EP1234618A1 - Vorrichtung und Verfahren zum Entfernen von mit von dem Boden geernteten Früchten vermischten Fremdkörpern - Google Patents

Vorrichtung und Verfahren zum Entfernen von mit von dem Boden geernteten Früchten vermischten Fremdkörpern Download PDFInfo

- Publication number

- EP1234618A1 EP1234618A1 EP01430008A EP01430008A EP1234618A1 EP 1234618 A1 EP1234618 A1 EP 1234618A1 EP 01430008 A EP01430008 A EP 01430008A EP 01430008 A EP01430008 A EP 01430008A EP 1234618 A1 EP1234618 A1 EP 1234618A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fruits

- foreign bodies

- conveyor

- dimensions

- bucket

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 235000013399 edible fruits Nutrition 0.000 title claims abstract description 121

- 238000000034 method Methods 0.000 title claims description 9

- 239000002689 soil Substances 0.000 title description 3

- 238000000605 extraction Methods 0.000 claims abstract description 4

- 238000012216 screening Methods 0.000 claims description 29

- 239000004575 stone Substances 0.000 claims description 13

- 230000001174 ascending effect Effects 0.000 claims description 8

- 230000000717 retained effect Effects 0.000 claims description 7

- 238000012549 training Methods 0.000 claims description 7

- 230000000694 effects Effects 0.000 claims description 5

- 230000008569 process Effects 0.000 claims description 4

- 230000005484 gravity Effects 0.000 claims description 3

- 238000011084 recovery Methods 0.000 claims 1

- 241000894007 species Species 0.000 description 15

- 238000003306 harvesting Methods 0.000 description 6

- 230000036961 partial effect Effects 0.000 description 6

- 208000031968 Cadaver Diseases 0.000 description 3

- 230000032258 transport Effects 0.000 description 3

- 241000207836 Olea <angiosperm> Species 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000005188 flotation Methods 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 244000144725 Amygdalus communis Species 0.000 description 1

- 235000014036 Castanea Nutrition 0.000 description 1

- 241001070941 Castanea Species 0.000 description 1

- 241000723382 Corylus Species 0.000 description 1

- 235000007466 Corylus avellana Nutrition 0.000 description 1

- 241001417527 Pempheridae Species 0.000 description 1

- 240000006711 Pistacia vera Species 0.000 description 1

- 244000007853 Sarothamnus scoparius Species 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 241000863032 Trieres Species 0.000 description 1

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 235000020224 almond Nutrition 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 230000002860 competitive effect Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 235000014571 nuts Nutrition 0.000 description 1

- 235000020233 pistachio Nutrition 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000000135 prohibitive effect Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/10—Screens in the form of endless moving bands

Definitions

- the present invention relates to a device and a method for separating the fruits harvested from the ground (such as, for example, olives, chestnuts, nuts, hazelnuts, almonds, pistachios, etc.) foreign bodies picked up with these: soil, stones, leaves, branches, twigs and others.

- fruits harvested from the ground such as, for example, olives, chestnuts, nuts, hazelnuts, almonds, pistachios, etc.

- Fruit harvesting on the ground is generally carried out by rotary brooms which equip the heads of harvesting machines. These sweepers pick up systematically all objects or bodies spilled on the ground up to the layer hard of it.

- Inclined vibrating screens are mounted one after the other. Fruits loaded with foreign bodies arrive on the first screen that will separate the fruits of smaller objects, soil and leaves, which will cross the meshes screen, while the fruits and larger objects, stones and twigs, go stay on the grid and be brought to the second screen placed after the first.

- This second screen is provided with a mesh grid of dimensions adapted to the size of the fruit. Only fruits and foreign bodies of dimensions equal to the fruit will cross this grid. Fruits and bodies remaining foreigners will then be collected and separated by flotation as explained previously.

- the object of the invention is to remedy this drawback and to provide a double sorting device easily embeddable on harvesting machines or on a mobile carrier, although the use in station of such a device is always possible.

