EP1289691B2 - Method for continuously casting a metal strand - Google Patents

Method for continuously casting a metal strand Download PDFInfo

- Publication number

- EP1289691B2 EP1289691B2 EP01942855A EP01942855A EP1289691B2 EP 1289691 B2 EP1289691 B2 EP 1289691B2 EP 01942855 A EP01942855 A EP 01942855A EP 01942855 A EP01942855 A EP 01942855A EP 1289691 B2 EP1289691 B2 EP 1289691B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- strip

- strand

- cooling

- model

- metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 40

- 238000005266 casting Methods 0.000 title claims abstract description 36

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 24

- 239000002184 metal Substances 0.000 title claims abstract description 24

- 238000001816 cooling Methods 0.000 claims abstract description 37

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 34

- 239000010959 steel Substances 0.000 claims abstract description 34

- 238000009749 continuous casting Methods 0.000 claims abstract description 29

- 238000004364 calculation method Methods 0.000 claims abstract description 28

- 239000002826 coolant Substances 0.000 claims abstract description 19

- 230000015572 biosynthetic process Effects 0.000 claims abstract description 17

- 230000009467 reduction Effects 0.000 claims abstract description 3

- 238000004088 simulation Methods 0.000 claims description 14

- 238000001556 precipitation Methods 0.000 claims description 13

- 239000000126 substance Substances 0.000 claims description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 11

- 238000007711 solidification Methods 0.000 claims description 9

- 230000008023 solidification Effects 0.000 claims description 9

- 238000001953 recrystallisation Methods 0.000 claims description 8

- 238000010586 diagram Methods 0.000 claims description 6

- 229910017112 Fe—C Inorganic materials 0.000 claims description 2

- 230000007704 transition Effects 0.000 claims 3

- 230000009466 transformation Effects 0.000 description 20

- 239000000463 material Substances 0.000 description 11

- 230000008569 process Effects 0.000 description 9

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 8

- 238000005096 rolling process Methods 0.000 description 8

- 229910001566 austenite Inorganic materials 0.000 description 7

- 230000006911 nucleation Effects 0.000 description 7

- 238000010899 nucleation Methods 0.000 description 7

- 239000000047 product Substances 0.000 description 7

- 238000006243 chemical reaction Methods 0.000 description 6

- 238000005094 computer simulation Methods 0.000 description 6

- 238000000844 transformation Methods 0.000 description 6

- 229910000859 α-Fe Inorganic materials 0.000 description 6

- 229910001563 bainite Inorganic materials 0.000 description 5

- 230000001419 dependent effect Effects 0.000 description 5

- 229910052782 aluminium Inorganic materials 0.000 description 4

- 229910052742 iron Inorganic materials 0.000 description 4

- PIGFYZPCRLYGLF-UHFFFAOYSA-N Aluminum nitride Chemical compound [Al]#N PIGFYZPCRLYGLF-UHFFFAOYSA-N 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 229910000734 martensite Inorganic materials 0.000 description 3

- 150000002739 metals Chemical class 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 229910001562 pearlite Inorganic materials 0.000 description 3

- 235000019362 perlite Nutrition 0.000 description 3

- 239000010451 perlite Substances 0.000 description 3

- 239000002244 precipitate Substances 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- -1 aluminum nitrides Chemical class 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000000498 cooling water Substances 0.000 description 2

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 230000003111 delayed effect Effects 0.000 description 2

- 230000029142 excretion Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000005204 segregation Methods 0.000 description 2

- 239000011573 trace mineral Substances 0.000 description 2

- 235000013619 trace mineral Nutrition 0.000 description 2

- 230000001052 transient effect Effects 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 239000012491 analyte Substances 0.000 description 1

- 238000013528 artificial neural network Methods 0.000 description 1

- 244000052616 bacterial pathogen Species 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 238000009529 body temperature measurement Methods 0.000 description 1

- 238000004422 calculation algorithm Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- PMHQVHHXPFUNSP-UHFFFAOYSA-M copper(1+);methylsulfanylmethane;bromide Chemical compound Br[Cu].CSC PMHQVHHXPFUNSP-UHFFFAOYSA-M 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 230000035784 germination Effects 0.000 description 1

- 238000005098 hot rolling Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 238000010310 metallurgical process Methods 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000004801 process automation Methods 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000002269 spontaneous effect Effects 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

- 238000009628 steelmaking Methods 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 238000012360 testing method Methods 0.000 description 1

- 229910052718 tin Inorganic materials 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

- 238000012795 verification Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/16—Controlling or regulating processes or operations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/16—Controlling or regulating processes or operations

- B22D11/22—Controlling or regulating processes or operations for cooling cast stock or mould

- B22D11/225—Controlling or regulating processes or operations for cooling cast stock or mould for secondary cooling

Definitions

- the invention relates to a method for continuously casting a metal strand, in particular a steel strand, wherein a strand drawn from a cooled fürierlcokille supported in a continuous casting mold downstream strand support means and cooled with coolant and optionally reduced in thickness and in which method values of a simulation model are constantly counted and in the sequence on-line cooling is set.

- thermodynamic changes in state of the strand are considered with great accuracy in further development of the above method, so that caused by such thermodynamic changes in state, for example, the disadvantages are responsible for internal cracks or edge cracks, reliably avoided.

- thermodynamic state changes of the entire strand such as changes in the surface temperature, the center temperature, the shell thickness, and also the mechanical state, such as the deformation behavior, etc.

- thermodynamic state changes of the entire strand are constantly included in a mathematical simulation model by solving the heat equation and it is the cooling of the strand in Depending on the calculated value of at least one of the thermodynamic state variables set, for the simulation, the strand thickness and the chemical analysis of the metal and the continuously measured casting speed are taken into account.

- precipitation formation and phase transformations in the cast product depend on the cooling rate, the temperature level and the deformation kinetics. It has been observed, for example, that in the case of delayed charging of slabs into an oven, e.g. due to long transport time, surface cracks (cracks) occur on the rolled product, which are due to damage along the grain boundaries. In particular, this applies to Aluminiumnitridausscheidept, which excrete increasingly at the grain boundaries and there obstruct the mobility of the grains to each other. Hot forming produces high stresses at the grain boundaries which, in the case of such precipitates, result in cracks after rolling. The excretion of A1N in the stable ⁇ range depends on the temperature-time history. The phase transformation of ⁇ into ⁇ , at temperatures between 900 ° C and 720 ° C, leads to almost spontaneous precipitation of the non-equilibrium aluminum nitrides.

- Another cause of surface cracks are segregations of trace elements, such as S, Sn, Cu, etc., at the grain boundaries. These segregations result in hot brittleness of the rolled product after rolling.

- the crack intensity is directly related to the starting grain size, ie, the larger the grain, the higher will be the crack intensity.

- the initial grain size is generally larger than cold-charged slabs which experience complete conversion of ⁇ to ⁇ .

- this effect can be positively influenced by a targeted temperature-time control, in particular, a rapid cooling to about 500 ° C, the precipitation processes favorably influenced. That Concentrated precipitation of nitrides at the austenite core boundaries is suppressed and replaced by a volume uniform distribution. Depending on the steel analysis and time of the temperature treatment, a fine pearlitic or bainitic microstructure results. Despite a low global loss of strength increases the material toughness. Local softening at the primary austenite grain boundaries is avoided and thus cracking is suppressed. The effect applies to both A1N excretions and trace elements that cause hot brittleness.

- the temperature control according to the prior art usually according to theoretical predictions and calculations.

- the amounts of water are controlled so that at different casting speeds in about the same surface temperatures are achieved on the strand.

- a temperature measuring device is used as the feedback, which measures the surface temperature of the cast product before and after the intensive application of water. These values are compared with those calculated and from these the optimum amount of water is determined after appropriate tests.

- the water control is thus purely coupled with the casting speed. Changes that occur due to transient conditions (short changes in speed, casting start with a cold machine, casting, etc.), can not be influenced, unless one uses a permanent temperature measurement. For this purpose, measuring instruments usually have only a low accuracy of measurement and are strongly influenced in particular by scale, which is located on the surface of the cast product. The feedback is inaccurate, a uniform intensive application of water is therefore not possible.

- Another disadvantage relates to the fact that with greatly varying casting speeds the optimum length of the distance in which the strand is to be intensively cooled to achieve a certain depth of influence of intensive cooling must change and it is not sufficient to change only the amount of water , If one has only inaccurate temperature signals to specify the optimum length or depth of the influence, one never reaches a desired optimum.

