EP1212525B1 - Collecteur d'admission comprenant un dispositif de régulation de l'écoulement dans une portion de conduit ou un passage et son procédé de fabrication - Google Patents

Collecteur d'admission comprenant un dispositif de régulation de l'écoulement dans une portion de conduit ou un passage et son procédé de fabrication Download PDFInfo

- Publication number

- EP1212525B1 EP1212525B1 EP00960770A EP00960770A EP1212525B1 EP 1212525 B1 EP1212525 B1 EP 1212525B1 EP 00960770 A EP00960770 A EP 00960770A EP 00960770 A EP00960770 A EP 00960770A EP 1212525 B1 EP1212525 B1 EP 1212525B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- manifold

- parts

- intake

- passage

- bearings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/104—Intake manifolds

- F02M35/108—Intake manifolds with primary and secondary intake passages

- F02M35/1085—Intake manifolds with primary and secondary intake passages the combustion chamber having multiple intake valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D9/00—Controlling engines by throttling air or fuel-and-air induction conduits or exhaust conduits

- F02D9/08—Throttle valves specially adapted therefor; Arrangements of such valves in conduits

- F02D9/10—Throttle valves specially adapted therefor; Arrangements of such valves in conduits having pivotally-mounted flaps

- F02D9/109—Throttle valves specially adapted therefor; Arrangements of such valves in conduits having pivotally-mounted flaps having two or more flaps

- F02D9/1095—Rotating on a common axis, e.g. having a common shaft

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/10242—Devices or means connected to or integrated into air intakes; Air intakes combined with other engine or vehicle parts

- F02M35/10255—Arrangements of valves; Multi-way valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/10314—Materials for intake systems

- F02M35/10321—Plastics; Composites; Rubbers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/1034—Manufacturing and assembling intake systems

- F02M35/10354—Joining multiple sections together

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D9/00—Controlling engines by throttling air or fuel-and-air induction conduits or exhaust conduits

- F02D9/08—Throttle valves specially adapted therefor; Arrangements of such valves in conduits

- F02D9/10—Throttle valves specially adapted therefor; Arrangements of such valves in conduits having pivotally-mounted flaps

- F02D9/107—Manufacturing or mounting details

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/104—Intake manifolds

- F02M35/112—Intake manifolds for engines with cylinders all in one line

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05C—INDEXING SCHEME RELATING TO MATERIALS, MATERIAL PROPERTIES OR MATERIAL CHARACTERISTICS FOR MACHINES, ENGINES OR PUMPS OTHER THAN NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES

- F05C2225/00—Synthetic polymers, e.g. plastics; Rubber

- F05C2225/08—Thermoplastics

Definitions

- the present invention relates to the field of controlling the flow of fluids, in particular gaseous fluids, and more particularly in the context of the air intake for heat engines, for example in connection with the intake manifolds, but also more generally, flow control devices in a passage by means of a member disposed in this passage and manipulated by a control shaft.

- the present invention more specifically relates to a device for regulating the flow in a conduit portion or a passage, an intake manifold comprising such a device and a method of manufacturing such a collector.

- a device for regulating or controlling the flow or flow in a passage of a portion of conduit or the like generally takes place, during one or more particular operations, either by mounting a transverse insert carrying the adjusting member in said pipe portion, after cutting an opening in the latter, or by setting up an intermediate pipe segment provided with said adjustment member between two spaced apart portions of said portion of conduit.

- US-A-5,813,380 shows an intake manifold according to the preamble of claim 1.

- the regulating device is mounted via the additional bearing structures pre-mounted on the control shaft of the regulating device and fixed in a portion forming portion of the manifold intake manifolds.

- the present invention is intended to overcome at least some of these disadvantages.

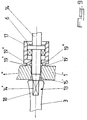

- FIG. 1 The figures of the accompanying drawings show a device for regulating the flow of a fluid, in particular gaseous fluid, in at least a portion of duct 2, a passage, an opening or the like (for example a portion of any fluid circulation circuit ) by means of a valve 3 or a similar rotary shutter member carried by a control shaft 4.