- the method of the invention successively, during a same fall of the products to be sorted and by means of at least one endless conveyor openwork, a first screening of the harvested products which retains foreign bodies larger than the size of the largest fruits of the harvested species and which allows fruit and foreign bodies of equal dimensions to pass through or less than the size of these larger fruits, then a second screening which retains the fruit and which allows the passage of bodies of dimensions smaller than the size of the smallest fruits of the said species.

- the device according to the invention comprises first screening means having openings or meshes sized to retain the bodies strangers larger than the size of the largest fruits of the harvested species and allow fruit and foreign bodies of dimensions to pass equal to or less than the size of these larger fruits, and second screening means arranged below said first screening means and having openings or meshes sized to retain the fruit and allow foreign bodies of dimensions smaller than the size of the smaller fruits of said species, said first and second means of screening being carried out in the form of at least one openwork endless conveyor which also provides transportation for sorted fruit.

- This process and this machine allow the extraction of all the bodies foreigners with dimensions larger than the largest fruits and lower than smaller fruits.

- the double sorting of harvested products carried out during the same drop of said products provides the additional advantage of avoiding rework which cause fruit injury.

- the double sorting is carried out at by means of an openwork endless conveyor whose conveyor belt is configured so that its upper active strand has two superimposed screens or a first upper screen with dimensioned openings or meshes to retain foreign bodies larger than the size of the biggest fruits of the harvested hope and to let pass the fruits and the bodies aliens of dimensions equal to or less than the dimensions of these larger fruit and a second lower screen with openings or meshes sized to retain fruit and allow foreign bodies to pass through dimensions smaller than the smallest fruits, this sorting transporter ensuring also transporting the fruit to a collection device and, on the other part, transport and ejection of foreign bodies whose caliber is greater than size of the largest fruits and separated from them.

- the transporter endless openwork consists of a succession of openwork buckets assembled side by side, so as to produce a bucket conveyor.

- each bucket of the bucket conveyor is consisting of a volume defining a cage which is delimited, in its part top on which the crop to be sorted arrives, by a grid with openings or meshes allowing fruit and foreign bodies to pass through dimensions equal to or less than the size of the largest fruits and, in its lower part, by a grid whose holes are slightly dimensioned smaller than the size of the smallest fruits.

- the front face of the buckets in considering the direction of advancement of these, is constituted by a smooth plate along its entire length, so that the fruit rolls easily over it to be emptied when said buckets tip or, when passing a drum, the centrifugal force will be sufficient.

- the upper grid of the buckets is mounted with swivel ability, to facilitate the evacuation of fruit when the buckets tip over when the conveyor tip ends unending.

- the articulation of the grid upper is carried out on the bucket which precedes the bucket covered by it, of so as to allow a "scales" type assembly facilitating the evacuation of the bodies bulky foreigners in the ascending part of the conveyor.

- a floating ramp is arranged in a rising part of the bucket conveyor, this floating ramp fulfilling two functions: - on the one hand, it facilitates the training of bodies aliens who are sandwiched between the conveyor buckets and said floating ramp, uphill and, on the other hand, it provides a slide effect to deflect outwardly the foreign bodies that fall, in the climb of the conveyor, at the exit of the ramp.

- the sorting device comprises two endless belt conveyors, one external conveyor having openings or meshes sized to retain the bodies strangers larger than the size of the largest fruits of the harvested species and allow fruit and foreign bodies of dimensions to pass equal to or less than the dimensions of these larger fruits, and a transporter internal housed in said external conveyor and having openings or mesh sized to retain fruit and allow foreign bodies to pass through of dimensions smaller than the smallest fruits of said species, a space delimited by the external conveyor separating the discharge ends said endless conveyors, so as to allow the unloading of the fruit sorted.

- a first screening of the harvested products so as to retain the bodies strangers larger than the size of the largest fruits of the harvested species and to allow only the fruits and foreign bodies of dimensions equal to or less than the dimensions of these larger fruits, then a second screening which retains the fruit and lets the foreign bodies of dimensions smaller than the smallest fruits of said species.