- the DE 196 12 420 A1 describes a method for achieving improved strand cooling at varying strand speed, model parameters such as mold length, strand geometry, strand velocity, melting temperature, enthalation enthalpy and cooling water volume being taken into account for different cooling models.

- the thermal model is extended with the functionality of a neural network to accommodate modeling parameters.

- a thermal modeling of the casting process coupled with a metallurgical modeling to influence the material properties online is not addressed here.

- phase proportions to a desired extent, such as e.g. For a steel strand, ensure phase fractions of ferrite, perlite, bainite and martensite, on the cast product - before or after rolling.

- thermodynamic changes in the state of the strand are taken into account in that under transient casting conditions, the surface temperatures of the strand only slightly from metallurgically required setpoints differ. This happens because the values of a simulation model are constantly included in the calculation and, as a result, the coolant quantity is set as a function of the calculated value. From the essay "IDS, TEMPSIMU, CASIM - THREE WINDOW APPLICATIONS FOR CONTINUOUS CASTING OF STEEL", presented at the 12th IAS Steelmaking Seminar, November 2-5, 1999, wholesome Aires, a method of the type mentioned is known.

- an off-line solidification model IDS an off-line steady-state heat transfer model TEMPSIMU and a dynamic on-line model CASIM, eg for calculating the sump peak and for controlling the secondary cooling are shown.

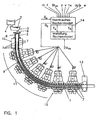

- the coupling of the models IDS, TEMPSIMU and CASIM is shown in FIG.

- the invention aims to avoid these disadvantages and difficulties and has set itself the task of further developing a continuous casting of the type described above in such a way that it is possible to pretend as the target formation of a desired microstructure of the metal, u.zw. for metals, i. Different chemical composition in steel continuous casting for all steel qualities to be cast or steel grades.

- thermodynamic state changes of the entire strand such as changes in surface temperature, center temperature, shell thickness by solving the equation of heat conduction and solving an equation describing the phase transformation kinetics constantly be taken into account and the cooling of the strand as a function of the calculated value of at least one of the thermodynamic Z is set for the simulation, the strand thickness and the chemical analysis of the metal and the continuously measured casting speed are taken into account; that a continuous phase transformation model of the metal is integrated into the calculation model, in particular according to Avrami; and that a current temperature TA calculated by the thermal calculation model is supplied on-line to the

- the Avrami equation describes in its general form all diffusion-controlled transformation processes for the respective temperature under isothermal conditions. By taking this equation into account in the calculation model, ferrite, pearlite and bainite fractions can be set in a very targeted manner during steel casting, u.zw. also taking into account a holding time at a certain temperature.

- the method is characterized in that with the calculation model thermal state changes of the entire strand, such as changes in surface temperature, the center temperature, the shell thickness, by solving the heat equation and solving a the Ausscheidungskinetik, in particular non-metallic and intermetallic precipitates, describing equation are constantly included and the cooling of the strand is set as a function of the calculated value of at least one of the thermodynamic state variables, wherein the strand thickness and the chemical analysis of the metal and the continuously measured casting speed are taken into account for the simulation, wherein advantageously the precipitation kinetics due to free phase energy and nucleation and use of thermodynamic parameters , in particular Gibb's energy, and Zener's germination is integrated into the computational model.

- Grain growth properties in particular taking into account recrystallization of the metal, are preferably integrated into the calculation model.

- dynamic and / or delayed and / or post recrystallization i. a recrystallization, which takes place later in an oven, are taken into account in the calculation model.

- a variable of the continuous casting influencing the structure formation is a on-line reduction in thickness prior to and / or after solidification of the strand in addition to the specific coolant quantity applied to the strand so that thermodynamic rolling, for example high-temperature rolling, also takes place during continuous casting.

- thermodynamic rolling at a surface temperature greater than A c3 can be considered.

- the mechanical state such as the deformation behavior

- the mechanical state is also always included in the calculation model by solving further model equations, in particular by solving the heat equation.

- a preferred embodiment is characterized in that quantitatively defined phase fractions are set by applying on-line calculated specific strand coolant amounts before and / or after the solidification of the strand.

- a defined microstructure is expediently set by applying an on-line calculated strand deformation before and / or after the solidification of the strand, which causes a recrystallization of the microstructure.

- An advantageous variant of the method according to the invention is characterized in that the specific final strand coolant quantity calculated after continuous casting of the strand in the end region of a secondary cooling zone in a cooling zone effecting enhanced cooling is set for the final casting phase conversion with setting of a quantitatively defined phase fraction of the strand.

- the calculation model to be used in accordance with the present invention calculates all the transformation temperatures and data necessary to predict and describe the transformation processes for the ferrite, perlite, bainite and martensite phase fractions.

- the temperature is defined as a function of time. Since the calculated conversion or precipitation fraction according to Avrami gives no information about the actual microstructure / quantity ratios, but only shows whether and how the equilibrium state is reached, the conversion components to the equilibrium lines from the iron / carbon are used to determine the structural component Diagram and also included in the calculation model. Nucleation events are accounted for due to the chemical Gibbs energy in the computational model (shown below for aluminum nitrides).

- ⁇ G chem ⁇ ⁇ G 0 AlN - R ⁇ T ⁇ ln X A ⁇ 1 + ln X N

- G 0 AlN is the standard Gibbs energy for the formation of AIN

- X A1 is the molar fraction of aluminum in the austenite volume

- X N is the average nitrogen content.

- ⁇ ⁇ G crit 16 ⁇ ⁇ 3 ⁇ ⁇ 2 ⁇ ⁇ G chem V AlN 2 gives the condition for nucleation again.

- ⁇ is the austenite / A1N interface energy.

- k B is the Boltzmann constant and D A1 is the spreading capacity of aluminum in austenite.

- Germ growth is considered according to Zener (for example, discussed in J. S. Kirkaldy, "Diffusion in the condensed state", The Universities Press, Harbor, 1985).

- the calculation process is carried out in two main stages. In the first stage, the number of germs currently formed is determined and in the second stage the growth of all previously formed precipitates is calculated.

- a steel strand 1 is formed from a molten steel 2 having a certain chemical composition by casting in a continuous casting mold 3.

- the molten steel 2 is poured from a ladle 4 via an intermediate vessel 5 and a pouring tube 6 extending from the tundish 5 into the continuous casting mold 3 by means of a pouring tube 6 formed in the casting mold 3 formed in the continuous casting mold 3.

- strand guide rollers 7 are provided for supporting the steel strand 1, which still has a liquid core 8 and initially only a very thin strand shell 9.

- the steel strand 1 emerging from the straight-through-die with a straight axis is deflected in a bending zone 10 into an arcuate path 11 and likewise supported therein by strand guide rollers 7.

- a directional zone 12 following the arcuate path 11 the steel strand 1 is again straightened and discharged via a discharge roller table or directly reduced in thickness on-line, e.g. by means of an on-line roll stand 13.

- this is cooled directly or indirectly - via strand guide rollers 7 provided with an internal cooling, whereby a certain temperature can be set on its surface up to a certain depth range.

- a computer 14 In the computer 14 are machine data m, the format f of the steel strand 1, material data, such as the chemical analysis St ch the molten steel 2, the casting state z, the casting speed v, the liquid steel temperature t fl , with the molten steel 2 enters the fürlglcolcille 3, and the desired microstructure ⁇ / ⁇ and optionally a deformation w of the steel strand 1, the way the strand guide is performed.

- This deformation can for example also be given by the straightening of the steel strand 1 in the straightening zone 12.

- the computer 14 is calculated using a metallurgical calculation model, which takes into account the phase conversion kinetics and nucleation kinetics according to the above-mentioned computational models, and a thermal calculation model that allows the temperature analysis due to the solution of the heat equation, a target amount of water Q s , u.zw. due to the current, already applied amount of water Q A , which is also entered into the computer.

- a metallurgical calculation model which takes into account the phase conversion kinetics and nucleation kinetics according to the above-mentioned computational models, and a thermal calculation model that allows the temperature analysis due to the solution of the heat equation, a target amount of water Q s , u.zw. due to the current, already applied amount of water Q A , which is also entered into the computer.

- the metallurgical calculation model takes into account the current steel analysis St ch in order to meet different material behavior.