- each valve assembly 3 / control axis 4 is integrated in the structure of the portion of conduit 2 concerned or in the structure of the part 1 comprising at least a portion of conduit 2, at an opening passageway being trapped, with rotational capability, between two complementary parts 2 ', 2 "or 1", 1 "' forming by assembly said conduit portion 2 or said part 1 and being mounted in receiving recesses 5, 5 'corresponding formed in the walls of the portions of conduits 2 and / or in one or bearings (s) or separate (s) corresponding 6 present (s) on at least one of the parts 1 ", 1" 'forming part 1.

- the invention applies both to a portion of duct 2 or to a single passage opening, to several portions of ducts 2 or openings connected or not to each other and disposed between them in any manner.

- the regulating device may comprise a set of valves 3 / axis 4 extending to several portions of ducts 2 or passage openings of the part 1 each comprising a valve 3, all these valves 3 being mounted or formed on a single control axis 4.

- conduit portion is meant herein any circular passage or not that can be closed by a movable member valve type. This passage may, where appropriate, be reduced to a simple through opening or passage opening, the axial or longitudinal dimension of the conduit portion 2 then being very reduced, or even zero.

- the assembling or connecting lines 2 "' resulting from the intimate contacting of the connection between the joining or joining surfaces of the two constituent parts 2' and 3, may be located in a perpendicular plane to the axis of the duct portion 2 concerned, but also extend in other directions to facilitate the assembly of parts 2 'and 2 ".

- control pin 4 is attached at one of the ends of the duct 2, being attached to wall portions (connecting for example two adjacent ducts) in staggered locations with respect to the duct wall.

- the support of the control shaft 4 and its rotational guidance can be provided, at least in part, by at least one bearing 6 outside the wall or walls of the portion (s) of conduit (s) 2 or of the part 1 considered (s), if appropriate formed by assembling two complementary parts each on the one of the parts 1 "and 1" 'or preformed exclusively on one of the two aforementioned parts.

- said control shaft 4 may comprise one or more cylindrical protrusions 9 or annular (disc) 9 ', formed of a alone holding with said axis 4 or reported on the latter by overmolding or mounting, and intended to cooperate with the support and guide bearings 6, 7 or with stops 10 for locking in translation of said control shaft 4.

- the protuberances 9, 9 ' may advantageously consist of a material resistant to wear and / or having a reduced coefficient of friction with the material constituting the support and guide bearings 6 and 7, the annular protuberances 9 in the form of sleeves can present discoidal stops 9 "at their opposite longitudinal ends so as to form locking sites in translation for the axis 4 after mounting.

- control shaft 4 may also comprise one or more rotational guiding bearings 11 which are pre-assembled, trapped and locked in formed support bearings 12 when assembling the two parts 2 'and 2 "or 1" and 1 "' component or the portion (s) of ducts 2 or piece 1.

- the pre-assembled rotational guide bearings 11, for example in the form of ball bearings or needle bearings, may optionally be completely encapsulated in the support bearings 12 so as to protect them and to block them in translation, which will make the stops superfluous. .

- control shaft 4 can be achieved either by using only one of the solutions described above, or by splicing them.

- the control axis 4 / valve (s) 3 assembly may be obtained either by fixing (for example welding, screwing, clipping, folding or other) metal valves on an axis (metal or not), or by overmolding valves on a metal or plastic axis (the guide protuberances 9 or the bearings 11 being placed on the axis before or after the overmoulding), or by molding in one piece of a shaft assembly / valves made of plastic material.

- connection between the parts 2 'and 2 "constituting the duct portion 2 and / or between the parts 1" and 1 "' constituting the part 1 may also be realized in different ways, such as for example mechanical connection, bonding, welding or other, depending on the nature of the material constituting said parts 2 'and 2 "or 1" and 1 "'.