- the device according to the invention is remarkable in that it comprises first screening means having openings or meshes dimensioned to retain foreign bodies of dimensions greater than the size of the largest fruits of the harvested species and let the fruits and foreign bodies of dimensions equal to or less than the size of these plus large fruits, and second screening means having openings or mesh sized to retain fruit and allow foreign bodies to pass through of dimensions smaller than the size of the smallest fruits of the said species, said first and second screening means being made in the form at least one openwork endless conveyor which also transports the fruits.

- Perforated openwork conveyor means any conveyor configured as an endless belt or belt with openings or meshes sized according to the size of the fruit of the species to be sorted, so that allow screening of the products spilled on said endless belt or belt.

- the device extraction of foreign bodies consists of an openwork endless conveyor whose conveyor belt 1 is configured so that its upper active strand 1A presents two superimposed screening systems, i.e. a first screening system upper screening with openings or meshes sized to pass only fruit and foreign bodies of equal dimensions or smaller than the size of the largest fruits and a second system of lower screening with openings or meshes sized for only allow foreign bodies of dimensions smaller than the size of the smallest fruits.

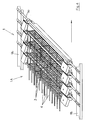

- this perforated sorting conveyor is constituted by a bucket conveyor comprising a succession of skeleton buckets assembled side by side.

- Each bucket 2 of this sorting conveyor consists of a volume defining a cage which is delimited, in its upper part on which arrives the crop to be sorted, by a grid 3 having openings or meshes 4 allowing only the fruits F and the foreign bodies of dimensions to pass equal to or less than the size of the largest fruits and, in its part lower, by a grid 5 whose holes or meshes 6 are of dimensions slightly smaller than the size of the smallest fruits.

- the bucket conveyor thus produced comprises a loading section 1C arranged horizontally or substantially horizontally and a section of 1D transport rising towards the discharge end 1E of said carrier.

- the buckets are made of steel grids, advantageously stainless. Their sides 7 on which are fixed, for example by welding, the bars of the lower grid 5 can be made of sheet metal.

- the cleaning efficiency of bodies smaller than the products to be sorted depends on the ratio between the surfaces full and the empty surfaces of the lower grid 5, that is to say that this grid must be made of the thinnest possible and most spaced bars possible, of course compatible with the size of the product to be sorted which must not not pass through said grid.

- the upper part of the bucket through which come and go the products to be sorted must consist of the smallest possible grid, so to limit as much as possible the entry into the bucket of bodies larger than the products sorting.

- the upper grid 3 of the buckets 2 is mounted with the ability to pivot around a horizontal or approximately horizontal axis, so to be able to occupy two positions, either: - a first position closed when the buckets are in the reception area 1C of the crop to be sorted and during their ascending path to the discharge end 1E, and, - a position open during their passage on said discharge end and during their return journey.

- the opening of the upper grid 3 of the buckets is obtained by the effect of the centrifugal force at the entry of the curve of the unloading zone 1E and this gate closes at the entrance to the reception area 1C, also by gravity or using a roller or pad fixedly installed on the frame supporting the carpet transporter sorter.

- the upper grid 3 of each bucket 2 is attached, by means of a joint 8, to the upper part of the bucket 2 which precedes the bucket covered by said grid.

- This characteristic arrangement which allows a mounting type scales facilitating the evacuation of bulky bodies in the ascending part of the conveyor, is visible in Figure 6 where we see the grid 3a fixed, by means of the articulation 8a, to the bucket 2a which precedes the bucket 2b covered by said grid.

- the front face of the buckets is constituted by a smooth plate 13 extending over the entire length said buckets and whose function is to facilitate the unloading of fruit when the bucket tilts.

- the sorting conveyor belt produced in the manner just described indicated is fixed on a carpet with bars 9 consisting of a succession of spaced bars 9a fixed, via their ends, to a pair 9b belts or chains.

- the pitch of the bars corresponds to the width of the buckets 2 which are fixed individually to said bars, preferably by means of one or more removable flanges 10.

- the movement of the sorting conveyor thus produced is controlled, from in a manner known per se, by one of its axes or motor shaft 11 which can be driven by a hydraulic motor (not shown) or otherwise.

