EP1247462A2 - Procédé et dispositif de génération d'une information concernant les propriétés d'un courant de fibres - Google Patents

Procédé et dispositif de génération d'une information concernant les propriétés d'un courant de fibres Download PDFInfo

- Publication number

- EP1247462A2 EP1247462A2 EP02005838A EP02005838A EP1247462A2 EP 1247462 A2 EP1247462 A2 EP 1247462A2 EP 02005838 A EP02005838 A EP 02005838A EP 02005838 A EP02005838 A EP 02005838A EP 1247462 A2 EP1247462 A2 EP 1247462A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- fiber strand

- signal

- fiber

- evaluation

- strand

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/32—Separating, ordering, counting or examining cigarettes; Regulating the feeding of tobacco according to rod or cigarette condition

- A24C5/34—Examining cigarettes or the rod, e.g. for regulating the feeding of tobacco; Removing defective cigarettes

- A24C5/3412—Examining cigarettes or the rod, e.g. for regulating the feeding of tobacco; Removing defective cigarettes by means of light, radiation or electrostatic fields

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/14—Machines of the continuous-rod type

- A24C5/18—Forming the rod

- A24C5/1871—Devices for regulating the tobacco quantity

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S131/00—Tobacco

- Y10S131/905—Radiation source for sensing condition or characteristic

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S131/00—Tobacco

- Y10S131/906—Sensing condition or characteristic of continuous tobacco rod

Definitions

- the invention relates to a device and a method for generating a statement about at least one property of a fiber strand of the tobacco processing industry Industry, especially a tobacco rod.

- DE 38 01 115 C2 describes a method and a device for determining the Density of a fiber strand by using a nuclear probe to produce a first Density signals and additionally an optical measuring head, in particular an infrared measuring head, used to generate a second density signal undesirable influences such as the type and color of the tobacco forming the fiber strand remove.

- DE 38 01 115 C2 corresponds to US-PS 48 65 054.

- DE 28 42 461 C2 describes a method and an arrangement for recognizing and Localizing malfunctions on cigarette making machines is known, wherein Test signals for the occurrence of different, one specific Characteristic signal components assigned to the machine element are monitored become. For this purpose, several test signals can be evaluated and related to each other be set, using a nuclear measuring head as a test signal generator becomes.

- DE 28 42 461 C2 corresponds to US-PS 42 80 187.

- DE 39 17 606 A1 In a method and an apparatus for producing cigarettes according to the DE 39 17 606 A1 describes a density measurement signal and at least one further measurement signal, which indicates another property of the tobacco rod, in legal Connected from which selected cigarette properties are shown, of which tensile resistance, burn-off time, nicotine content, condensate content, Carbon monoxide content and hardness are mentioned.

- DE 39 17 606 A1 corresponds to US Pat. No. 4,967,739.

- DE 197 05 260 A1 describes a method and an arrangement for detecting at least one property of a substance, in particular the wet mass and / or the dry weight of tobacco, by evaluating the by the presence of the Substance caused detuning a radio frequency resonator described Microwaves are supplied from a corresponding radiation source. This becomes generates a high-frequency signal influenced by the substance Resonance frequency shift and damping compared to one of the material uninfluenced reference signal can be determined to determine the property of the To be able to determine the substance.

- DE 197 05 260 A1 corresponds to US Pat. No. 6,163 158th

- US 4,638,817 A describes a tobacco delivery control, the two radiometric Has density sensors, from whose signals a differential signal is formed. If this difference signal exceeds a limit that is considered normal, an alarm signal is generated.

- EP 0 339 250 B1 describes a system for controlling the tobacco filling quantity in one Cigarette manufacturing machine described, which is a first radiometric Density measuring device in front of a trimmer and a second radiometric density measuring device at a point where the already wrapped tobacco rod passes, and a forward control and a control loop, the actuator of which is the trimmer, having.

- EP 0 339 250 B1 corresponds to US Pat. No. 4,920,987.

- EP 0 793 425 B1 discloses a method and an apparatus for Diagnosing mechanical problems in cigarette manufacturing. This is a Weight sensor provided from its signals by means of fast Fourier frequency analysis Error messages are generated that may be abnormal Show condition.

