EP1200656B1 - Method and device for producing melt-spun continuous threads - Google Patents

Method and device for producing melt-spun continuous threads Download PDFInfo

- Publication number

- EP1200656B1 EP1200656B1 EP00943920A EP00943920A EP1200656B1 EP 1200656 B1 EP1200656 B1 EP 1200656B1 EP 00943920 A EP00943920 A EP 00943920A EP 00943920 A EP00943920 A EP 00943920A EP 1200656 B1 EP1200656 B1 EP 1200656B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- preparation

- threads

- filaments

- thread

- draw

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D5/00—Formation of filaments, threads, or the like

- D01D5/08—Melt spinning methods

- D01D5/096—Humidity control, or oiling, of filaments, threads or the like, leaving the spinnerettes

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B11/00—Treatment of selected parts of textile materials, e.g. partial dyeing

- D06B11/0003—Treatment of selected parts of textile materials, e.g. partial dyeing of fibres, slivers or rovings

- D06B11/0006—Treatment of selected parts of textile materials, e.g. partial dyeing of fibres, slivers or rovings in connection with a spinning step

Definitions

- the invention relates to a method for producing melt-spun endless Multi-color yarn according to the preamble of claim 1 and a device for performing the method according to the preamble of claim 5.

- DE 196 49 809 A1 describes a method for spinning, drawing and winding a synthetic thread in which the thread is subjected to heat treatment is subjected. Before the heat treatment, the thread receives a preparation and a post-treatment after the heat treatment. The procedure is not for crimped multi-colored yarns can be used.

- EP 0 784 109 A2 describes a method and a device for generating a described multi-colored yarns, in which differently colored or differently colored Partial threads are treated so that before a final joint Compacting the individual threads again, individually another so-called Subcompacted, merged, compacted and wound up. Again, the goal is a compactness of the threads and distinguishable To achieve colors in the yarn.

- a the first compacting is arranged directly behind the preparation; this causes, that part of the preparation is driven out of the thread by the compacting is and is therefore lost to the manufacturing process. This part continues nebulizing the preparation due to the action of compressed air; because of this one There is a risk to the health of the operating personnel and the environment that mist is caught and disposed of. Finally, they form through the compacting created nodes an inhomogeneity and disrupt the stretching.

- the invention is for the production of various multicolored yarn qualities such as e.g. BCF (Bulced Continuous Filament; carpet fiber) suitable.

- BCF Bending Continuous Filament; carpet fiber

- the process includes the Steps spinning and cooling the filaments, preparing and stripping the filaments summarized filaments, drawing, texturing, compacting and winding.

- Filament describes in the designs a single fiber, while thread or yarn is an aggregated variety of filaments.

- a thread or a Yarn is composed of several threads, which are before a merger processed separately.

- the object of the invention is a method for producing melt-spun continuous filaments with the minimal use of aids, such as compressed air and preparation agent, an optimal thread run on the godets at the same time high occupancy, better behavior in further treatment steps, such as Stretching and texturing, and a great color contrast for multi-colored threads is achieved.

- Another object is to provide a device for performing the to create method according to the invention.

- the first object is according to the invention by the characterizing features of the claim 1 solved.

- the preparation agent that is applied in a first place in this way has enough time to penetrate far into the thread and to close here to distribute; this process is particularly intensified when the deflection element is deflected, where the thread is subjected to flexing.

- the second preparation causes the preparation as a whole largely evenly over the entire surface of all filaments and can be applied without a significant excess. This favors the heat transfer between thread and godet and further processing, such as. a stretch.

- a thread keeps a compact shape without splitting. This makes it possible to pull many threads over a godet, and / or to drive a large number of loops without a compacting for this is required. At the same time, very high thread speeds are possible. The The risk of filament breakage is reduced.

- the limitation of the amount of preparation agent according to claim 3 prevents losses and environmental damage from spraying the agent off the thread.

- Claim 5 solves the second problem.

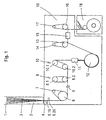

- the figure shows an apparatus for producing a multi-colored melt-spun Continuous yarn using the example of three colors.

- a spinning shaft 2.1, 2.2, 2.3 arranged in which the different dyed or staining filaments 3.1, 3.2, 3.3, which the nozzle plates 1.1, 1.2, 1.3 leave, be cooled.