- the sorting conveyor according to the invention is provided with means making it possible to subject the conveyor belt to vibrations in the loading and screening zone 1C.

- vibrations can be generated by the meeting of the bars transverse 9a of the drive belt 9 with rollers 12 free in rotation and supported by the chassis of the sorting conveyor.

- Fruits F and C1 foreign bodies of equal or smaller dimensions at the size of said fruits pass through the upper grid 3 of the cups which retain on the other hand stones or other foreign bodies C2 of dimensions greater than the size of the fruit. As they continue to fall, the fruits fall into the buckets and are retained by the lower grid 5 of these which leaves pass foreign bodies of dimensions equal to or less than the size of the fruits. After this double screening operated in the same fall, only remain in cups, fruit and foreign bodies of a size equal to that of said fruit and whose percentage compared to that of said fruits is low.

- the remaining fruits and foreign bodies are transported towards the unloading end 1E of the sorting conveyor which pours them into a bucket 14 or similar container, as a result of which said foreign bodies remaining are removed by a conventional method, for example, using a floatation separator.

- This function is fulfilled by an ejection slide 15 resting on the buckets 2, in the ascending portion 1D of the sorting conveyor 1.

- This slide 15 consists of a plate of width substantially equal to the width of the bucket conveyor and it is fixed, via its upper end and by means of joints 16 with a horizontal axis, at the end of a pair of symmetrical connecting rods 18 themselves fixed, via their end lower, and by means of articulations with horizontal axis 19, to the chassis 22 of the conveyor.

- the slide 15 rests, by gravity effect, on the upper grid 3 buckets 2. It is thus mounted floating on an ascending portion of the belt transporter sorter. It has a lower end or front end 15a curled up.

- the action of the ejection slide 15 can be supplemented by that of a release means covering the entire width of the bucket conveyor and making it possible to stop, detach buckets, and return to said slide, foreign bodies which have remained on said buckets after having exceeded the slide (mainly twigs or small branches that remain hung on the pan racks).

- This detachment means can advantageously consist of a cylindrical rotary brush 17 with horizontal axis perpendicular to the direction of the conveyor, installed above and near the upper end of the toboggan.

- the device of the invention can also advantageously include a branch drive system and / or a device to assist with stone training, extracted from products spilled in the area of reception of the conveyor-sorter.

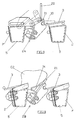

- the device for driving the branches ( Figures 8 and 9) is, according to the embodiment illustrated by way of advantageous example only, constituted by at least one special bucket or basket 2A mounted in place of a standard basket 2 of the bucket conveyor.

- This special 2A basket has a grid or comb pivoting upper 20 subject to means controlling its tilting, so that said drive grid 20 is open and oriented perpendicular or substantially perpendicular to the external surface of the sorting conveyor belt in the loading area 1C, and closed and oriented parallel or substantially to said external surface on the rest of the route from said sorting conveyor belt to the entrance to the loading area.

- This training grid extends over the entire width of the conveyor belt sorter 1, and basket 2A has no capacity for loading fruit.

- This basket is also topped with a fixed grid 23.

- the drive grid 20 retracts (traced in lines interrupted in Figure 9) and the branches are entrained by the stones on said slide and ejected from the sorting conveyor belt.

- FIG. 9 An example of the means to ensure the lifting of the grid drive 20 in a prominent position in the loading area 1C and its retraction out of said zone, is illustrated in FIG. 9.

- the assistance device for driving stones ( Figures 10 and 11) is, according to the embodiment illustrated as an advantageous example, also consisting of at least one special 2B basket mounted in place of a basket standard 2 of the bucket conveyor.

- This 2B basket does not have a grid pivoting upper, but a grid or fixed comb 21 arranged so prominent in relation to the external surface of the sorting conveyor belt.

- This fixed grid has a tilted back position relative to the path of the mat endless and it also extends over the entire width of the sorting conveyor belt 1, and the basket 2B has no capacity for loading fruit.

- This special basket is, moreover, surmounted by a fixed grid 24. It is understood that the grid or comb 21 allows you to train stones, wood, branches, etc. which are retained on the sorting conveyor belt, especially in the ascending zone of this one.

