EP1224366B2 - Joint bridging device - Google Patents

Joint bridging device Download PDFInfo

- Publication number

- EP1224366B2 EP1224366B2 EP00975913A EP00975913A EP1224366B2 EP 1224366 B2 EP1224366 B2 EP 1224366B2 EP 00975913 A EP00975913 A EP 00975913A EP 00975913 A EP00975913 A EP 00975913A EP 1224366 B2 EP1224366 B2 EP 1224366B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- joint

- profile

- leg

- legs

- base profile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F19/00—Other details of constructional parts for finishing work on buildings

- E04F19/02—Borders; Finishing strips, e.g. beadings; Light coves

- E04F19/06—Borders; Finishing strips, e.g. beadings; Light coves specially designed for securing panels or masking the edges of wall- or floor-covering elements

- E04F19/065—Finishing profiles with a T-shaped cross-section or the like

- E04F19/067—Finishing profiles with a T-shaped cross-section or the like with means preventing a tipping movement

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F19/00—Other details of constructional parts for finishing work on buildings

- E04F19/02—Borders; Finishing strips, e.g. beadings; Light coves

- E04F19/06—Borders; Finishing strips, e.g. beadings; Light coves specially designed for securing panels or masking the edges of wall- or floor-covering elements

- E04F19/062—Borders; Finishing strips, e.g. beadings; Light coves specially designed for securing panels or masking the edges of wall- or floor-covering elements used between similar elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F19/00—Other details of constructional parts for finishing work on buildings

- E04F19/02—Borders; Finishing strips, e.g. beadings; Light coves

- E04F19/06—Borders; Finishing strips, e.g. beadings; Light coves specially designed for securing panels or masking the edges of wall- or floor-covering elements

- E04F19/065—Finishing profiles with a T-shaped cross-section or the like

- E04F19/066—Finishing profiles with a T-shaped cross-section or the like fixed onto a base profile by means of a separate connector

Definitions

- the invention relates to a Fugenüberb Wegungsan extract for a floor, in particular for bridging a joint in a parquet floor with different heights of the opposite joint edges according to the preamble of claims 1, 2 and 3.

- Such a joint bridging arrangement which consists of an L-shaped base profile and a covering profile attached to the base profile.

- the base profile is in this case fastened by a screw on the floor, wherein the one leg of the L-shaped base profile protrudes upward into the joint.

- the covering profile covers the joint and has two legs projecting downwards into the gap, which laterally engage around the limb of the L-shaped profile and thereby bring about lateral guidance of the covering profile.

- the attachment of the cover profile to the base profile is effected by a screw which is screwed through a hole in the cover in a threaded drive channel, which is arranged in the upwardly projecting into the joint leg of the base profile.

- a disadvantage of the above-described known joint bridging arrangement is the fact that in terms of height adjustment of the joint bridging arrangement, there is only a relatively small margin, since the two legs of the cover profile must laterally comprise the upwardly projecting leg of the base profile to ensure a lateral guidance.

- EPC EP 1020590 A2 a joint bridging arrangement is known in which an intermediate part is fixed to a cover profile neither via a latching nor via a screw connection.

- the invention is therefore an object of the invention to provide a joint bridging arrangement of the type described above, which has an expanded scope in terms of height adjustment.

- the invention includes the general technical teaching not to attach the cover directly to the base profile, but to arrange an intermediate part between the base profile and the cover.

- the intermediate part is in this case stackable, so that the margin in terms of height adjustment by inserting any number of intermediate parts can be extended almost arbitrarily.

- the intermediate part has on its underside two legs arranged next to one another, which laterally surround the upwardly projecting leg of the base profile.

- the intermediate part preferably has a leg on the upper side, which is laterally encompassed by two legs arranged on the underside of the covering profile in order to ensure lateral guidance.

- the attachment of the cover profile to the intermediate part or the attachment of the intermediate part to the base profile can be done in various ways.

- the cover profile is screwed to the intermediate part, wherein in the upwardly projecting leg of the intermediate part a threaded drive channel is provided as a socket for the screw.

- a threaded drive channel is provided as a socket for the screw.

- the attachment of the cover profile on the intermediate part can be effected by a latching.

- the present invention is not limited in its application to floor joints, but can generally be used for bridging joints, with the joint bridging arrangement according to the invention is particularly advantageous for bridging joints in parquet floors.

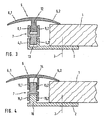

- the joint bridging arrangement has a base profile 2 which is screwed tightly to the floor by means of a screw 3, which is shown only schematically.

- the base profile 2 is formed substantially L-shaped and has two legs 4.1 and 4.2, which protrude from the base plate of the base profile 2 at right angles up into the joint, with the two legs 4.1 and 4.2 in the longitudinal direction substantially over the extend the entire length of the joint.

- the joint bridging arrangement according to FIG. 1 has a covering profile 5 with two covering wings 6.1 and 6.2, the two covering wings 6.1 and 6.2 resting on both sides of the joint on the parquet floor 1.

- an intermediate part 7 is arranged, which expands the scope in terms of height adjustment of the joint bridging arrangement with respect to the known Fugenüberbrückungsan extract described above.