- a large number of filaments 3.1, 3.2, 3.3 is in front of the further treatment in each case combined into a single thread 4.1, 4.2, 4.3.

- Galette 6 and deflection roller 7 form the first trigger element.

- a second preparation device 9.1, 9.2, 9.3 arranged between the godet 6 and a first pair of godets 8 .

- the pair of godets 8 consists of two vertically spaced, each drivable and heatable godets 8.1, 8.2 and is multiple, e.g. 5 to 13 times wrapped in threads 4.1, 4.2, 4.3. Behind it is a second one Pair of godets 10, which is also wrapped several times by the threads 4.1, 4.2, 4.3.

- the associated godets 10.1, 10.2 can each be driven and both horizontally and also vertically spaced.

- the threads 4.1, 4.2, 4.3 are combined behind the godet 10.1.

- a texturing device 11 is also arranged, followed by one drivable cooling roller 12. After the cooling roller 12, the thread 4 passes over a drivable Galette 13 and a deflection roller 14 to the compacting device 15. The thread 4 is then via a drivable godet 16 and a deflection roller 17 to a winding device 18 led.

- the entire device from the first preparation device 5, but without the winding device 18, is expediently mounted on a frame 19.

- the threads 4.1, 4.2, 4.3 are in the first preparation device 5.1, 5.2, 5.3 wetted with preparation agent; the amount is e.g. approx. 75% of the total amount required.

- the preparation agent causes that the threads 4.1, 4.2, 4.3 largely during the further processing are compact and that good heat transfer between threads and e.g. Galette is achieved.

- the threads 4.1, 4.2, 4.3 are on the godet 6 and the deflection 7 withdrawn and fed to the second preparation device 9. Because the preparation, that was applied to the first preparation device 5.1, 5.2, 5.3, could largely penetrate the threads 4.1, 4.2, 4.3, it is now possible to remove the missing Apply the amount of preparation for optimal processing. without a significant excess being required.

- the threads 4.1, 4.2, 4.3 are then known Stretched by means of the pairs of godets 8, 10 and then combined in the Texturing device 11 crimped, cooled on the cooling roll 12, in the compacting device 15 tangled and finally by means of the winding machine 18 on spools wound.

- the godets 13, 16 with the deflection rollers 14, 17 each serve the trigger of thread 4.

- the device shown as an example in the figure can also be designed such that several, e.g. 2, 4, 6 or 8 threads 4 can be processed simultaneously and in parallel.

Abstract

Description

Die Erfindung betrifft ein Verfahren zur Herstellung von schmelzersponnenem endlosem

Mehrfarbengarn gemäß dem Oberbegriff des Anspruchs 1 sowie eine Vorrichtung

zur Durchführung des Verfahrens gemäß dem Oberbegriff des Anspruchs 5.The invention relates to a method for producing melt-spun endless

Multi-color yarn according to the preamble of

Bei der Herstellung von schmelzersponnenen Endlosfäden besteht das Problem, daß die Fäden, die nicht weiter behandelt werden, beim Abziehen und Verstrecken auf den Galetten aufspleißen, daß heißt, die einzelnen Filamente laufen auseinander und einzelne Fäden vermischen sich untereinander. Hierdurch werden die Laufruhe des Fadens, die maximal mögliche Belegung einer Galette und bei mehrfarbigen Fäden die Klarheit der einzelnen Farben negativ beeinflußt.The problem with the production of melt-spun continuous filaments is that the threads that are not further treated, when pulling and stretching on the Splicing off godets means that the individual filaments diverge and individual ones Threads mix together. This will make the Thread, the maximum possible occupancy of a godet and, for multi-colored threads, the Clarity of the individual colors is negatively affected.

Die DE 196 49 809 A1 beschreibt ein Verfahren zum Spinnen, Verstrecken und Aufspulen eines synthetischen Fadens, bei dem der Faden einer Wärmebehandlung unterworfen wird. Vor der Wärmebehandlung erhält der Faden eine Vorpräparation und nach der Wärmebehandlung eine Nachpräparation. Das Verfahren ist nicht für gekräuselte mehrfarbige Garne einsetzbar.DE 196 49 809 A1 describes a method for spinning, drawing and winding a synthetic thread in which the thread is subjected to heat treatment is subjected. Before the heat treatment, the thread receives a preparation and a post-treatment after the heat treatment. The procedure is not for crimped multi-colored yarns can be used.

