EP1377436B1 - Technisches gewebe mit asymmetrisch gelöcherten fliesen - Google Patents

Technisches gewebe mit asymmetrisch gelöcherten fliesen Download PDFInfo

- Publication number

- EP1377436B1 EP1377436B1 EP02712694A EP02712694A EP1377436B1 EP 1377436 B1 EP1377436 B1 EP 1377436B1 EP 02712694 A EP02712694 A EP 02712694A EP 02712694 A EP02712694 A EP 02712694A EP 1377436 B1 EP1377436 B1 EP 1377436B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pattern

- tiles

- apertures

- tile

- sequence

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004744 fabric Substances 0.000 title claims abstract description 78

- 230000035699 permeability Effects 0.000 claims abstract description 16

- 238000000926 separation method Methods 0.000 claims description 15

- 238000007689 inspection Methods 0.000 description 9

- 238000000034 method Methods 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 2

- 238000009941 weaving Methods 0.000 description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- 238000009954 braiding Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000009950 felting Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000009940 knitting Methods 0.000 description 1

- 238000010137 moulding (plastic) Methods 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 238000012876 topography Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/10—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material

- B32B3/14—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material characterised by a face layer formed of separate pieces of material which are juxtaposed side-by-side

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21F—PAPER-MAKING MACHINES; METHODS OF PRODUCING PAPER THEREON

- D21F1/00—Wet end of machines for making continuous webs of paper

- D21F1/0027—Screen-cloths

- D21F1/0063—Perforated sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2201/00—Details relating to filtering apparatus

- B01D2201/18—Filters characterised by the openings or pores

- B01D2201/184—Special form, dimension of the openings, pores of the filtering elements

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/16—Two dimensionally sectional layer

- Y10T428/163—Next to unitary web or sheet of equal or greater extent

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/16—Two dimensionally sectional layer

- Y10T428/163—Next to unitary web or sheet of equal or greater extent

- Y10T428/164—Continuous two dimensionally sectional layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/17—Three or more coplanar interfitted sections with securing means

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/18—Longitudinally sectional layer of three or more sections

- Y10T428/183—Next to unitary sheet of equal or greater extent

- Y10T428/187—Continuous sectional layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/19—Sheets or webs edge spliced or joined

- Y10T428/192—Sheets or webs coplanar

- Y10T428/193—Double faced corrugated sheets or webs connected

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/19—Sheets or webs edge spliced or joined

- Y10T428/192—Sheets or webs coplanar

- Y10T428/197—Sheets or webs coplanar with noncoplanar reinforcement

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24273—Structurally defined web or sheet [e.g., overall dimension, etc.] including aperture

- Y10T428/24322—Composite web or sheet

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

- Y10T428/249923—Including interlaminar mechanical fastener

Definitions

- This invention relates to a permeable industrial fabric of the type which is assembled into at least two plies from a plurality of separate tiles including apertures and in which the two plies are held together by jointing structures made integrally with the tiles.

- the jointing structures are incorporated at primary selected locations according a symmetrical pattern, and the apertures in the tiles which provide the required fabric open area are incorporated at secondary and tertiary selected locations according two more patterns, at least one of which is asymmetrical. This combination of symmetry and asymmetry allows for some control over the open area of the assembled fabric.

- An industrial papermaking fabric consisting of such plastic tiles is known, for example, from DE 34 44 082 A1.

- An upper tile of this known fabric is provided with a first sequence of apertures of substantially rectangular shape extending in the cross machine direction, whereas the lower tile is provided with a second sequence of apertures also having a substantially rectangular shape extending in the machine direction of the paper making fabric.

- the apertures in the lower tile are of a size larger than the apertures in the upper tile.

- the apertures in the lower tile communicate with two apertures in the upper tile.

- the tiles are attached to each other by integral jointing structures which need not be located along the periphery of the tiles, it is possible to create a large area of fabric, or a loop of fabric, having a high tensile strength without any apparent seams, such as paper making machine fabrics where any perceptible difference in fabric permeability caused by the presence of a seam can cause unacceptable defects in the paper product being made.

- the design of the tiles is chosen with care, it is also possible to include fibres or monofilaments between the plies of a multi-ply fabric, thus transferring tensile loads from the joints between the tiles to the fibres.

- the tile design largely determines the properties of the fabric. If different fabric properties are desired, a different design of tile has to be used.

- the tiles in each of at least two plies include integral jointing structures which are arranged in the tiles in a first symmetrical pattern, with the consequence that when the tiles are superposed upon each other to bond the plies together the tiles in one ply can be differently oriented relative to the other ply and yet will still bond together.

- the tiles used in each ply also include apertures, which are arranged in each of the sets of tiles in patterns, at least one of which is asymmetrical.