- the intermediate part 7 on its underside two legs 8.1 and 8.2 engage around the outside in the mounted state laterally and thereby cause a side guide of the intermediate part 2 relative to the base profile 2.

- the intermediate part on its upper side two legs 9.1 and 9.2 which are encompassed on its outside by two arranged on the underside of the cover 5 legs 10.1 and 10.2, so that the leg pairs 9.1, 10.1 and 9.2, 10.2 a side guide Cover profile 5 relative to the intermediate part 7 effect.

- the attachment of the cover 5 and the intermediate part 7 to the base profile 2 is effected by a screw 11 which is inserted through corresponding holes in the cover 5 and the intermediate part 7.

- the margin for height adjustability can be further extended by stacking a plurality of intermediate pieces 7 vertically one above the other.

- the width covered by the two legs 8.1 and 8.2 of the intermediate part is therefore substantially equal to the outer width of the two legs 9.1 and 9.2 of the intermediate part 7 in order to ensure stackability.

- a leg 12 is integrally formed in this embodiment on the underside of the cover 5, which also has a detent on its two side surfaces, which engages in the mounted state in the detent of the legs 9.1 and 9.2 of the intermediate part.

- FIG. 3 reproduced embodiment of the invention also largely coincides with the embodiments described above, so that in the following also the same reference numerals are used and reference is made to avoid repetition of the above description.

- FIG. 3 illustrated embodiment with respect to the embodiments described above is essentially that the attachment of the cover 5, the intermediate part 7 and the base profile 2 to each other exclusively by locking.

- the attachment of the cover 5 at the intermediate part 7 takes place in the same manner as in Figure 2, so that in this regard Reference is made to the above description.

- the intermediate part 7 For attachment of the intermediate part 7 to the base profile 2, the intermediate part 7 in this embodiment on its underside a single leg 13, on the side surfaces along the joint a detent is attached.

- the two upwardly projecting legs 4.1, 4.2 of the base profile 2 in this case also carry on their inside along the joint a detent into which engages the detent of the leg 13, and the intermediate part 7 thus fixed vertically.

- the joint bridging arrangement according to FIG. 3 advantageously allows installation without tools, since the attachment is made exclusively by locking.

- FIG. 4 illustrated embodiment of a joint bridging arrangement according to the invention is almost complete with the in FIG. 3 reproduced embodiment, so that reference is largely made to the above description.

- FIG. 4 illustrated embodiment consists essentially in that the arrangement of the legs is geometrically reversed.

- the cover 5 has on its underside the two legs 10.1 and 10.2, whose inner sides bear detents.

- a leg 14 is integrally formed, which is laterally encompassed in the mounted state of the two legs 10.1 and 10.2 of the cover 5 and also carries notches, so that the cover 5 is fixed by the latching vertical to the intermediate part 7 ,

- the intermediate part 7 On its underside, the intermediate part 7 corresponding to two juxtaposed legs 15.1 and 15.2, while at the top of the base plate of the base profile 2, a right-angled upwardly projecting leg 16 is formed in the mounted state of the two legs 15.1 and 15.2 of the intermediate part. 7 is laterally encompassed and thereby causes a lateral guidance of the intermediate part 7 relative to the base profile 2. In addition, cause the arranged on the inside of the legs 15.1, 15.2 and on the outside of the leg 16 notches a vertical fixation of the intermediate part 7 relative to the base profile. 2

- FIG. 5 illustrated embodiment of the joint bridging arrangement according to the invention in turn largely agrees with the in FIG. 4 illustrated embodiment, so that reference is largely made to the above description.

- FIG. 5 illustrated embodiment An essential difference of in FIG. 5 illustrated embodiment with respect to in FIG. 4 illustrated embodiment is that the attachment of the cover 5 on the intermediate part 7 is not done by a catch, but by a screw.

- a threaded drive channel is arranged in the upwardly projecting leg 14 of the intermediate part 7, in which a screw 17 engages, which is inserted through a hole in the top of the cover.

Abstract

Description

Die Erfindung betrifft eine Fugenüberbrückungsanordnung für einen Fußboden, insbesondere zur Überbrückung einer Fuge in einem Parkettfußboden mit unterschiedlicher Höhenlage der gegenüberliegenden Fugenränder gemäß dem Oberbegriff der Ansprüche 1, 2 und 3.The invention relates to a Fugenüberbrückungsanordnung for a floor, in particular for bridging a joint in a parquet floor with different heights of the opposite joint edges according to the preamble of

Aus der

Nachteilig an der vorstehend beschriebenen bekannten Fugenüberbrückungsanordnung ist jedoch die Tatsache, daß hinsichtlich der Höhenverstellbarkeit der Fugenüberbrückungsanordnung nur ein relativ geringer Spielraum besteht, da die beiden Schenkel des Abdeckprofils den nach oben ragenden Schenkel des Basisprofils seitlich umfassen müssen, um eine Seitenführung zu gewährleisten.A disadvantage of the above-described known joint bridging arrangement, however, is the fact that in terms of height adjustment of the joint bridging arrangement, there is only a relatively small margin, since the two legs of the cover profile must laterally comprise the upwardly projecting leg of the base profile to ensure a lateral guidance.