- the current temperature T A calculated by the thermal calculation model is supplied on-line to the metallurgical calculation model and this continuously calculates the desired setpoint temperature T s , on the basis of which the thermal calculation model calculates and automatically sets the setpoint water quantity Q s for the individual strand cooling sections.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Treatment Of Steel In Its Molten State (AREA)

Abstract

Description

Die Erfindung betrifft ein Verfahren zum Stranggießen eines Metallstranges, insbesondere eines Stahlstranges, wobei ein Strang aus einer gekühlten Durchlauflcokille ausgezogen, in einer der Durchlaufkokille nachgeordneten Strangstützeinrichtung gestützt und mit Kühlmittel gekühlt sowie gegebenenfalls dickenreduziert wird und bei welchem Verfahren Werte eines Simulationsmodells ständig mitgerechnet werden und in der Folge on-line die Kühlung eingestellt wird.The invention relates to a method for continuously casting a metal strand, in particular a steel strand, wherein a strand drawn from a cooled Durchlauflcokille supported in a continuous casting mold downstream strand support means and cooled with coolant and optionally reduced in thickness and in which method values of a simulation model are constantly counted and in the sequence on-line cooling is set.

Es ist eine beim Stranggießen bekannte Anforderung, die Kühlung eines kontinuierlich gegossenen Stranges derart einzustellen, daß die Strangobertlächentemperatur vorgegebenen Werten, die gegebenenfalls vom Alter eines Querschnittselementes des Stranges abhängen, möglichst nahekommt. Dies ist insbesondere bei Strangverzögerungen und/oder Strangbeschleunigungen von besonderer Bedeutung.It is a known in continuous casting requirement to adjust the cooling of a continuously cast strand so that the Stangobertlächentemperatur given values that may depend on the age of a cross-sectional element of the strand as close as possible. This is of particular importance in particular for strand delays and / or strand accelerations.

Aus der AT-B - 300.238 ist ein Verfahren zum Kühlen eines aus einer Durchlaufkokille austretenden Stranges bekannt, wobei die Sollwerte der Kühlwassermenge in Abhängigkeit von der chemischen Zusammensetzung des Strangmaterials, der Erstarrungszeit und weiters in Abhängigkeit vom augenblicklichen Integralwert der Gießgeschwindigkeit während des Weges des Stranges bis zur jeweiligen Kühlzone eingestellt werden, so daß die Strangoberflächentemperatur vorbestimmbar bleibt.From AT-B-300.238 a method for cooling a strand emerging from a continuous casting mold is known, wherein the setpoints of the amount of cooling water, depending on the chemical composition of the strand material, the solidification time and further depending on the instantaneous integral value of the casting speed during the path of the strand be set to the respective cooling zone, so that the strand surface temperature remains pre-definable.

Weiters ist es aus der

Aus der

Diese bekannten Verfahren ermöglichen Korrekturen der Kühlinittelmengen, die in erster Linie von der Gießgeschwindigkeit abhängen, also gießgeschwindigkeitsabhängige Regelungen, wobei jedoch die tatsächlichen thermodynamischen Zustandsänderungen des Stranges unberücksichtigt bleiben. Der Stand der Technik berücksichtigt also nur - kommt es zu einem Abweichen der tatsächlichen Gießgeschwindigkeit von der Gießgeschwindigkeit, für die die Strangkühlung eingestellt ist - Tendenzen, ohne jedoch den tatsächlichen Verhältnissen gerecht zu werden.These known methods make it possible to correct the quantities of cooling agent which depend primarily on the casting speed, that is, casting-speed-dependent controls, but disregard the actual thermodynamic state changes of the strand. Thus, the prior art only takes into account - if the actual casting speed deviates from the casting speed for which the strand cooling is adjusted - tendencies are taken into account, but without doing justice to the actual conditions.

Gemäß der

Hierzu werden thermodynamische Zustandsänderungen des gesamten Stranges, wie Änderungen der Oberflächentemperatur, der Mittentemperatur, der Schalenstärke, und auch der mechanische Zustand, wie das Verformungsverhalten, etc., in einem mathematischen Simulationsmodell durch Lösen der Wärmeleitungsgleichung ständig mitgerechnet und es wird die Kühlung des Stranges in Abhängigkeit des errechneten Wertes mindestens einer der thermodynamischen Zustandsgrößen eingestellt, wobei für die Simulation die Strangdicke und die chemische Analyse des Metalles sowie die ständig gemessene Gießgeschwindigkeit berücksichtigt werden.For this purpose, thermodynamic state changes of the entire strand, such as changes in the surface temperature, the center temperature, the shell thickness, and also the mechanical state, such as the deformation behavior, etc., are constantly included in a mathematical simulation model by solving the heat equation and it is the cooling of the strand in Depending on the calculated value of at least one of the thermodynamic state variables set, for the simulation, the strand thickness and the chemical analysis of the metal and the continuously measured casting speed are taken into account.

Beim Direktverbund einer Stranggießanlage mit einem Walzwerk hängen Ausscheidungsbildung und Phasenumwandlungen im Gußprodukt von der Kühlrate, dem Temperaturniveau und von der Deformationskinetik ab. Es wurde beispielsweise beobachtet, daß im Falle eines zeitlich verzögerten Chargierens von Brammen in einen Ofen, z.B. infolge langer Transportzeit, Oberflächenrisse (Netzrisse) am Walzprodukt entstehen, welche auf eine Schädigung entlang der Korngrenzen zurückzuführen sind. Insbesondere trifft dies auf Aluminiumnitridausscheidungen zu, welche sich verstärkt an den Korngrenzen ausscheiden und dort die Mobilität der Körner zueinander behindern. Bei einer Warmumformung entstehen an den Korngrenzen hohe Spannungen, welche im Falle solcher Ausscheidungen in Rissen nach dem Walzen enden. Die Ausscheidung von A1N im stabilen γ-Bereich ist von der Temperatur-Zeitgeschichte abhängig. Durch die Phasenumwandlung von γ in α, bei Temperaturen zwischen 900°C und 720°C, kommt es zur annähernd spontanen Ausscheidung der sich nicht im Gleichgewicht befindlichen Aluminiumnitride.In the direct assembly of a continuous casting plant with a rolling mill, precipitation formation and phase transformations in the cast product depend on the cooling rate, the temperature level and the deformation kinetics. It has been observed, for example, that in the case of delayed charging of slabs into an oven, e.g. due to long transport time, surface cracks (cracks) occur on the rolled product, which are due to damage along the grain boundaries. In particular, this applies to Aluminiumnitridausscheidungen, which excrete increasingly at the grain boundaries and there obstruct the mobility of the grains to each other. Hot forming produces high stresses at the grain boundaries which, in the case of such precipitates, result in cracks after rolling. The excretion of A1N in the stable γ range depends on the temperature-time history. The phase transformation of γ into α, at temperatures between 900 ° C and 720 ° C, leads to almost spontaneous precipitation of the non-equilibrium aluminum nitrides.

Zur Vermeidung der mit A1N-Ausscheidungen verbundenen Nachteile ist es bekannt (

Eine andere Ursache von Oberflächenrissen sind Seigerungen von Spurenelementen, wie S, Sn, Cu etc., an den Korngrenzen. Diese Seigerungen resultieren in Heißbrüchigkeit des Walzproduktes nach dem Walzen. Die Rissintensität steht in einem direkten Zusammenhang mit der Ausgangskorngröße, d.h. je größer das Korn ist, umso höher wird die Rissintensität sein. In einem Direktverbundsystem ist die Ausgangskorngröße im allgemeinen größer als bei kalt chargierten Brammen, welche eine vollständige Umwandlung von γ in α erfahren.Another cause of surface cracks are segregations of trace elements, such as S, Sn, Cu, etc., at the grain boundaries. These segregations result in hot brittleness of the rolled product after rolling. The crack intensity is directly related to the starting grain size, ie, the larger the grain, the higher will be the crack intensity. In a direct composite system, the initial grain size is generally larger than cold-charged slabs which experience complete conversion of γ to α.

Auch dieser Effekt kann durch eine gezielte Temperatur-Zeitsteuerung positiv beeinflußt werden, wobei insbesondere eine rasche Abkühlung auf ca. 500°C die Ausscheidungsvorgänge günstig beeinflußt. D.h. eine konzentrierte Ausscheidung von Nitriden an den Austenitkomgrenzen wird unterdrückt und durch eine über das Volumen gleichmäßige Verteilung ersetzt. Je nach Stahlanalyse und Zeit der Temperaturbehandlung entsteht eine fein perlitische oder bainitische Gefügestruktur. Trotz einer geringen globalen Festigkeitseinbuße erhöht sich damit die Materialzähigkeit. Lokale Entfestigung an den primären Austenitkorngrenzen werden vermieden und folglich wird die Rißbildung unterdrückt. Der Effekt gilt sowohl für A1N-Ausscheidungen als auch für Spurenelemente, welche Heißbrüchigkeit hervorrufen.Also, this effect can be positively influenced by a targeted temperature-time control, in particular, a rapid cooling to about 500 ° C, the precipitation processes favorably influenced. That Concentrated precipitation of nitrides at the austenite core boundaries is suppressed and replaced by a volume uniform distribution. Depending on the steel analysis and time of the temperature treatment, a fine pearlitic or bainitic microstructure results. Despite a low global loss of strength increases the material toughness. Local softening at the primary austenite grain boundaries is avoided and thus cracking is suppressed. The effect applies to both A1N excretions and trace elements that cause hot brittleness.