- the open area is determined by the overlap of the apertures in the sets of tiles making up each ply, the use of at least one asymmetric pattern for the apertures allows a larger choice of open area, over a range of from complete aperture overlap, to the minimum possible aperture overlap.

- the orientation of the tiles in one ply relative to the tiles in another ply will determine the relative positions of both the symmetrically arranged jointing structures and the apertures, at least one set of which is asymmetrically arranged, thus controlling the open area of the assembled fabric. It is thus also apparent that the maximum open area is determined by the proportion of the area of each tile which can be taken up by the apertures and yet still retain a desired level of mechanical strength and a desired level of flexibility in the assembled fabric.

- this invention seeks to provide an industrial fabric having a preselected permeability, including at least a first ply, consisting of a first set of tiles, and a second ply, consisting of a second set of tiles, attached to each other, each of which plies includes a plurality of tiles, wherein:

- both the second pattern and the third pattern are asymmetrical.

- the second pattern is symmetrical and the third pattern is asymmetrical.

- the relationship between the tiles in the first set and the tiles in the second set is chosen from the following options:

- the fabric includes a first set of tiles forming the first ply, and a second set of tiles forming the second ply, wherein:

- the fabric includes a first set of tiles forming the first ply, and a second set of tiles forming the second ply, wherein:

- the tiles include a jointing structure including a first part and a cooperating second part

- the first set of tiles includes both the first part and the second part of the jointing structure

- the second set of tiles includes both the first part and the second part of the jointing structure.

- the first part of the jointing structure is the same as the second part of the jointing structure, or the first part of the jointing structure is not the same as the second part of the jointing structure.

- the number of theoretically possible combinations is even higher: the theoretically possible number of combinations will be 49; i.e. for each of the seven ways of orienting the first and second plies, there are seven ways of adding the third ply.

- the number of useful combinations will be somewhat lower, because at least some of these possibilities will provide fabrics with the same open areas. However, although the open area is the same, the open spaces through the assembled fabric will likely be differently shaped, be of different sizes, and/or be differently located.

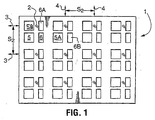

- the tile shown generally as 1 in Figure 1 is substantially rectangular. Upstanding pins 2 are incorporated into the tile 1 at primary selected locations in a first symmetrical pattern.

- the pins 2 are the male half of the jointing structure which holds the two plies together.

- the pins 2 are arranged in rows and columns which extend in the directions of the arrows 3 and 4.

- the separation between the rows 3 and the columns 4 is the same, as indicated by the distance S 2 .

- the first symmetrical pattern, and hence the grid pattern is a repeating square.

- the minimum space defined by the grid pattern is one square with a pin 2 at each corner; if desired, a larger defined space including several squares can be used.

- the tile 1 also includes two sequences of apertures.

- the first sequence of larger apertures 5 is placed in the tile at secondary selected locations. Inspection of Figure 1 shows that the distance between adjacent large apertures 5, for example between large apertures 5 and 5A in one direction, and between large apertures 5 and 5B in the other direction, is not constant. It is thus apparent that the secondary locations selected for the sequence of larger apertures 5 conform to a second asymmetrical pattern.

- the second sequence of smaller apertures 6 is placed in the tile at tertiary selected locations. Inspection of Figure 1 also shows that the distance between adjacent small apertures 6, for example between small apertures 6 and 6A in one direction, and between small apertures 6 and 6B in the other direction, is not constant.

- this tile includes three patterns: the first pattern is symmetrical, and the second and third patterns are each asymmetrical. In this instance, the second and third patterns are also substantially the same, and are located differently with respect to the grid pattern. Further, when the two asymmetrical patterns for the larger and smaller apertures are taken together, the combined repeating pattern is still asymmetrical. Further inspection of this tile shows that combination of the areas of all the apertures 5 and 6 gives an open area of approximately 27% of the tile area. It can also be seen that in the tile 1 the notional lines of the grid pattern defined by the location of the pins in one direction passes through the apertures, and in the other direction passes between them.

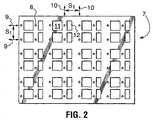

- the tile 7 shown in Figure 2 includes holes 8, which are the female half of the jointing structure.

- the holes 8 extend in a grid pattern defined by the notional lines 9 and 10, in each direction. In both directions, the grid lines 9 and 10 are separated by the distance S 1 .

- Comparison of the tiles 1 and 7 shows that both grid patterns are the same, as both are a repeating square.

- the tile 7 also includes two sets of apertures, comprising the larger apertures 11 and the smaller apertures 12. Comparison with Figure 1 shows these are arranged to the same two asymmetric patterns as those used in tile 1 for the apertures 5 and 12.

