EP1301712B1 - Monobloc housing for vacuum pump - Google Patents

Monobloc housing for vacuum pump Download PDFInfo

- Publication number

- EP1301712B1 EP1301712B1 EP01958136A EP01958136A EP1301712B1 EP 1301712 B1 EP1301712 B1 EP 1301712B1 EP 01958136 A EP01958136 A EP 01958136A EP 01958136 A EP01958136 A EP 01958136A EP 1301712 B1 EP1301712 B1 EP 1301712B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- motor

- pump

- casing

- stator

- vacuum pump

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/0042—Driving elements, brakes, couplings, transmissions specially adapted for pumps

- F04C29/0085—Prime movers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01C—ROTARY-PISTON OR OSCILLATING-PISTON MACHINES OR ENGINES

- F01C21/00—Component parts, details or accessories not provided for in groups F01C1/00 - F01C20/00

- F01C21/10—Outer members for co-operation with rotary pistons; Casings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C23/00—Combinations of two or more pumps, each being of rotary-piston or oscillating-piston type, specially adapted for elastic fluids; Pumping installations specially adapted for elastic fluids; Multi-stage pumps specially adapted for elastic fluids

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C23/00—Combinations of two or more pumps, each being of rotary-piston or oscillating-piston type, specially adapted for elastic fluids; Pumping installations specially adapted for elastic fluids; Multi-stage pumps specially adapted for elastic fluids

- F04C23/008—Hermetic pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/0042—Driving elements, brakes, couplings, transmissions specially adapted for pumps

- F04C29/005—Means for transmitting movement from the prime mover to driven parts of the pump, e.g. clutches, couplings, transmissions

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/04—Heating; Cooling; Heat insulation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C2220/00—Application

- F04C2220/10—Vacuum

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C2240/00—Components

- F04C2240/50—Bearings

- F04C2240/51—Bearings for cantilever assemblies

Definitions

- the present invention relates to pumping units with dry vacuum pumps for the realization of a high vacuum, for use in particular in the semiconductor industry for lowering the pressure in the process chambers from the atmosphere .

- the invention relates more particularly to pumping units with vacuum pumps with a double rotor, comprising a pump stator with at least one axial internal cavity in which two parallel pump rotors are mounted which are rotatably mounted on corresponding bearings and coupled according to their first end by gears locked in an oil sump.

- the first end of one of the rotors is extended by a coaxial motor shaft engaged in the rotor of a drive motor of the vacuum pump.

- the motor includes a stator having a stator winding and is enclosed in a motor housing following the gear oil sump.

- JP-60 259 791 proposes a vacuum pump, of the "oil-free screw” type, comprising a pump stator and two parallel rotors housed in the stator cavity. Both rotors are rotatably mounted and supported by magnetic bearings at each end. The female rotor is extended by a shaft engaged in the rotor of an electric motor.

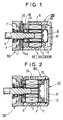

- FIG. 1 there is a longitudinal sectional view showing the first end of the stator 1 of the vacuum pump 100, with a motor shaft 2 extending the pump rotor not shown.

- the driving shaft 2 is engaged in a motor block 200 while being secured to the motor rotor 3.

- the motor rotor 3 is rotatably mounted on bearings inside the motor stator 4 comprising a stator winding 11 fed by electrical conductors not shown.

- the motor stator assembly 4 - motor rotor 3 is inserted in a motor housing 5.

- Seals can seal around the motor shaft 2 at the inlet of the motor housing 5, to isolate as much as possible the interior atmosphere of the motor housing 5 with respect to the upstream compartment 7 containing a set of coupling gears 8 between two parallel rotors of the vacuum pump 100.

- the gear set 8 transmits the rotational movement between both rotors, only one of the rotors being coupled in line with the drive shaft 2.

- the upstream compartment 7 of the gears 8 contains lubricating oil of the gear.

- an additional bearing 15a is placed between the gears 8 and the motor rotor 3.

- the known structure illustrated in FIG. figure 1 comprises a coaxial bell-shaped liner 9, the base 10 of which is sealingly embedded around its entire periphery between two parts of the motor casing 5, namely a main part 51 and a fixing base 52.

- the waterproof jacket 9 comprises a cylindrical intermediate portion 90 which is engaged in the air gap between the motor stator 4 and the motor rotor 3, and which is connected on the one hand to the base of the liner and to a top 91.

- a first disadvantage of such a known structure is its complexity, in that it is necessary to assemble and to provide several parts, including the sealed liner 9, and the two-part engine housing 51 and 52. This increases the cost of realization of the vacuum pump.

- a second disadvantage is that the presence of the cylindrical intermediate portion 90 of the sealed liner 9 engaged in the air gap between the motor stator 4 and the motor rotor 3 requires keeping a gap of relatively large thickness, which increases the consumption. of electrical energy necessary for driving the vacuum pump 100.