Die Temperatursteuerung erfolgt gemäß dem Stand der Technik üblicherweise entsprechend theoretischer Vorhersagen und Berechnungen. Die Wassermengen werden so gesteuert, daß bei unterschiedlichen Gießgeschwindigkeiten in etwa gleiche Oberflächentemperaturen am Strang erreicht werden. Üblicherweise wird dazu als Rückkoppelung eine Temperaturmeßeinrichtung verwendet, welche die Oberflächentemperatur des Gußproduktes vor und nach der intensiven Wasserbeaufschlagung mißt. Diese Werte werden mit berechneten verglichen und daraus nach entsprechenden Versuchen die optimale Wassermenge bestimmt.The temperature control according to the prior art usually according to theoretical predictions and calculations. The amounts of water are controlled so that at different casting speeds in about the same surface temperatures are achieved on the strand. Usually, a temperature measuring device is used as the feedback, which measures the surface temperature of the cast product before and after the intensive application of water. These values are compared with those calculated and from these the optimum amount of water is determined after appropriate tests.

Die Wassersteuerung ist also rein mit der Gießgeschwindigkeit gekoppelt. Veränderungen, welche aufgrund von instationären Zuständen entstehen (kurze Geschwindigkeitsänderungen, Gießbeginn bei kalter Maschine, Gießende etc.), können damit nicht beeinflußt werden, außer man bedient sich einer permanenten Temperaturmessung. Hierzu dienende Messinstrumente haben üblicherweise nur eine geringe Meßgenauigkeit und werden stark inbesondere durch Zunder, welcher sich auf der Oberfläche des Gußproduktes befindet, beeinflußt. Die Rückkoppelung ist ungenau, ein gleichmäßiges intensives Beaufschlagen mit Wasser ist daher nicht möglich.The water control is thus purely coupled with the casting speed. Changes that occur due to transient conditions (short changes in speed, casting start with a cold machine, casting, etc.), can not be influenced, unless one uses a permanent temperature measurement. For this purpose, measuring instruments usually have only a low accuracy of measurement and are strongly influenced in particular by scale, which is located on the surface of the cast product. The feedback is inaccurate, a uniform intensive application of water is therefore not possible.

Ein weiterer Nachteil betrifft den Umstand, daß sich bei stark veränderten Gießgeschwindigkeiten die optimale Länge der Strecke, in der der Strang intensiv zu kühlen ist, zur Erzielung einer bestimmten Tiefe des Einflusses der intensiven Kühlung verändern muß und es nicht ausreicht, nur die Wassermenge zu verändern. Hat man zur Vorgabe der optimalen Länge bzw. Tiefe des Einflußbereiches nur ungenaue Temperatursignale, erreicht man nie ein angestrebtes Optimum.Another disadvantage relates to the fact that with greatly varying casting speeds the optimum length of the distance in which the strand is to be intensively cooled to achieve a certain depth of influence of intensive cooling must change and it is not sufficient to change only the amount of water , If one has only inaccurate temperature signals to specify the optimum length or depth of the influence, one never reaches a desired optimum.

Der Aufsatz H.P. Hougrady et al.; Möglichkeiten und Grenzen einer Simulation des Werkstoffverhaltens, Stahl und Eisen; Bd 116, Nr. 4 April 1996, Seiten 109 bis 113, gibt einen grundlegenden Überblick in Modelle, insbesondere physikalisch basierte Modelle, die zur Beschreibung von werkstoffkundlichen Vorgängen beim Verarbeiten von Metallen, insbesondere bei Walzprozessen, benutzt werden können. In diesem Dokument wird die Anwendbarkeit dieser Modelle zur Nachbildung von metallurgischen Vorgängen und deren Verifikation mit experimenteller Laborarbeit beschrieben. Hierdurch ist es möglich, sich grundlegend über physikalische Modelle zur Beschreibung von Phasenumwandlungen und Rekristallisation beim Walzumformen zu informieren. Ein Bezug auf eine Onlinemodellierung bzw. Regelung von Phasenumwandlungen des zu vergießenden Metalls in Stranggießanlagen ist in diesem Dokument nicht gegeben.The article H.P. Hougrady et al .; Possibilities and limits of a simulation of material behavior, steel and iron; Bd 116, No. 4 April 1996, pages 109 to 113, gives a basic overview of models, in particular physically based models, which can be used to describe materials science processes in the processing of metals, in particular in rolling processes. This document describes the applicability of these models to the simulation of metallurgical processes and their verification with experimental laboratory work. This makes it possible to learn fundamentally about physical models for describing phase transformations and recrystallization during roll forming. A reference to an online modeling or control of phase transformations of the metal to be cast in continuous casting plants is not given in this document.

Das Dokument C. Biegus et al.; Ermittlung von Werkstoffdaten zur Gefügesimulation, Stahl und Eisen, Bd 116 Nr. 5, 1996, Seiten 43 bis 49 zeigt Methoden auf, die es erlauben, Werkstoffeigenschaften experimentell zu ermitteln, die zur physikalisch basierten Modellierung von Phasenumwandlungen bzw. Rekristallisation notwendig sind.The document C. Biegus et al .; Determination of material data for microstructure simulation, steel and iron, Bd 116 No. 5, 1996, pages 43 to 49 shows methods that allow to experimentally determine material properties that are necessary for the physically based modeling of phase transformations or recrystallization.

Die

In der

Gemäß der

Gemäß dem Stand der Technik wird die Stahlqualität nicht berücksichtigt. Dies hat zur Folge, daß manche (empfindliche) Stahlgüten überkühlt und unnötig thermisch beansprucht werden. Andererseits wird bei manch anderer Stahlsorte der gewünschte Effekt der Phasenumwandlung nicht erreicht. Insbesondere ist es nicht möglich, Phasenanteile in einem gewünschten Ausmaß, wie z.B. für einen Stahlstrang Phasenanteile an Ferrit, Perlit, Bainit und Martensit, am Gußprodukt - vor oder nach einer Walzung - sicherzustellen.According to the state of the art, steel quality is not considered. This has the consequence that some (sensitive) steel grades are overcooled and unnecessarily thermally stressed. On the other hand, with some other types of steel the desired effect of phase transformation is not achieved. In particular, it is not possible to add phase proportions to a desired extent, such as e.g. For a steel strand, ensure phase fractions of ferrite, perlite, bainite and martensite, on the cast product - before or after rolling.

Ein Verfahren der eingangs beschriebenen Art ist aus der

Die Erfindung bezweckt die Vermeidung dieser Nachteile und Schwierigkeiten und stellt sich die Aufgabe, ein Stranggießverfahren der eingangs beschriebenen Art dahingehend weiterzuentwickeln, daß es möglich ist, als Zielvorgabe die Ausbildung eines gewünschten Gefüges des Metalls vorgeben zu können, u.zw. für Metalle, d.h. unterschiedlicher chemischer Zusammensetzung beim Stahl-Stranggießen für sämtliche zu gießenden Stahlqualitäten bzw. Stahlgüten. Beim Stahl-Stranggießen soll es inbesondere möglich sein, eine bestimmte Ferrit-, Perlit-Struktur einzustellen und/oder Ausscheidungen, wie Aluminiumnitridausscheidungen, an den Korngrenzen zu vermeiden.The invention aims to avoid these disadvantages and difficulties and has set itself the task of further developing a continuous casting of the type described above in such a way that it is possible to pretend as the target formation of a desired microstructure of the metal, u.zw. for metals, i. Different chemical composition in steel continuous casting for all steel qualities to be cast or steel grades. In the case of continuous steel casting, it should be possible in particular to set a specific ferrite, perlite structure and / or to avoid precipitations, such as aluminum nitride precipitations, at the grain boundaries.