- the open area for the tile 7 is the same as that of tile 1 at approximately 27%. It can also be seen that in the tile 7 the notional lines of the grid pattern defined by the location of the pins in one direction passes through the apertures, and in the other direction passes between them.

- each ply will include each tile in the same orientation, it is easiest to consider the orientations in which only two superposed tiles can be jointed together. In practise, after jointing the assembled fabric will normally be passed through a pair of heated press rolls to deform the protruding ends of the pins 2 to enhance joint integrity.

- Both the pins 2 and the holes 8 are incorporated into the tile according to the same symmetrical pattern. But because the pins 2 are twice as far apart as the holes 8, there are at least 16 different orientations in which these two tiles can be jointed together. These are shown in Figures 3 - 18. In these Figures, the darkened area within the apertures indicates the area of the aperture in one tile which is obstructed by the other tile. In Figures 4 - 18 one tile is moved from the orientation shown in Figure 3 to a different orientation relative to the other tile, so that its pins engage the holes in the other tile differently. Because the holes and pins are to the same square pattern, with the square for the pins twice that of the holes, one tile can be moved one or two squares in each of the four different directions. The tile can also be rotated through four possible positions, and the pins will still engage into the holes.

- the approximate open areas shown in Table 2 can be calculated, as a percentage of the tile total area; the resulting measured permeabilities are also given.

- the permeabilities were measured in m 3 /hr/m 2 using a Frazier Air Permeometer, available from Frazier Precision Instruments, Silver Spring, Maryland, USA, according to the method set out in ASTM D 737-96.

- the air orifice used was 2.54cm square, and the air pressure differential was 12.7mm water.

- the spread in permeability values measured by this technique on the same fabric can be at least plus or minus 5%.

- the tile shown generally as 15 in Figure 19 is substantially rectangular. Upstanding pins 2 are incorporated into the tile 15 at selected locations.

- the pins 2 are the male half of the jointing structure which holds the two plies together.

- the pins 2 are arranged in pairs of rows which extend in the directions of the arrows 17 and 18 and in columns which extend in the direction of the arrows 19.

- the separation between the rows 17 is S 2

- the separation between the rows 18 is also S 2 .

- the separation between an adjacent pair of rows 17 and 18 is S 3 .

- the separation between the columns 19 is the distance S 2 .

- the pins 16 are arranged in two symmetrical patterns which are the same, for each of which the grid pattern is a repeating square.

- the minimum space defined by the grid pattern is one square with a pin 16 at each corner; if desired, a larger defined space including several squares can be used.

- the tile 15 also includes two sequences of apertures, not one, each of which is to an asymmetrical pattern.

- the first sequence of apertures 20 is placed in the tile at secondary selected locations. Inspection of Figure 19 shows that the distance between adjacent apertures 20, for example between apertures 20 and 20A in one direction, and between apertures 20 and 20B in another direction, is not the same: the secondary locations selected for the sequence of apertures 20 conform to a second asymmetrical pattern.

- the second sequence of apertures 21 is placed in the tile at tertiary selected locations. Inspection of Figure 19 also shows that although the apertures 20 and 21 are the same size and shape, the distance between apertures 21 and 21A in one direction, and between apertures 21 and 21B in another direction, is not constant: the tertiary locations selected for the sequence of apertures 21 conforms to a third asymmetrical pattern. It can also be seen that this tile includes four patterns: the first pattern is symmetrical and is used twice, and the second and third patterns are each asymmetrical. In this instance, the second and third patterns are also substantially the same, and are located differently with respect to the grid pattern. Further inspection of this tile shows that combination of the areas of all the apertures 20 and 21 gives an open area of approximately 25% of the tile area.

- the tile 25 shown in Figure 20 includes holes 26, which are the female half of the jointing structure, and two sets of apertures 27 and 28 which are each arranged to the same asymmetrical patterns as the apertures 20 and 21 respectively in the tile 15. Maximum open area is therefore obtained when the fabric is assembled with apertures 20 and 21 located directly above apertures 28 and 27 respectively.

- the arrangement of the holes 26 is more complex.

- the holes 26 are arranged in columns, which are the distance S 3 apart as shown at 26A and 26B: the columns are thus set at half the distance S 2 used for the square pattern for the pins 16 in tile 15.

- the holes 26 are also arranged in two sets of rows, as at 28 and 29 which correlate with the notional lines forming the axes of the square grid pattern.

- the spacing between adjacent rows 28 and 29 is not the same, and hence the overall pattern appears to be asymmetric.

- the distance between pairs of rows 28 and between pairs of rows 29 is the same, and is S 1 .

- there are two symmetrical square patterns of holes one of which is off set a short distance along the axis of the notional grid defined by the first set of jointing structures.

