Lagerschale bildet, die zusammen mit der Lagerschale des Reflektor eine Lageröffnung für das Lagerungsmittel der Blendenwelle ist und die Lagerschale des Halters ein radial nach innen gerichtetes und die Anlagefläche für die Dreipunktanlage aufweisendes Anlageelement aufweist. Der Halter kann kostengünstig aus einer Blechplatine ausgestanzt sein, wobei das Anlageelement ein aus dem Halter herausgebogener Blechabschnitt ist.The shielding means of the shutter shaft is protected against damage is arranged and securely held when the holder forms a bearing shell, the together with the bearing shell of the reflector, a bearing opening for the Storage means of the diaphragm shaft is and the bearing shell of the holder a radial inward and the contact surface for the three-point system having exhibiting contact element. The holder can cost-effectively from a Be punched sheet metal blank, wherein the contact element from the holder bent sheet metal section is.

Nach einer bevorzugten Ausführungsform ist die Blendenwelle mit einem Lagerungsmittel an einem freien Endabschnitt durch den Halter und die Lagerschale des Reflektors radial und axial gehaltert, während die Blendenwelle mit dem anderen freien Endabschnitt in einem am Reflektor gehalterten Antriebsmittel der Blendenwelle radial zur Drehachse gehaltert und axial schwimmend gelagert ist. Dadurch können zwischen der Blendenwelle und dem Antriebsmittel keine Verspannungen auftreten. Die Blendenwelle ist durch das Antriebsmittel genau zum äußeren Brennort des Reflektors gehalten, wenn das Antriebsmittel zwischen der Vorder- und Rückseite des Reflektors an einer Reflektorseite an Halteelementen des Reflektors befestigt sind, wobei parallel zur Drehachse der Blendenwelle Positionierungsmittel von Reflektor und Antriebsmittel ineinandergesteckt sind, die das die Blendenwelle halternde Antriebsmittel zur Reflexionsfläche des Reflektors positionieren.According to a preferred embodiment, the diaphragm shaft is provided with a Storage means at a free end portion by the holder and the Bearing shell of the reflector radially and axially supported while the Shield shaft with the other free end section in one on the reflector salaried drive means of the diaphragm shaft supported radially to the axis of rotation and is mounted axially floating. This allows between the aperture shaft and the drive means no tensions occur. The aperture is held by the drive means exactly to the outer focal point of the reflector, when the drive means between the front and back of the reflector on a reflector side are attached to holding elements of the reflector, wherein Positioning means of reflector parallel to the rotation axis of the shutter shaft and drive means are inserted into each other, which holds the diaphragm shaft holder Position the drive unit towards the reflecting surface of the reflector.

Bei einer anderen vorteilhaften Weiterbildung der Erfindung ist die Blendenwelle mit jeweils einem an ihren beiden Endabschnitten angeordneten Lagerungsmittel von dem Halter in einer Lagerschale des Reflektors gehaltert ist, wobei ein Endabschnitt der Blendenwelle mit einem am Reflektor angeordneten Antriebsmittel über ein Getriebe gekoppelt ist. Dadurch sind beide Lagerschalen des Reflektors und die Reflexionsfläche des Reflektors zusammen von ein und demselben verstellbaren Werkzeugteil entformt und somit ist die Blendenwelle sehr genau zu dem äußeren Brennort des elliptischen Reflektors angeordnet.In another advantageous embodiment of the invention, the diaphragm shaft each arranged with one at its two end portions Storage means supported by the holder in a bearing shell of the reflector is, wherein an end portion of the diaphragm shaft with one on the reflector arranged drive means is coupled via a transmission. Thereby are both bearing shells of the reflector and the reflection surface of the reflector demolded from one and the same adjustable tool part and Thus, the aperture is very close to the outer focal point of the arranged elliptical reflector.

Ein weiterer besonderer Vorteil der Erfindung besteht darin, dass der Halter die Lichtaustrittsöffnung des Reflektors umgibt und sowohl zur Halterung des Scheinwerfers als auch eines Abschatters dient, der benachbart zur Blendenwelle verläuft und zumindest in einer Drehstellung der Blendenwelle zusammen mit der Blendenwelle störende Lichtstrahlen abschirmt. Dadurch ist für den Halter der Blendenwelle kein gesondertes Teil notwendig. Another particular advantage of the invention is that the holder the Light exit opening of the reflector surrounds and both for holding the Headlamps as well as a Abschatters, which adjacent to Aperture shaft extends and at least in a rotational position of the diaphragm shaft shields interfering light rays together with the aperture. This is for the holder of the diaphragm shaft no separate part necessary.

