EP1147525B1 - Method and device for producing composite insulators - Google Patents

Method and device for producing composite insulators Download PDFInfo

- Publication number

- EP1147525B1 EP1147525B1 EP99968343A EP99968343A EP1147525B1 EP 1147525 B1 EP1147525 B1 EP 1147525B1 EP 99968343 A EP99968343 A EP 99968343A EP 99968343 A EP99968343 A EP 99968343A EP 1147525 B1 EP1147525 B1 EP 1147525B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- core

- screening

- appliance

- mould

- screen

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B19/00—Apparatus or processes specially adapted for manufacturing insulators or insulating bodies

Definitions

- the invention relates to a method for producing composite insulators According to the preamble of the first claim and a device for Production of composite insulators according to the preamble of the nineteenth Claim.

- High voltage insulators are out of the conventional materials Porcelain and glass increasingly also manufactured as composite insulators.

- Composite insulators consist of a rod or tubular core, which is in turn, for example composed of glass fibers reinforced epoxy resin and a screen sheath, divided into a sheath around the core with a number spaced, plate-shaped umbrellas or one or more spiral Umbrellas, wherein the screen cover of a material with insulating properties consists.

- These materials include elastomeric materials, for example polymeric plastics. With such materials, the core can easily wrap, before by means of a subsequent thermal treatment of the material final obtains its desired mechanical and electrical properties.

- the core of a composite insulator serves to absorb the forces generated by the Suspension acting on the insulator, and therefore carries at its ends appropriately designed fittings, usually made of metal.

- the screen cover should electrical flashovers, usually due to weather conditions prevent.

- Composite insulators have compared to the conventional insulators made of glass or Porcelain the advantage that they are much lighter. Besides, they have due the dirt and water-repellent material of the shield covers very good Isolation properties and are therefore particularly suitable for areas with strong polluted atmosphere. This property is only achieved if the Coating of the core is not interrupted at any point or lifted off the core, for example, by joints, seams or columns.

- the object of the present invention is a method and a device to imagine with which the manufacture of composite insulators with any Number of annular shields and a continuous screen cover is possible.

- An inventive Device for producing the composite insulators is characterized by the Features of claim nineteen.

- the shape While the core is being stopped, the shape is filled with the Material of the screen cover filled and a screen formed

- the mold is opened, the screen released and the advance of the core is initiated again.

- the supply of the material is so controlled that the order of the material is not interrupted until that Umbrella shell is completely made.

- the screen cover at any point of the composite insulator joints, seams or columns.

- the surface of the screens can adhere to the mold walls stay. This makes the umbrellas difficult to shape and it is the Risk of their surface being damaged.

- the tendency to stick may be due to the material can be, but also by the adhesion of the screen surface to the shaping Surfaces of the mold, the mold walls, are caused when the supply of Air is difficult to the places where the screen surface of the mold walls should solve.

- step in forming the umbrellas advantageous: filling the Shape is monitored with at least one pressure sensor on or in the mold. at a certain, the degree of desired filling corresponding pressure the mold opens a given gap. For this purpose, first in Feed direction of the core forward mold half in the feed direction of the core shifted, for example, by about a millimeter to the pressure on the Reduce material and solve its adhesion to the mold walls. Only after the mold is fully opened to release the screen.

- the adhesion to the shaping surfaces of the mold can be so great be that their overcoming must be supported by further process steps.

- the Detachment of the screen surface by air supply to the screen surface, in particular at particularly endangered areas of the screen such as the umbrella root, supported become.

- channels are provided in the mold walls, which on the forming surfaces finish.

- the channels are shaping Surface closed by valves which then open when peeling the screen surfaces of the mold walls creates a negative pressure. The replacement can be assisted with compressed air injected through the valves.

- the detachment of the screen surfaces from the mold walls can also be mechanical by rotating at least one mold half opposite the other around the Longitudinal axis of the core are supported, possibly on the mold walls adhering material is released due to the shearing motion.

- the seen in the transport direction forward mold half must be at least two parts be formed to by opening in a substantially radial direction, through Pull apart or open, to clear the way for the screen.

- Both mold halves can also be designed in two parts.

- opening the mold the halves of one half of the mold can be offset in time from the halves of the mold other half of the mold to be opened, the part halves turn in a in the substantially radial direction away from the core.