Aus der entsprechend Artikel 54.(3) EPÜ zu berücksichtigenden

Der Erfindung liegt somit die Aufgabe zugrunde, eine Fugenüberbrückungsanordnung der vorstehend beschriebenen Art zu schaffen, die hinsichtlich der Höhenverstellbarkeit einen erweiterten Spielraum aufweist.The invention is therefore an object of the invention to provide a joint bridging arrangement of the type described above, which has an expanded scope in terms of height adjustment.

Diese Aufgabe wird, ausgehend von der vorstehend beschriebenen bekannten Fugenüberbrückungsanordnung gemäß dem Oberbegriff der Ansprüche 1, 2 und 3, durch die kennzeichnenden Merkmale der Ansprüche 1, 2 und 3 gelöst.This object is achieved, starting from the above-described known joint bridging arrangement according to the preamble of

Die Erfindung umfaßt die allgemeine technische Lehre, das Abdeckprofil nicht direkt an dem Basisprofil zu befestigen, sondern zwischen dem Basisprofil und dem Abdeckprofil ein Zwischenteil anzuordnen.The invention includes the general technical teaching not to attach the cover directly to the base profile, but to arrange an intermediate part between the base profile and the cover.

Vorzugsweise ist das Zwischenteil hierbei stapelbar, so daß der Spielraum hinsichtlich der Höhenverstellbarkeit durch Einsetzen einer beliebigen Anzahl von Zwischenteilen nahezu beliebig erweitert werden kann.Preferably, the intermediate part is in this case stackable, so that the margin in terms of height adjustment by inserting any number of intermediate parts can be extended almost arbitrarily.

In einer Ausführungsform weist das Zwischenteil an seiner Unterseite zwei nebeneinander angeordnete Schenkel auf, die den nach oben ragenden Schenkel des Basisprofils seitlich umgreifen. An der Oberseite weist das Zwischenteil dagegen vorzugsweise einen Schenkel auf, der von zwei an der Unterseite des Abdeckprofils angeordneten Schenkeln seitlich umgriffen wird, um eine Seitenführung zu gewährleisten.In one embodiment, the intermediate part has on its underside two legs arranged next to one another, which laterally surround the upwardly projecting leg of the base profile. On the other hand, the intermediate part preferably has a leg on the upper side, which is laterally encompassed by two legs arranged on the underside of the covering profile in order to ensure lateral guidance.

Die Befestigung des Abdeckprofils an dem Zwischenteil bzw. die Befestigung des Zwischenteils an dem Basisprofil kann in verschiedener Weise erfolgen. In einer Variante der Erfindung wird das Abdeckprofil am Zwischenteil festgeschraubt, wobei in dem nach oben ragenden Schenkel des Zwischenteils ein Gewindetreibkanal als Fassung für die Schraube vorgesehen ist. Es ist jedoch auch möglich, an den aneinander anliegenden Schenkeln von Basisprofil und Zwischenteil Rastungen vorzusehen, so daß das Zwischenteil lediglich auf das Basisteil aufgedrückt werden muß. In gleicher Weise kann die Befestigung des Abdeckprofils an dem Zwischenteil durch eine eine Verrastung erfolgen.The attachment of the cover profile to the intermediate part or the attachment of the intermediate part to the base profile can be done in various ways. In a variant of the invention, the cover profile is screwed to the intermediate part, wherein in the upwardly projecting leg of the intermediate part a threaded drive channel is provided as a socket for the screw. However, it is also possible to provide detents on the adjoining legs of the base profile and intermediate part, so that the intermediate part only has to be pressed onto the base part. In the same way, the attachment of the cover profile on the intermediate part can be effected by a latching.

Die vorliegende Erfindung ist hinsichtlich ihrer Anwendung nicht auf Fußbodenfugen beschränkt, sondern läßt sich allgemein zur Überbrückung von Fugen verwenden, wobei sich die erfindungsgemäße Fugenüberbrückungsanordnung besonders vorteilhaft zur Überbrückung von Fugen in Parkettfußböden eignet.The present invention is not limited in its application to floor joints, but can generally be used for bridging joints, with the joint bridging arrangement according to the invention is particularly advantageous for bridging joints in parquet floors.

Andere vorteilhafte Weiterbildungen der Erfindung sind im Unteranspruch gekennzeichnet bzw. werden nachstehend zusammen mit der Beschreibung der bevorzugten Ausführungsbeispiele der Erfindung anhand der Figuren näher dargestellt. Es zeigen:

Figur 1- eine Querschnittsdarstellung einer nicht-erfindungsgemäßen Fugenüberbrückungsanordnung mit einer Befestigung von Abdeckprofil, Zwischenteil und Basisprofil durch eine einzige Schraube,

Figur 2- eine Querschnittsdarstellung einer anderen einer nicht-erfindungsgemäßen Fugenüberbrückungsanordnung, bei der das Zwischenteil an dem Basisprofil festgeschraubt wird, während das Abdeckprofil durch eine Verrastung an dem Zwischenteil befestigt ist,

- Figur 3

- eine Querschnittsdarstellung eines erfindungsgemäßen Ausführungsbeispiels, bei dem sämtliche Bauteile durch Verrastung miteinander verbunden sind,

- Figur 4

- ein anderes Ausführungsbeispiel mit einer gegenüber

Figur 3 umgekehrten Anordnung der Schenkel, Figur 5- ein erfindungsgemäßes Ausführungsbeispiel, bei dem das Zwischenteil durch eine Verrastung an dem Basisprofil befestigt ist, wohingegen das Abdeckprofil an dem Zwischenteil festgeschraubt ist.