- EP 0 793 425 B1 corresponds to US Pat. No. 5,582,192.

- the object of the present invention is to provide an apparatus and a method of to propose the type mentioned at the beginning, which makes it possible to make a statement about the fiber structure and in particular about deviations from a medium fiber structure to obtain.

- a device is proposed according to the invention a first measuring device to form an essentially only the density of the Fiber strand indicating first measurement signal, a second measuring device for Forming an essentially a function of density of the fiber strand and Second measurement signal representing fiber shape and an evaluation device which the first and second measurement signals provide information about the fiber structure, especially the deviations from a medium fiber structure, indicating Evaluation signal determined.

- this object is achieved with a method with the steps of an essentially only the first measurement signal indicating the density of the fiber strand generate a second measurement signal that essentially performs a function Density of the fiber strand and fiber shape represents, and from the first and second Measurement signals provide information about the fiber structure, especially the deviations of an average fiber structure to determine the evaluation signal.

- a first radiation source is preferably used to penetrate the fiber strand Beta and / or microwave radiation emitted and after penetration of the fiber strand is detected by a first sensor, which in the generates essentially only the first measuring signal indicating the density of the fiber strand.

- a first measurement signal for the density of the fiber strand with beta or Microwave radiation generated on the fiber strand which has so far been in the rest at least some of the aforementioned known methods and devices as The basis for the weight control served.

- infrared light radiation penetrating the fiber strand is preferred emitted by a second radiation source and detected by a second sensor, which is a function of the density of the fiber strand and fiber shape representative second measurement signal generated.

- the second measurement signal is Absorption of infrared light generated by the fiber strand. This is due to the infrared light absorption obtained second measurement signal is not only of density, but also to a large extent on the shape of the fibers and especially on the Fiber length dependent.

- weight control is based on this structure dependency based on infrared light absorption failed.

- the infrared light absorption also depends on the fiber shape. Because by Linkage with that which essentially only indicates the density of the fiber strand first measurement signal, which thus represents an essentially 'pure' density signal According to the invention, the desired evaluation signal from the infrared light absorption won, which is essentially determined only by the fiber shape.

- this evaluation signal falls below or below a limit value to be regarded as normal a fault in the process flow can be concluded.

- the evaluation device should preferably emit a corresponding warning signal.

- the fault areas can be expanded accordingly by further configurations enclose.

- the difference between the first and second measurement signals can be determined.

- the fiber structure is formed by forming the difference value between which essentially represents a pure density signal first measurement signal and the density-dependent and structure-dependent second Measurement signal determined.

- the first and second measuring devices can along the transport path of the Fiber strand can be arranged one behind the other, the order of arrangement is basically arbitrary.

- the first and second Measurement signals determined on the finished fiber strand.

- the first measurement signal which essentially only indicates the density, can preferably additionally also as an actual value for a control device for controlling the Weight of the fiber strand to be used.

- a device for Production of the fiber strand and a subsequent device for transport and are provided for wrapping the fiber strand produced stands out characterized in that a third measuring device to form an essentially only the Density of the fiber strand indicating third measurement signal in the manufacturing device, preferably at the exit, the first and second are provided Measuring devices on the transport device after the covering of the fiber strand are arranged and the evaluation device additionally the third measurement signal used.

- a third measuring device to form an essentially only the Density of the fiber strand indicating third measurement signal in the manufacturing device, preferably at the exit

- the first and second are provided Measuring devices on the transport device after the covering of the fiber strand are arranged and the evaluation device additionally the third measurement signal used.

- an infrared light radiation can be used.

- Comparison can be recognized. For example, in a double strand machine Comparison of the two strands on an anomalous final mix or an anomalous one Tobacco destruction in a tobacco path, for example due to component wear, getting closed. Furthermore, a comparison between different Machines that are fed by the same feeder are closed that the currently created tababmi mix no longer complies with the norm if all machines show approximately the same deviation, or that one machine There is a fault on the way from the feeder to the cigarette machine, if only at a deviation is determined in a machine, for example from a incorrect adjustment or component wear results.