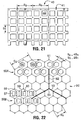

- FIG. 21 A further possibility is illustrated in Figure 21.

- the jointing structures as at 41 are arranged to the same pattern as that used in tiles 1 and 7 discussed above.

- the tile 40 includes one set of apertures 42, which are located in a symmetrical pattern within the notional grid lines set by the jointing structures 41. This has the same dimension as in tiles 1 and 7; the distances S 1 and S 2 are the same in all three tiles. It then follows that a tile having the symmetrical pattern of apertures shown in tile 40 can be engaged to tiles having the same patterns as tiles 1 and 7. However due to the symmetrical pattern chosen for the apertures 42 the number of ways in which tile 40 can be oriented relative to either of tiles 1 or 7 is far fewer, and hence the choices for fabric open area percentage are far fewer.

- the jointing structures define an essentially square area arranged on an essentially square grid, in which the notional grid axes are perpendicular.

- the symmetrical patterns in these tiles all have two axis symmetry.

- This invention is not limited to patterns which require the axes of the grid pattern to be perpendicular to each other. It is possible to use at least three axis symmetry, with the jointing structures located in a pattern for which the repeating unit in the grid pattern is a regular hexagon.

- a tile incorporating three axis symmetry is shown in Figure 22. Two possible aperture arrangements are also shown.

- the jointing structures 51 are located in a hexagonal arrangement, which is symmetrical.

- the grid defined by those structures then has three axes, as shown schematically at 52, 53 and 54.

- S 1 of adjacent structures there are six possible different orientations obtainable by rotating one tile relative to the other, instead of the four orientations obtained with a square grid pattern.

- tile 50 also uses the same pin and hole jointing structure.

- each hexagonal space includes a single hexagonal opening. Inspection of the are 50A shows that the apertures 55 and 56 are both off set in different directions relative to the sides of the hexagons, and are thus arranged to an asymmetrical pattern.

- each hexagonal space includes rectangular apertures. Inspection of the area 50B shows that the large apertures 57 and 60 are both off set in different directions relative to the sides of the hexagons, and are thus arranged to an asymmetrical pattern. Similarly, the small apertures 58 and 59 are both off set in different directions relative to the sides of the hexagons, and are thus arranged to a similar but different asymmetrical pattern.

- any combination of the options 50A and 50B can be taken. By combining the six possible rotation orientations, with lateral movement along the three grid axes, a multitude of possible pairings are available.

- the jointing structure is a simple pin and cooperating hole arrangement. Many other possible jointing structures have been described. Some of these, as in the pin and hole, require two different structures, and others do not, the joint being made between two structures which are the same. The only limitations on the jointing structures are that first that they can be engaged to provide a joint with adequate strength, and second that they can be incorporated into the tiles at the selected locations with sufficient accuracy.

Landscapes

- Finishing Walls (AREA)

- Woven Fabrics (AREA)

- Laminated Bodies (AREA)

- Paper (AREA)

- Glass Compositions (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

- Dowels (AREA)

Claims (17)

- Technisches Gewebe mit einer im Voraus gewählten Durchlässigkeit, umfassend zumindest eine erste, aus einem ersten Satz von Fliesen (1, 15, 40, 50) bestehende Lage und eine zweite, aus einem zweiten Satz von Fliesen (7, 25, 40, 50) bestehende Lage, die aneinander befestigt sind, wobei jede der Lagen mehrere Fliesen umfasst, wobei(a) jede Fliese (1, 7, 15, 25, 40, 50) einstückige, an ausgewählten Primärpositionen in die Fliese eingearbeitete Fügestrukturen (2, 8, 16, 26, 41; 51) gemäß einem ersten, symmetrischen Muster enthält, das auch ein Gittermuster auf zumindest einer Oberfläche der Fliese definiert;(b) jede Fliese im ersten Fliesensatz zumindest eine erste Folge von an ausgewählten Sekundärpositionen gemäß einem zweiten Muster in die Fliese eingearbeiteten Durchlässen (5; 6; 20, 21; 42; 55; 56; 57; 58; 59; 60) gleicher Größe und Form enthält;(c) jede Fliese im zweiten Fliesensatz zumindest eine zweite Folge von an ausgewählten Tertiärpositionen gemäß einem dritten Muster in die Fliese eingearbeiteten Durchlässen (11; 12; 27; 28; 42; 55; 56; 57; 58; 59; 60) gleicher Größe und Form enthält;(d) die in jede Fliese eingearbeiteten Fügestrukturen (2, 8; 16, 26, 41; 50) geformte Strukturen umfassen, die ineinander greifen und sich gegenseitig verriegeln, um eine Verbindung zwischen aufeinandergelegten Fliesen bereitzustellen;(e) sich das erste, symmetrische Muster im zusammengesetzten Gewebe in der Ebene der jeweiligen Lage erstreckt;(f) sich das zweite und das dritte Muster im zusammengesetzten Gewebe in der Ebene der jeweiligen Lage erstrecken;(g) zumindest eines der Muster der aus der dem zweiten und dem dritten Muster bestehenden Gruppe im Hinblick auf die Symmetrieachsen des ersten Musters asymmetrisch ist; und(h) die aufeinandergelegten Lagen so zusammengesetzt werden, dass das erste, symmetrische Muster und das zweite Muster in der ersten Lage relativ zum ersten, symmetrischen Muster und zum dritten Muster in der dritten Lage ausgerichtet sind, um ein zusammengesetztes Gewebe mit der im Voraus gewählten Durchlässigkeit bereitzustellen.