- FIG. 12 illustrates another embodiment of the device for extracting foreign bodies mixed with fruits harvested from the ground.

- the device consists of two carriers endless openwork, an external conveyor 31 and an internal conveyor 32 housed in the space delimited by said external transporter, so that said carriers have overlapping sections 31A and 32A, respectively, in the zone Z for the dumping of products P collected on the ground.

- the endless belt constituting the external conveyor 31 constitutes a first screening means and it has openings or meshes 31a dimensioned to retain foreign bodies C2 of dimensions greater than the size of the larger fruits of the harvested species and let the fruits and bodies pass aliens of dimensions equal to or less than the size of these larger fruit, while the endless belt of the internal conveyor 32 constitutes a second screening means having openings or meshes 32a sized for retain the fruits F and allow the passage of foreign bodies of smaller dimensions the size of the smallest fruits of said species.

- the external belt 31 can be made up of bars spaced 25 mm apart, while that the internal belt is made up of bars spaced 9 mm apart.

- the endless belts 31 and 32 are preferably subjected to means known per se allowing them to transmit vibrations.

- the two strands of the endless openwork belts 31 and 32 and in particular the strand higher of these have parallel, horizontal or substantially horizontal, said belts 31 and 32 circulating in the same direction, according to arrows in Figure 12, their drive being assured of in a manner known per se, by a motorization (not shown) coupled to their drum motors 33 and 34, respectively.

- the unloading end 32B of the internal endless belt 32 is located at distance from the discharge end 31B of the external endless belt 32, so that a space E is provided between said ends, this space allowing unloading of sorted fruit F, which are, for example, received in a bucket 14 or other container.

- Products collected from the ground are dumped into the loading area of the device.

- Fruits F and C1 foreign bodies of equal or smaller dimensions at the size of said fruits fall on the loading section 31A of the mat external perforated conveyor 31 and pass through the grid formed by it, which retains, on the other hand, stones or other foreign bodies C2 of dimensions larger than the size of the largest fruits of the harvested species.

- the fruit falls on the underlying section 32A of the internal perforated conveyor belt 32 and are retained by it which allows foreign bodies C1 to pass through which are smaller than the size of the smaller fruits of the said species, these small foreign bodies falling on the ground or in a container, after crossing the strands lower endless openwork belts 31 and 32.

- the fruits F retained by the internal perforated endless conveyor 32 are routed to the unloading end 32B of the latter which the pours through an underlying section of the lower strand of the conveyor without end openwork 31, in a bucket 14 or other similar container.

Landscapes

- Apparatuses For Bulk Treatment Of Fruits And Vegetables And Apparatuses For Preparing Feeds (AREA)

- Harvesting Machines For Root Crops (AREA)

- Preparation Of Fruits And Vegetables (AREA)

- Sorting Of Articles (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES01430008T ES2223756T3 (es) | 2001-02-22 | 2001-02-22 | Dispositivo y procedimiento para extraer cuerpos extraños mezclados con frutos cosechados en el suelo. |

| EP01430008A EP1234618B1 (de) | 2001-02-22 | 2001-02-22 | Vorrichtung und Verfahren zum Entfernen von mit von dem Boden geernteten Früchten vermischten Fremdkörpern |

| AT01430008T ATE270927T1 (de) | 2001-02-22 | 2001-02-22 | Vorrichtung und verfahren zum entfernen von mit von dem boden geernteten früchten vermischten fremdkörpern |

| DE60104278T DE60104278D1 (de) | 2001-02-22 | 2001-02-22 | Vorrichtung und Verfahren zum Entfernen von mit von dem Boden geernteten Früchten vermischten Fremdkörpern |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP01430008A EP1234618B1 (de) | 2001-02-22 | 2001-02-22 | Vorrichtung und Verfahren zum Entfernen von mit von dem Boden geernteten Früchten vermischten Fremdkörpern |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1234618A1 true EP1234618A1 (de) | 2002-08-28 |