Aus der EP 0 485 871 B1 sind ein Verfahren und eine Vorrichtung bekannt geworden, wobei unterschiedlich gefärbte Teilfäden nach einer Präparation einzeln vorkompaktiert, vereinzelt auf Galetten verstreckt und anschließend gemeinsam texturiert, kompaktiert und auf einer Spule aufgewickelt werden, wobei die Vorkompaktierung während des Verstreckens wieder rückgängig gemacht wird. Durch das Vorkompaktieren soll erreicht werden, daß die Teilfäden einen gewissen Zusammenhalt während der Verarbeitung haben und das fertige Garn klar unterscheidbare Farben aufweist.A method and a device have become known from EP 0 485 871 B1, differently dyed partial threads individually precompacted after preparation, occasionally stretched on godets and then textured and compacted together and wound on a spool, the pre-compaction during of the stretching is reversed again. By precompacting should be achieved that the part threads a certain cohesion during the Have processing and the finished yarn has clearly distinguishable colors.

In der EP 0 784 109 A2 sind ein Verfahren und eine Vorrichtung zur Erzeugung eines mehrfarbigen Garnes beschrieben, bei dem unterschiedlich gefärbte oder anders anfärbende Teilfäden so behandelt werden, daß vor einer endgültigen gemeinsamen Kompaktierung die Teilfäden wieder vereinzelt, einzeln einer weiteren sogenannten Nachkompaktierung unterworfen, zusammengeführt, kompaktiert und aufgespult werden. Auch hier ist es das Ziel, eine Kompaktheit der Teilfäden und unterscheidbare Farben im Garn zu erzielen.EP 0 784 109 A2 describes a method and a device for generating a described multi-colored yarns, in which differently colored or differently colored Partial threads are treated so that before a final joint Compacting the individual threads again, individually another so-called Subcompacted, merged, compacted and wound up. Again, the goal is a compactness of the threads and distinguishable To achieve colors in the yarn.

Die bekannten Verfahren weisen eine Reihe von Nachteilen auf. Eine Kompaktierung erfolgt meistens mittels Druckluft; diese Energieart ist sehr teuer, so daß die Herstellungskosten der Fäden mit der Anzahl der Kompaktiervorgänge stark ansteigen. Eine erste Kompaktierung ist unmittelbar hinter der Präparation angeordnet; dies bewirkt, daß durch die Kompaktierung ein Teil des Präparationsmittels aus dem Faden ausgetrieben wird und somit für den Herstellprozeß verloren ist. Weiterhin wird dieser Teil des Präparationsmittels infolge der Wirkung der Druckluft vernebelt; da hierdurch eine Gefährdung der Gesundheit des Bedienungspersonals und der Umwelt entsteht, muß jener Nebel aufgefangen und entsorgt werden. Schließlich bilden die durch die Kompaktierung erzeugten Knoten eine Inhomogenität und stören die Verstreckung.The known methods have a number of disadvantages. A compacting mostly done with compressed air; this type of energy is very expensive, so that the manufacturing costs of threads increase sharply with the number of compacting processes. A the first compacting is arranged directly behind the preparation; this causes, that part of the preparation is driven out of the thread by the compacting is and is therefore lost to the manufacturing process. This part continues nebulizing the preparation due to the action of compressed air; because of this one There is a risk to the health of the operating personnel and the environment that mist is caught and disposed of. Finally, they form through the compacting created nodes an inhomogeneity and disrupt the stretching.