- a pre-distributor 2 is loaded with loose tobacco in portions from a lock 1.

- a removal roller 3 of the pre-distributor 2 supplements a storage container 4 in a controlled manner with tobacco, from which an endless belt and various in Fig. 1 Unspecified roles of guided steep conveyor 5 takes tobacco and one Storage shaft 6 is fed in a controlled manner.

- a pin roller 7 takes out of the storage shaft 6 a uniform flow of tobacco from a knockout roller 8 from the pins of Pin roller 7 knocked out and onto an endless belt over various in Fig. 1st Unspecified rollers guided and at constant speed peripheral scattering cloth 9 is thrown.

- a formed on the spreading cloth 9 Tobacco fleece is thrown into a classifying device 11, which is an air curtain generated, the larger or heavy parts of tobacco pass while everyone else Tobacco particles from the air flow of the air curtain into one of a pin roller 12 and a wall 13 formed funnel 14 are directed.

- the tobacco is transferred from the pin roller 12 into a tobacco duct 16 against a strand conveyor 17 hurled, on which the tobacco by means of a vacuum chamber 18th sucked air is kept and piled up as a tobacco rod.

- a leveler or Trimmer 19 which essentially consists of a pair of in the plane of the transport direction of the tobacco rod arranged, rotating letters and a deflector , removes excess tobacco from the tobacco rod by the leveler 19 separates the excess tobacco and thus the tobacco rod thus formed cut a desired thickness.

- the tobacco rod is then placed on a cigarette paper strip that is guided in synchronization 21 laid.

- the cigarette paper strip 21 is pulled off a bobbin 22 by a printing unit 23 guided, via various roles not shown in FIG. 1 transported and placed on a driven format belt 24. That too as Endless belt provided and guided over several roles, not shown Format tape 24 transports the tobacco rod and the cigarette paper strip 21 through a format 26 in which the cigarette paper strip 21 around the tobacco rod is folded so that an edge protrudes from a not shown Glue apparatus is glued in a known manner. Then the adhesive seam is closed and dried from a tandem seam sheet 27.

- a cigarette rod 28 thus formed passes through a rod density measuring device 29, which Equalizer 19 controls, and is of a knife apparatus 31 in double length Cut 32 cigarettes.

- the double-length cigarettes 32 are from one Controlled arms 33 having a transfer device 34 of a transfer drum 36 passed to a filter attachment machine 37, on the cutting drum 38 of which they are a circular knife into individual cigarettes.

- About unspecified Rolling endless conveyor belts 39, 41 convey excess tobacco into one below the storage container 4 arranged container 42, from which the recirculated Tobacco is removed again from the steep conveyor 5.

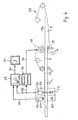

- FIG. 2 schematically shows an arrangement or measuring arrangement for determining the Fiber structure or tobacco structure of that produced in a machine according to FIG. 1 Tobacco rod shown.

- FIG. 2 The arrangement of FIG. 2 is implemented in the machine of FIG. 1. Accordingly, in FIG. 2 the strand conveyor 17 already shown in FIG. 1 is shown again, which consists of an endless belt which is guided over a plurality of rollers, which are not described in more detail.

- the lower run 17a of the strand conveyor 17 runs in the transport direction A of the tobacco rod S.

- the vacuum chamber 18 (not shown in FIG. 2, but indicated in FIG. 1), the tobacco T is against the underside of the lower strand 17a Strand conveyor 17 sucked and held there, as shown in FIG. 2.

- the leveler 19 which, as has already been explained with reference to FIG. 1, separates excess tobacco T R to form the tobacco rod S.

- FIG. 2 A section of the format tape 24 from the machine according to FIG. 1 is also shown in FIG. 2.

- the format tape 24 takes over the tobacco rod S from the strand conveyor 17 and thus also serves, inter alia, as a transport device downstream of the strand conveyor 17.

- the cigarette paper strip 21 carried by the format tape 24 is omitted in FIG. 2.

- a first measuring device 50 in front of the knife apparatus 31, which in Fig. 1 is arranged.