- control shaft 4 may be located centrally with respect to the (x) valve (s) 3 or, if appropriate, eccentric or off-center, so as not to disturb the flow in position d opening or maximum passage of said valves 3 (see in this regard the French patent application No. 99 02531 in the name of the applicant).

- the two parts 2 'and 2 "or 1" and 1 "' constituting the conduit portion 2 and / or the part 1 are made of thermoplastic material and are assembled by vibration welding, the planes of the seal being configured and arranged in such a way that they allow, if necessary, the installation of the control pin 4 / valve 3 on or in one at least of said two parts or between them.

- Sealing at the passages of the axis 4 may be obtained by forming a seal at the time of assembly, by a separate sealing element reported before or after assembly or by reporting an additional part or part 17 by vibration welding at the outer face of the passage (s) concerned (s), this additional portion may, where appropriate, contain a support bearing and guide 6, 12 axially sealed.

- the passage 15 ' is first formed during the assembly of the parts 1 "and 1"' by superposition at the portions of their respective opposed weld seams 19 'and 19 "(FIGS. 8A and 8B), so as to obtain a cross-sealed passage 15 'whose external opening opening is surrounded (on the outer face of the workpiece 1) with two portions of semicircular cords (FIG. 8C) forming together a circular bead surrounding said opening.

- the circular bead 19 "'coinciding with a sealing piece 17 is then applied to the two semicircular cords 19' and 19" and their assembly is made by vibration welding (FIG. 8D: side elevation view) to obtain a set of parts 1 and 17 waterproof.

- the present invention also relates to an intake manifold or distributor 1 comprising at least one, and preferably several, intake manifolds 2, in the form of duct portions intended to connect the manifold chamber or distributor to the cylinder heads, and constituted by assembling at least two complementary parts 1 ", 1" 'of thermoplastic material by vibration welding (see FIGS. 3 to 5 and 7 to 9).

- This intake manifold or distributor 1 is characterized in that at least some of the tubes 2 or passage openings thereof, and preferably all, comprise a control device as described above, integrated in the structure of said collector or distributor 1 and forming a flow control assembly comprising a plurality of valves 3 mounted or formed on a single control axis 4 passing through said intake manifolds 2 or passage openings and provided at one of its ends with means 13, in particular at least one coupling in rotation, with a transmission mechanism 14 connected to an actuator 14 'or with an actuator directly.

- the control shaft 4 provided with valves 3 extends transversely close to one of the ends of the intake manifolds 2, namely at its junction zone with the wall 1 'of the chamber of the collector 1 or at its junction zone with the mounting plate on the yokes, the support bearings 12 and, where appropriate, the guide bearings 6, 7, as well as the translational locking stops 10 of the control shaft 4, being at least partially, and preferably in all, formed on said wall 1 'of the collector chamber or on said fixing plate.

- stops 10 may be formed either by protuberances of the wall 1 '( Figures 3), or by recesses thereof ( Figures 5).

- Said control axis 4 / valve 3 assembly may in particular be located at the intake manifold interface 2 / manifold chamber 1 or intake manifold interface 2 / cylinder heads.

- said assembly may be sandwiched between two parts 1 "and 1"'forming the chamber of said collector or distributor and having a plane or an assembly line or junction crossing said tubing interface region / collector at the open openings of said pipes in the chamber of said manifold ( Figures 3 to 5).

- the sealed chamber 15 formed by the assembly of the two parts 1 "and 1"'of the collector 1 is closed at the passage 15' for the outward control pin portion 4 carrying the securing means 13 or for the operating rod 14 "re-entrant mechanism transmission 14, by joining, by vibration welding, at the opening or the outer face of said passage 15 ', a third hollow portion 17 enclosing at least one component of the transmission mechanism 14 and / or at least one bearing 6, 12 with axial sealing, this third part 17 being secured after formation of the part 1.

- the entire axis 4 / valves 3 extends entirely into the sealed enclosure 15.