Diese Aufgabe wird bei einem Verfahren der eingangs beschriebenen Art dadurch gelöst, daß zur Ausbildung eines gewünschten Gefüges im gegossenen Strang das Stranggießen unter on-line-Berechnung unter Zugrundelegung eines die Ausbildung des gewünschten Gefüges des Metalles beschreibenden Rechenmodells durchgeführt wird, wobei die Gerugeausbildung beinflussende Variable des Stranggießverfahrens, wie zum Beispiel die zur Kühlung des Stranges vorgesehene spezifische Kühlmittelmenge, on-line-dynamisch, d.h. während des laufenden Gießens eingestellt werden, und dass mit dem Rechenmodell thermodynamische Zustandsänderungen des gesamten Stranges, wie Änderungen der Oberflächentemperatur, der Mittentemperatur, der Schalenstärke durch Lösen der Wärmeleitungsgleichung und Lösen von einer die Phasen-Umwandlungskinetik beschreibenden Gleichung ständig mitgerechnet werden und die Kühlung des Stranges in Abhängigkeit des errechneten Wertes mindestens einer der thermodynamischen Zustandsgrößen eingestellt wird, wobei für die Simulation die Strangdicke und die chemische Analyse des Metalles sowie die ständig gemessene Gießgeschwindigkeit berücksichtigt werden;

dass in das Rechenmodell ein kontinuierliches Phasen-Umwandlungsmodell des Metalles integriert ist, insbesondere nach Avrami;

und dass eine durch das thermische Rechenmodell errechnete aktuelle Temperatur TA on-line dem metallurgischen Rechenmodell zugeführt wird und dieses laufend die gewünschte Soll-Temperatur TS errechnet, aufgrund der das thermische Rechenmodell die Soll-Wassermenge QS für die einzelnen Strangkühlungsabschnitte errechnet und automatisch einstellt.This object is achieved in a method of the type described above, characterized in that the formation of a desired microstructure in the cast strand, the continuous casting is carried out under on-line calculation on the basis of a formation of the desired structure of the metal descriptive computer model, wherein the noise education influential variable the continuous casting process, such as the specific coolant quantity provided for cooling the strand, being on-line dynamically, ie adjusted during ongoing casting; and that with the computational model, thermodynamic state changes of the entire strand, such as changes in surface temperature, center temperature, shell thickness by solving the equation of heat conduction and solving an equation describing the phase transformation kinetics constantly be taken into account and the cooling of the strand as a function of the calculated value of at least one of the thermodynamic Z is set for the simulation, the strand thickness and the chemical analysis of the metal and the continuously measured casting speed are taken into account;

that a continuous phase transformation model of the metal is integrated into the calculation model, in particular according to Avrami;

and that a current temperature TA calculated by the thermal calculation model is supplied on-line to the metallurgical calculation model and this continuously calculates the desired nominal temperature TS, on the basis of which the thermal calculation model calculates and automatically sets the desired amount of water QS for the individual strand cooling sections.

Durch die erfindungsgemäße Koppelung der Berechnung der Temperatur des Stranges mit dem Rechenmodell, das die Ausbildung eines bestimmten zeit- und temperaturabhängigen Gefüges des Metalles beinhaltet, ist es möglich, die Variablen des Stranggießverfahrens, die die Gerugeausbildung beeinflussen, wie z.B. die auf die Strangoberfläche aufzubringende Kühlmittelmenge, der chemischen Analyse des Metalles, sowie der örtlichen Temperaturgeschichte des Stranges anzupassen. Hierdurch kann gezielt eine gewünschte Gefügestruktur im weitesten Sinn (Korngröße, Phasenausbildung, Ausscheidungen) im oberflächennahen Bereich des Stranges erreicht werden.By coupling the computation of the temperature of the strand with the computational model involving the formation of a particular time- and temperature-dependent microstructure of the metal, it is possible to use the variables of the continuous casting process which influence the formation of the groove, e.g. to adapt the amount of coolant to be applied to the strand surface, the chemical analysis of the metal, as well as the local temperature history of the strand. In this way, a desired microstructure in the broadest sense (particle size, phase formation, precipitations) in the near-surface region of the strand can be achieved in a targeted manner.

Die Avrami-Gleichung beschreibt in ihrer allgemeinen Form alle diffusionsgesteuerten Umwandlungsvorgänge für die jeweilige Temperatur unter isothermen Bedingungen. Durch Berücksichtigung dieser Gleichung im Rechenmodell können ganz gezielt beim Stahl-Stranggießen Ferrit-, Perlit- und Bainit-Anteile eingestellt werden, u.zw. auch unter Berücksichtigung einer Haltezeit bei bestimmter Temperatur.The Avrami equation describes in its general form all diffusion-controlled transformation processes for the respective temperature under isothermal conditions. By taking this equation into account in the calculation model, ferrite, pearlite and bainite fractions can be set in a very targeted manner during steel casting, u.zw. also taking into account a holding time at a certain temperature.

Vorzugsweise ist das Verfahren dadurch gekennzeichnet, daß mit dem Rechenmodell thermische Zustandsänderungen des gesamten Stranges, wie Änderungen der Oberflächentemperatur, der Mittentemperatur, der Schalenstärke, durch Lösen der Wärmeleitungsgleichung und Lösen einer die Ausscheidungskinetik, insbesondere nichtmetallischer und intermetallischer Ausscheidungen, beschreibenden Gleichung ständig mitgerechnet werden und die Kühlung des Stranges in Abhängigkeit des errechneten Wertes mindestens einer der thermodynamischen Zustandsgrößen eingestellt wird, wobei für die Simulation die Strangdicke und die chemische Analyse des Metalles sowie die ständig gemessene Gießgeschwindigkeit berücksichtigt werden, wobei vorteilhaft die Ausscheidungskinetik aufgrund freier Phasenenergie und Keimbildung und Verwendung thermodynamischer Grundgrößen, insbesondere der Gibb'schen Energie, und das Keimwachstum nach Zener in das Rechenmodell integriert ist.Preferably, the method is characterized in that with the calculation model thermal state changes of the entire strand, such as changes in surface temperature, the center temperature, the shell thickness, by solving the heat equation and solving a the Ausscheidungskinetik, in particular non-metallic and intermetallic precipitates, describing equation are constantly included and the cooling of the strand is set as a function of the calculated value of at least one of the thermodynamic state variables, wherein the strand thickness and the chemical analysis of the metal and the continuously measured casting speed are taken into account for the simulation, wherein advantageously the precipitation kinetics due to free phase energy and nucleation and use of thermodynamic parameters , in particular Gibb's energy, and Zener's germination is integrated into the computational model.

Zweckmäßig werden auch Gefügcmengenverhältnisse in Gleichgewichtszuständen gemäß Mehrstoffsystem-Diagrarnmen, insbesondere gemäß Fe-C-Diagramm, in das Rechenmodell integriert.Appropriately Gefügcmengenverhältnisse in equilibrium states according to multi-material Diagrarnmen, in particular according to Fe-C diagram, are integrated into the calculation model.

Vorzugsweise sind in das Rechenmodell Kornwachstumseigenschaften, insbesondere unter Berücksichtigung von Rekristallisation des Metalles, integriert. Hierbei kann eine dynamische und/oder verzögerte und/oder eine post-Rekristallisation, d.h. eine Rekristallisation, die später in einem Ofen stattfindet, im Rechenmodell berücksichtigt werden.Grain growth properties, in particular taking into account recrystallization of the metal, are preferably integrated into the calculation model. Here, dynamic and / or delayed and / or post recrystallization, i. a recrystallization, which takes place later in an oven, are taken into account in the calculation model.

Vorzugsweise wird als die Gefügeausbildung beeinflussende Variable des Stranggießens eine während des Ausförderns des Stranges stattfindende Dickenreduktion vor und/oder nach Durcherstarrung des Stranges zusätzlich zur den Strang beaufschlagenden spezifischen Kühlmittelmenge on-line eingestellt, so daß auch während des Stranggießens stattfindende thermodynamische Walzungen, beispielsweise Hochtemperatur-thermodynamische Walzungen bei einer Oberflächentemperatur größer Ac3 berücksichtigt werden können.Preferably, a variable of the continuous casting influencing the structure formation is a on-line reduction in thickness prior to and / or after solidification of the strand in addition to the specific coolant quantity applied to the strand so that thermodynamic rolling, for example high-temperature rolling, also takes place during continuous casting. thermodynamic rolling at a surface temperature greater than A c3 can be considered.

Weiters wird vorzugsweise mit dem Rechenmodell auch der mechanische Zustand, wie das Verformungsverhalten, durch Lösen weiterer Modellgleichungen, insbesondere durch Lösen der Wärmeleitgleichung ständig mitgerechnet.Furthermore, the mechanical state, such as the deformation behavior, is also always included in the calculation model by solving further model equations, in particular by solving the heat equation.