| EP1234618B1 EP1234618B1 (de) | 2004-07-14 |

Family

ID=8183164

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01430008A Expired - Lifetime EP1234618B1 (de) | 2001-02-22 | 2001-02-22 | Vorrichtung und Verfahren zum Entfernen von mit von dem Boden geernteten Früchten vermischten Fremdkörpern |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1234618B1 (de) |

| AT (1) | ATE270927T1 (de) |

| DE (1) | DE60104278D1 (de) |

| ES (1) | ES2223756T3 (de) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109174604A (zh) * | 2018-11-26 | 2019-01-11 | 何翔 | 一种水果筛分机 |

| CN110063116A (zh) * | 2018-10-22 | 2019-07-30 | 黄中山 | 油莎豆收获机 |

| CN114192406A (zh) * | 2021-12-07 | 2022-03-18 | 苏州市职业大学 | 一种可调节分拣大小的水果分拣装置及其分拣方法 |

| CN115245906A (zh) * | 2021-12-20 | 2022-10-28 | 浙江理工大学 | 一种智能水果大小筛选分装系统及筛选分装方法 |

| US12364199B2 (en) * | 2018-06-29 | 2025-07-22 | Aussie Wine Group Holdings Pty Ltd. | Separator for a fruit collection unit |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3957158B1 (de) * | 2020-08-18 | 2023-09-27 | Wolf Anlagen-Technik GmbH & Co. KG | Klappband |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2116006A (en) * | 1936-06-17 | 1938-05-03 | Thys Edouard | Hop and stem separator |

| FR1290889A (fr) * | 1961-03-04 | 1962-04-20 | Corbeil Const Mec | Tablier transporteur pour machines agricoles |

| EP0265669A2 (de) * | 1986-10-28 | 1988-05-04 | Maschinenfabrik Bezner GmbH & Co. KG | Sortiermaschine |

| US4846282A (en) * | 1984-11-23 | 1989-07-11 | Danieli & C. Officine Mecchaniche Spa | Machine to restore railway road beds with a continuous endless-conveyor riddle |

| US5860533A (en) * | 1993-06-22 | 1999-01-19 | Reekie Manufacturing Limited | Grader |

| US5887729A (en) * | 1994-11-18 | 1999-03-30 | Sugiyama; Hiroaki | Automatic sorting apparatus |

-

2001

- 2001-02-22 EP EP01430008A patent/EP1234618B1/de not_active Expired - Lifetime

- 2001-02-22 AT AT01430008T patent/ATE270927T1/de not_active IP Right Cessation

- 2001-02-22 DE DE60104278T patent/DE60104278D1/de not_active Expired - Lifetime

- 2001-02-22 ES ES01430008T patent/ES2223756T3/es not_active Expired - Lifetime

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2116006A (en) * | 1936-06-17 | 1938-05-03 | Thys Edouard | Hop and stem separator |

| FR1290889A (fr) * | 1961-03-04 | 1962-04-20 | Corbeil Const Mec | Tablier transporteur pour machines agricoles |

| US4846282A (en) * | 1984-11-23 | 1989-07-11 | Danieli & C. Officine Mecchaniche Spa | Machine to restore railway road beds with a continuous endless-conveyor riddle |

| EP0265669A2 (de) * | 1986-10-28 | 1988-05-04 | Maschinenfabrik Bezner GmbH & Co. KG | Sortiermaschine |

| US5860533A (en) * | 1993-06-22 | 1999-01-19 | Reekie Manufacturing Limited | Grader |

| US5887729A (en) * | 1994-11-18 | 1999-03-30 | Sugiyama; Hiroaki | Automatic sorting apparatus |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US12364199B2 (en) * | 2018-06-29 | 2025-07-22 | Aussie Wine Group Holdings Pty Ltd. | Separator for a fruit collection unit |

| CN110063116A (zh) * | 2018-10-22 | 2019-07-30 | 黄中山 | 油莎豆收获机 |

| CN109174604A (zh) * | 2018-11-26 | 2019-01-11 | 何翔 | 一种水果筛分机 |

| CN114192406A (zh) * | 2021-12-07 | 2022-03-18 | 苏州市职业大学 | 一种可调节分拣大小的水果分拣装置及其分拣方法 |