- the axis 4 does not pass through the zones or lines of assembly by welding, the two valves 3 at the opposite ends of the axis 4 being mounted cantilever and the valve 3 located near the passage 15 'being provided with an axial blind channel 18, for example rectangular section , for the reception by fitting of the end of the operating rod 14 "and forming the securing means 13.

- the actuating mechanism of the control pin 4 may allow the displacement of the valves 3 between an open position and a closed position (total or not), the extreme positions being defined by one or more mechanical stops associated with the control axis and preferably located near the actuator 14 '.

- the displacement between the opening and closing positions can be carried out either in all or nothing, or proportionally.

- connection between the control shaft 4 and the transmission mechanism 14 may be effected either outside or preferably inside the sealed enclosure formed during assembly of the two constituent parts 1 " and 1 "'of the collector 1, the aforesaid female or male piece then extending, in a sealed manner, through a corresponding through orifice 15'.

- the assembly of the shaft 4 / valve 3 assembly is made by interlocking or snapping on said first part 1 "and the assembly of the two parts 1". and 1 "'carries a sealed enclosure around said assembly with the exception of a drive passage 15', the latter being sealed during coupling of the transmission mechanism 14 with the control shaft 4.

- the basis of the invention is to proceed, initially, to the assembly of the control shaft assembly 4 / valve (s) 3 on a part 1 ", 2 'or between two parts 1 "and 1"',2' and 2 "(said assembly being optionally held in place by bearing portions 5, 5 ', 6 or 11) then, in a second step, to perform the assembly operation of the two parts 1 "and 1"',2' and 2 "constituting the conduit portion 2, the collector or distributor 1 or any other object or structure for (e) to comprise a regulating device according to the invention.

- the invention makes it possible to arrive at a technical solution that minimizes the operations necessary for setting up and mounting the regulating device (without interfering with the existing manufacturing process and without lengthening it), which is not bulky and leads to a complete integration of the control device (impact protection), while guaranteeing a reliable seal.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Valve Housings (AREA)

- Control Of Throttle Valves Provided In The Intake System Or In The Exhaust System (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Characterised By The Charging Evacuation (AREA)

- Air-Flow Control Members (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9910999 | 1999-08-31 | ||

| FR9910999A FR2797931B1 (fr) | 1999-08-31 | 1999-08-31 | Dispositif de regulation de l'ecoulement dans une portion de conduit ou un passage et collecteur comprenant un tel dispositif |

| PCT/FR2000/002413 WO2001016473A1 (fr) | 1999-08-31 | 2000-08-31 | Dispositif de regulation de l'ecoulement dans une portion de conduit ou un passage et collecteur comprenant un tel dispositif |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1212525A1 EP1212525A1 (fr) | 2002-06-12 |

| EP1212525B1 true EP1212525B1 (fr) | 2006-07-26 |

Family

ID=9549482

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00960770A Expired - Lifetime EP1212525B1 (fr) | 1999-08-31 | 2000-08-31 | Collecteur d'admission comprenant un dispositif de régulation de l'écoulement dans une portion de conduit ou un passage et son procédé de fabrication |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US6895926B1 (nl) |

| EP (1) | EP1212525B1 (nl) |

| JP (1) | JP4549596B2 (nl) |

| AT (1) | ATE334305T1 (nl) |

| DE (1) | DE60029598T2 (nl) |

| FR (1) | FR2797931B1 (nl) |

| WO (1) | WO2001016473A1 (nl) |

Families Citing this family (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10131109A1 (de) * | 2001-06-27 | 2003-01-09 | Mann & Hummel Filter | Verfahren zur Herstellung eines Schaltklappenverbandes |

| FR2833061B1 (fr) | 2001-12-05 | 2006-10-06 | Mark Iv Systemes Moteurs Sa | Dispositif de regulation du debit dans une portion de conduit ou analogue |

| JP4463488B2 (ja) * | 2003-03-27 | 2010-05-19 | 本田技研工業株式会社 | スロットルボディ |

| FR2864167B1 (fr) * | 2003-12-19 | 2006-02-24 | Mark Iv Systemes Moteurs Sa | Collecteur d'admission en deux parties et son procede de fabrication |