- Another disadvantage is that the presence of the sealed liner 9 leads to increasing the length of the engine, by moving the motor stator 4 and the motor rotor 3 away from the vacuum pump 100, increasing the door-to-door false of the motor shaft; this increases the vibration of the motor, and the noise generated by the vacuum pump assembly 100 - motor block 200, and requires the presence of the additional bearing 15a between the gears 8 and the motor rotor 3.

- Another disadvantage is also that the waterproof jacket, made of metal, is subjected to an alternating magnetic field in the air gap of the motor. This results in induction currents in the material forming the sealed jacket, energy losses and additional heating of the engine. These losses increase with the frequency of the magnetic field, and become prohibitive in a four-pole motor powered with double frequency.

- JP 07 317673 a screw pump for various fluids.

- the drive motor is disposed in an intermediate region of one of the rotor shafts, between the shaft coupling gears and the pump rotors.

- the crankcase is separate from the coupling gear housing.

- the structure is neither planned nor adapted to solve the specific problems of vacuum pump sealing.

- the object of the present invention is in particular to avoid the drawbacks of known vacuum pump structures, by proposing a new double rotor vacuum pump pumping unit structure associated with a motor whose sealing is at the simpler level less expensive, and more efficient.

- the purpose of the invention is to eliminate the watertight liner 9, by replacing it with other means to effectively seal against the migration of oil and gases through the engine to the atmosphere.

- the one-piece common casing has an intermediate wall between a first compartment containing the motor and a second compartment containing the gear set, with a passage for the drive shaft and with a dynamic seal to ensure sealing around the motor shaft between the first compartment and the second compartment.

- the one-piece common housing may advantageously comprise an axial end opening sealingly closed by a shutter door.

- a further vibration reduction is obtained by providing that the one-piece common housing is connected to the first end of the pump stator via a bearing support comprising a first guide bearing of the motor shaft disposed as close to the engine. This reduces the cantilever of the motor shaft.

- the reduction in length and cantilever is further promoted by the fact that the impregnation of the motor stator in the sealed resin allows to bring it closer to its housing, because the isolation distances can be reduced by the dielectric quality of the waterproof resin.

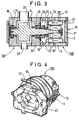

- a vacuum pump pumping unit according to the invention as illustrated on the Figures 2 to 4 comprises a double rotor vacuum pump 100 driven by a motor unit 200 supplied with electrical energy by a supply line 12.

- the vacuum pump 100 comprises a pump stator 1 having at least one axial inner cavity 13 in which are housed two parallel pump rotors rotatably mounted on corresponding bearings.

- a pump stator 1 having at least one axial inner cavity 13 in which are housed two parallel pump rotors rotatably mounted on corresponding bearings.

- the pump rotors 14 held in the pump stator 1 at its first end by a first bearing 15 and held at its second end by a second bearing 16.

- the two pump rotors such as the pump rotor 14 are coupled at their first end by a set of gears 17 enclosed in an oil sump 18.

- the first end of the pump rotor 14 is extended by the coaxial motor shaft 2 penetrating into the motor housing 5.

- the motor shaft 2 is engaged in the motor rotor 3, itself rotatably mounted in the motor stator 4 of the motor housing 5.

- the motor stator 4 comprises a stator winding 11 ( figure 2 ).

- the engine casing 5 and the oil sump 18 form a unitary common casing, advantageously made of metal and secured to the first end of the pump stator 1.

- the winding stator 11 of the motor unit 200 is embedded in a watertight resin 19 ( figure 2 ), which provides oil and gas tightness, preventing the outflow of oil and gas along the conductors of the power line 12 of the engine.

- the one-piece common housing 5, 18 has an axial end opening 20, sealingly closed by a shutter 21 with the interposition of an annular seal 22.

- the one-piece common housing comprises, between the motor housing portion 5 and the oil sump portion 18, an intermediate wall 23, separating the first compartment 24 containing the motor 3, 4 and the second compartment 25 containing the gear set 17, with an axial passage for the drive shaft and with a dynamic seal 6 to ensure as much as possible a seal around the drive shaft 2 between the first compartment 24 and the second compartment 25.

- the one-piece common housing 5, 18 is connected to the first end of the pump stator 1 via a bearing support 26 comprising the first bearing 15 for guiding the driving shaft 2.

- the first bearing 15 is placed closer to the engine block 200, to reduce the cantilever of the motor shaft 2.

- suction inlet 27 and the discharge outlet 28 of the vacuum pump 100 are also distinguished.

- the engine casing 5 comprises a duct 29 for conduction of cooling fluid.