- FIG. 1

- a cross-sectional view of a non-inventive joint bridging arrangement with a fastening of cover profile, intermediate part and base profile by a single screw,

- FIG. 2

- a cross-sectional view of another of a non-inventive joint bridging arrangement, in which the intermediate part is screwed to the base profile, while the cover is attached by a latching to the intermediate part,

- FIG. 3

- a cross-sectional view of an embodiment according to the invention, in which all components are interconnected by latching,

- FIG. 4

- another embodiment with an opposite

FIG. 3 reverse arrangement of the legs, - FIG. 5

- an inventive embodiment in which the intermediate part is secured by a latching on the base profile, whereas the cover is screwed to the intermediate part.

Die in Figur 1 wiedergegebene Querschnittsdarstellung einer nicht-erfindungsgemäßen Fugenüberbrückungsanordnung dient vorzugsweise zur Überbrückung von Fugen in einem Parkettfußboden 1, wobei der Parkettfußboden 1 zur Vereinfachung lediglich auf einer Seite der Fuge dargestellt ist. Zur Fixierung der Fugenüberbrükkungsanordnung an dem Fußboden weist die Fugenüberbrückungsanordnung ein Basisprofil 2 auf, das durch eine nur schematisch dargestellte Schraube 3 an dem Fußboden festgeschraubt wird. Das Basisprofil 2 ist im wesentlichen L-förmig ausgebildet und weist zwei Schenkel 4.1 und 4.2 auf, die von der Grundplatte des Basisprofils 2 so rechtwinklig nach oben in die Fuge hinein abstehen, wobei sich die beiden Schenkel 4.1 und 4.2 in Längsrichtung im wesentlichen über die gesamte Länge der Fuge erstrecken.The reproduced in Figure 1 cross-sectional view of a non-inventive joint bridging arrangement is preferably used to bridge joints in a

Weiterhin weist die Fugenüberbrückungsanordnung gemäß Figur 1 ein Abdeckprofil 5 mit zwei Abdeckflügeln 6.1 und 6.2 auf, wobei die beiden Abdeckflügel 6.1 und 6.2 beidseitig der Fuge auf dem Parkettfußboden 1 aufliegen.Furthermore, the joint bridging arrangement according to FIG. 1 has a covering

In vertikaler Richtung zwischen dem Abdeckprofil 5 und dem Basisprofil 2 ist ein Zwischenteil 7 angeordnet, das den Spielraum hinsichtlich der Höhenverstellbarkeit der Fugenüberbrückungsanordnung gegenüber den eingangs beschriebenen bekannten Fugenüberbrückungsanordnungen erweitert. So weist das Zwischenteil 7 an seiner Unterseite zwei Schenkel 8.1 und 8.2 auf, die im montierten Zustand die beiden Schenkel 4.1 und 4.2 des Basisprofils 2 seitlich außen umgreifen und dadurch eine Seitenführung des Zwischenteils 2 relativ zu dem Basisprofil 2 bewirken. Darüber hinaus weist das Zwischenteil an seiner Oberseite zwei Schenkel 9.1 und 9.2 auf, die an ihrer Außenseite von zwei an der Unterseite des Abdeckprofils 5 angeordneten Schenkeln 10.1 und 10.2 umgriffen werden, so daß die Schenkelpaare 9.1, 10.1 bzw. 9.2, 10.2 eine Seitenführung des Abdeckprofils 5 relativ zu dem Zwischenteil 7 bewirken.In the vertical direction between the

Die Befestigung des Abdeckprofils 5 und des Zwischenteils 7 an dem Basisprofil 2 erfolgt durch eine Schraube 11, die durch entsprechende Bohrungen in dem Abdeckprofil 5 und dem Zwischenteil 7 eingeführt wird.The attachment of the

Bei dem vorstehend beschriebenen Ausführungsbeispiel der Fugenüberbrückungsanordnung kann der Spielraum hinsichtlich der Höhenverstellbarkeit weiter ausgedehnt werden, indem mehrere Zwischenteile 7 vertikal übereinander gestapelt werden. Die von den beiden Schenkeln 8.1 und 8.2 des Zwischenteils umfaßte lichte Breite ist deshalb im wesentlichen gleich der Außenbreite der beiden Schenkel 9.1 und 9.2 des Zwischenteils 7, um eine Stapelbarkeit zu gewährleisten.In the above-described embodiment of the joint bridging arrangement, the margin for height adjustability can be further extended by stacking a plurality of

Das in Figur 2 dargestellte Ausführungsbeispiel einer Fugenüberbrückungsanordnung stimmt weitgehend mit dem vorstehend beschriebenen und in Figur 1 dargestellten Ausführungsbeispiel überein, so daß im folgenden für übereinstimmende Bauteile dieselben Bezugszeichen verwendet werden und diesbezüglich zur Vermeidung von Wiederholungen auf die vorstehende Beschreibung verwiesen wird.The illustrated in Figure 2 embodiment of a joint bridging arrangement is largely consistent with the embodiment described above and shown in Figure 1, so that the following reference numerals are used for matching components and reference is made in this regard to avoid repetition of the above description.