- the first measuring device 50 has a first radiation source 52, which is a beta or microwave radiation penetrating the tobacco rod S. transmits, and a first sensor 54, which is on the opposite Side of the continuous tobacco rod S is arranged and the radiation after penetration of the tobacco rod S and a first measurement signal 56 emits.

- the first measuring device 50 is a second one Downstream of the measuring device 60, which the tobacco rod S also passes through.

- the second measuring device 60 has a second radiation source 62 which transmits infrared light emits the tobacco rod S, and a second sensor 64 which detects the infrared light after penetration of the tobacco rod S detected and a corresponding second Measurement signal 66 generated.

- the second sensor 64 is related to FIG second radiation source 62 also on the opposite side of the Tobacco strand S arranged, as can also be seen in FIG. 2.

- the first measuring signal 56 generated by the first measuring device 50 is concerned is a signal for tobacco density, while this is due to infrared light absorption second measurement signal 66 obtained by the second measuring device 60 not only by the Tobacco density, but also to a large extent from the tobacco structure and in particular depends on the fiber length.

- the first and second are in a downstream evaluation device 68 Measuring signals 56 and 66 evaluated so that an evaluation signal 70 is generated therefrom which gives a statement about the fiber structure.

- the evaluation device 68 the first and second measurement signals 56 and 66 to one another linked that with the help of essentially only the density of the tobacco rod S indicating the first measurement signal 56 the density from the second measurement signal 66 calculated out and thereby the evaluation signal 70 from the second measurement signal 66 is obtained, which is essentially determined only by the tobacco structure. This can preferably be done by forming the difference between the first and second Measurement signals 56 and 66 take place.

- the evaluation signal 70 is then sent from the evaluation device 68 to a monitoring device 72 transmitted, which may have a monitor, for example based on the evaluation signal 70, a statement about the fiber structure is made visible accordingly.

- a second embodiment is shown, which differs from the first embodiment 2 differs in that in the direction of movement of the tobacco rod S considered, the second measuring device 60 directly behind the equalizer 19 and thus in the exit area of the strand conveyor 17 and in front of the first measuring device 50 is arranged.

- the first Measurement signal 56 from the first measuring device 50 also for weight control is used.

- the first measurement signal 56 also serves as an actual signal for a controller 74, which generates a corresponding control signal 76, the one Actuator 78 controls with which the density and thus the weight of the tobacco rod S is set.

- FIG. 5 shows a fourth embodiment, which differs from the first embodiment 2 differs in that in addition to the first and second Measuring devices 50 and 60, a third measuring device 80 is provided, which approximately the same location as the second measuring device 60 in the second embodiment 3 sits.

- the third measuring device 80 has the same structure as that second measuring device 60, thus works optically using infrared red light and has a third radiation source 82 which penetrates the tobacco rod S. Infrared light radiation generated, and a third sensor 84, which is related to the Tobacco strand S sits on the opposite side and the infrared light radiation after penetration of the tobacco rod S detected and a corresponding third Measurement signal 86 generated.

- This third measurement signal 86 is in the evaluation device 68 compared to signal 66.

- the signals differ from each other, it will Deviation forwarded to the monitoring device 72 and there for display brought.

- the deviation of the signals 86 and 66 points to one of the tobacco rod S. between the third sensor 84 and the second sensor 64. This is one Indication of an incorrect setting or wear of the format 26 from FIG. 1.

- Fig. 6 is a system of four parallel working cigarette rod machines I to IV shown, for example in the manner of the embodiment shown in Fig. 1 can be trained.

- Each of these four machines I to IV has, among other things, one Measuring arrangement according to the first embodiment shown in FIG. 2, that in FIG. 6 For reasons of clarity, only in connection with machine IV in detail is shown.

- the machines are together is networked and is also a central comparison and analysis device 90 provided to which the evaluation devices 68 of the individual machines in each case are connected.

- the comparison and analysis device 90 evaluates the Evaluation signals from the individual machines in a comparative analysis and emits a corresponding data signal 92, on the one hand to the display device 72 returned to each machine and also to one not shown central data acquisition is transmitted.

- the comparative evaluation is particularly useful for double-strand machines where each strand of a twin strand machine is considered a separate machine becomes.