Die Erfindung ist für die Herstellung verschiedener mehrfarbiger Garnqualitäten wie z.B. BCF (Bulced Continuous Filament; Teppichfaser) geeignet. Der Prozeß umfaßt die Schritte Spinnen und Kühlen der Filamente, Präparieren und Abziehen der zu Teilfäden zusammengefaßten Filamente, Verstrecken, Texturieren, Kompaktieren und Aufspulen. Filament beschreibt in den Ausführungen eine einzelne Faser, während Faden oder Garn eine zusammengefaßte Vielzahl von Filamenten ist. Ein Faden bzw. ein Garn ist aus mehreren Teilfäden zusammengesetzt, die vor einem Zusammenschluß getrennt bearbeitet werden.The invention is for the production of various multicolored yarn qualities such as e.g. BCF (Bulced Continuous Filament; carpet fiber) suitable. The process includes the Steps spinning and cooling the filaments, preparing and stripping the filaments summarized filaments, drawing, texturing, compacting and winding. Filament describes in the designs a single fiber, while thread or yarn is an aggregated variety of filaments. A thread or a Yarn is composed of several threads, which are before a merger processed separately.

Aufgabe der Erfindung ist es, ein Verfahren zur Herstellung schmelzersponnener Endlosfäden aufzuzeigen, bei dem mit minimalem Einsatz von Hilfsmitteln, wie z.B. Druckluft und Präparationsmittel, ein optimaler Fadenlauf auf den Galetten bei einer gleichzeitig hohen Belegung, besseres Verhalten bei weiteren Behandlungsschritten, wie Verstrecken und Texturieren, und bei mehrfarbigen Fäden ein großer Farbkontrast erzielt wird. Eine weitere Aufgabe besteht darin, eine Vorrichtung zur Durchführung des erfindungsgemäßen Verfahrens zu schaffen.The object of the invention is a method for producing melt-spun continuous filaments with the minimal use of aids, such as compressed air and preparation agent, an optimal thread run on the godets at the same time high occupancy, better behavior in further treatment steps, such as Stretching and texturing, and a great color contrast for multi-colored threads is achieved. Another object is to provide a device for performing the to create method according to the invention.

Die erste Aufgabe ist erfindungsgemäß durch die kennzeichnenden Merkmale des Anspruchs

1 gelöst. Das Präparationsmittel, das an einer ersten Stelle aufgetragen wird,

hat auf diese Weise genügend Zeit, weit in den Faden einzudringen und sich hier zu

verteilen; dieser Prozeß wird besonders bei der Umlenkung am Abzugsorgan verstärkt,

wo der Faden einer Walkarbeit unterworfen ist. Die zweite Präparation bewirkt, daß

das Präparationsmittel insgesamt weitestgehend gleichmäßig auf die gesamte Oberfläche

aller Filamente und ohne wesentlichen Überschuß aufgetragen werden kann. Dies

begünstigt den Wärmeübergang zwischen Faden und Galetten und die weitere Bearbeitung,

wie z.B. eine Verstreckung. Ein Faden behält eine kompakte Form ohne aufzuspleißen.

Hierdurch ist es möglich, viele Fäden über eine Galette zu ziehen,

und/oder eine große Umschlingungszahl zu fahren, ohne daß hierfür eine Kompaktierung

erforderlich ist. Gleichzeitig sind sehr hohe Fadengeschwindigkeiten möglich. Die

Gefahr eines Filamentbruches ist reduziert.The first object is according to the invention by the characterizing features of the

Die Begrenzung der Präparationsmittelmenge nach Anspruch 3 verhindert Verluste und Umweltbeeinträchtigungen durch Abspritzen des Mittels vom Faden.The limitation of the amount of preparation agent according to claim 3 prevents losses and environmental damage from spraying the agent off the thread.

Nach Anspruch 4 können die für die nachfolgenden Verfahrensschritte optimal wirkenden Präparationsmittel eingesetzt werden.According to claim 4, those acting optimally for the subsequent process steps can Preparations are used.

Anspruch 5 löst die zweite Aufgabe.Claim 5 solves the second problem.

Die Zeichnung dient der Erläuterung der Erfindung anhand eines vereinfacht und schematisch dargestellten Ausführungsbeispiels.The drawing serves to explain the invention using a simplified and schematic illustrated embodiment.

Die Figur zeigt eine Vorrichtung zur Herstellung eines mehrfarbigen schmelzersponnenen Endlosgarns am Beispiel für drei Farben.The figure shows an apparatus for producing a multi-colored melt-spun Continuous yarn using the example of three colors.