- the structure according to the invention simultaneously ensures a better cooling of the pump stator part 1 close to the engine block 200, thanks to the continuous metal structure formed by the unitary common housing 5, 18, distinct from the sealed resin which is confined to the interior of said one-piece housing 5, 18. Also, by shortening the cantilever of the drive shaft 2, the vibrations are avoided and the noise generated by the vacuum pumping unit is reduced. It thus becomes possible to avoid the use of an additional bearing (15a, Figure 1 ) between the gears 17 and the motor rotor 3. In other words, as shown in FIG. figure 3 , the drive shaft 2 is then cantilevered from the first guide bearing 15, that is to say along the motor shaft section 2 carrying the motor rotor 3 and the gears 17.

- the length of the motor stator, and the resulting cantilever can be further reduced, for an identical motor torque, by using a motor 4, 4 four-pole powered double frequency 2F (in practice 200 Hz for example ), instead of a two-pole motor powered at a single frequency F (in practice 100 Hz for example). Due to the absence of airtight liner in the air gap, the use of a 2F dual-frequency powered four-pole motor is possible without creating excessive losses of performance. This was not possible with the known sealed jacket structures, since 2F dual frequency operation created excessive yield losses.

Abstract

Description

La présente invention concerne les groupes de pompage à pompes à vide sèches destinées à la réalisation d'un vide poussé, pour une utilisation notamment dans l'industrie du semi-conducteur pour abaisser la pression dans les chambres de procédé à partir de l'atmosphère.The present invention relates to pumping units with dry vacuum pumps for the realization of a high vacuum, for use in particular in the semiconductor industry for lowering the pressure in the process chambers from the atmosphere .

L'invention concerne plus spécialement les groupes de pompage à pompes à vide à double rotor, comprenant un stator de pompe avec au moins une cavité intérieure axiale dans laquelle sont logés deux rotors de pompe parallèles montés rotatifs sur des paliers correspondants et couplés selon leur première extrémité par des engrenages enfermés dans un carter d'huile. La première extrémité de l'un des rotors est prolongée par un arbre moteur coaxial engagé dans le rotor d'un moteur d'entraînement de la pompe à vide. Le moteur comprend un stator ayant un bobinage de stator et est enfermé dans un carter moteur faisant suite au carter d'huile des engrenages.The invention relates more particularly to pumping units with vacuum pumps with a double rotor, comprising a pump stator with at least one axial internal cavity in which two parallel pump rotors are mounted which are rotatably mounted on corresponding bearings and coupled according to their first end by gears locked in an oil sump. The first end of one of the rotors is extended by a coaxial motor shaft engaged in the rotor of a drive motor of the vacuum pump. The motor includes a stator having a stator winding and is enclosed in a motor housing following the gear oil sump.

Des structures connues de groupes de pompage à vide sont décrites dans

Dans les groupes de pompage à vide, l'une des difficultés est d'assurer une étanchéité satisfaisante dans le moteur d'entraînement de la pompe à vide, pour interdire la sortie d'huile et de gaz vers l'extérieur à travers le moteur, notamment le long des conducteurs d'alimentation du bobinage de stator du moteur. En effet, du fait de la vitesse de rotation très élevée de la pompe à vide, par exemple de l'ordre de 6 000 tours par minute, il est difficile d'assurer une étanchéité suffisante par les joints d'étanchéité dynamiques prévus autour de l'arbre moteur entre le moteur et l'engrenage. Il en résulte une tendance au passage d'huile vers l'extérieur à travers le moteur. Egalement, les pompes à vide utilisées dans les procédés industriels contienent des gaz toxiques et polluants auxquels il faut absolument interdire le passage vers l'atmosphère environnante.In vacuum pumping units, one of the difficulties is to ensure a satisfactory seal in the drive motor of the vacuum pump, to prevent the exit of oil and gas to the outside through the engine , especially along the power supply conductors of the motor stator winding. Indeed, because of the very high speed of rotation of the vacuum pump, for example of the order of 6,000 revolutions per minute, it is difficult to ensure sufficient sealing by the dynamic seals provided around the motor shaft between the motor and the gear. This results in a tendency for the oil to pass to the outside through the engine. Vacuum pumps used in industrial processes also contain toxic and polluting gases which must absolutely be prevented from entering the surrounding atmosphere.

Dans une pompe à vide connue, illustrée sur la

L'efficacité des joints d'étanchéité est insuffisante pour s'opposer suffisamment au passage de l'huile de lubrification des engrenages 8 et au passage des gaz toxiques provenant de la pompe à vide 100 jusqu'à l'atmosphère extérieure à travers le bloc moteur 200, et notamment le long des conducteurs d'alimentation du bobinage de stator 11 du moteur. Pour interdire la migration de l'huile et des gaz vers l'atmosphère extérieure à travers le bloc moteur 200, la structure connue illustrée sur la

Un premier inconvénient d'une telle structure connue est sa complexité, par le fait qu'il est nécessaire d'assembler et de prévoir plusieurs pièces, comprenant la chemise étanche 9, et le carter de moteur en deux parties 51 et 52. Cela augmente le coût de réalisation de la pompe à vide.A first disadvantage of such a known structure is its complexity, in that it is necessary to assemble and to provide several parts, including the sealed