- the machines I and II and the Machines III and IV each form a double strand machine.

- FIG. 7 shows an example of a possible modification compared to the system of FIG. 6, which differs in that the fourth embodiment according to Fig. 5 is implemented in the individual machines, which for the sake of Clarity is again only shown using machine IV.

Landscapes

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10117081 | 2001-04-06 | ||

| DE10117081A DE10117081A1 (de) | 2001-04-06 | 2001-04-06 | Vorrichtung und Verfahren zur Erzeugung einer Aussage über die Eigenschaft(en) eines Faserstranges |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1247462A2 true EP1247462A2 (fr) | 2002-10-09 |

| EP1247462A3 EP1247462A3 (fr) | 2004-04-07 |

Family

ID=7680557

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02005838A Withdrawn EP1247462A3 (fr) | 2001-04-06 | 2002-03-14 | Procédé et dispositif de génération d'une information concernant les propriétés d'un courant de fibres |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US6814082B2 (fr) |

| EP (1) | EP1247462A3 (fr) |

| DE (1) | DE10117081A1 (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102987550A (zh) * | 2011-09-13 | 2013-03-27 | 豪尼机械制造股份公司 | 用于调节烟草加工业制品的至少一个参数的调节装置 |

| CN103442603A (zh) * | 2011-03-30 | 2013-12-11 | 豪尼机械制造股份公司 | 烟草加工业的棒状制品的至少一种物理特性的空间位置分辨的测量 |

| EP2873334B1 (fr) | 2013-11-19 | 2019-01-30 | Hauni Maschinenbau GmbH | Procédé et dispositif de détection de défauts d'homogénéité d'une tige de matériau de l'industrie de traitement du tabac |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10354759A1 (de) * | 2003-11-21 | 2005-06-30 | Hauni Maschinenbau Ag | Gleitschuh |

| DE102009056064A1 (de) * | 2009-11-30 | 2011-06-01 | Hauni Maschinenbau Ag | Leimauftrageinrichtung und -verfahren für eine Maschine der Tabak verarbeitenden Industrie |

| DE102012209954A1 (de) * | 2012-06-14 | 2013-12-19 | Hauni Maschinenbau Ag | Verfahren und Vorrichtung zur Erkennung von Stranginhomogenitäten eines Materialstrangs der Tabak verarbeitenden Industrie |

| DE102015105353A1 (de) | 2015-04-09 | 2016-10-13 | Hauni Maschinenbau Gmbh | Saugbandförderer und Strangmaschine der Tabak verarbeitenden Industrie, Verwendung und Verfahren zum Messen von Materialeigenschaften eines Materialstrangs der Tabak verarbeitenden Industrie |

| CN109187881A (zh) * | 2018-09-30 | 2019-01-11 | 云南中烟工业有限责任公司 | 一种口用型无烟气烟草制品品质表征方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2842461A1 (de) * | 1978-09-29 | 1980-04-10 | Hauni Werke Koerber & Co Kg | Verfahren und anordnung zum erkennen und lokalisieren von fehlfunktionen an stabfoermige rauchartikel herstellenden maschinen |

| DE3400410A1 (de) * | 1983-01-22 | 1984-07-26 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Verfahren und vorrichtung zum herstellen eines bewegten faserstrangs der tabakverarbeitenden industrie |

| DE3422434A1 (de) * | 1983-06-29 | 1985-01-03 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Verfahren und vorrichtung zum herstellen eines tabakstrangs |

| DE3801115A1 (de) * | 1987-01-31 | 1988-08-11 | Hauni Werke Koerber & Co Kg | Verfahren und vorrichtung zum bestimmen der dichte eines faserstrangs der tabakverarbeitenden industrie |

| EP0339250A1 (fr) * | 1988-04-28 | 1989-11-02 | Japan Tobacco Inc. | Dispositif de contrôle de la charge de tabac dans une machine de fabrication de cigarettes |

| EP0656181A2 (fr) * | 1993-12-03 | 1995-06-07 | G.D Societa' Per Azioni | Procédé et dispositif pour déterminer la densité d'un courant de matière fibreuse dans une machine de fabrication de cigarette |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60234575A (ja) | 1984-05-08 | 1985-11-21 | 日本たばこ産業株式会社 | シガレツト製造機の中味たばこ量制御装置 |