Eine bevorzugte Ausführungsform ist dadurch gekennzeichnet, daß mengenmäßig definierte Phasenanteile durch Aufbringen on-line errechneter spezifischer Strang-Kühlmittelmengen vor und/oder nach der Durcherstarrung des Stranges eingestellt werden.A preferred embodiment is characterized in that quantitatively defined phase fractions are set by applying on-line calculated specific strand coolant amounts before and / or after the solidification of the strand.

Weiters wird zweckmäßig ein definiertes Gefüge durch Aufbringen einer on-line errechneten Strangverformung vor und/oder nach der Durcherstarrung des Stranges, welche eine Rekristallisation des Gefüges bewirkt, eingestellt.Furthermore, a defined microstructure is expediently set by applying an on-line calculated strand deformation before and / or after the solidification of the strand, which causes a recrystallization of the microstructure.

Eine vorteilhafte Variante des erfindungsgemäßen Verfahrens ist dadurch gekennzeichnet, daß die zur das Stranggießen abschließende Phasenumwandlung mit Einstellung eines mengenmäßig definierten Phasenanteiles des Stranges errechnete spezifische Strang-Kühlmittelmenge nach Durcherstarrung des Stranges im Endbereich einer Sekundärkühlzone in einer eine verstärkte Kühlung bewirkenden Kühlzone eingestellt wird.An advantageous variant of the method according to the invention is characterized in that the specific final strand coolant quantity calculated after continuous casting of the strand in the end region of a secondary cooling zone in a cooling zone effecting enhanced cooling is set for the final casting phase conversion with setting of a quantitatively defined phase fraction of the strand.

Die Erfindung ist nachfolgend für das Stahlstranggießen näher erläutert. Eine Anwendung des erfindungsgemäßen Verfahrens für andere Metalle kann analog zu den nachstehenden Ausführungen vorgenommen werden.The invention is explained in more detail below for the steel strand casting. An application of the method according to the invention for other metals can be carried out analogously to the following statements.

Das erfindungsgemäß zu verwendende Rechenmodell läßt aufgrund einer vorgegebenen chemischen Analyse des Stahls, der Austenitkomgröße und der Temperaturgeschichte des Stranges sämtliche Umwandlungstemperaturen und -daten, die zur Vorhersage und Beschreibung der Umwandlungsvorgänge für die Phasenanteile Ferrit, Perlit, Bainit und Martensit notwendig sind, berechnen.The calculation model to be used in accordance with the present invention, based on a given chemical analysis of the steel, austenite size and temperature history of the strand, calculates all the transformation temperatures and data necessary to predict and describe the transformation processes for the ferrite, perlite, bainite and martensite phase fractions.

Hierfür wird zunächst ein Kohlenstoffäquivalent für die einzelnen Legierungsbestandteile errechnet. Daraus ergeben sich analysenabhängige Starttemperaturen für die Ferritumwandlung, für die Perlitumwandlung, die Bainitbildung und die Martensitbildung (aufgrund des Eisen/KohIcnstoff-Diagramms).For this purpose, a carbon equivalent for the individual alloy components is first calculated. This results in analyte-dependent starting temperatures for the ferrite transformation, for the pearlite transformation, the bainite formation and the martensite formation (on the basis of the iron / carbon diagram).

Aufgrund der Avrami-Gleichung, die in ihrer allgemeinen Form alle diffusionsgesteuerten Umwandlungsvorgänge für die jeweilige Temperatur unter isothermen Bedingungen beschreibt, lassen sich Grundgleichungen für die Umwandlungskurven ermitteln.

worin X der Mengenanteil der umgewandelten Phase und b und n Parameter bedeuten, die abhängig sind von der Keimbildung und dem Wachstum der gebildeten Phase. Diese Parameter b und n sind analysenabhängig und können durch Dilatometer-Versuche bestimmt werden. Im Zusammenhang mit ZTU-Diagrammen lassen sich mit Hilfe der Avrami-Gleichung sowohl die Start- und die Endzeit als auch die Temperatur für die Ferrit-, Perlit- und Bainit-Umwandlung unter isothermischen Bedingungen berechnen.Based on the Avrami equation, which describes in its general form all diffusion-controlled transformation processes for the respective temperature under isothermal conditions, basic equations for the transformation curves can be determined.

where X is the proportion of the converted phase and b and n are parameters which are dependent on the nucleation and the growth of the phase formed. These parameters b and n are analysis-dependent and can be determined by dilatometer experiments. In the context of ZTU diagrams, the Avrami equation can be used to calculate both the start and end times as well as the temperature for ferrite, perlite and bainite transformation under isothermal conditions.

Um nicht-isothermische Umwandlungen zu berücksichtigen, also die in der Stranggießanlage stattfindende - gegebenenfalls auch ungleichmäßig stattfindende - Kühlung des Stranges voll berücksichtigen zu können, wird aufgrund der im Rechner gespeicherten ZTU-Schaubilder und der Abhängigkeit der Temperatur als eine Funktion der Zeit der Anteil an umgewandeltem Material berechnet, u.zw. durch eine Integration der Avrami-Gleichung über die Kühlzeit des Stranges (vgl. T.T. Pham, E.B. Hawbolt, J.K. Brimacombe: "Preciding the onset of transformation under non continuous cooling conditions. II Application to austenite - pearlite transformation", Met. Mat. Trans. A, 26A, pp. 1993-2000, 1995).

wobei ts(T) eine virtuelle Beginnzeit der Umwandlung bei einer Temperatur T in Übereinstimmung zur tatsächlich umgewandelten Menge bedeutet.In order to take into account non-isothermal transformations, that is, to fully take into account the cooling of the strand taking place in the continuous casting plant - possibly also unevenly taking place - the fraction becomes due to the ZTU graphs stored in the computer and the dependence of the temperature as a function of time converted material, u.zw. by integrating the Avrami equation over the cooling time of the strand (see TT Pham, EB Hawbolt, JK Brimacombe: "Preciding the onset of transformation under non-continuous cooling conditions.", Application of austenite-pearlite transformation, Met. Mat. Trans A, 26A, pp. 1993-2000, 1995).

where t s (T) means a virtual start time of the conversion at a temperature T in accordance with the actually converted amount.

Für diesen Berechnungsalgorithmus wird die Temperatur als Funktion der Zeit definiert. Da der berechnete Umwandlungs- bzw. Ausscheidungsanteil nach Avrami keine Auskunft über die tatsächlichen Gefüge/Mengen-Verhältnisse gibt, sondern lediglich erkennen läßt, ob und wie der Gleichgewichtszustand erreicht wird, werden zur Bestimmung des Gefügeanteils die Umwandlungsanteile auf die Gleichgewichtslinien aus dem Eisen/Kohlenstoff-Diagramm bezogen und ebenfalls im Rechenmodell berücksichtigt.

Keimbildungsvorgänge werden aufgrund der chemischen Gibb'schen Energie bzw. Phasenenergie im Rechenmodell berücksichtigt (nachstehend für Aluminiumnitride gezeigt).

wobei G0 AlN die Standard Gibb'sche Energie für die Bildung von AIN, XA1 der Molanteil von Aluminium im Austenitvolumen und XN der Durchschnittsstickstoffgehalt bedeuten. Die Keimbildungsrate läßt sich wie folgt berechnen:

worin S die Dichte der Keimbildung im Austenit bedeutet.

gibt die Bedingung für die Keimbildung wieder. Hierin ist σ die Austenit/A1N-Grenzflächenenergie. kB ist die Boltzmannkonstante und DA1 das Ausbreitungsvermögen von Aluminium in Austenit.For this calculation algorithm, the temperature is defined as a function of time. Since the calculated conversion or precipitation fraction according to Avrami gives no information about the actual microstructure / quantity ratios, but only shows whether and how the equilibrium state is reached, the conversion components to the equilibrium lines from the iron / carbon are used to determine the structural component Diagram and also included in the calculation model.

Nucleation events are accounted for due to the chemical Gibbs energy in the computational model (shown below for aluminum nitrides).

where G 0 AlN is the standard Gibbs energy for the formation of AIN, X A1 is the molar fraction of aluminum in the austenite volume and X N is the average nitrogen content. The nucleation rate can be calculated as follows:

where S is the density of nucleation in austenite.

gives the condition for nucleation again. Here, σ is the austenite / A1N interface energy. k B is the Boltzmann constant and D A1 is the spreading capacity of aluminum in austenite.

Das Keimwachstum wird nach Zener berücksichtigt (z.B. abgehandelt in J.S. Kirkaldy, "Diffusion in the condensed state", The Universities Press, Belfast, 1985).Germ growth is considered according to Zener (for example, discussed in J. S. Kirkaldy, "Diffusion in the condensed state", The Universities Press, Belfast, 1985).