- Gewebe nach Anspruch 1, wobei im Hinblick auf die Symmetrieachsen des ersten Musters sowohl das zweite Muster als auch das dritte Muster asymmetrisch sind.

- Gewebe nach Anspruch 1, wobei im Hinblick auf die Symmetrieachsen des ersten Musters das zweite Muster symmetrisch und das dritte Muster asymmetrisch ist.

- Gewebe nach Anspruch 1, wobei das Verhältnis zwischen den Fliesen im ersten Satz und den Fliesen im zweiten Satz gleich einem Element der aus den folgenden möglichen Verhältnissen bestehenden Gruppe ist:(i) Die Fliesen im ersten Satz und die Fliesen im zweiten Satz sind identisch, und das zweite Muster und das dritte Muster sind im Hinblick auf die Symmetrieachsen des ersten Musters beide asymmetrisch;(ii) bei den Fliesen im ersten Satz und bei den Fliesen im zweiten Satz ist das zweite Muster nicht mit dem dritten Muster identisch;(iii) bei den Fliesen im ersten Satz und bei den Fliesen im zweiten Satz haben die Durchlässe in der ersten Folge die gleiche Form wie die Durchlässe in der zweiten Folge, die Durchlässe in der ersten Folge haben nicht die gleiche Größe wie die Durchlässe in der zweiten Folge, und das zweite Muster und das dritte Muster sind im Hinblick auf die Symmetrieachsen des ersten Musters beide asymmetrisch;(iv) bei den Fliesen im ersten Satz und bei den Fliesen im zweiten Satz haben die Durchlässe in der ersten Folge die gleiche Form wie die Durchlässe in der zweiten Folge, die Durchlässe in der ersten Folge haben nicht die gleiche Größe wie die Durchlässe in der zweiten Folge, und das zweite Muster ist nicht mit dem dritten Muster identisch;(v) bei den Fliesen im ersten Satz und bei den Fliesen im zweiten Satz haben die Durchlässe in der ersten Folge nicht die gleiche Form wie die Durchlässe in der zweiten Folge, die Durchlässe in der ersten Folge haben nicht die gleiche Größe wie die Durchlässe in der zweiten Folge, das zweite Muster ist mit dem dritten Muster identisch, und das zweite Muster und das dritte Muster sind im Hinblick auf die Symmetrieachsen des ersten Musters beide asymmetrisch;(vi) bei den Fliesen im ersten Satz und bei den Fliesen im zweiten Satz haben die Durchlässe in der ersten Folge nicht die gleiche Form wie die Durchlässe in der zweiten Folge, die Durchlässe in der ersten Folge haben nicht die gleiche Größe wie die Durchlässe in der zweiten Folge, und das zweite Muster ist nicht mit dem dritten Muster identisch;(vii) bei den Fliesen im ersten Satz liegt die Folge von Durchlässen im zweiten Muster innerhalb eines vom Gittermuster definierten Bereichs;(viii) bei den Fliesen im ersten Satz liegt die Folge von Durchlässen im zweiten Muster nicht innerhalb eines vom Gittermuster definierten Bereichs;(ix) bei den Fliesen im zweiten Satz liegt die Folge von Durchlässen im dritten Muster innerhalb eines vom Gittermuster definierten Bereichs; und(x) bei den Fliesen im zweiten Satz liegt die Folge von Durchlässen im dritten Muster nicht innerhalb eines vom Gittermuster definierten Bereichs.