| US4920987A (en) | 1986-10-31 | 1990-05-01 | Japan Tobacco Inc. | Device for controlling the content of tobacco on a cigarette manufacturing machine |

| DE3725366A1 (de) * | 1987-07-31 | 1989-02-09 | Hauni Werke Koerber & Co Kg | Vorrichtung zur messung der dichte eines tabakstranges |

| DE3917606A1 (de) | 1988-06-11 | 1989-12-14 | Hauni Werke Koerber & Co Kg | Verfahren und vorrichtung zum herstellen von zigaretten |

| US4967739A (en) | 1988-06-11 | 1990-11-06 | Korber Ag | Method of and apparatus for making rod-shaped articles of the tobacco processing industry |

| US5582192A (en) | 1994-11-22 | 1996-12-10 | Lorillard Tobacco Company | Method and apparatus for diagnosing mechanical problems, particularly in cigarette makers |

| US6163158A (en) | 1996-02-20 | 2000-12-19 | Hauni Maschinenbau Ag | Method of and apparatus for ascertaining at least one characteristic of a substance |

| DE19705260B4 (de) | 1996-02-20 | 2008-12-24 | Hauni Maschinenbau Ag | Anordnung zum Erfassen mindestens einer dielektrischen Eigenschaft eines Stoffes |

| JP2000333663A (ja) * | 1999-05-25 | 2000-12-05 | Japan Tobacco Inc | 喫味用物品若しくはその部品の密度検出装置 |

-

2001

- 2001-04-06 DE DE10117081A patent/DE10117081A1/de not_active Withdrawn

-

2002

- 2002-03-14 EP EP02005838A patent/EP1247462A3/fr not_active Withdrawn

- 2002-04-05 US US10/116,120 patent/US6814082B2/en not_active Expired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2842461A1 (de) * | 1978-09-29 | 1980-04-10 | Hauni Werke Koerber & Co Kg | Verfahren und anordnung zum erkennen und lokalisieren von fehlfunktionen an stabfoermige rauchartikel herstellenden maschinen |

| DE3400410A1 (de) * | 1983-01-22 | 1984-07-26 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Verfahren und vorrichtung zum herstellen eines bewegten faserstrangs der tabakverarbeitenden industrie |

| DE3422434A1 (de) * | 1983-06-29 | 1985-01-03 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Verfahren und vorrichtung zum herstellen eines tabakstrangs |

| DE3801115A1 (de) * | 1987-01-31 | 1988-08-11 | Hauni Werke Koerber & Co Kg | Verfahren und vorrichtung zum bestimmen der dichte eines faserstrangs der tabakverarbeitenden industrie |

| EP0339250A1 (fr) * | 1988-04-28 | 1989-11-02 | Japan Tobacco Inc. | Dispositif de contrôle de la charge de tabac dans une machine de fabrication de cigarettes |

| EP0656181A2 (fr) * | 1993-12-03 | 1995-06-07 | G.D Societa' Per Azioni | Procédé et dispositif pour déterminer la densité d'un courant de matière fibreuse dans une machine de fabrication de cigarette |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103442603A (zh) * | 2011-03-30 | 2013-12-11 | 豪尼机械制造股份公司 | 烟草加工业的棒状制品的至少一种物理特性的空间位置分辨的测量 |

| CN103442603B (zh) * | 2011-03-30 | 2017-03-22 | 虹霓机械制造有限公司 | 烟草加工业的棒状制品的至少一种物理特性的空间位置分辨的测量 |

| CN102987550A (zh) * | 2011-09-13 | 2013-03-27 | 豪尼机械制造股份公司 | 用于调节烟草加工业制品的至少一个参数的调节装置 |

| CN102987550B (zh) * | 2011-09-13 | 2016-04-13 | 豪尼机械制造股份公司 | 用于调节烟草加工业制品的至少一个参数的调节装置 |

| EP2873334B1 (fr) | 2013-11-19 | 2019-01-30 | Hauni Maschinenbau GmbH | Procédé et dispositif de détection de défauts d'homogénéité d'une tige de matériau de l'industrie de traitement du tabac |

| EP2873334B2 (fr) † | 2013-11-19 | 2023-09-13 | Körber Technologies GmbH | Procédé et dispositif de détection de défauts d'homogénéité d'une tige de matériau de l'industrie de traitement du tabac |