| CN115245906A (zh) * | 2021-12-20 | 2022-10-28 | 浙江理工大学 | 一种智能水果大小筛选分装系统及筛选分装方法 |

| CN115245906B (zh) * | 2021-12-20 | 2023-12-19 | 浙江理工大学 | 一种智能水果大小筛选分装系统及筛选分装方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE60104278D1 (de) | 2004-08-19 |

| ATE270927T1 (de) | 2004-07-15 |

| EP1234618B1 (de) | 2004-07-14 |

| ES2223756T3 (es) | 2005-03-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2030498B1 (de) | Sortiermaschine mit Rollenförderern, zum Entfernen von mit von dem Boden geernteten kleinen Früchten vermischten Fremdkörpern | |

| EP1002467B1 (de) | Vorrichtung zum abbeeren vonTrauben vor der Weinherstellung | |

| FR2920277A1 (fr) | Egrappoir lineaire a mouvements oscillants alternatifs | |

| FR2950615A1 (fr) | Chaine de dechargement de palettes | |

| FR2474272A1 (fr) | Systeme d'alimentation pour l'ensemble de traitement d'une moissonneuse-batteuse | |

| EP1706003A2 (de) | Entrappungsvorrichtung und -verfahren für erntemaschinen | |

| EP1234618B1 (de) | Vorrichtung und Verfahren zum Entfernen von mit von dem Boden geernteten Früchten vermischten Fremdkörpern | |

| FR2795599A1 (fr) | Dispositif de tri pour machines de recolte de baies et machines de recolte equipees de ce trieur | |

| FR2825390A1 (fr) | Dispositif de nettoyage de plage | |

| FR2815053A1 (fr) | Dispositif de nettoyage de plage | |

| FR2814331A1 (fr) | Systeme a rouleau de chargement motorise pour une presse a balles rondes | |

| FR2984682A1 (fr) | Procede et dispositif de tri pneumatique de la recolte de petits fruits, et machine de recolte en faisant application. | |

| FR2535165A1 (fr) | Dispositif de ramassage de la volaille | |

| FR2675007A1 (fr) | Dispositif de collecte et de convoyage de baies et fruits dans une machine de recolte. | |

| FR2815057A1 (fr) | Dispositif de nettoyage de plage | |

| FR2815056A1 (fr) | Poste de recuperation de dechets destine a un dispositif de nettoyage de plage | |

| EP1638386B1 (de) | Aufbewahrungsvorrichtung für gemüse, insbesondere lauch, und verfahren hierfür | |

| EP1053957A1 (de) | Vorrichtung zum Sammeln von Gegenständen sowie Sammelbehälter | |

| FR2622765A1 (fr) | Procede et dispositif pour manutentionner des produits recoltes mecaniquement en eliminant de ceux-ci les dechets legers,arraches au cours de la recolte | |

| FR2516743A1 (fr) | Machine a vendanger | |

| CH188820A (fr) | Installation pour le triage des ordures ménagères. | |

| FR2624689A1 (fr) | Equipement pour la recolte des tomates | |

| CA1268140A (fr) | Selectionneuse-cribleuse | |

| FR2657335A1 (fr) | Convoyeur pour machine a vendanger. | |

| FR2513091A1 (fr) | Machine pour l'egrappage, l'effeuillage et le lavage des olives |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20030131 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17Q | First examination report despatched |

Effective date: 20030505 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 60104278 Country of ref document: DE Date of ref document: 20040819 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: FRENCH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041014 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041014 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041015 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20040714 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050222 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050228 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050228 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050228 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050228 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2223756 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050415 |

|

| BERE | Be: lapsed |

Owner name: *PELLENC IBERICA S.L. Effective date: 20050228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| BERE | Be: lapsed |

Owner name: *PELLENC IBERICA S.L. Effective date: 20050228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041214 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20170223 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20170223 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20181031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180222 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20200302 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20210729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20210223 |