Ein wesentlicher Unterschied der in Figur 2 dargestellten Fugenüberbrückungsanordnung gegenüber der in Figur 1 dargestellten Fugenüberbrückungsanordnung besteht darin, daß die Befestigung des Abdeckprofils 5 an dem Zwischenteil 7 nicht durch eine Verschraubung, sondern durch eine Verrastung erfolgt. Hierzu ist bei diesem Ausführungsbeispiel an der Unterseite des Abdeckprofils 5 ein Schenkel 12 angeformt, der an seinen beiden Seitenflächen ebenfalls eine Rastung aufweist, die im montierten Zustand in die Rastung der Schenkel 9.1 und 9.2 des Zwischenteils eingreift.An essential difference between the joint bridging arrangement shown in FIG. 2 and the joint bridging arrangement shown in FIG. 1 is that the attachment of the covering

Die Befestigung des Zwischenteils 7 an dem Basisprofil 2 erfolgt jedoch in herkömmlicher und vorstehend beschriebener Weise durch eine Schraube 11. Bei der Montage der Fugenüberbrückungsanordnung wird also zunächst das Zwischenteil 7 an dem Basisprofil 2 festgeschraubt, was ohne das Abdeckprofil 5 einfach möglich ist. Anschließend wird das Abdeckprofil 5 dann in einfacher Weise auf das Zwischenteil 7 aufgedrückt.The attachment of the

Das in

Der Unterschied des in

Zur Befestigung des Zwischenteils 7 an dem Basisprofil 2 weist das Zwischenteil 7 in dieser Ausführungsform an seiner Unterseite einen einzigen Schenkel 13 auf, an dessen Seitenflächen entlang der Fuge eine Rastung angebracht ist. Die beiden nach oben ragenden Schenkel 4.1, 4.2 des Basisprofils 2 tragen hierbei an ihrer Innenseite entlang der Fuge ebenfalls eine Rastung, in die die Rastung des Schenkels 13 eingreift, und das Zwischenteil 7 somit vertikal fixiert.For attachment of the

Die Fugenüberbrückungsanordnung gemäß

Das in

Der Unterschied des in

An seiner Unterseite weist das Zwischenteil 7 entsprechend zwei nebeneinander angeordnete Schenkel 15.1 und 15.2 auf, während an der Oberseite der Grundplatte des Basisprofils 2 ein rechtwinklig nach oben ragender Schenkel 16 angeformt ist, der im montierten Zustand von den beiden Schenkeln 15.1 und 15.2 des Zwischenteils 7 seitlich umgriffen wird und dadurch eine Seitenführung des Zwischenteils 7 relativ zu dem Basisprofil 2 bewirkt. Darüber hinaus bewirken die an der Innenseite der Schenkel 15.1, 15.2 und an der Außenseite des Schenkels 16 angeordneten Rastungen eine vertikale Fixierung des Zwischenteils 7 relativ zu dem Basisprofil 2.On its underside, the

Das in

Ein wesentlicher Unterschied des in

Claims (4)

- A joint bridging arrangement for a floor, in particular for bridging a joint in a parquet floor with different height levels of the opposite joint edges, comprising a base profile (2) to be mounted on the floor and having at least one leg (4.1, 4.2) protruding upwards into the joint,

a cover profile (5) for covering the joint and having one leg (12) protruding downwards into the joint, and

a mounting element for mounting the cover profile (5) to the base profile (2) in a height-adjustable manner,

characterized in that

between the base profile (2) and the cover profile (5) at least an intermediary part (7) is arranged for extending the height adjustability, wherein the intermediary part (7) is fixed at its bottom to the base profile (2) and at its top to the cover profile (5),

wherein the base profile (2) comprises two legs (4.1, 4.2) arranged side by side and protruding upwards into the joint,

wherein the intermediary part (7) comprises a leg (13) at its bottom, which leg is encompassed on its sides by the two legs (4.1, 4.2) of the base profile (2) in its mounted state,

wherein the intermediary part (7) comprises two legs (9.1, 9.2) on its top, said legs encompassing in its mounted state the leg (12) of the cover profile (5) on its sides,

wherein the legs of the base profile (2) and of the intermedlary part (7) positioned adjacent to one another comprise detents on their contacting surfaces for attaching the cover profile (5) to the intermediary part (7),

wherein the legs of the cover profile (5) and of the intermediary part (7) positioned adjacent to one another comprise detents on their contacting surfaces for attaching the cover profile (5) to the intermediary part (7). - The joint bridging arrangement for a floor, in particular for bridging the joint in a parquet floor with different height levels of the opposite joint edges, comprising a base profile (2) to be mounted on the floor and having a leg (16) protruding upwards Into the joint,

a cover profile (5) for covering the joint and having at least one leg (12) protruding downwards into the joint, and

a mounting element for mounting the cover profile (5) to the base profile (2) in a height-adjustable manner,

characterized in that

between the base profile (2) and the cover profile (5) at least an intermediary part (7) is arranged for extending the height adjustability, wherein the intermediary part (7) is fixed at its bottom to the base profile (2) and at its top to the cover profile (5),