Das Rechenverfahren geht in zwei Hauptstufen vor sich. In der ersten Stufe wird die Anzahl der aktuell gebildeten Keime bestimmt und in der zweiten Stufe wird das Wachstum aller vorhergehend gebildeten Ausscheidungen berechnet.The calculation process is carried out in two main stages. In the first stage, the number of germs currently formed is determined and in the second stage the growth of all previously formed precipitates is calculated.

Zur weiteren Erläuterung der Erfindung dient die beiliegende Figur.To further explain the invention, the accompanying figure is used.

Gemäß dieser wird ein Stahlstrang 1 aus einer Stahlschmelze 2 mit einer bestimmten chemischen Zusammensetzung durch Gießen in einer Durchlaufkokille 3 gebildet. Die Stahlschmelze 2 wird aus einer Gießpfanne 4 über ein Zwischengefäß 5 und ein vom Zwischengefäß 5 mittels eines unter den in der Durchlaufkokille 3 gebildeten Gießspiegel reichenden Gießrohres 6 in die Durchlaufkokille 3 gegossen. Unterhalb der Durchlaufkokille 3 sind Strangführungsrollen 7 zur Abstützung des Stahlstranges 1 vorgesehen, der noch einen flüssigen Kern 8 und zunächst eine nur sehr dünne Strangschale 9 aufweist.According to this, a

Der aus der Durchlaufkokille mit gerader Achse austretende Stahlstrang 1 wird in einer Biegezone 10 in eine Kreisbogenbahn 11 umgelenkt und in dieser ebenfalls durch Strangführungsrollen 7 gestützt. In einer der Kreisbogenbahn 11 nachfolgenden Richtzone 12 wird der Stahlstrang 1 wiederum geradegerichtet und über einen Auslaufrollgang ausgefördert oder direkt on-line dickenreduziert, z.B. mittels eines on-line angeordneten Walzgerüstes 13.The

Zur Kühlung des Stahlstranges 1 wird dieser direkt oder indirekt - über mit einer Innenkühlung versehene Strangführungsrollen 7 - gekühlt, wodurch an seiner Oberfläche bis in einen gewissen Tiefenbereich eine bestimmte Temperatur eingestellt werden kann.For cooling the

Die Versorgung des Stahlstranges 1 mit der für das gewünschte Gefüge des Stahlstranges 1 notwendigen Kühlmittelmenge erfolgt über einen geschlossenen oder offenen Regelkreis mittels eines Rechners 14. In den Rechner 14 werden Maschinendaten m, das Format f des Stahlstranges 1, Materialdaten, wie die chemische Analyse Stch der Stahlschmelze 2, der Gießzustand z, die Gießgeschwindigkeit v, die Flüssigstahltemperatur tfl, mit der die Stahlschmelze 2 in die Durchlauflcolcille 3 eintritt, sowie das gewünschte Gefüge α/γ und gegebenenfalls eine Verformung w des Stahlstranges 1, die am Wege der Strangführung durchgeführt wird, eingegeben. Diese Verformung kann z.B. auch durch das Geraderichten des Stahlstranges 1 in der Richtzone 12 gegeben sein.The supply of the

In dem Rechner 14 wird anhand eines metallurgischen Rechenmodells, das die Phasenumwandlungskinetik und Keimbildungskinetik gemäß der oben angegebenen Rechenmodelle berücksichtigt, und eines thermischen Rechenmodells, das die Temperaturanalyse aufgrund der Lösung der Wärmeleitungsgleichung ermöglicht, eine Soll-Wassermenge Qs errechnet, u.zw. aufgrund der aktuellen, bereits aufgebrachten Wassermenge QA, die ebenfalls in den Rechner eingegeben wird.In the

Eine Lösung der Wärmeleitungsgleichung mittels eines Prozeßrechners ist Stand der Technik und z.B. in der

Das metallurgische Rechenmodell berücksichtigt die aktuelle Stahlanalyse Stch, um unterschiedlichen Werkstoffverhalten gerecht zu werden. Die durch das thermische Rechenmodell errechnete aktuelle Temperatur TA wird on-line dem metallurgischen Rechenmodell zugeführt und dieses errechnet laufend die gewünschte Soll-Temperatur Ts, aufgrund der das thermische Rechenmodell die Soll-Wassermenge Qs für die einzelnen Strangkühlungsabschnitte errechnet und automatisch einstellt.The metallurgical calculation model takes into account the current steel analysis St ch in order to meet different material behavior. The current temperature T A calculated by the thermal calculation model is supplied on-line to the metallurgical calculation model and this continuously calculates the desired setpoint temperature T s , on the basis of which the thermal calculation model calculates and automatically sets the setpoint water quantity Q s for the individual strand cooling sections.

Claims (10)

- Method for the continuous casting of a metal strip, in particular of a steel strip (1), wherein a strip (1) is extracted from a cooled open-ended mould (3), is supported in a strip-supporting means (7, 11) arranged downstream of the open-ended mould (3) and is cooled with a coolant as well as optionally reduced in thickness and in which method values of a simulation model are permanently included in the calculation and, subsequently, cooling is adjusted on-line, characterized in that, to form a desired texture within the cast strip, continuous casting is carried out by an on-line calculation based upon an arithmetic model describing the formation of the desired texture of the metal, wherein variables of the continuous casting method affecting the formation of the texture, such as, e.g., the specific amount of coolant provided for cooling the strip, are adjusted in an on-line dynamic fashion, i.e. while casting takes place; in that thermodynamic changes of state of the entire strip such as changes in surface temperature, central temperature, shell thickness are permanently included in the calculation of the arithmetic model by solving the heat conduction equation and solving an equation describing the phase transition kinetics and the cooling of the strip is adjusted as a function of the calculated value of at least one of the thermodynamic state quantities, wherein, for simulation, the strip thickness and the chemical analysis of the metal as well as the continuously measured casting rate are taken into account; in that a continuous phase transition model of the metal is integrated in the arithmetic model, in particular in accordance with Avrami; and in that a current temperature TA, calculated by the thermal arithmetic model, is fed online to the metallurgical arithmetic model and the latter continuously calculates the desired setpoint temperature TS, on the basis of which the thermal arithmetic model calculates and automatically sets the setpoint amount of water QS for the individual strip cooling sections.

- Method according to Claim 1, characterized in that thermal changes of state of the entire strip such as changes in surface temperature, central temperature, shell thickness are permanently included in the calculation of the arithmetic model by solving the heat conduction equation and solving an equation describing the precipitation kinetics, in particular of nonmetallic and intermetallic precipitations, and the cooling of the strip is adjusted as a function of the calculated value of at least one of the thermodynamic state quantities, wherein, for simulation, the strip thickness and the chemical analysis of the metal as well as the continuously measured casting rate are taken into account.

- Method according to Claim 2, characterized in that the precipitation kinetics due to free phase energy and nucleus formation and the use of thermodynamic primary quantities, in particular Gibbs' energy, and the nucleus growth according to Zener are integrated in the arithmetic model.

- Method according to one or several of Claims 1 to 3, characterized in that quantitative relations of texture in conditions of equilibrium according to diagrams of multicomponent systems, in particular according to the Fe-C diagram, are also integrated in the arithmetic model.

- Method according to one or several of Claims 1 to 4, characterized in that grain growth characteristics, especially in consideration of the recrystallization of the metal, are integrated in the arithmetic model.

- Method according to one or several of Claims 1 to 5, characterized in that, as a variable of continuous casting affecting the formation of the texture, a reduction in thickness occurring during the discharge of the strip is adjusted on-line prior to and/or after complete solidification of the strip in addition to the specific amount of coolant supplied to the strip.

- Method according to one or several of Claims 1 to 6, characterized in that the mechanical state such as the deformation behaviour is also permanently included in the calculation of the arithmetic model by solving further model equations, in particular by solving the heat conduction equation.

- Method according to one or several of Claims 1 to 7, characterized in that quantitatively defined phase portions are adjusted prior to and/or after complete solidification of the strip by applying specific amounts of strip coolant, which have been calculated on-line.

- Method according to one or several of Claims 1 to 8, characterized in that a defined texture is adjusted prior to and/or after complete solidification of the strip by applying a strip deformation, which has been calculated on-line and causes recrystallization of the texture.