Un second inconvénient est que la présence de la portion intermédiaire cylindrique 90 de chemise étanche 9 engagée dans l'entrefer entre le stator de moteur 4 et le rotor de moteur 3 nécessite de garder un entrefer d'épaisseur relativement grande, ce qui augmente la consommation d'énergie électrique nécessaire pour l'entraînement de la pompe à vide 100.A second disadvantage is that the presence of the cylindrical

Un autre inconvénient est que la présence de la chemise étanche 9 conduit à augmenter la longueur du moteur, en éloignant le stator de moteur 4 et le rotor de moteur 3 à l'écart de la pompe à vide 100, augmentant le porte-à-faux de l'arbre moteur ; cela augmente les vibrations du moteur, et le bruit généré par l'ensemble pompe à vide 100 - bloc moteur 200, et nécessite la présence du roulement supplémentaire 15a entre les engrenages 8 et le rotor de moteur 3.Another disadvantage is that the presence of the sealed

Un autre inconvénient est aussi que la chemise étanche, réalisée en métal, est soumise à un champ magnétique alternatif dans l'entrefer du moteur. Il en résulte des courants d'induction dans la matière formant la chemise étanche, des pertes d'énergie et un échauffement supplémentaire du moteur. Ces pertes augmentent avec la fréquence du champ magnétique, et deviennent prohibitives dans un moteur à quatre pôles alimenté à fréquence double.Another disadvantage is also that the waterproof jacket, made of metal, is subjected to an alternating magnetic field in the air gap of the motor. This results in induction currents in the material forming the sealed jacket, energy losses and additional heating of the engine. These losses increase with the frequency of the magnetic field, and become prohibitive in a four-pole motor powered with double frequency.

On connaît par ailleurs du

On connaît aussi du

La présente invention a notamment pour objet d'éviter les inconvénients des structures connues de pompes à vide, en proposant une nouvelle structure de groupe de pompage à pompe à vide à double rotor associée à un moteur dont l'étanchéité soit à la fois plus simple, moins onéreuse, et plus efficace.The object of the present invention is in particular to avoid the drawbacks of known vacuum pump structures, by proposing a new double rotor vacuum pump pumping unit structure associated with a motor whose sealing is at the simpler level less expensive, and more efficient.

L'invention vise à supprimer la chemise étanche 9, en la remplaçant par d'autres moyens pour assurer efficacement l'étanchéité s'opposant à la migration de l'huile et des gaz à travers le moteur vers l'atmosphère.The purpose of the invention is to eliminate the

Pour atteindre ces objets ainsi que d'autres, un groupe de pompage à pompe à vide à double rotor selon l'invention comprend un stator de pompe avec au moins une cavité intérieure axiale dans laquelle sont logés deux rotors de pompe parallèles montés rotatifs sur des paliers correspondants et couplés à leur première extrémité par un jeu d'engrenages enfermé dans un carter d'huile, la première extrémité de l'un des rotors de pompe étant prolongé par un arbre moteur coaxial engagé dans le rotor d'un bloc moteur d'entraînement de la pompe à vide, le bloc moteur ayant un bobinage de stator et étant enfermé dans un carter de moteur faisant suite au carter d'huile ; selon l'invention :

- le carter de moteur et le carter d'huile forment un carter commun monobloc raccordé à la première extrémité du stator de pompe de la pompe à vide,

- à l'intérieur du carter commun monobloc le bobinage de stator du bloc moteur est noyé dans une résine étanche assurant une étanchéité interdisant la sortie d'huile et de gaz vers l'extérieur le long des conducteurs d'alimentation.

- the motor casing and the oil sump form a one-piece casing connected to the first end of the pump stator of the vacuum pump,

- inside the one-piece common housing the stator winding of the engine block is embedded in a waterproof resin providing a seal preventing the exit of oil and gas outwards along the supply conductors.

On évite ainsi le recours à des moyens d'étanchéité plus encombrants et plus onéreux, de sorte que le coût de production est réduit et la fiabilité du groupe de pompage est améliorée.This avoids the use of sealing means more bulky and more expensive, so that the production cost is reduced and the reliability of the pumping unit is improved.

On évite également les pertes résultant des courants d'induction qui sont inévitablement générés dans la masse de matière constituant une chemise étanche engagée dans l'entrefer entre rotor et stator du moteur.Losses resulting from induction currents which are inevitably generated in the mass of material constituting a sealed jacket engaged in the air gap between the rotor and the stator of the motor are also avoided.