In der Zeichnung sind zwei Ausführungsbeispiele nach der Erfindung dargestellt

und zwar zeigen

Ein in den Figuren 1 und 2 dargestellter Scheinwerfer für Fahrzeuge ist als

Projektionsmodul ausgebildet, dass einen elliptischen Reflektor 1, eine im

Scheitelbereich des Reflektors 1 angeordnete Lichtquelle 28, eine Linse 4

sowie eine zwischen dem Reflektor 1 und der Linse 2 angeordnete

Blendenwelle 5 aufweist. Die Linse 2 ist in ein tischförmiges Gestell 25

eingesetzt, das am vorderen Randbereich 8 des Reflektors 1 befestigt ist.

Der Reflektor 1 weist einen inneren und äußeren Brennort 2 und 3 auf. Dem

inneren Brennort ist die Lichtquelle 28 und dem äußeren Brennort 3 der mittlere

obere Abschnitt der Blendenwelle 5 zugeordnet. Als Lichtquelle 28 dient eine

Hochdruckgasentladungslampe, die an ihrem Sockel eine Zündeinrichtung 27

trägt.A headlight for vehicles shown in FIGS. 1 and 2 is designed as a projection module that has an

The

Die Blendenwelle 5 ist mittels Druckgießen zum Beispiel aus einer Magnesiumoder

Aluminiumlegierung hergestellt. Sie kann auch aus einem langgestreckten

Hohlkörper aus Blech bestehen, wobei die Kontur der Mantelfläche des

Hohlkörpers durch Erzeugen eines inneren Hochdrucks hergestellt ist (nicht

dargestellt). An ihren freien Endabschnitten weist die Blendenwelle 5 jeweils

Lagerungsmittel 10 auf, mit denen die Blendenwelle 5 an dem vorderen

Randbereich 8 des Reflektors 1 gelagert ist.The

Die Blendenwelle 5 ist senkrecht zur optischen Achse 6 des Scheinwerfers in

horizontaler Richtung gelagert. Ein Endabschnitt der Blendenwelle 5 ist mit

einem als Antriebsmittel 20 dienenden Motor (nicht dargestellt) gekoppelt,

mittels dessen die Blendenwelle 5 in vorgegebene Drehstellungen verbringbar

ist. Eine Ansteuerelektronik für den Motor ist in das Antriebsmittel 20 integriert.

Das Antriebsmittel 20 weist ein Gehäuse auf, das an Halteelementen 21 des

Reflektors 1 befestigt ist. Die Halteelement 21 sind an den Reflektor 1

angeformte Ansätze, an denen mittels Schrauben oder Nieten das

Antriebsmittel 20 am Reflektor 1 festsetzbar ist. Das Antriebsmittel 20 und somit

die Halteelemente 21 sind zwischen der vorderen und rückwärtigen Seite des

Reflektors 1 angeordnet. Der Reflektor 1 weist auf zwei sich gegenüberliegen

Seiten Halteelemente 21 auf, damit das Antriebsmittel 20 wahlweise auf beiden

Seiten des Reflektors 1 anbringbar ist. The

Die Mantelflächen der Blendenwelle 5 ist derart ausgebildet, dass in

unterschiedlichen um die Drehachse 7 der Blendenwelle 5 verstellten

Drehstellungen Brennlinien 8 des optischen Lichtsystems gebildet werden,

mittels derer Hell-Dunkel-Grenzen unterschiedlichter abgeblendeter Lichtfiguren

wie beispielsweise symmetrisches und asymmetrisches Abblendlicht für

Rechts- und Linksverkehr erzeugt werden. Die Mantelfläche der Blendenwelle 5

ist zumindest in dem die Brennlinien aufweisenden Bereich gekrümmt

ausgebildet und weist mindesten einen zwei Brennlinien verlaufenden

Flächenabschnitt auf, der unterschiedlich zu einer Zylinderfläche ausgebildet

ist. Die Mantelfläche der Blendenwelle 5 verläuft somit in dem Flächenabschnitt

unregelmäßig (nicht dargestellt). Weiterhin weist die Mantelfläche der

Blendenwelle 5 eine Abflachung für Fernlicht auf (nicht dargestellt).The lateral surfaces of the

Zwischen dem die Linse 4 tragenden Gestell 25 und dem vorderen

Randbereich 8 des Reflektors 1 ist ein rahmenartiger Halter 9 angeordnet, der

an der der Linse 4 zugewandten Seite des vorderen Randbereichs 8 anliegt.