- the Heat treatment may be limited to the curing of the surface, so that The umbrella can be easily shaped.

- the final heat treatment would then take place in a further process step. But the heat treatment can also the entire required process for curing the material of the Cover screen.

- the faucets are attached, with those at the one Side of the insulator itself and on the other side the electrical conductor is attached.

- the ends of the core must be free from Be the material of the screen cover.

- an inventive Composite insulator is first used when the beginning of the core from the Device for applying the material of the screen sheath emerges, the order of the Material exposed as long as that for the attachment of the fitting provided length has left the device. If at the end of the core of the Point is reached, from which he should wear the fitting, the supply of the material interrupted. The coat then tears at the further advancement of the core at the Device for applying the material from and the core remains naked.

- Another way to obtain a sheath-free end of the core is to the rod with continuous promotion of the shell material jerkily around the piece to advance, which should remain free. Due to its viscosity ruptures the Sheath material from advancing and is only reapplied when the core with the usual feed rate through the device for Applying the screen cover is transported.

- a simplification of the workflow for the production of a composite insulator is achieved, if not each core individually of the device for applying the material the screen cover must be supplied. If provided for the cores rod or the tube of glass fiber reinforced plastic is so long that at least two Composite insulators can be made one after another, can be a finished molded Composite insulator or at least the already finished molded part of the composite insulator be guided by a heater without a support on the still uncured material of the shielding is required. Then the Composite insulator or at least the part of the composite insulator, already the Heat treatment was subjected to the heat treatment Unaiding wearing part, which is the device for applying the Material of the shield has already left.

- the manufacturing process can also be carried out continuously, if in each case a following core with the previous core to a continuous rod or tube of great length is connected. With a corresponding quality of connection of the rods or Tubes together there is the possibility of composite insulators of different Length to manufacture one after the other.

- the length of the composite insulators will not more determined by the length of the individually supplied cores, but by the predetermined number of screens.

- the cores are then separated when the given number of screens and thus the given length of a Composite insulator is achieved.

- the connection can for example by a Sticking together of the rods or pipes or a thermal bonding done.

- connection of the rods or tubes should only be used to To produce a continuous rod or a continuous pipe of great length and the joints do not meet the mechanical requirements for the core meet a composite insulator, such a junction as a body for Separating finished composite insulators are set.

- the composite insulators can advantageously be moved so that after the application of the material of the shielding shell already formed parts of the composite insulator to produce the required material properties of finished screen sheath are thermally treated, while the material for Forming of the remaining part of the composite insulator or already for Forming the subsequent composite insulator on the continuous core is applied when due to the supply of long rods or tubes for individual separation of cores continuous production of Composite insulators is provided.

- the material for Forming of the remaining part of the composite insulator or already for Forming the subsequent composite insulator on the continuous core is applied when due to the supply of long rods or tubes for individual separation of cores continuous production of Composite insulators is provided.

- these process variants must, in Contrary to the state of the art, no longer on the complete completion a composite insulator to be serviced before the required thermal Treatment can be done.

- the heating section which is the composite insulator is equipped with a hot air blower, which ensures a uniform Temperature distribution and thus for a uniform heating of the screen cover provides.

- the material of the shielding shell has a correspondingly high dipole moment, for example, silicone rubber (HTV) or ethylene-propylene copolymer (EPM) also a vulcanization with high-energy radiation, for example with a microwave, possible.

- HTV silicone rubber

- EPM ethylene-propylene copolymer

- the handling of the composite insulators during their manufacture becomes particular facilitated by the fact that at least one already finished composite insulator that still connected via the core with the following, not yet finished composite insulator is supported by a conveyor.

- the conveyor is the Heating device downstream.

- the continuous bar or the continuous one Pipe from which the finished composite insulators are cut off is on one side Side in the drive rollers of the feed device for the rod or tube stored and on the other side by a finished composite insulator supported. This makes it possible, a not yet ready composite insulator without Supporting his still soft umbrella case during its shaping and subsequent thermal treatment to transport. A deformation or Damage to the screen cover is avoided.

- the conveyor can for example, be a non-driven conveyor belt on which already finished Composite insulators rest with the outer circumference of their screens.