Selon une réalisation avantageuse, le carter commun monobloc comporte une paroi intermédiaire entre un premier compartiment contenant le moteur et un second compartiment contenant le jeu d'engrenages, avec un passage pour l'arbre moteur et avec un joint d'étanchéité dynamique pour assurer l'étanchéité autour de l'arbre moteur entre le premier compartiment et le second compartiment.According to an advantageous embodiment, the one-piece common casing has an intermediate wall between a first compartment containing the motor and a second compartment containing the gear set, with a passage for the drive shaft and with a dynamic seal to ensure sealing around the motor shaft between the first compartment and the second compartment.

Pour la commodité de montage, le carter commun monobloc peut avantageusement comporter une ouverture axiale d'extrémité obturée de manière étanche par une trappe d'obturation.For ease of assembly, the one-piece common housing may advantageously comprise an axial end opening sealingly closed by a shutter door.

Une réduction supplémentaire des vibrations est obtenue en prévoyant que le carter commun monobloc est raccordé à la première extrémité du stator de pompe par l'intermédiaire d'un support de roulement comprenant un premier palier de guidage de l'arbre moteur disposé au plus près du moteur. On réduit ainsi le porte-à-faux de l'arbre moteur. La réduction de longueur et de porte-à-faux est encore favorisée par le fait que l'imprégnation du stator de moteur dans la résine étanche autorise à le rapprocher plus près de son carter, car les distances d'isolement peuvent être réduites grâce à la qualité diélectrique de la résine étanche.A further vibration reduction is obtained by providing that the one-piece common housing is connected to the first end of the pump stator via a bearing support comprising a first guide bearing of the motor shaft disposed as close to the engine. This reduces the cantilever of the motor shaft. The reduction in length and cantilever is further promoted by the fact that the impregnation of the motor stator in the sealed resin allows to bring it closer to its housing, because the isolation distances can be reduced by the dielectric quality of the waterproof resin.

D'autres objets, caractéristiques et avantages de la présente invention ressortiront de la description suivante de modes de réalisation particuliers, faite en relation avec les figures jointes, parmi lesquelles:

- la

figure 1 est une vue en coupe longitudinale d'un bloc moteur selon une structure connue ; - la

figure 2 est une vue en coupe longitudinale d'une structure de bloc moteur selon un mode de réalisation de la présente invention ; - la

figure 3 est une vue schématique en coupe longitudinale montrant un groupe de pompage à vide selon un autre mode de réalisation de la présente invention ; et - la

figure 4 est une vue en perspective du carter de moteur et du carter d'engrenage selon un mode de réalisation de la présente invention.

- the

figure 1 is a longitudinal sectional view of an engine block according to a known structure; - the

figure 2 is a longitudinal sectional view of an engine block structure according to an embodiment of the present invention; - the

figure 3 is a schematic longitudinal sectional view showing a vacuum pumping unit according to another embodiment of the present invention; and - the

figure 4 is a perspective view of the motor housing and the gear case according to one embodiment of the present invention.

Un groupe de pompage à pompe à vide selon l'invention tel qu'illustré sur les

La pompe à vide 100 comprend un stator de pompe 1 ayant au moins une cavité intérieure 13 axiale dans laquelle sont logés deux rotors de pompe parallèles montés rotatifs sur des paliers correspondants. Sur les figures, on a représenté seulement l'un des rotors de pompe 14, tenu dans le stator de pompe 1 à sa première extrémité par un premier palier 15 et tenu à sa seconde extrémité par un second palier 16.The

Les deux rotors de pompe tels que le rotor de pompe 14 sont couplés à leur première extrémité par un jeu d'engrenages 17 enfermé dans un carter d'huile 18.The two pump rotors such as the pump rotor 14 are coupled at their first end by a set of gears 17 enclosed in an

La première extrémité du rotor de pompe 14 est prolongée par l'arbre moteur 2 coaxial pénétrant dans le carter de moteur 5. L'arbre moteur 2 est engagé dans le rotor de moteur 3, lui-même monté en rotation dans le stator de moteur 4 contenu dans le carter de moteur 5. Le stator de moteur 4 comprend un bobinage de stator 11 (

Selon l'invention, le carter de moteur 5 et le carter d'huile 18 forment un carter commun monobloc, avantageusement réalisé en métal et solidarisé à la première extrémité du stator de pompe 1. A l'intérieur du carter commun monobloc, le bobinage de stator 11 du bloc moteur 200 est noyé dans une résine étanche 19 (

Dans la réalisation illustrée sur les

Le carter commun monobloc comporte, entre la partie carter de moteur 5 et la partie carter d'huile 18, une paroi intermédiaire 23, séparant le premier compartiment 24 contenant le moteur 3, 4 et le second compartiment 25 contenant le jeu d'engrenages 17, avec un passage axial pour l'arbre moteur et avec un joint d'étanchéité dynamique 6 pour assurer autant que possible une étanchéité autour de l'arbre moteur 2 entre le premier compartiment 24 et le second compartiment 25.The one-piece common housing comprises, between the