| JP2005248987A (ja) * | 2004-03-01 | 2005-09-15 | Denso Corp | 軸受支持装置 |

| DE102004021125A1 (de) * | 2004-04-29 | 2005-12-01 | Mann + Hummel Gmbh | Klappenanordnung im Flanschbereich eines Ansaugsystems einer Brennkraftmaschine |

| JP2006002601A (ja) * | 2004-06-16 | 2006-01-05 | Mitsubishi Electric Corp | インテークマニホールド、およびその製造方法 |

| JP4626409B2 (ja) * | 2005-06-03 | 2011-02-09 | 日産自動車株式会社 | エンジンのインテークマニホールド |

| US7438087B1 (en) | 2005-09-30 | 2008-10-21 | Taylor Innovations, L.L.C. | Overpressure rotary valve assembly with locking pin and collapsible member |

| FR2891886B1 (fr) * | 2005-10-07 | 2010-04-02 | Mark Iv Systemes Moteurs Sa | Dispositif de regulation a clapet et collecteur d'admission comprenant au moins un tel dispositif |

| JP2007138840A (ja) * | 2005-11-18 | 2007-06-07 | Denso Corp | 吸気装置およびその製造方法 |

| JP4636328B2 (ja) * | 2006-01-20 | 2011-02-23 | アイシン精機株式会社 | 吸気制御装置 |

| CN101490099B (zh) * | 2006-07-12 | 2013-03-27 | 诺瓦提斯公司 | 用于制备隐形眼镜的可光化交联的共聚物 |

| JP2008038759A (ja) * | 2006-08-07 | 2008-02-21 | Toyota Motor Corp | 内燃機関の可変吸気装置 |

| DE102006039827A1 (de) * | 2006-08-25 | 2008-02-28 | Mahle International Gmbh | Schaltvorrichtung zum Steuern einer Gasströmung |

| US7370671B2 (en) * | 2006-10-06 | 2008-05-13 | Taylor Innovations, L.L.C. | Valve activation assembly which mechanically collapses a collapsible member in response to both overpressure and underpressure conditions |

| DE102007005686B4 (de) * | 2007-02-05 | 2009-01-02 | Siemens Ag | Saugrohranlage für eine Brennkraftmaschine |

| KR100789646B1 (ko) | 2007-03-14 | 2007-12-27 | 주식회사 케피코 | 가솔린 엔진에 사용되는 텀블 컨트롤 밸브 조립체 |

| KR100831582B1 (ko) * | 2007-03-14 | 2008-05-22 | 주식회사 케피코 | 가솔린 엔진에 사용되는 텀블 컨트롤 밸브 조립체 |

| FR2927124B1 (fr) * | 2008-02-05 | 2013-02-22 | Mark Iv Systemes Moteurs Sa | Procede de realisation d'une plaque support pour corps de clapets et plaque support |

| KR101114085B1 (ko) * | 2008-07-14 | 2012-02-21 | 기아자동차주식회사 | 가변 흡기 매니폴드의 밸브 샤프트 지지구조 |

| US8316812B2 (en) * | 2008-09-09 | 2012-11-27 | Mark Iv Systemes Moteurs Usa, Inc. | Dual output flow control actuator |

| JP5243288B2 (ja) * | 2009-02-02 | 2013-07-24 | 愛三工業株式会社 | 軸受装置 |

| JP2011220143A (ja) * | 2010-04-06 | 2011-11-04 | Denso Corp | 内燃機関の吸気装置 |

| FR2983250B1 (fr) * | 2011-11-28 | 2013-12-20 | Valeo Sys Controle Moteur Sas | Systeme d'admission de gaz pour un moteur de vehicule |

| DE102011087234A1 (de) * | 2011-11-28 | 2013-05-29 | Mahle International Gmbh | Frischluftzuführeinrichtung |