- Gewebe nach Anspruch 1, wobei das Gewebe einen ersten, die erste Lage bildenden Satz von Fliesen und einen zweiten, die zweite Lage bildenden Satz von Fliesen umfasst, wobeia) bei den Fliesen (1) des ersten Satzes jede Fliese einstückige, an ersten ausgewählten Primärpositionen in die Fliese eingearbeitete Fügestrukturen (2) gemäß einem ersten, symmetrischen Muster umfasst, das ein erstes Gittermuster definiert;b) bei den Fliesen (7) des zweiten Satzes jede Fliese einstückige, an zweiten ausgewählten Primärpositionen in die Fliese eingearbeitete Fügestrukturen (8) gemäß einem ersten, symmetrischen Muster umfasst, das ein zweites Gittermuster definiert; undc) der lineare Abstand S2 zwischen benachbarten Fügestrukturen (2) auf einer Achse (3, 4) des ersten Gittermusters und der lineare Abstand S1 zwischen benachbarten Fügestrukturen auf der gleichen Achse (9, 10) des zweiten Gittermusters im Verhältnis S2 = nS1 zueinander in Beziehung stehen, wobei n für eine ganze Zahl steht.

- Gewebe nach Anspruch 5, wobei das zweite und das dritte Muster identisch sind und das zweite und das dritte Muster im Hinblick auf die Symmetrieachsen des ersten Musters beide asymmetrisch sind.

- Gewebe nach Anspruch 1, wobei das Gewebe einen ersten, die erste Lage bildenden Satz von Fliesen und einen zweiten, die zweite Lage bildenden Satz von Fliesen umfasst, wobeia) bei den Fliesen (1) des ersten Satzes jede Fliese einstückige, an ersten ausgewählten Primärpositionen in die Fliese eingearbeitete Fügestrukturen (2) gemäß einem ersten, symmetrischen Muster umfasst, das ein erstes Gittermuster definiert;b) bei den Fliesen (7) des zweiten Satzes jede Fliese einstückige, an zweiten ausgewählten Primärpositionen in die Fliese eingearbeitete Fügestrukturen (8) gemäß einem ersten, symmetrischen Muster umfasst, das ein zweites Gittermuster definiert;c) der lineare Abstand S2 zwischen benachbarten Fügestrukturen auf einer Achse (3, 4) des ersten Gittermusters und der lineare Abstand S1 zwischen benachbarten Fügestrukturen auf der gleichen Achse (9, 10) des zweiten Gittermusters im Verhältnis S2 = nS1 zueinander in Beziehung stehen, wobei n für eine ganze Zahl steht;d) jede Fliese (1, 2) sowohl im ersten Satz als auch im zweiten Satz eine erste Folge von an ersten ausgewählten Sekundärpositionen gemäß einem vierten Muster in die Fliese eingearbeiteten Durchlässen (5; 11) umfasst;e) jede Fliese (1, 2) sowohl im ersten Satz als auch im zweiten Satz eine zweite Folge von an zweiten ausgewählten Sekundärpositionen gemäß einem fünften Muster in die Fliese eingearbeiteten Durchlässen (6, 12) umfasst;f) zumindest ein Muster aus der Gruppe, die aus dem vierten Muster und dem fünften Muster gebildet wird, im Hinblick auf die Symmetrieachsen des ersten Musters asymmetrisch ist.

- Gewebe nach Anspruch 7, wobei das vierte Muster und das fünfte Muster im Hinblick auf die Symmetrieachsen des ersten Musters beide asymmetrisch sind.

- Gewebe nach Anspruch 1, wobei die Fliesen eine einen ersten Teil (2) und einen damit zusammenwirkenden zweiten Teil (8) umfassende Fügestruktur umfassen, wobei der erste Fliesensatz den ersten Teil der Fügestruktur und der zweite Fliesensatz den zweiten Teil der Fügestruktur umfasst.

- Gewebe nach Anspruch 9, wobei der erste Teil der Fügestruktur mit dem zweiten Teil der Fügestruktur identisch ist.

- Gewebe nach Anspruch 10, wobei der erste Teil (2) der Fügestruktur nicht mit dem zweiten Teil der Fügestruktur (8) identisch ist.

- Gewebe nach Anspruch 1, wobei die Fliesen eine einen ersten Teil und einen damit zusammenwirkenden zweiten Teil umfassende Fügestruktur umfassen, wobei der erste Fliesensatz sowohl den ersten Teil als auch den zweiten Teil der Fügestruktur umfasst und der zweite Fliesensatz sowohl den ersten Teil als auch den zweiten Teil der Fügestruktur umfasst.

- Gewebe nach Anspruch 12, wobei der erste Teil der Fügestruktur mit dem zweiten Teil der Fügestruktur identisch ist.

- Gewebe nach Anspruch 12, wobei der erste Teil der Fügestruktur nicht mit dem zweiten Teil der Fügestruktur identisch ist.

- Gewebe nach Anspruch 1, wobei bei dem Fliesensatz zumindest einer Lage das erste, symmetrische Muster zweimal, an ersten Primärpositionen und an zweiten Primärpositionen, eingearbeitet ist und die ersten Primärpositionen entlang einer Achse des Gittermusters von den zweiten Primärpositionen getrennt sind.