- Method according to one or several of Claims 1 to 8, characterized in that a final phase transition, optionally in consideration of a subsequent retransition, is adjusted after complete solidification of the strip in a cooling zone causing enhanced cooling.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT01942855T ATE346706T1 (en) | 2000-06-02 | 2001-06-01 | METHOD FOR CONTINUOUS CASTING A METAL STRAND |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0097200A AT409352B (en) | 2000-06-02 | 2000-06-02 | METHOD FOR CONTINUOUSLY casting a METAL STRAND |

| AT9722000 | 2000-06-02 | ||

| PCT/AT2001/000183 WO2001091943A1 (en) | 2000-06-02 | 2001-06-01 | Method for continuously casting a metal strand |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1289691A1 EP1289691A1 (en) | 2003-03-12 |

| EP1289691B1 EP1289691B1 (en) | 2006-11-29 |

| EP1289691B2 true EP1289691B2 (en) | 2012-07-11 |

Family

ID=3683713

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01942855A Expired - Lifetime EP1289691B2 (en) | 2000-06-02 | 2001-06-01 | Method for continuously casting a metal strand |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1289691B2 (en) |

| AT (2) | AT409352B (en) |

| DE (1) | DE50111555D1 (en) |

| WO (1) | WO2001091943A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022201922A1 (en) | 2022-02-24 | 2023-08-24 | Sms Group Gmbh | Method for planning and/or controlling and/or regulating a manufacturing process in a metallurgical production plant with several consecutive process steps |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT411026B (en) * | 2001-11-30 | 2003-09-25 | Voest Alpine Ind Anlagen | METHOD FOR CONTINUOUS CASTING |

| DE102005036068A1 (en) * | 2005-08-01 | 2007-02-08 | Siemens Ag | Modeling method for the time course of the state of a steel volume by a computer and corresponding objects |

| DE102004001037A1 (en) * | 2004-01-03 | 2005-07-28 | Sms Demag Ag | Diversified control of secondary cooling of a continuous casting plant |

| AT413951B (en) * | 2004-06-11 | 2006-07-15 | Voest Alpine Ind Anlagen | METHOD FOR CONTINUOUSLY GASING A METAL STRUCTURE |

| DE102006056683A1 (en) | 2006-01-11 | 2007-07-12 | Sms Demag Ag | Continuous casting of metal profiles, first cools cast strip then permits thermal redistribution to re-heat surface before mechanical deformation |

| DE102007058109A1 (en) * | 2007-12-03 | 2009-06-04 | Sms Demag Ag | Device for controlling or regulating a temperature |

| AT506976B1 (en) * | 2008-05-21 | 2012-10-15 | Siemens Vai Metals Tech Gmbh | METHOD FOR CONTINUOUSLY GASING A METAL STRUCTURE |

| AT506847B1 (en) * | 2008-05-21 | 2011-07-15 | Siemens Vai Metals Tech Gmbh | METHOD FOR CONTINUOUSLY GASING A METAL STRUCTURE |

| DE102009048567B4 (en) | 2008-10-23 | 2022-07-21 | Sms Group Gmbh | Method and arrangement for cooling a cast strand in a continuous casting plant |

| DE102008055650A1 (en) | 2008-10-29 | 2010-05-06 | Sms Siemag Aktiengesellschaft | Method for minimizing energy demand and carbon dioxide ejection in a continuous furnace arranged downstream to a thin-slab plant, comprises entering material dependent cool strategy and threshold value in model calculator |

| AT507590A1 (en) † | 2008-11-20 | 2010-06-15 | Siemens Vai Metals Tech Gmbh | METHOD AND CONTINUOUS CASTING SYSTEM FOR MANUFACTURING THICK BRAMMS |

| DE102009049897B4 (en) | 2009-10-20 | 2023-09-14 | Sms Group Gmbh | Method and device for continuously casting a metal strand |

| KR101806819B1 (en) * | 2011-02-07 | 2017-12-08 | 프리메탈스 테크놀로지스 오스트리아 게엠베하 | Method for regulating a temperature or a temperature profile of a strand by positioning a movable cooling nozzle in a strand guide of a strand casting system |

| DE102011082158A1 (en) | 2011-09-06 | 2013-03-07 | Sms Siemag Ag | Casting, in particular continuous casting |

| EP2633929A1 (en) | 2012-03-01 | 2013-09-04 | Siemens Aktiengesellschaft | Modelling of a casting-rolling assembly |

| DE102013212713A1 (en) | 2013-06-28 | 2014-12-31 | Sms Siemag Ag | A method for casting a metal strand and method for determining the temperature of a cast metal strand |

| DE102015223788A1 (en) | 2015-11-30 | 2017-06-01 | Sms Group Gmbh | Method of continuous casting of a metal strand and cast strand obtained by this method |

| DE102017213842A1 (en) * | 2017-08-08 | 2019-02-14 | Sms Group Gmbh | Method and plant for continuous casting of a metallic product |

| CN118404021B (en) * | 2024-06-27 | 2024-09-24 | 江西铜业集团铜板带有限公司 | Ultrathin copper plate and strip process control optimization method |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE759738A (en) * | 1969-12-03 | 1971-05-17 | Schloemann Ag | PROCESS FOR COOLING BAR MATERIAL COMING OUT OF AN OPEN-END LINGOTIER AND DEVICE FOR CARRYING OUT THIS PROCESS |

| AT408197B (en) * | 1993-05-24 | 2001-09-25 | Voest Alpine Ind Anlagen | METHOD FOR CONTINUOUSLY casting a METAL STRAND |

| US5697423A (en) * | 1994-03-30 | 1997-12-16 | Lauener Engineering, Ltd. | Apparatus for continuously casting |

| DE19508476A1 (en) * | 1995-03-09 | 1996-09-12 | Siemens Ag | Control system for a plant in the basic material or processing industry or similar |

| DE19612420C2 (en) * | 1996-03-28 | 2000-06-29 | Siemens Ag | Method and device for controlling the cooling of a strand in a continuous caster |

-

2000

- 2000-06-02 AT AT0097200A patent/AT409352B/en not_active IP Right Cessation

-

2001

- 2001-06-01 WO PCT/AT2001/000183 patent/WO2001091943A1/en active IP Right Grant

- 2001-06-01 EP EP01942855A patent/EP1289691B2/en not_active Expired - Lifetime

- 2001-06-01 AT AT01942855T patent/ATE346706T1/en not_active IP Right Cessation

- 2001-06-01 DE DE50111555T patent/DE50111555D1/en not_active Expired - Lifetime

Non-Patent Citations (2)

| Title |

|---|

| 12th IAS Steelmaking Seminar, 2. - 5.11.1999, Buenos Aires, S. 488-497 † |

| Automation & Process Control Session - Paper No. 44, A. 1-6, Mai 1996 † |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022201922A1 (en) | 2022-02-24 | 2023-08-24 | Sms Group Gmbh | Method for planning and/or controlling and/or regulating a manufacturing process in a metallurgical production plant with several consecutive process steps |

| EP4235318A1 (en) | 2022-02-24 | 2023-08-30 | SMS Group GmbH | Method for planning and/or controlling a production process in a metallurgical production plant, involving several sequential process steps |

Also Published As

| Publication number | Publication date |

|---|---|

| AT409352B (en) | 2002-07-25 |

| EP1289691B1 (en) | 2006-11-29 |

| ATE346706T1 (en) | 2006-12-15 |

| WO2001091943A1 (en) | 2001-12-06 |

| ATA9722000A (en) | 2001-12-15 |

| DE50111555D1 (en) | 2007-01-11 |

| EP1289691A1 (en) | 2003-03-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1289691B2 (en) | Method for continuously casting a metal strand | |

| EP3184202B1 (en) | Method for continuously casting a metal strand | |

| EP2753439B1 (en) | Casting method, more particularly continuous casting method | |

| AT408623B (en) | METHOD FOR MONITORING AND CONTROLLING THE QUALITY OF ROLLING PRODUCTS FROM HOT ROLLING PROCESSES | |

| EP3096896B1 (en) | Method for optimally producing metal steel and iron alloys in hot-rolled and thick plate factories using a microstructure simulator, monitor, and/or model | |

| AT408197B (en) | METHOD FOR CONTINUOUSLY casting a METAL STRAND | |

| DE102019208736A1 (en) | Method for casting a cast strand in a continuous caster | |

| EP1448330B1 (en) | Method for continuous casting | |

| DE60125562T2 (en) | METHOD OF MANUFACTURING REQUESTED STEEL BANDS | |

| WO2023089012A1 (en) | Method for the production of a hot-rolled strip from a fine-grained steel material | |

| EP3384260B1 (en) | Method and system for the open-loop and/or closed-loop control of a heating of a cast or rolled metal product | |

| EP3733323A1 (en) | Method and continuous casting plant for casting a cast strand | |