wherein the cover profile (5) comprises two legs (10.1, 10.2) arranged side by side and protruding downwards into the joint,

wherein the intermediary part (7) comprises a leg (14) on its top, which leg is encompassed on its sides by the legs (10.1, 10,2) of the cover profile (5) in its mounted state,

wherein the intermediary part (7) comprises two legs (15.1, 15.2) on its bottom encompassing the leg (16) of the base profile (2) on its sides in its mounted state,

wherein the legs of the base profile (2) and of the intermedlary part (7) positioned adjacent to one another comprise detents on their contacting surfaces for attaching the intermediary part (7) to the base profile (2),

wherein the legs of the cover profile (twice) and of the intermediary part (7) positioned adjacent to one another comprise detents on their contacting surfaces for attaching the cover profile (5) to the intermediary part (7). - The joint bridging arrangement for a floor, in particular for bridging the joint in a parquet floor with different height levels of the opposite joint edges, comprising a base profile (2) to be mounted to the floor and having at least one leg (4.1, 4.2) protruding upwards into the joint,

a cover profile (5) for covering the joint and having at least one leg (10.1, 10.2) protruding downwards into the joint, and

a mounting element (17) for mounting the cover profile (5) to the base profile (2) in a height-adjustable manner,

characterized in that

between the base profile (2) and the cover profile (5) at least one intermediary part (7) is arranged for extending the height adjustability, wherein the intermediary part (7) is attached at its bottom to the base profile (2) and at its top to the cover profile (5),

wherein the cover profile (5) comprises two legs (10.1, 10.2) arranged side by side and protruding downwards into the joint,

wherein the Intermediary part (7) comprises a leg (14) on its top, which leg is encompassed on Its sides by the legs (10.1, 10.2) of the cover profile (5) in its mounted state,

wherein a thread-forming channel is provided in the leg (14) arranged on the top of the intermediary part (7) for mounting the cover profile (5) to the intermediary part (7) by means of a screw (17). - The joint bridging arrangement according to one of claims 1, 2 or 3, characterized in that the Intermediary part (7) is stackable for being able to extend the height adjustability by inserting multiple intermediary parts (7).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19951516 | 1999-10-26 | ||

| DE19951516A DE19951516C2 (en) | 1999-10-26 | 1999-10-26 | Joint bridging arrangement |

| PCT/EP2000/010512 WO2001031141A1 (en) | 1999-10-26 | 2000-10-25 | Joint bridging device |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP1224366A1 EP1224366A1 (en) | 2002-07-24 |

| EP1224366B1 EP1224366B1 (en) | 2003-08-27 |

| EP1224366B2 true EP1224366B2 (en) | 2010-06-30 |

| EP1224366B9 EP1224366B9 (en) | 2012-08-08 |

Family

ID=7926904

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00975913A Expired - Lifetime EP1224366B9 (en) | 1999-10-26 | 2000-10-25 | Joint bridging device |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP1224366B9 (en) |

| AT (1) | ATE248271T1 (en) |

| DE (2) | DE19951516C2 (en) |

| DK (1) | DK1224366T4 (en) |

| ES (1) | ES2207558T5 (en) |

| PT (1) | PT1224366E (en) |

| WO (1) | WO2001031141A1 (en) |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE503861C2 (en) | 1994-10-24 | 1996-09-23 | Perstorp Flooring Ab | Process for making a skirting board |

| US20030084634A1 (en) | 2001-11-08 | 2003-05-08 | Oliver Stanchfield | Transition molding |

| US6898911B2 (en) | 1997-04-25 | 2005-05-31 | Pergo (Europe) Ab | Floor strip |

| US7131242B2 (en) | 1995-03-07 | 2006-11-07 | Pergo (Europe) Ab | Flooring panel or wall panel and use thereof |

| SE9500810D0 (en) | 1995-03-07 | 1995-03-07 | Perstorp Flooring Ab | Floor tile |

| US7992358B2 (en) | 1998-02-04 | 2011-08-09 | Pergo AG | Guiding means at a joint |

| SE514645C2 (en) | 1998-10-06 | 2001-03-26 | Perstorp Flooring Ab | Floor covering material comprising disc-shaped floor elements intended to be joined by separate joint profiles |

| SE518184C2 (en) | 2000-03-31 | 2002-09-03 | Perstorp Flooring Ab | Floor covering material comprising disc-shaped floor elements which are joined together by means of interconnecting means |

| FR2815983B1 (en) * | 2000-11-02 | 2003-06-06 | Michel Grosjean | JOINT COVER |

| SG111031A1 (en) * | 2001-10-01 | 2005-05-30 | L & K Engineering Co Ltd | Honeycomb plate structure with joining assembly |

| US7207143B2 (en) | 2001-11-08 | 2007-04-24 | Pergo (Europe) Ab | Transition molding and installation methods therefor |

| DE10322633B3 (en) * | 2003-05-20 | 2004-11-25 | Müller, Werner | Rail arrangement for covering or bridging joints, especially for floors |

| DE20309990U1 (en) | 2003-06-29 | 2003-09-04 | Fiedler Karl Heinz | baseboard |

| DE10349932A1 (en) | 2003-10-24 | 2005-05-25 | Herm. Friedr. Künne Gmbh & Co. | Floor profile assembly for bridging gap between floor coverings has base profile and cover profile with connecting web unit with ball and socket articulated join for adapting to different heights |