- the Composite insulators are moved solely by the advance of the core. Of the Feed takes place by means of a feed device through the device for Applying the material of the screen cover through.

- the conveyor belt is moving only by the composite insulators resting on it.

- the Conveyor can also be driven. Their drive with the Drive the rod or tube synchronously done.

- FIG. 1 shows the construction of a composite insulator according to the invention, such as FIG he the inventive device for the production of composite insulators before Separating from the core of the subsequent composite insulator leaves.

- the composite insulator 1 consists of a core 2, which is provided with a screen cover. 3 is covered.

- the shield shell 3 is divided into a shell 4 and annular Screens 5. For the sake of clarity, only one screen 5 is shown here.

- One Composite insulator has five sections.

- the section A represents the first end 6. It has no jacket 4. This free end 6 has a dimension 8, the Attachment of a fitting, not shown here is required.

- section B is the core 2 coated with a jacket 4.

- section C is the annular Screen 5 and in section D, the core 2 is also coated with a jacket 4.

- the region E comprises the second end 7 of the insulator 1 and has the dimension 9, which is required for attachment of the other, not shown here fitting. At the region E is in turn followed by an area A of the following insulator 101 which is not fully illustrated here and not yet complete should be completed.

- the core 2 and the core 102 of the subsequent composite insulator 101 in the present embodiment a continuous rod 14.

- the core can also be formed from tubes.

- the jacket-free one follows End 7 of the core 2 of the composite insulator 1, to the separation point 10, the first end 106 of the core 102 of the composite insulator 101, on which also a valve should be attached. This end 106 is therefore also free in a length 108 from the jacket 4.

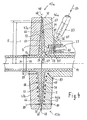

- Figure 2 shows schematically an embodiment of an inventive Device 11 for the production of composite insulators. It is only the invention contributing features shown and described.

- the apparatus 11 for producing composite insulators comprises in the present Embodiment essentially means 12 for applying the Material of the shield sheaths 3, a feed rod 13 via a long rod 14 is supplied from glass fiber reinforced plastic from which the cores 2, 102 of the Composite insulators 1, 101 are formed. Furthermore, the device 11 includes a Form 15 for shaping the screens 5, in front of the device 12 for application the material of the shield sheaths 3 is arranged. Close to the device 12 in the present embodiment, a heating section 16 for thermal Treatment of the material of the screen cover, a transport device 17 and a Separator 18 for separating the finished composite insulators 1 from the rod 14 on. The rod 14 is made by forming shorter sections 19 is composed. While the cores 2 of the finished composite insulators 1 of the rod 14 are separated before entering the device 12 for Applying the material of the shield covers 3 new sections 19 added, so that a continuous production of composite insulators is possible.

- connection of two sections, rods or tubes depends on the envisaged procedures. If only composite insulators are to be produced exactly As long as the interconnected bars or tubes, each bar forms or every tube a core. These cores only need each other so far to be connected, that a common transport is possible. That's enough For example, already the connection of two at the end faces abutting rods or pipes by means of adhesive tape.

- the Connecting the sections 19 with the end of the rod 14 takes place permanently through Gluing in an adhesive device 21, which is shown in Figure 3.

- She is the one Device 12 for applying the material of the shield covers 3 connected upstream.

- the Adhesive device 21 may for example by means of rollers 22 on a suspension rail 23 slidably suspended to during the gluing process the To be able to join feed movement of the rod 14.

- the adhesive device 21 stops with a fixed gripper 24 the rod 14 during the bonding process firmly.

- the portion 19 is fed via support rollers 28, whose distance from one another is adjustable to the diameter of the sections.

- adhesive is applied to the end face 20 of the rod 14 applied.

- the portion 19 by means of the gripper 25 in the direction of arrow 30th with its end face 20 against the wetted with adhesive end face 20 of the rod 14th pressed and held until the adhesive bond is resilient. While this time travels the adhesive device 21 in the feed direction 31 of the rod 14, which is possible by running on the hanging rail 23.

- the grippers 24 and 25 are opened and the adhesive device 12 at the still free end of the just glued portion 19 driven to there the glue next section.

- the production of composite insulators can be fully automatic, with the Processes in the individual devices by means of a control device 32nd be coordinated with each other.

- the individual facilities are via signal and Control lines 33 connected to the controller 32.