Der rahmenartige Halter 9 ist aus einer Blechplatine ausgestanzt und weist im

Bereich der Blendenwelle 5 einen Abschatter 24 auf, der zusammen mit der

Blendenwelle 5 störende Lichtstrahlen abschirmt. Der Abschatter 24 ist

streifenförmig ausgeführt und verläuft in seiner Längsausdehnung parallel zur

Drehachse 7 der Blendenwelle 5. Die Drehachse 7 ist definiert durch die

Lagerungsmittel 10 der Blendenwelle 5, die den beiden freien Endabschnitten

der Blendenwelle 5 angeordnet sind.Between the frame 4 carrying the

In Figur 3 sind beide Lagermittel 10 der Blendenwelle 5 des ersten

Ausführungsbeispiels gezeigt. Die beiden Lagerungsmittel 10 weisen jeweils

einen Lagerzapfen 16 auf, dessen Mittelachse die Drehachse 7 ist. Das

Lagerungsmittel 10 , das von dem Antriebsmittel 20 weiter entfernt liegt, weist

ein auf den Lagerzapfen 16 im Presssitz aufgeschobenes Wälzlager 17 auf.

Das Wälzlager 17 greift in eine Lagerschale 12 des Reflektors 1 ein und liegt an

zwei Positionierungsflächen 13 der Lagerschale 12 an. Die

Positionierungsflächen 13 stehen in einem spitzen Winkel zueinander und

fixieren die Blendenwelle sehr genau zu der Reflexionsfläche 23 des Reflektors

1. Jeweils zu beiden Seiten der Positionierungsflächen 13 weist die

Lagerschale 12 des Reflektors 1 Anlageflächen 15 auf, die zusammen mit den

Positionierungsflächen 13 eine Aufnahmenut für das Wälzlager 17 bilden. Die

Anlageflächen 15 fixieren die Blendenwelle 5 in ihrer Längsausdehnung. Die

Lagerschale 12 des Reflektors 1 und die Reflexionsfläche 23 des Reflektors 1

sind zusammen von einem Werkzeugteil entformt. In der Lagerschale 12 des

Reflektors 1 ist das Wälzlager 17 durch einen die Lagerschale 12

überspannenden Abschnitt 11 des Halters 9 gehalten. Der Abschnitt 11 bildet

ebenfalls eine Lagerschale 18, die zusammen mit der Lagerschale 12 des

Reflektors 1 eine Lageröffnung für das Wälzlager 17 bilden. Der Abschnitt 11

weist ein aus seinem zentralen Bereich herausgedrücktes Anlageelement 19

auf, das unter Vorspannung mit einer Anlageseite 14 an dem Wälzlager 17

anliegt und zusammen mit den Positionierungsflächen 13 eine Dreipunktanlage

für das Wälzlager 17 bildet. Die Blendenwelle 5 ist im Bereich des

Antriebsmittels 20 mit seinem Lagerzapfen 16 axial schwimmend in einer

Lagerstelle des Antriebsmittels 20 gelagert. Das Antriebsmittel 20 und der

Reflektor 1 weisen ineinandergreifende Positionierungsmittel 22 auf, durch die

die Blendenwelle 5 genau zur Reflexionsfläche 23 des Reflektors 1 fixiert

gehalten ist. Die Positionierungsmittel 22 bestehen aus Zapfen des

Antriebsmittels 20, die in entsprechende Löcher des Reflektors 1 spielfrei

eingreifen. Die Steckrichtung der Positionierungsmittel 22 verläuft parallel zur

Drehachse 7 der Blendenwelle 5. Der Reflektor 1 und der Halter 9 weisen auf

der Seite des Antriebsmittel 20 auch eine nicht genutzte Lagerschale 12 bzw.