Bei der in der Figur dargestellten Vorrichtung ist jeweils unmittelbar unter drei Düsenplatten

1.1, 1.2, 1.3 ein Spinnschacht 2.1, 2.2, 2.3 angeordnet, in dem die unterschiedlich

gefärbten oder anfärbenden Filamente 3.1, 3.2, 3.3, welche die Düsenplatten 1.1,

1.2, 1.3 verlassen, gekühlt werden. Eine Vielzahl Filamente 3.1, 3.2, 3.3 wird vor der

weiteren Behandlung jeweils zu einem einzelnen Faden 4.1, 4.2, 4.3 zusammengefaßt.

Hinter jedem Spinnschacht 2.1, 2.2, 2.3 ist eine erste Präparationsvorrichtung 5.1, 5.2,

5.3 angeordnet, die aus mehreren Präpariereinheiten, die unmittelbar hintereinander

angeordnet sind, aufgebaut sein kann. Die präparierten Fäden 4.1, 4.2, 4.3 umschlingen

mehrfach, z.B. 1,5 bis 2-fach eine antreibbare Galette 6 und eine Umlenkrolle 7.

Galette 6 und Umlenkrolle 7 bilden das erste Abzugsorgan. Zwischen der Galette 6

und einem ersten Galettenpaar 8 ist jeweils eine zweite Präparationsvorrichtung 9.1,

9.2, 9.3 angeordnet. Das Galettenpaar 8 besteht aus zwei vertikal beabstandeten, jeweils

antreibbaren und beheizbaren Galetten 8.1, 8.2 und ist mehrfach, z.B. 5 bis 13-fach

von den Fäden 4.1, 4.2, 4.3 umschlungen. Dahinter befindet sich ein zweites

Galettenpaar 10, das ebenfalls mehrfach von den Fäden 4.1, 4.2, 4.3 umschlungen ist.

Die zugehörigen Galetten 10.1, 10.2 sind jeweils antreibbar und sowohl horizontal als

auch vertikal beabstandet. Hinter der Galette 10.1 sind die Fäden 4.1, 4.2, 4.3 zusammengefaßt.

Es ist weiter eine Texturiereinrichtung 11 angeordnet, gefolgt von einer

antreibbaren Kühlwalze 12. Nach der Kühlwalze 12 gelangt der Faden 4 über eine antreibbare

Galette 13 und eine Umlenkrolle 14 zur Kompaktiervorrichtung 15. Der Faden

4 ist dann über eine antreibbare Galette 16 und eine Umlenkrolle 17 zu einer Aufspulvorrichtung

18 geführt. Die gesamte Vorrichtung ab der ersten Präparationsvorrichtung

5, aber ohne die Aufspulvorrichtung 18, ist zweckmäßig auf einem Gestell 19 montiert.In the device shown in the figure is directly under three nozzle plates

1.1, 1.2, 1.3 a spinning shaft 2.1, 2.2, 2.3 arranged in which the different

dyed or staining filaments 3.1, 3.2, 3.3, which the nozzle plates 1.1,

1.2, 1.3 leave, be cooled. A large number of filaments 3.1, 3.2, 3.3 is in front of the

further treatment in each case combined into a single thread 4.1, 4.2, 4.3.

Behind each spinning shaft 2.1, 2.2, 2.3 there is a first preparation device 5.1, 5.2,

5.3 arranged, which consist of several preparation units, the one behind the other

are arranged, can be constructed. Loop the prepared threads 4.1, 4.2, 4.3

several times, e.g. 1.5 to 2 times a

Im Betrieb wird geschmolzener, unterschiedlich gefärbter oder anfärbender Kunststoff

durch die Düsenplatten 1.1, 1.2, 1.3 gepreßt und zu Filamenten 3.1, 3.2, 3.3 ersponnen.