- the device 12 When starting the device 11 for the production of composite insulators 1 is a rod 14 in the feed direction 31 through the open drive rollers 34 of the Feed device 13 in the spray head 35 of the device 12 for applying the Material of the shield shell introduced.

- the device 12 is in the present Embodiment an extruder.

- the material 36 from which the screen covers. 3 are molded in the present embodiment an HTV silicone rubber. He is as a band of a supply roll in a known manner by a rotating Worm 37 drawn into the extruder 39 and annular by a rod 14 surrounding nozzle in the spray head 35 and in evenly thick layer on the rod 14 applied.

- the application of the material 36 for the screen cover 3 occurs evenly, the drive 40 of the screw 37 via a synchronization controller 41 connected to the feed device 13 of the rod 14.

- the screen cover 3 well on the core 102 of the still to be produced Composite insulator 101 adheres is in a device 42, in the present Embodiment of the feed device 13 is connected upstream and the rod 14th goes through, applied an adhesive. Furthermore, a length measuring device 43 provided, which rests with a Tastrad 44 on the surface of the rod 14. With the length measuring device 43, the feed of the rod 14 is monitored, the length of the Cores 2 and 102 and the distances of the screens measured from each other and the Separator 18 and the order of the material of the screen covers 3 controlled.

- the rod 14 is inserted so far into the spray head 35 that its front page with the outlet opening of the annular nozzle, not shown here matches. Then it will be the feed device 13 is turned on, the extruder 12, the means for Applying the material 36 of the screen covers 3, but not yet. Only when the staff 14, which is from now on the future core of a new composite insulator to the the by the attachment of the valve predetermined length 8, section A in Figure 1, from the spray head 35 is exited, the extruder 12 is turned on and the Material 36 applied to form a screen cover 3. This is the first coat 4 formed. After the predetermined by the controller 32 length through the length measuring device 43 has been detected, the feed of the rod 14th stopped. Section B of the composite insulator is thus made.

- the screw 37 continues to promote the Material 36 for forming the screen cover 3 in the area C. This swells the extrudate 45 from the application nozzle concentrically around the rod 14. After the time is the Promotion of the extrudate 45 stopped and formed from a screen 5.

- a mold 15 For shaping a screen 5, a mold 15 is used. It consists of two Halves 46 and 47, wherein the first half 46 directly to the front of the Spray head 35 is arranged, at which the rod 14 exits.

- the second mold half 47 is, seen in the transport direction 31 of the rod 14, behind the first mold half 46th arranged.

- the two mold halves 46 and 47 are divided in a plane 48 in the is substantially perpendicular to the longitudinal axis 26 of the rod 14, as through the right angle 49 is indicated. While the first mold half 46 fixed to the Spray head 35 is connected, the second mold half 47 along the longitudinal axis 26 of the rod 14 for closing in the direction of the first mold half 46 and to Opening are moved away from her, as indicated by the double arrow 50.

- the second mold half 47 at least once again divided into two halves 51 and 52, wherein the Dividing plane 53 is perpendicular to the first dividing plane 48 and through the Longitudinal axis 26 of the rod 14 goes.

- the division of the mold half 47 allows their Partial halves 51 and 52 substantially radially to the longitudinal axis 26 of the rod 14, ie in to move substantially in the division plane 48, as by the double arrow 54 is hinted at.

- the two halves 51 and 52 of the mold half 47 can by means of a device 55 are opened and closed, as with the double arrow 54th is also indicated. Possible, but not shown here, is also a unfolding the two halves as two wings.

- the device takes over 55 even the opening and closing of the two mold halves 46 and 47 for Shaping the screens.

- the device 55 is connected via a control line 33 with the Control device 32 connected.

- the shape of a screen 5 can also be made so that the mold 15 already is closed when the feed of the rod 14 is stopped. That for the Forming a screen provided extrudate 45 is then in the closed Form promoted. Again, the flow rate of the extrudate from the Control device 32 are preset over time. It is also possible Control of the filling quantity via pressure sensors in the form 15 or on the walls the mold halves 46 and 47, as not shown here.

- the mold half 47 Since the mold half 47 is again divided into two halves 51 and 52, can whose parting line creates a ridge. To avoid this as far as possible by a corresponding shaping of the edges of the partial halves, for example By rounding, the formation of a sharp and thus disturbing ridge avoided become.