| KR101531331B1 (ko) * | 2013-12-30 | 2015-06-25 | 말레동현필터시스템 주식회사 | 흡기매니폴드용 가변흡기밸브 모듈 및 그 제조방법 |

| DE102015204604A1 (de) * | 2015-03-13 | 2016-09-15 | Mahle International Gmbh | Saugmodul einer Frischluftanlage |

| JP6396267B2 (ja) | 2015-08-25 | 2018-09-26 | 株式会社マーレ フィルターシステムズ | 内燃機関の吸気装置 |

| USD858579S1 (en) * | 2018-03-29 | 2019-09-03 | Wen Chen | Air flap |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6288875U (nl) * | 1985-11-22 | 1987-06-06 | ||

| FR2606115B1 (fr) * | 1986-10-31 | 1989-03-10 | Peugeot | Vanne a papillon notamment pour vehicule automobile et son application a un carburateur |

| DE3833846A1 (de) * | 1987-10-16 | 1989-04-27 | Volkswagen Ag | Sauganordnung fuer eine brennkraftmaschine mit einer drall und/oder turbulenz erzeugenden klappe |

| JP2501786Y2 (ja) * | 1990-10-03 | 1996-06-19 | ブラザー工業株式会社 | 軸受の支持構造 |

| DE4499626T1 (de) * | 1993-12-10 | 1996-02-22 | Mitsubishi Motors Corp | Ansaugsteuervorrichtung für einen Mehrzylinder-Verbrennungsmotor |

| JPH08277717A (ja) * | 1995-04-06 | 1996-10-22 | Du Pont Kk | 吸気制御バルブを備えた樹脂吸気系 |

| US5875758A (en) * | 1995-04-06 | 1999-03-02 | E. I. Du Pont De Nemours And Company | Resin air intake system provided with intake control valve |

| DE19523870A1 (de) * | 1995-06-30 | 1997-01-02 | Mann & Hummel Filter | Ansaugeinrichtung aus thermoplastischem Kunststoff |

| DE19726162C1 (de) * | 1997-06-20 | 1999-01-28 | Bosch Gmbh Robert | Ansaugluftverteiler |

| US6098586A (en) * | 1997-08-27 | 2000-08-08 | Siemens Canada Limited | Integrated intake manifold and air cleaner system |

| US5979871A (en) * | 1998-03-30 | 1999-11-09 | Ford Motor Company | Clamshell throttle valve assembly |

| US6135418A (en) * | 1999-02-10 | 2000-10-24 | Eaton Corporation | Low-leakage air valve for variable air intake system |

-

1999

- 1999-08-31 FR FR9910999A patent/FR2797931B1/fr not_active Expired - Lifetime

-

2000

- 2000-08-31 US US10/069,507 patent/US6895926B1/en not_active Expired - Lifetime

- 2000-08-31 DE DE60029598T patent/DE60029598T2/de not_active Expired - Lifetime

- 2000-08-31 JP JP2001519999A patent/JP4549596B2/ja not_active Expired - Fee Related

- 2000-08-31 WO PCT/FR2000/002413 patent/WO2001016473A1/fr active IP Right Grant

- 2000-08-31 EP EP00960770A patent/EP1212525B1/fr not_active Expired - Lifetime

- 2000-08-31 AT AT00960770T patent/ATE334305T1/de not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| JP4549596B2 (ja) | 2010-09-22 |

| DE60029598T2 (de) | 2007-07-19 |

| FR2797931B1 (fr) | 2001-10-05 |

| DE60029598D1 (de) | 2006-09-07 |

| JP2003508668A (ja) | 2003-03-04 |

| EP1212525A1 (fr) | 2002-06-12 |

| US6895926B1 (en) | 2005-05-24 |

| FR2797931A1 (fr) | 2001-03-02 |

| ATE334305T1 (de) | 2006-08-15 |

| WO2001016473A1 (fr) | 2001-03-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1212525B1 (fr) | Collecteur d'admission comprenant un dispositif de régulation de l'écoulement dans une portion de conduit ou un passage et son procédé de fabrication | |