| DE202004000726U1 (en) * | 2004-01-17 | 2004-04-15 | Fiedler, Karl-Heinz | baseboard |

| GB2422104B (en) * | 2004-12-08 | 2008-08-13 | Whiting Richard A | An engaging assembly for a floor covering |

| GB0519531D0 (en) * | 2005-09-24 | 2005-11-02 | Whiting Richard A | Engaging assembly for flooring |

| DE202006004903U1 (en) * | 2006-03-24 | 2006-06-01 | Herm. Friedr. Künne Gmbh & Co. | Cover arrangement with magnet system |

| EP2076638A4 (en) | 2006-10-18 | 2011-05-11 | Pergo AG | Transitions having disparate surfaces |

| GB0626007D0 (en) * | 2006-12-29 | 2007-02-07 | Whiting Richard A | Engaging assembly for a floor covering |

| DE202007000716U1 (en) | 2007-01-17 | 2007-03-29 | Fiedler, Karl-Heinz | Profiled rail for covering or bridging gaps between two adjacent floor coverings has H-shaped block component fastened in positive-locking manner by vertical H-walls between downwards orientated ribs of cover rail |

| WO2008116490A1 (en) * | 2007-03-26 | 2008-10-02 | Proverum Ag | Profiled cover strip system for a covering, especially for a finishing an edge and/or a covering a joint and/or for a cable duct |

| CA2697573A1 (en) | 2009-03-27 | 2010-09-27 | Pergo (Europe) Ab | Joint cover assembly and kit comprising this joint cover assembly as well as installation method therefor |

| DE102010004717A1 (en) | 2010-01-15 | 2011-07-21 | Pergo (Europe) Ab | Set of panels comprising retaining profiles with a separate clip and method for introducing the clip |

| CA2906474C (en) | 2010-05-10 | 2018-12-18 | Pergo (Europe) Ab | Set of panels |

| DE102012107007A1 (en) * | 2012-07-31 | 2014-02-06 | Küberit Profile Systems GmbH & Co. KG | Tiltable floor profile arrangement |

| DE102016014441A1 (en) | 2016-12-06 | 2018-06-07 | Markus Claudius Proll | Adapter for joint covering device |

| DE102016014442A1 (en) | 2016-12-06 | 2018-06-07 | Markus Claudius Proll | Adapter for joint covering device |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4385850A (en) † | 1979-05-08 | 1983-05-31 | Spacetrekker Products Limited | Device for joining panels edge-to-edge |

| EP0321634B1 (en) † | 1987-12-23 | 1992-06-10 | Herm. Friedr. Künne GmbH & Co. | Removible transition profile for floor joints |

| DE9301717U1 (en) † | 1993-02-08 | 1993-04-08 | Seiss, Helmut, 8074 Gaimersheim, De | |

| DE4136177A1 (en) † | 1991-11-02 | 1993-05-06 | Helmuth J. 8074 Gaimersheim De Seiss | Constructional kit of profiled strips - has mounting foot temporarily positioning covering strip in anchoring strip and movable on it |

| DE9412987U1 (en) † | 1994-08-11 | 1994-10-27 | Seis Helmut | Profile rail system for bridging joints or edges on coverings |

| EP1020590A2 (en) † | 1999-01-15 | 2000-07-19 | Daniele Fontana | Joint element for floorings |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3634729A1 (en) * | 1986-10-31 | 1987-05-27 | Manfred Neu | COMPONENT FOR FIXING GLASS PANELS |

| DE9116524U1 (en) * | 1991-12-17 | 1992-12-17 | Schlueter Systems Gmbh, 5860 Iserlohn, De | |

| DE29611649U1 (en) * | 1996-07-04 | 1996-09-12 | Seis Helmuth J | Device for fixing a cover rail for a step |

-

1999

- 1999-10-26 DE DE19951516A patent/DE19951516C2/en not_active Expired - Fee Related

-

2000

- 2000-10-25 ES ES00975913T patent/ES2207558T5/en not_active Expired - Lifetime

- 2000-10-25 AT AT00975913T patent/ATE248271T1/en active

- 2000-10-25 DK DK00975913.5T patent/DK1224366T4/en active

- 2000-10-25 DE DE50003473T patent/DE50003473D1/en not_active Expired - Lifetime

- 2000-10-25 WO PCT/EP2000/010512 patent/WO2001031141A1/en active Search and Examination