- Gewebe nach Anspruch 1, wobei das erste, symmetrische Muster eine Zweiachsensymmetrie aufweist und das Gittermuster aus einer Folge von Quadraten besteht.

- Gewebe nach Anspruch 1, wobei das erste, symmetrische Muster eine Dreiachsensymmetrie aufweist und das Gittermuster aus einer Folge von regelmäßigen Sechsecken besteht.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0106776 | 2001-03-19 | ||

| GBGB0106776.8A GB0106776D0 (en) | 2001-03-19 | 2001-03-19 | Asymmetric tile aperture industrial fabric |

| PCT/CA2002/000370 WO2002074529A1 (en) | 2001-03-19 | 2002-03-18 | Industrial fabric with asymmetrically apertured tiles |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1377436A1 EP1377436A1 (de) | 2004-01-07 |

| EP1377436B1 true EP1377436B1 (de) | 2006-06-07 |

Family

ID=9911018

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02712694A Expired - Lifetime EP1377436B1 (de) | 2001-03-19 | 2002-03-18 | Technisches gewebe mit asymmetrisch gelöcherten fliesen |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US6902787B2 (de) |

| EP (1) | EP1377436B1 (de) |

| JP (1) | JP2004523672A (de) |

| AT (1) | ATE328727T1 (de) |

| AU (1) | AU2002244579B2 (de) |

| CA (1) | CA2440766C (de) |

| DE (1) | DE60212105T2 (de) |

| GB (1) | GB0106776D0 (de) |

| WO (1) | WO2002074529A1 (de) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AU2015320307A1 (en) | 2014-09-25 | 2017-03-16 | Gpcp Ip Holdings Llc | Methods of making paper products using a multilayer creping belt, and paper products made using a multilayer creping belt |

| US9938666B2 (en) | 2015-05-01 | 2018-04-10 | The Procter & Gamble Company | Unitary deflection member for making fibrous structures having increased surface area and process for making same |

| US10933577B2 (en) | 2015-05-01 | 2021-03-02 | The Procter & Gamble Company | Unitary deflection member for making fibrous structures having increased surface area and process for making same |

| US9976261B2 (en) | 2015-05-01 | 2018-05-22 | The Procter & Gamble Company | Unitary deflection member for making fibrous structures having increased surface area and process for making same |

| WO2016205103A1 (en) | 2015-06-19 | 2016-12-22 | The Procter & Gamble Company | Seamless unitary deflection member for making fibrous structures having increased surface area |

| US10233593B2 (en) | 2016-03-24 | 2019-03-19 | The Procter & Gamble Company | Unitary deflection member for making fibrous structures and process for making same |

| US10683614B2 (en) * | 2016-10-27 | 2020-06-16 | The Procter & Gamble Company | Deflecting member for making fibrous structures |

| US10865521B2 (en) | 2016-10-27 | 2020-12-15 | The Procter & Gamble Company | Deflecting member for making fibrous structures |

| US10815618B2 (en) | 2016-10-27 | 2020-10-27 | The Procter & Gamble Company | Deflecting member for making fibrous structures |

| US10676865B2 (en) * | 2016-10-27 | 2020-06-09 | The Procter & Gamble Company | Deflecting member for making fibrous structures |

| JP6661020B2 (ja) * | 2017-03-01 | 2020-03-11 | 株式会社オプトニクス精密 | 篩 |

| US11396725B2 (en) | 2017-10-27 | 2022-07-26 | The Procter & Gamble Company | Deflecting member for making fibrous structures |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4469221A (en) * | 1982-09-24 | 1984-09-04 | Scapa Inc. | Papermakers fabric of link and pintle construction |

| US4537658A (en) * | 1982-09-30 | 1985-08-27 | Scapa Inc. | Papermakers fabric constructed of extruded slotted elements |

| US4541895A (en) * | 1982-10-29 | 1985-09-17 | Scapa Inc. | Papermakers fabric of nonwoven layers in a laminated construction |

| US4579771A (en) * | 1984-08-10 | 1986-04-01 | Asten Group, Inc. | Laminated spiral mesh papermakers fabric |

| DE3444082A1 (de) * | 1984-12-04 | 1986-08-07 | Andreas Kufferath GmbH & Co KG, 5160 Düren | Entwaesserungsband, insbesondere als bespannung fuer den nassbereich von papiermaschinen |

| DE3735709C2 (de) | 1987-10-22 | 1995-08-10 | Heimbach Gmbh Thomas Josef | Papiermaschinenband |

| US4842905A (en) * | 1988-02-03 | 1989-06-27 | Asten Group, Inc. | Tessellated papermakers fabric and elements for producing the same |

| JPH09238714A (ja) * | 1996-03-04 | 1997-09-16 | Ykk Corp | 合成樹脂製の一体成形面ファスナー |

| US6124015A (en) * | 1996-04-18 | 2000-09-26 | Jwi Ltd. | Multi-ply industrial fabric having integral jointing structures |

| EP1035251B1 (de) | 1999-03-12 | 2002-01-09 | Thomas Josef Heimbach Gesellschaft mit beschränkter Haftung & Co. | Entwässerungsband für Papiermaschinen |