Dans la réalisation avantageuse illustrée sur les

Sur la

Egalement, le carter de moteur 5 comporte une canalisation 29 de conduction de fluide de refroidissement.Also, the

La structure selon l'invention assure simultanément un meilleur refroidissement de la partie de stator de pompe 1 proche du bloc moteur 200, grâce à la structure métallique continue formée par le carter commun monobloc 5, 18, distincte de la résine étanche qui est confinée à l'intérieur dudit carter commun monobloc 5, 18. Egalement, en raccourcissant le porte-à-faux de l'arbre moteur 2, on évite les vibrations et on réduit le bruit généré par le groupe de pompage à vide. Il devient ainsi possible d'éviter le recours à un roulement supplémentaire (15a,

La longueur du stator moteur, et le porte-à-faux qui en résulte, peuvent encore être réduits, pour un couple moteur identique, en utilisant un moteur 3, 4 à quatre pôles alimenté à fréquence double 2F (en pratique 200 Hz par exemple), à la place d'un moteur à deux pôles alimenté à fréquence simple F (en pratique 100 Hz par exemple). Grâce à l'absence de chemise étanche dans l'entrefer, l'utilisation d'un moteur à quatre pôles alimenté à fréquence double 2F est possible sans créer de pertes exagérées de rendement. Cela n'était pas possible avec les structures connues à chemise étanche, car le fonctionnement à fréquence double 2F créait des pertes de rendement trop importantes.The length of the motor stator, and the resulting cantilever, can be further reduced, for an identical motor torque, by using a

Claims (6)

- A dual-rotor vacuum pump unit (100) comprising a pump stator (1) with at least one axial internal cavity (13) receiving two parallel pump rotors (14) mounted to rotate on corresponding bearings (15, 16) and coupled together at a first end by a set of gears (17) enclosed in a casing (18) containing oil, the first end of one of the pump rotors (14) being extended axially by a drive shaft (2) engaged in the rotor (3) of a motor unit (200) for driving the vacuum pump (100), the motor unit (200) having a stator coil (11) and being enclosed in a motor casing (5) extending the gear casing (18),

the vacuum pump unit being characterized in that:- the motor casing (5) and the gear casing (18) form a common one-piece casing connected to the first end of the pump stator (1) of the vacuum pump (100); and- inside the common one-piece casing, the stator coil (11) of the motor unit (200) is embedded in a leakproof resin (19) providing sealing that prevents oil and gas escaping to the outside. - A pump unit according to claim 1, characterized in that the common one-piece casing (5, 18) includes in intermediate wall (23) between a first compartment (24) containing the motor (3, 4) and a second compartment (25) containing the set of gears (17), and including a passage for the drive shaft (2) with a dynamic seal (6) to provide sealing around the drive shaft (2) between the first compartment (24) and the second compartment (25).

- A pump unit according to claim 1, characterized in that the common one-piece casing (5, 18) has an axial end opening (20) closed in a leakproof manner by a closure hatch (21).

- A pump unit according to claim 1, characterized in that the common one-piece casing (5, 18) is connected to the first end of the pump stator (1) via a bearing support (26) having a first bearing (15) for guiding the drive shaft (2) and disposed as close as possible to the motor unit (200).

- A pump unit according to claim 4, characterized in that the drive shaft (2) is cantilevered-out from the first guide bearing (15).

- A pump unit according to claim 1, characterized in that the motor (3, 4) is a four-pole motor fed at double frequency (2F).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0009401 | 2000-07-18 | ||

| FR0009401A FR2812040B1 (en) | 2000-07-18 | 2000-07-18 | MONOBLOCK HOUSING FOR VACUUM PUMP |

| PCT/FR2001/002314 WO2002006675A2 (en) | 2000-07-18 | 2001-07-17 | Monobloc housing for vacuum pump |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1301712A2 EP1301712A2 (en) | 2003-04-16 |

| EP1301712B1 true EP1301712B1 (en) | 2009-02-25 |

Family

ID=8852631

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01958136A Expired - Lifetime EP1301712B1 (en) | 2000-07-18 | 2001-07-17 | Monobloc housing for vacuum pump |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6644942B2 (en) |

| EP (1) | EP1301712B1 (en) |

| JP (1) | JP2004504537A (en) |

| AT (1) | ATE423906T1 (en) |

| DE (1) | DE60137772D1 (en) |

| FR (1) | FR2812040B1 (en) |

| WO (1) | WO2002006675A2 (en) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB0208742D0 (en) | 2002-04-17 | 2002-05-29 | Bradford Particle Design Ltd | Particulate materials |

| JP2003269345A (en) * | 2002-03-13 | 2003-09-25 | Aisin Seiki Co Ltd | Motor-driven oil pump |

| JP4085969B2 (en) * | 2003-11-27 | 2008-05-14 | 株式会社豊田自動織機 | Electric roots type compressor |