- 2000-10-25 PT PT00975913T patent/PT1224366E/en unknown

- 2000-10-25 EP EP00975913A patent/EP1224366B9/en not_active Expired - Lifetime

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4385850A (en) † | 1979-05-08 | 1983-05-31 | Spacetrekker Products Limited | Device for joining panels edge-to-edge |

| EP0321634B1 (en) † | 1987-12-23 | 1992-06-10 | Herm. Friedr. Künne GmbH & Co. | Removible transition profile for floor joints |

| DE4136177A1 (en) † | 1991-11-02 | 1993-05-06 | Helmuth J. 8074 Gaimersheim De Seiss | Constructional kit of profiled strips - has mounting foot temporarily positioning covering strip in anchoring strip and movable on it |

| DE9301717U1 (en) † | 1993-02-08 | 1993-04-08 | Seiss, Helmut, 8074 Gaimersheim, De | |

| DE9412987U1 (en) † | 1994-08-11 | 1994-10-27 | Seis Helmut | Profile rail system for bridging joints or edges on coverings |

| EP1020590A2 (en) † | 1999-01-15 | 2000-07-19 | Daniele Fontana | Joint element for floorings |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19951516A1 (en) | 2001-06-07 |

| DK1224366T4 (en) | 2010-11-01 |

| EP1224366A1 (en) | 2002-07-24 |

| DK1224366T3 (en) | 2003-12-29 |

| EP1224366B9 (en) | 2012-08-08 |

| PT1224366E (en) | 2004-01-30 |

| DE19951516C2 (en) | 2003-04-24 |

| ATE248271T1 (en) | 2003-09-15 |

| WO2001031141A1 (en) | 2001-05-03 |

| ES2207558T5 (en) | 2010-11-25 |

| EP1224366B1 (en) | 2003-08-27 |

| DE50003473D1 (en) | 2003-10-02 |

| ES2207558T3 (en) | 2004-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1224366B2 (en) | Joint bridging device | |

| DE2501099A1 (en) | FASTENING CLIP | |

| DE3132855C2 (en) | ||

| DE3107661A1 (en) | CONNECTING DEVICE | |

| EP0399955B1 (en) | Locking element for securing a cover to a frame | |

| DE3803292C2 (en) | ||

| EP3369341B1 (en) | Wall element for a frame of a drawer | |

| EP0067970B1 (en) | Fastening device for facing elements on outer wall | |

| EP0818591B1 (en) | Mounting member | |

| EP0804698B1 (en) | Handle for sanitary tapware | |

| DE19707741C2 (en) | hinge | |

| DE2744052A1 (en) | FITTINGS FOR DOORS AND WALLS MADE OF GLASS | |

| CH691949A5 (en) | Assemblable tray support. | |

| CH690132A5 (en) | Drainage channel. | |

| DE8533571U1 (en) | table | |

| DE19747887C2 (en) | Holding element | |

| DE19846577C2 (en) | Electrical device with a connection clip and a connection clip receptacle for connection to a second electrical device | |

| EP0867626B1 (en) | Fastening means for a screw preassembly | |

| DE3613655C1 (en) | In furniture, walls or the like. insertable locking rail and method for inserting such a locking rail | |

| DE3641163C2 (en) | ||

| DE102020114795B4 (en) | Fastener | |

| DE19540540C2 (en) | Connection of printed circuit board and connector and plug-in card provided with it for electronic devices | |

| DE19745073A1 (en) | Connecting member for joining components for pieces of furniture | |

| EP0257207B1 (en) | Support for connecting the head of a panel front mounted control- and/or signal device, with its contact- and/or lamp-element | |

| EP2997315A2 (en) | System for assembling two components |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20020515 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030827 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030827 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50003473 Country of ref document: DE Date of ref document: 20031002 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031025 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20031127 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20031222 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENTANWAELTE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2207558 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| ET | Fr: translation filed | ||

| 26 | Opposition filed |

Opponent name: XAVER GRUENWALD Effective date: 20040526 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: XAVER GRUENWALD |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLAH | Information related to despatch of examination report in opposition + time limit modified |

Free format text: ORIGINAL CODE: EPIDOSCORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20100630 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: RPEO |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T4 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: HERM. FRIEDR. KUENNE GMBH & CO. Free format text: HERM. FRIEDR. KUENNE GMBH & CO.#ROEMERWEG 9#58513 LUEDENSCHEID (DE) -TRANSFER TO- HERM. FRIEDR. KUENNE GMBH & CO.#ROEMERWEG 9#58513 LUEDENSCHEID (DE) |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50003473 Country of ref document: DE Representative=s name: PATENTANWAELTE STAEGER & SPERLING PARTNERSCHAF, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50003473 Country of ref document: DE Representative=s name: PATENTANWAELTE STAEGER & SPERLING PARTNERSCHAF, DE Effective date: 20120319 Ref country code: DE Ref legal event code: R081 Ref document number: 50003473 Country of ref document: DE Owner name: KUEBERIT PROFILE SYSTEMS GMBH & CO. KG, DE Free format text: FORMER OWNER: SONDERMANN, FRANK, 57489 DROLSHAGEN, DE Effective date: 20120319 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20151021 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20151021 Year of fee payment: 16 Ref country code: IT Payment date: 20151028 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20151020 Year of fee payment: 16 Ref country code: SE Payment date: 20151021 Year of fee payment: 16 Ref country code: FR Payment date: 20151023 Year of fee payment: 16 Ref country code: BE Payment date: 20151019 Year of fee payment: 16 Ref country code: ES Payment date: 20151028 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161031 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20161031 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20161025 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20170630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161025 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170426 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161031 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20161031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030827 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20181119 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20181019 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20181022 Year of fee payment: 19 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161026 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20181019 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20181220 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50003473 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20191101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200501 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191031 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 248271 Country of ref document: AT Kind code of ref document: T Effective date: 20191025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191025 |