Diese werden im Spinnschacht 2 durch z.B. einen Luftstrom abgekühlt, so daß

der Kunststoff der Filamente 3.1, 3.2, 3.3 erstarrt. Die zu einzelnen Fäden 4.1, 4.2, 4.3

zusammengefaßten Filamente 3 sind bis vor der Texturierung 11 getrennt gehalten, so

daß jeweils eine separate Behandlung erfolgt. Dies ist zum einen durch eine entsprechende

Fadenführung und zum anderen durch die Kompaktheit eines Fadens 4.1, 4.2,

4.3 infolge der Präparierung gewährleistet. Die Fäden 4.1, 4.2, 4.3 werden in der

ersten Präparationsvorrichtung 5.1, 5.2, 5.3 mit Präparationsmittel benetzt; die Menge

beträgt z.B. ca. 75 % der insgesamt erforderlichen Menge. Das Präparationsmittel bewirkt,

daß die Fäden 4.1, 4.2, 4.3 während der weiteren Verarbeitung weitestgehend

kompakt sind und daß ein guter Wärmeübergang zwischen Fäden und z.B. Galette

erzielt wird. Die Fäden 4.1, 4.2, 4.3 werden über die Galette 6 und die Umlenkung 7

abgezogen und der zweiten Präparationsvorrichtung 9 zugeführt. Da das Präparationsmittel,

das bei der ersten Präparationsvorrichtung 5.1, 5.2, 5.3 aufgetragen wurde,

weitgehend in die Fäden 4.1, 4.2, 4.3 eindringen konnte, ist es jetzt möglich, die fehlende

Menge an Präparationsmittel für die optimale Weiterverarbeitung aufzutragen.

ohne daß ein nennenswerter Überschuß erforderlich ist. Es ist auch möglich, ein zweites

Präparationsmittel zu benutzen. Die Fäden 4.1, 4.2, 4.3 werden dann in bekannter

Weise mittels der Galettenpaare 8, 10 verstreckt und dann zusammengefaßt in der

Texturiervorrichtung 11 gekräuselt, auf der Kühlwalze 12 gekühlt, in der Kompaktiervorrichtung

15 getangelt und schließlich mittels der Aufspulmaschine 18 auf Spulen

gewickelt. Die Galetten 13, 16 mit den Umlenkrollen 14, 17 dienen jeweils dem Abzug

des Fadens 4.Melted, differently colored or staining plastic is used in operation

pressed through the nozzle plates 1.1, 1.2, 1.3 and spun into filaments 3.1, 3.2, 3.3.

These are in the

Die in der Figur beispielhaft dargestellte Vorrichtung kann auch so ausgeführt sein, daß mehrere, z.B. 2, 4, 6 oder 8 Fäden 4 gleichzeitig und parallel verarbeitet werden.The device shown as an example in the figure can also be designed such that several, e.g. 2, 4, 6 or 8 threads 4 can be processed simultaneously and in parallel.

Claims (7)

- A method of producing melt-spun continuous multi-colour yam from a plurality of filaments, wherein the differently dyed filaments or filaments capable of being dyed differently are combined in groups to form at least two threads and are drawn off,

with at least the further steps:characterized in that at least one second preparation is carried out downstream of the first draw-off member and before the stretching.preparation, in which a preparation of the threads with a preparation agent is carried out at least upstream of a first draw-off member,stretching,texturing, in which the threads are crimped,cooling,compacting, andwinding up the threads, - A method according to Claim 1, characterized in that the threads are held separately until the stretching inclusive, and are then combined as yam and are jointly textured, cooled, compacted and wound up.

- A method according to Claim 1 or 2, characterized in that during the first preparation only as many preparation agents are applied as to ensure a satisfactory running on the first draw-off member.

- A method according to Claims 1 to 3, characterized in that different preparation agents are used during the first preparation and the second preparation.

- A device for producing melt-spun continuous multi-colour yam from a plurality of filaments (3), wherein the differently dyed filaments (3.1, 3.2, 3.3) or filaments (3.1, 3.2, 3.3) capable of being dyed differently are combined in groups to form at least two threads (4.1, 4.2, 4.3), with at leastcharacterized in that a second preparation device (9.1, 9.2, 9.3) is arranged between the draw-off member (6, 7) and the first pair of galettes (8.1, 8.2).a draw-off member comprising a galette (6) and a reversing roller (7),at least one preparation device (5.1, 5.2, 5.3), wherein one is arranged upstream of the draw-off member,two pairs of galettes (8, 10) between which the threads (4) are stretched,a texturing device (11),a cooling roller (12),a compacting device (15), anda winding device (18),

- A device according to Claim 5, characterized in that the second preparation device (9.1, 9.2, 9.3) is arranged separately for each thread (4.1, 4.2, 4.3).