| JPWO2006001342A1 (en) * | 2004-06-28 | 2008-04-17 | 松下電器産業株式会社 | Air pump |

| JP2006077699A (en) * | 2004-09-10 | 2006-03-23 | Yamaha Marine Co Ltd | Lubricating structure for supercharging device |

| JP2006083713A (en) * | 2004-09-14 | 2006-03-30 | Yamaha Marine Co Ltd | Lubricating structure of supercharger |

| JP4614853B2 (en) | 2005-09-26 | 2011-01-19 | ヤマハ発動機株式会社 | Turbocharger mounting structure |

| JP2008025477A (en) * | 2006-07-21 | 2008-02-07 | Jtekt Corp | Electric pump |

| PL2425820T3 (en) | 2007-02-11 | 2015-08-31 | Map Pharmaceuticals Inc | Method of therapeutic administration of dhe to enable rapid relief of migraine while minimizing side effect profile |

| JP4762301B2 (en) * | 2008-12-19 | 2011-08-31 | 三菱電機株式会社 | Electric motor for compressor, compressor and refrigeration cycle apparatus |

| FR2943744A1 (en) * | 2009-03-24 | 2010-10-01 | Inergy Automotive Systems Res | ROTARY PUMP |

| CN103107647B (en) * | 2011-11-11 | 2015-06-03 | 中国科学院沈阳科学仪器股份有限公司 | Motor for dry-type vacuum pump |

| WO2014095291A1 (en) * | 2012-12-20 | 2014-06-26 | Sulzer Pumpen Ag | Multiphase pump with separator, wherein the process fluid lubricates and cools the pump |

| US9394314B2 (en) | 2012-12-21 | 2016-07-19 | Map Pharmaceuticals, Inc. | 8′-hydroxy-dihydroergotamine compounds and compositions |

| EP3597922A1 (en) * | 2018-07-19 | 2020-01-22 | Agilent Technologies, Inc. (A Delaware Corporation) | Vacuum pumping system having an oil-lubricated vacuum pump |

| CN111963427B (en) * | 2019-05-20 | 2022-06-14 | 复盛实业(上海)有限公司 | Screw compressor |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2940661A (en) * | 1957-01-14 | 1960-06-14 | Heraeus Gmbh W C | Vacuum pumps |

| JPS57189246U (en) * | 1981-05-26 | 1982-12-01 | ||

| JPS60259791A (en) * | 1984-06-04 | 1985-12-21 | Hitachi Ltd | Oilfree screw vacuum pump |

| JPS63277885A (en) * | 1987-05-06 | 1988-11-15 | Kobe Steel Ltd | Oil-free screw type vacuum pump |

| FR2637655B1 (en) * | 1988-10-07 | 1994-01-28 | Alcatel Cit | SCREW PUMP TYPE ROTARY MACHINE |

| JPH0515101A (en) * | 1991-06-28 | 1993-01-22 | Asmo Co Ltd | Resin-molded type rotating electric machine |

| JPH05240181A (en) * | 1991-07-09 | 1993-09-17 | Ebara Corp | Multistage vacuum pump device |

| JPH0587076A (en) * | 1991-09-27 | 1993-04-06 | Ebara Corp | Screw type vacuum pump |

| JPH0569389U (en) * | 1992-02-21 | 1993-09-21 | セイコー精機株式会社 | Dry vacuum pump |

| IT1259848B (en) * | 1992-11-27 | 1996-03-28 | Hydor Srl | SYNCHRONOUS ELECTRIC MOTOR, PARTICULARLY FOR IMMERSIBLE PUMPS AND INCORPORATING PUMP SUCH MOTOR |

| JP3874430B2 (en) * | 1994-05-25 | 2007-01-31 | 株式会社荏原製作所 | Screw fluid machinery |

| JPH08100779A (en) * | 1994-10-04 | 1996-04-16 | Matsushita Electric Ind Co Ltd | Vacuum pump |

| KR100382308B1 (en) * | 1995-03-20 | 2003-07-10 | 가부시키 가이샤 에바라 세이사꾸쇼 | Vacuum pump |

| JP3315581B2 (en) * | 1995-03-20 | 2002-08-19 | 株式会社荏原製作所 | Vacuum pump |

| DK0834017T3 (en) * | 1995-06-21 | 2000-04-25 | Sterling Ind Consult Gmbh | vacuum pump |

| JPH1155923A (en) * | 1997-07-30 | 1999-02-26 | Mitsuba Corp | Brushless motor |

| JPH11356022A (en) * | 1998-06-03 | 1999-12-24 | Mitsubishi Electric Corp | Molded motor |

| JP2000170680A (en) * | 1998-09-30 | 2000-06-20 | Aisin Seiki Co Ltd | Vacuum pump |

| JP4185598B2 (en) * | 1998-10-02 | 2008-11-26 | 株式会社日立産機システム | Oil-cooled screw compressor |

| US6069421A (en) * | 1999-08-30 | 2000-05-30 | Electric Boat Corporation | Electric motor having composite encapsulated stator and rotor |

| JP3562763B2 (en) * | 2000-01-31 | 2004-09-08 | 東芝テック株式会社 | In-line pump |

| US6457950B1 (en) * | 2000-05-04 | 2002-10-01 | Flowserve Management Company | Sealless multiphase screw-pump-and-motor package |