18 auf. Dadurch und weil der Reflektor auch auf der anderen Seite

Halteelemente 21 und Positionierungsmittel 22 für das Antriebsmittel 20

aufweist, kann das Antriebsmittel 20 und das Wälzlager 17 wahlweise auf der

einen oder anderen Seite des Reflektors 1 montiert werden. In Figure 3, both bearing means 10 of the

Bei dem in Figur 6 dargestellten zweiten Ausführungsbeispiel weisen beide

Lagerungsmittel 10 der Blendenwelle 5 jeweils ein Wälzlager 17 auf, das in

jeweils einer Lagerschlager 12 des Reflektors 1 durch den Halter 9 gehalten

sind. Das den Halteelementen 21 des Reflektors 1 befestigten Antriebsmittel 20

ist über ein Getriebe 26 mit der Blendenwelle 5 gekoppelt. In the second embodiment shown in Figure 6, both

Storage means 10 of the

- 1.1.

- Reflektorreflector

- 2.Second

- innerer Brennortinner burning place

- 3.Third

- äußerer BrennortOuter burning place

- 4.4th

- Linselens

- 5.5th

- Blendenwelleshutter shaft

- 6.6th

- optische Achseoptical axis

- 7.7th

- Drehachseaxis of rotation

- 8.8th.

- vordere Randbereich des Reflektorsfront edge area of the reflector

- 9.9th

- Halterholder

- 10.10th

- Lagerungsmittelstorage means

- 11.11th

- Abschnitt des HaltersSection of the holder

- 12.12th

- Lagerschale des ReflektorsBearing shell of the reflector

- 13.13th

- Positionierungsflächen der LagerschalePositioning surfaces of the bearing shell

- 14.14th

- Anlageseite des Abschnitts des HaltersInvestment side of the section of the holder

- 15.15th

- Anlagefläche der LagerschaleBearing surface of the bearing shell

- 16.16th

- Lagerzapfenpivot

- 17.17th

- Wälzlagerroller bearing

- 18.18th

- Lagerschale des HaltersBearing shell of the holder

- 19.19th

- Anlageelement des HaltersInvestment element of the holder

- 20.20th

- Antriebsmitteldrive means

- 21.21st

- Halteelemente des ReflektorsRetaining elements of the reflector

- 22.22nd

- Positionierungsmittelpositioning means

- 23.23rd

- Reflexionsflächereflecting surface

- 24.24th

- AbschatterA shielding device

- 25.25th

- tischförmiges Gestelltable-shaped frame

- 26.26th

- Getriebetransmission

- 27.27th

- Zündeinrichtungignition device

- 28.28th

- Lichtquellelight source

Claims (13)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10340962 | 2003-09-05 | ||

| DE10340962A DE10340962A1 (en) | 2003-09-05 | 2003-09-05 | Headlights for vehicles |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1512904A2 true EP1512904A2 (en) | 2005-03-09 |

| EP1512904A3 EP1512904A3 (en) | 2007-12-19 |

| EP1512904B1 EP1512904B1 (en) | 2010-01-20 |

Family

ID=34129661

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04020697A Expired - Lifetime EP1512904B1 (en) | 2003-09-05 | 2004-09-01 | Vehicle headlamp |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1512904B1 (en) |

| AT (1) | ATE456001T1 (en) |

| DE (2) | DE10340962A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010031743A1 (en) * | 2008-09-16 | 2010-03-25 | Hella Kgaa Hueck & Co. | Headlamp for vehicles, and production method for diaphragm device |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005021705A1 (en) * | 2005-05-11 | 2006-11-16 | Hella Kgaa Hueck & Co. | Projection headlamp for vehicle, has lens positioned ahead of the reflector in the light exit direction |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19921907A1 (en) | 1999-05-12 | 2000-11-16 | Hella Kg Hueck & Co | Headlights for vehicles |

| DE10047207A1 (en) | 2000-09-23 | 2002-04-11 | Hella Kg Hueck & Co | Headlights for vehicles |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5373424A (en) * | 1992-10-21 | 1994-12-13 | Koito Manufacturing Co., Ltd. | Automotive projection headlamp |

| FR2721686B1 (en) * | 1994-06-28 | 1996-09-13 | Valeo Vision | Projector of the elliptical type, comprising a tilting cover. |

| DE19739089A1 (en) * | 1997-09-06 | 1999-03-11 | Hella Kg Hueck & Co | Headlights for vehicles |

-

2003

- 2003-09-05 DE DE10340962A patent/DE10340962A1/en not_active Withdrawn

-

2004

- 2004-09-01 DE DE502004010663T patent/DE502004010663D1/en not_active Expired - Lifetime