-

2001

- 2001-03-19 GB GBGB0106776.8A patent/GB0106776D0/en not_active Ceased

-

2002

- 2002-03-18 AT AT02712694T patent/ATE328727T1/de not_active IP Right Cessation

- 2002-03-18 WO PCT/CA2002/000370 patent/WO2002074529A1/en active IP Right Grant

- 2002-03-18 JP JP2002573222A patent/JP2004523672A/ja active Pending

- 2002-03-18 AU AU2002244579A patent/AU2002244579B2/en not_active Ceased

- 2002-03-18 US US10/471,766 patent/US6902787B2/en not_active Expired - Fee Related

- 2002-03-18 DE DE60212105T patent/DE60212105T2/de not_active Expired - Fee Related

- 2002-03-18 EP EP02712694A patent/EP1377436B1/de not_active Expired - Lifetime

- 2002-03-18 CA CA002440766A patent/CA2440766C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ATE328727T1 (de) | 2006-06-15 |

| US6902787B2 (en) | 2005-06-07 |

| GB0106776D0 (en) | 2001-05-09 |

| DE60212105D1 (de) | 2006-07-20 |

| EP1377436A1 (de) | 2004-01-07 |

| CA2440766C (en) | 2005-06-28 |

| US20040109972A1 (en) | 2004-06-10 |

| JP2004523672A (ja) | 2004-08-05 |

| WO2002074529A1 (en) | 2002-09-26 |

| CA2440766A1 (en) | 2002-09-26 |

| DE60212105T2 (de) | 2006-12-14 |

| AU2002244579B2 (en) | 2005-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1377436B1 (de) | Technisches gewebe mit asymmetrisch gelöcherten fliesen | |

| EP1659212B1 (de) | Zweilagiges technisches Gewebe | |

| EP1662039B1 (de) | Zweilagiges technisches Gewebe | |

| EP1662040B1 (de) | Zweilagiges technisches Gewebe | |

| CA2606639C (en) | Bulk enhancing forming fabrics | |

| AU2002244579A1 (en) | Asymmetric Tile Aperture Industrial Fabric | |

| CA2516882C (en) | Industrial two-layer fabric | |

| EP1362142B1 (de) | Papiermaschinen gewebe | |

| US5507915A (en) | Multi-layered papermakers fabric for thru-dryer application | |

| EP0431750A2 (de) | Mehrlagiges Papiermachergewebe für einen Durchblasetrockner | |

| CA2759358C (en) | Industrial two-layer fabric | |

| KR100631247B1 (ko) | 심 영역에 부가적인 실을 사용한 제지 직물 | |

| KR20010034760A (ko) | 직물과 솔기 구조 | |

| CA2590162A1 (en) | Multi-pin pin seam for an industrial fabric | |

| WO2023002684A1 (ja) | 工業用織物 | |

| KR102437753B1 (ko) | 분진포집효율성을 향상시킨 다층 마스크 및 제조방법 | |

| US4923740A (en) | Multilayer forming fabric with high open area | |

| JPH06123039A (ja) | 建設工事用メッシュ状シート | |

| KR100528373B1 (ko) | 성형 직물 | |

| JPS592066Y2 (ja) | 使用限界表示スリング | |

| KR20070006817A (ko) | 드라이어 직물 이음부 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20030918 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17Q | First examination report despatched |

Effective date: 20040227 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ASTENJOHNSON, INC. |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060607 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060607 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 60212105 Country of ref document: DE Date of ref document: 20060720 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ABREMA AGENCE BREVETS ET MARQUES GANGUILLET & HUMP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060907 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060918 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061107 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070319 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060908 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20080307 Year of fee payment: 7 Ref country code: GB Payment date: 20080307 Year of fee payment: 7 Ref country code: SE Payment date: 20080318 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20080331 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20080402 Year of fee payment: 7 Ref country code: DE Payment date: 20080328 Year of fee payment: 7 Ref country code: FR Payment date: 20080320 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080312 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070318 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060607 |

|

| BERE | Be: lapsed |

Owner name: *ASTENJOHNSON INC. Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060607 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090318 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090318 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090318 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091001 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091123 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090318 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090319 |