Also Published As

| Publication number | Publication date |

|---|---|

| US20020144699A1 (en) | 2002-10-10 |

| EP1247462A3 (fr) | 2004-04-07 |

| US6814082B2 (en) | 2004-11-09 |

| DE10117081A1 (de) | 2002-10-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60116641T2 (de) | Verfahren und vorrichtung zur herstellung von zigaretten mit langsamer flammenausbreitung | |

| EP2243385B1 (fr) | Surveillance de capsule dans des filtres de l'industrie de traitement du tabac | |

| DE102009016500B4 (de) | Verfahren zum Betrieb einer Filterstrangmaschine und Filterstrangmaschine | |

| EP2238845B2 (fr) | Procédé de contrôle optique d'une bande de papier d'enveloppement de l'industrie de traitement du tabac | |

| EP0724846A1 (fr) | Procédé et dispositif de fabrication de cigarettes à filtre | |

| DE3149670A1 (de) | Vorrichtung zur herstellung eines fortlaufenden strangs zur verwendung in der zigarettenindustrie | |

| EP1480532A1 (fr) | Dispositif de mesure et de reglage simultanes en continu de la quantite d'acetate et de triacetine dans des bouts filtres dans la fabrication des cigarettes | |

| DE2815025C2 (de) | Verfahren und Anordnung zum Bilden eines Filterstranges | |

| DE4308093A1 (de) | Verfahren und Maschine zum Aufbereiten von Filtertowmaterial | |

| EP1247462A2 (fr) | Procédé et dispositif de génération d'une information concernant les propriétés d'un courant de fibres | |

| EP1325683B1 (fr) | Procédé et dispositif pour la production d'un courant de fibres dans l'industrie du tabac | |

| DE2800748A1 (de) | Verfahren und vorrichtung zum bilden eines stranges aus fasern aus tabak oder aus einem anderen rauchfaehigen material | |

| DE69817779T2 (de) | Einbringung von rauchmodifizierenden mitteln in rauchartikeln | |

| EP2026669A1 (fr) | Procédé pour faire fonctionner une machine de fabrication de boudins et machine de fabrication de boudins | |

| EP1649764B1 (fr) | Procédé et dispositif pour la production de filtres | |

| EP2570037A2 (fr) | Dispositif de réglage destiné à régler au moins un paramètre d'un article de l'industrie de traitement du tabac | |

| EP1275311A2 (fr) | Dispositif pour préparer un courant de fibres dans l'industrie du tabac | |

| DE10203095A1 (de) | Verfahren und Vorrichtung zum Messen des Durchmessers von Zigarettenstrang- oder stabförmigen Erzeugnissen der Tabak verarbeitenden Industrie | |

| EP3761811A1 (fr) | Convoyeur à bande d'aspiration et machine à boudins de l'industrie de traitement du tabac et utilisation d'un équipement de mesure dans un convoyeur à bande d'aspiration d'une machine à boudins de l'industrie de traitement du tabac | |

| EP1424016B1 (fr) | Bande transporteuse pour le transport d'une tige de produit de l'industrie du tabac | |

| DE3738983A1 (de) | Verfahren und vorrichtung zur herstellung eines faserstrangs der tabakverarbeitenden industrie | |

| DE2842969A1 (de) | Verfahren und anordnung zum bilden eines ueberwachungssignals an strangmaschinen der tabakverarbeitenden industrie | |

| EP1321049B1 (fr) | Méthode et appareil de mesure d'humidité de cigarettes avant l'empaquetage | |

| WO2019072625A1 (fr) | Dispositif et système pour fabriquer des produits en forme de tiges issus de l'industrie du tabac | |

| EP0284640B1 (fr) | Dispositif pour déterminer en continu deux propriétés physiques des éléments d'un article fumable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20040920 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20061003 |