-

2000

- 2000-07-18 FR FR0009401A patent/FR2812040B1/en not_active Expired - Fee Related

-

2001

- 2001-07-17 WO PCT/FR2001/002314 patent/WO2002006675A2/en active Application Filing

- 2001-07-17 DE DE60137772T patent/DE60137772D1/en not_active Expired - Lifetime

- 2001-07-17 US US10/088,168 patent/US6644942B2/en not_active Expired - Fee Related

- 2001-07-17 AT AT01958136T patent/ATE423906T1/en not_active IP Right Cessation

- 2001-07-17 EP EP01958136A patent/EP1301712B1/en not_active Expired - Lifetime

- 2001-07-17 JP JP2002512545A patent/JP2004504537A/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| US20020150484A1 (en) | 2002-10-17 |

| JP2004504537A (en) | 2004-02-12 |

| EP1301712A2 (en) | 2003-04-16 |

| US6644942B2 (en) | 2003-11-11 |

| FR2812040B1 (en) | 2003-02-07 |

| ATE423906T1 (en) | 2009-03-15 |

| FR2812040A1 (en) | 2002-01-25 |

| DE60137772D1 (en) | 2009-04-09 |

| WO2002006675A2 (en) | 2002-01-24 |

| WO2002006675A3 (en) | 2002-03-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1301712B1 (en) | Monobloc housing for vacuum pump | |

| BE1014892A5 (en) | Screw compressor oil free. | |

| CA2606069C (en) | Gearbox drive shaft of turbojet accessory machines; modular supplementary machine | |

| EP0882892B1 (en) | Scroll type machine | |

| EP0499504B1 (en) | Rotating machine of the compressor or turbine type for the compression or expansion of a dangerous gas | |

| FR2559847A1 (en) | VOLUME MACHINE FOR COMPRESSING A FLUID | |

| FR2574870A1 (en) | SPIRAL TYPE FLUID DISPLACEMENT APPARATUS | |

| CA2621837C (en) | Aircraft engine oil removal system | |

| FR3114353A1 (en) | Improved dynamic seal for sealing an aircraft engine module | |

| EP0097549B1 (en) | Device to realize the sealing of a submersible motor, and such a motor | |

| FR3057029A1 (en) | TURBOPROPULSEUR COMPRISING AN INTEGRATED ELECTRICITY GENERATOR | |

| FR2548752A1 (en) | LIQUID GASKET FOR GASES WITH FLUID SCAN | |

| FR2572770A1 (en) | ROTARY INTERNAL COMBUSTION ENGINE | |

| FR2565295A1 (en) | OIL-TIGHT ROTARY VACUUM PUMP | |

| EP3907391B1 (en) | Relay for accessories | |

| FR2986568A1 (en) | Enclosure for supporting e.g. oil pump, in gear housing of turbomotor i.e. turbojet, has sealing device sealing rotary shaft passage through wall, where sealing device includes water seal and cover for removably closing shaft passage | |

| EP3999729B1 (en) | Epicyclic reduction gear for a turbomachine | |

| JPH094570A (en) | Pump device | |

| EP3999730B1 (en) | Epicyclic reduction gear for a turbomachine | |

| FR2497019A1 (en) | Cooling system for high-speed rotating electrical machine - uses cooling liquid to obtain partial evacuation of machine interior | |

| EP1473462B1 (en) | Cartridge compressor unit | |

| WO2020030373A1 (en) | Multi-stage turbomachine | |

| FR3135755A1 (en) | Accessory relay box for a turbomachine | |

| WO2021123657A1 (en) | Turbogenerator for aircraft, comprising an improved oil system | |

| FR2520061A1 (en) | Hydrodynamic compressor shaft sealing joint - has two seal rings and labyrinth gland to form oil clearances |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20020328 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17Q | First examination report despatched |

Effective date: 20061221 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL LUCENT |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 60137772 Country of ref document: DE Date of ref document: 20090409 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090525 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090812 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090605 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| BERE | Be: lapsed |

Owner name: ALCATEL LUCENT Effective date: 20090731 |

|

| 26N | No opposition filed |

Effective date: 20091126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090717 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090225 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20110804 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110726 Year of fee payment: 11 Ref country code: DE Payment date: 20110804 Year of fee payment: 11 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120717 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130329 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120731 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130201 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120717 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60137772 Country of ref document: DE Effective date: 20130201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CA Effective date: 20150521 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CA Effective date: 20150521 |