| EP2322779B1 (fr) | Procédé de fabrication d'un collecteur d'admission et collecteur correspondant | |

| FR2884585A1 (fr) | Assemblage de connecteur rapide bloque en rotation | |

| EP1610045B1 (fr) | Electrovanne, en particulier pour être installée sur un reservoir de liquide sous pression de gaz | |

| EP2060746B1 (fr) | Vanne de décharge dans une turbomachine | |

| FR2891886A1 (fr) | Dispositif de regulation a clapet et collecteur d'admission comprenant au moins un tel dispositif | |

| EP1497582B1 (fr) | Dispositif de raccordement etanche, en particulier pour un circuit d'admission d'air de moteur de vehicule automobile. | |

| FR2803649A1 (fr) | Dispositif de connexion | |

| FR2831217A1 (fr) | Filtre a air, conduit d'admission et ensemble constitue d'un filtre et d'un conduit d'admission de ce genre | |

| EP2910826B1 (fr) | Vanne à boisseau sphérique rotatif et son procédé de fabrication | |

| EP0473474A1 (fr) | Boîte à eau d'un échangeur de chaleur principal, en particulier pour véhicules automobiles, contenant un échangeur de chaleur secondaire | |

| FR2874059A1 (fr) | Injecteur de carburant | |

| EP1056969B1 (fr) | Raccord encliquetable pour conduit de fluide | |

| FR2711234A1 (fr) | Echangeur de chaleur à lames utile notamment comme refroidisseur d'huile. | |

| FR2716767A1 (fr) | Boîtier recevant au moins une plaque de circuit imprimé. | |

| EP1155271B1 (fr) | Echangeur thermique a plaques, a vanne integree | |

| EP0581637B1 (fr) | Robinet à boisseau cylindrique | |

| WO2011036410A1 (fr) | Module fonctionnel integrant un repartiteur et une rampe d'injection et son procede de fabrication | |

| FR2883620A1 (fr) | Dispositif de regulation a clapet, piece multicanaux comportant de tels dispositifs et procede de realisation | |

| EP0217993A1 (fr) | Robinet à obturateur tournant perfectionné, procédé pour son assemblage et obturateur équipant un tel robinet | |

| EP1052386B1 (fr) | Dispositif à clapet, collecteur d'admission comportant au moins un tel dispositif et son procédé de fabrication | |

| FR2905159A1 (fr) | Dispositif de regulation a clapet et collecteur d'admission comprenant au moins un tel dispositif. | |

| FR3139035A1 (fr) | Distributeur de fluide caloporteur pour un circuit de refroidissement et procede de fabrication | |

| FR3086311A1 (fr) | Boite pour armatures de liaison en attente et procede de montage des armatures de liaison dans ladite boite d'attente | |

| FR2864167A1 (fr) | Collecteur d'admission en deux parties et son procede de fabrication |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20020329 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17Q | First examination report despatched |

Effective date: 20041206 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: INTAKE MANIFOLD COMPRISING A DEVICE FOR REGULATING FLOW IN A DUCT PORTION OR AN INTAKE PASSAGE AND MANUFACTURING METHOD OF THE SAME |

|

| RTI1 | Title (correction) |

Free format text: INTAKE MANIFOLD COMPRISING A DEVICE FOR REGULATING FLOW IN A DUCT PORTION OR AN INTAKE PASSAGE AND MANUFACTURING METHOD OF THE SAME |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060726 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060726 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060726 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060726 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 |

|

| REF | Corresponds to: |

Ref document number: 60029598 Country of ref document: DE Date of ref document: 20060907 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061026 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061106 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20061018 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061226 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070427 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070629 |

|

| BERE | Be: lapsed |

Owner name: MARK IV SYSTEMES MOTEURS (SOCIETE ANONYME) Effective date: 20060831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061027 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060726 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080825 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080827 Year of fee payment: 9 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090831 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20190722 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 60029598 Country of ref document: DE |