- 2004-09-01 EP EP04020697A patent/EP1512904B1/en not_active Expired - Lifetime

- 2004-09-01 AT AT04020697T patent/ATE456001T1/en not_active IP Right Cessation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19921907A1 (en) | 1999-05-12 | 2000-11-16 | Hella Kg Hueck & Co | Headlights for vehicles |

| DE10047207A1 (en) | 2000-09-23 | 2002-04-11 | Hella Kg Hueck & Co | Headlights for vehicles |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010031743A1 (en) * | 2008-09-16 | 2010-03-25 | Hella Kgaa Hueck & Co. | Headlamp for vehicles, and production method for diaphragm device |

Also Published As

| Publication number | Publication date |

|---|---|

| DE502004010663D1 (en) | 2010-03-11 |

| EP1512904B1 (en) | 2010-01-20 |

| ATE456001T1 (en) | 2010-02-15 |

| EP1512904A3 (en) | 2007-12-19 |

| DE10340962A1 (en) | 2005-05-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3516813C2 (en) | ||

| DE4029123C2 (en) | ||

| DE69721459T2 (en) | Vehicle headlights with adjusting device for the reflector | |

| DE19922142C2 (en) | Motor vehicle headlamps | |

| EP0355528B1 (en) | Dipped vehicle headlamp | |

| EP1660809B1 (en) | Headlight for vehicles | |

| DE4407108C2 (en) | Vehicle headlights with an adjustable aperture arrangement | |

| EP1033528A2 (en) | Vehicle headlamp | |

| EP0381851B1 (en) | Dimmed headlamp for motor vehicles | |

| DE19546271B4 (en) | Headlamp for vehicles with a swiveling reflector | |

| DE19855686C2 (en) | Motor vehicle headlights with a composite reflector arrangement | |

| DE4228891A1 (en) | Adjusting vehicle headlamp fitting - has open profile thread with spring clip to hold adjuster into thread. | |

| DE2353322A1 (en) | HEADLIGHTS FOR MOTOR VEHICLES | |

| EP1512904B1 (en) | Vehicle headlamp | |

| DE4421355C2 (en) | Adjustment arrangement for a reflector for a vehicle headlight | |

| WO2022043039A1 (en) | Motor vehicle headlamp | |

| EP1052446A2 (en) | Vehicle headlamp | |

| DE19749181A1 (en) | Headlamp arrangement for motor vehicle with reflector and light source | |

| EP0985871A2 (en) | Headlamp and method of making the same | |

| EP0640510B1 (en) | Positioning device for a vehicle headlamp reflector | |

| EP0636831B1 (en) | Screen for a non-dazzling headlamp of a motor vehicle | |

| WO2010031743A1 (en) | Headlamp for vehicles, and production method for diaphragm device | |

| DE102006041428A1 (en) | Projection system for motor vehicle lamp, has adjusting ring that is provided between lens carrier and lens, where ring and lens are moved in axial direction of system over rotatory movement of ring relative to lens carrier | |

| EP1650492B1 (en) | Headlamp for vehicles and and its manufacturing method | |

| DE10213453A1 (en) | Headlight for automobile has main reflector and bulb unit that can be positioned relative to lens set in fixed position |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F21W 101/10 20060101ALN20071109BHEP Ipc: F21V 14/08 20060101AFI20041102BHEP |

|

| 17P | Request for examination filed |

Effective date: 20080701 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 502004010663 Country of ref document: DE Date of ref document: 20100311 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20100120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100520 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100501 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100421 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100420 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 |

|

| 26N | No opposition filed |

Effective date: 20101021 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 |

|

| BERE | Be: lapsed |

Owner name: HELLA KGAA HUECK & CO. Effective date: 20100930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100930 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100901 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100120 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20170830 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502004010663 Country of ref document: DE Owner name: HELLA GMBH CO. KGAA, DE Free format text: FORMER OWNER: HELLA KGAA HUECK CO., 59557 LIPPSTADT, DE Ref country code: DE Ref legal event code: R081 Ref document number: 502004010663 Country of ref document: DE Owner name: HELLA GMBH & CO. KGAA, DE Free format text: FORMER OWNER: HELLA KGAA HUECK & CO., 59557 LIPPSTADT, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180901 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210714 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20210720 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004010663 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220930 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230401 |