- A device according to Claim 5 or 6, characterized in that the preparation device (5, 9.1, 9.2, 9.3) comprises two immediately adjacent preparation units.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19929817 | 1999-06-30 | ||

| DE19929817A DE19929817B4 (en) | 1999-06-30 | 1999-06-30 | Method and device for producing melt-spun continuous filaments |

| PCT/EP2000/006008 WO2001002633A1 (en) | 1999-06-30 | 2000-06-28 | Method and device for producing melt-spun continuous threads |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1200656A1 EP1200656A1 (en) | 2002-05-02 |

| EP1200656B1 true EP1200656B1 (en) | 2004-05-12 |

Family

ID=7912958

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00943920A Expired - Lifetime EP1200656B1 (en) | 1999-06-30 | 2000-06-28 | Method and device for producing melt-spun continuous threads |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6814828B1 (en) |

| EP (1) | EP1200656B1 (en) |

| JP (1) | JP2003504522A (en) |

| AT (1) | ATE266752T1 (en) |

| DE (2) | DE19929817B4 (en) |

| WO (1) | WO2001002633A1 (en) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10116959A1 (en) * | 2001-04-05 | 2002-10-10 | Neumag Gmbh & Co Kg | Device for melt spinning and depositing several spinning cables |

| CN100400728C (en) * | 2001-09-11 | 2008-07-09 | 诺马格有限及两合公司 | Spinning-drawing-coiling deformation devices |

| DE10326850A1 (en) * | 2003-06-14 | 2004-12-30 | Saurer Gmbh & Co. Kg | Device for spinning and treating synthetic threads |

| ITMI20041137A1 (en) * | 2004-06-04 | 2004-09-04 | Fare Spa | APPARATUS FOR THE TREATMENT OF SYNTHETIC YARNS |

| US8850786B2 (en) | 2009-06-05 | 2014-10-07 | INVISTA North America S.à.r.l. | Systems and methods for intermittently colored yarn |

| WO2012052203A1 (en) | 2010-10-21 | 2012-04-26 | Oerlikon Textile Gmbh & Co. Kg | Method for producing a multifilament composite thread and melt spinning device |

| CN103911676B (en) * | 2014-04-03 | 2016-03-16 | 湖州厉华妤婕联合纺织有限公司 | A kind of melt-spun generating apparatus |

| CN109338550A (en) * | 2018-04-04 | 2019-02-15 | 苏州帝达化纤机械制造有限公司 | A kind of spinning equipment of bulked continuous filament |

| CN109930276A (en) * | 2019-04-09 | 2019-06-25 | 龙福环能科技股份有限公司 | Polylactic acid produces drafting system and the application of texturized fiber |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1066697A (en) * | 1964-04-07 | 1967-04-26 | Du Pont | Bulked filament bundles and process for producing them |

| US3427192A (en) * | 1964-05-20 | 1969-02-11 | Deering Milliken Res Corp | Textile sizing composition |

| JPS60246808A (en) * | 1984-05-21 | 1985-12-06 | Toray Ind Inc | Production of synthetic fiber |

| DE3735752C2 (en) * | 1986-10-29 | 1994-03-31 | Barmag Barmer Maschf | Process for the production of plain yarn from polyamide or polyester |

| US4995884A (en) * | 1989-12-08 | 1991-02-26 | Henkel Corporation | Polyalphaolefin emulsions for fiber and textile applications |

| DE69107411T2 (en) * | 1990-11-10 | 1995-07-20 | Barmag Barmer Maschf | Method and device for combining threads of different colors to make a multi-colored yarn. |

| US5350529A (en) * | 1992-08-28 | 1994-09-27 | E. I. Du Pont De Nemours And Company | Low fume finish for wet air-jet texturing |

| DE19649809A1 (en) * | 1995-12-05 | 1997-06-12 | Barmag Barmer Maschf | Spin-drawing high shrinkage synthetic yarn using very hot heating surfaces |

| CN1078636C (en) * | 1996-01-12 | 2002-01-30 | 里特机械公司 | Method and apparatus for producing multicolored yarn from differently coloured part-threads of endless filament |

-

1999

- 1999-06-30 DE DE19929817A patent/DE19929817B4/en not_active Expired - Fee Related

-

2000

- 2000-06-28 WO PCT/EP2000/006008 patent/WO2001002633A1/en active IP Right Grant

- 2000-06-28 EP EP00943920A patent/EP1200656B1/en not_active Expired - Lifetime

- 2000-06-28 US US09/979,957 patent/US6814828B1/en not_active Expired - Fee Related

- 2000-06-28 AT AT00943920T patent/ATE266752T1/en not_active IP Right Cessation

- 2000-06-28 JP JP2001508402A patent/JP2003504522A/en active Pending

- 2000-06-28 DE DE50006424T patent/DE50006424D1/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003504522A (en) | 2003-02-04 |

| ATE266752T1 (en) | 2004-05-15 |

| DE19929817A1 (en) | 2001-01-11 |

| DE19929817B4 (en) | 2004-07-15 |

| US6814828B1 (en) | 2004-11-09 |

| EP1200656A1 (en) | 2002-05-02 |

| WO2001002633A1 (en) | 2001-01-11 |

| DE50006424D1 (en) | 2004-06-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0784109B1 (en) | Method and apparatus for the manufacture of a multi-coloured yarn composed of differentially dyed continuous filament yarns | |

| EP2630279B1 (en) | Method for producing a multifilament composite thread and melt spinning device | |

| DE3720237A1 (en) | METHOD FOR PRODUCING AIR BLOW TEXTURED SEWING THREAD | |

| DE10235936A1 (en) | Synthetic textile spinning and spool winding assembly has line of spinning jets and a draw-down galette transverse to the line of winding stations | |

| EP2283174A2 (en) | Method for melt-spinning, drawing, and winding up a multifilament, and apparatus for carrying out said method | |

| EP0133198B1 (en) | Method and apparatus for making a non twisted crimped yarn from at least two bundles of filaments having different colours or dyeing properties | |

| EP2567008B1 (en) | Process and apparatus for melt-spinning, drawing and winding multiple synthetic threads | |

| EP1200656B1 (en) | Method and device for producing melt-spun continuous threads | |

| DE2953527C2 (en) | Method and device for the production of fancy yarn | |

| EP0718424B1 (en) | Draw texturing apparatus for synthetic yarns | |

| EP1838908B1 (en) | Method and device for melt-spinning and texturing a plurality of multifilament threads | |

| DE19746878B4 (en) | Method for producing a multicomponent thread | |

| DE2855763C2 (en) | ||

| DE2328499A1 (en) | SPINNING LINES AND SPINNING LINK TEXTURING OF MULTIFILE YARNS | |

| WO2019034488A1 (en) | Method and device for producing a multifilament fully drawn yarn from a polyamide melt | |

| EP3568510A1 (en) | Device and method for producing a multicolor yarn | |

| EP3041978A1 (en) | Melt-spinning process and melt-spinning apparatus for producing a crimped thread | |

| EP2673406A1 (en) | Method and device for texturing a synthetic thread | |

| DE10124162A1 (en) | Air-textured thread and process for its production | |

| WO2017063913A1 (en) | Method and device for producing fine multifilament threads | |

| DE1660400C3 (en) | Process for the production of compact multifilament yarns | |

| WO2003002796A1 (en) | Method and device for producing yarns, and a yarn produced according to said method | |

| DE3243998C2 (en) | ||

| EP1527219A1 (en) | Method and device for spinning and texturing synthetic threads | |

| DE3813898A1 (en) | Process for producing air jet textured sewing thread |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20020130 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SAURER GMBH & CO. KG |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040512 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040512 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040512 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040512 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040512 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040512 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50006424 Country of ref document: DE Date of ref document: 20040617 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KEMENY AG PATENTANWALTBUERO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040812 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040812 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040812 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040823 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20040512 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050215 |

|

| EN | Fr: translation not filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20060608 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20060613 Year of fee payment: 7 Ref country code: CH Payment date: 20060613 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060630 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20060821 Year of fee payment: 7 |

|

| BERE | Be: lapsed |

Owner name: *SAURER G.M.B.H. & CO. K.G. Effective date: 20070630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041012 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080101 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070628 |