- the mold half 47 for shaping the bottom of the Umbrellas be provided so that with the one-piece mold half 46, the top of the Umbrellas can be formed completely burr-free.

- the mold 15 After the shaping of a screen 5, the mold 15 has the screen without Release damage to its surface.

- the mold halves 46 and 47 must be carefully opened, so that the screen surface is not damaged. It can be done this way be that filling the mold 15 by means not shown here pressure sensors is monitored. At a given, the degree of desired filling corresponding pressure, the mold is opened a predetermined gap. This will be First, the mold half 47 in total slowly and in the direction of the longitudinal axis 26th of the rod 14 retracted, for example by about one millimeter, to the pressure to reduce the material and to solve its adhesion to the mold walls.

- the mold is fully opened to release the umbrella and the two Part halves 51 and 52 radially to the longitudinal axis 26, in the direction of arrow 54, pulled apart.

- the screen 5 is lifted from the mold half 46.

- the extruder 12 With switching on the feed device 13 for advancing the rod 14 is at the same time the extruder 12 is turned on, so that the screen 5 without Interruption of the coating of the jacket connects.

- the length of the applied Mantels 4 to the formation of another screen is through the Control device 32 determined. After by the length measuring 43, the predetermined length of the shell 4 has been found, the Feed device 13 stopped and composite insulators with multiple screens the shaping of another screen takes place.

- the extruder 12th is subordinate.

- a thermal treatment of the still soft material of the shield shell 3 so that he required for an insulator obtained mechanical and electrical properties.

- the heating section 16 is a continuous furnace in the present embodiment.

- the Heat treatment of the raw screen covers is done according to the inventive method with hot air. This is a uniform, a local Overheating avoiding heating of the screen covers ensured.

- the hot air is generated by means of a blower 56 with a downstream heater 57 and blown evenly into the continuous furnace 16.

- the temperature and the Air flow rate are controlled by the controller 32.

- the length of the Continuous furnace 16 and the thermal treatment of the screen cover are on the Material of the screen and the feed rate of the rod 14 tuned.

- the order is via the controller 32 of the material 36 of the screen cover 3 is stopped while the advancement of the rod 14 continues.

- the order of the Material of the shield shell remains interrupted until the Length measuring device 43 has determined that the rod 14 by such a distance has been advanced, which corresponds to the length used to attach the fittings on the just finished with the screen cover and the subsequent, still composite insulator to be produced is required.

- the thickness of the Saw blade of the separator 18 taken into account. After that, the application of the Material for the shield shell of the following composite insulator again added.

- two finished composite insulators 1 are already on the transport device 17 accumulated.

- the Separator 18 At the transport device 17 is the Separator 18 at such a distance from its beginning, the guide roller 59, arranged that in addition to two completely finished composite insulators 1 also still at least one already fully cured screen 5 one more composite insulator 101 to be finished rests on the conveyor belt 58. Thereby becomes a good support of the still to be finished composite insulator 101 reached.

- the separator 18 is with respect to the length of the produced Composite insulators can be moved into appropriate positions, as with the double arrow 60 is indicated. For this purpose, the separator 18, for example, with rollers 61 be slidably suspended on a suspension rail 62.

- the separator 18 After a Positioning by the length measuring device 43 from the controller 32 at directs a location of the transport device 17, where on the conveyor belt 58 the Separation point 10 between two composite insulators 1 is located, for separating at the Cut point 10 delivered and retracted after the separation process again, such as indicated by the double arrow 63.

- the separation of the finished Composite insulators occur whenever a screen is being formed and the Feed device 13 of the rod 14 is.

- the separator 18 fixed with a the Verbundisolator 1 undeliverable gripper 64 the end 7 of the separated Composite insulator during the separation process. From the still continuous bar 14, the core 2 of the insulator 1 is separated with a saw 65. After this Separation process, the gripper 64 is opened and withdrawn and the Separator 18 returns to its original position.

- the severed Composite insulator 1 can now be removed for further processing or will when restarting the transport device 17 to a not shown here Transported collection point.

- the formation of the rod 14 can be chosen so that each glued rod only as long as the core of a composite insulator. That would be each splice at the same time again a separation point 10 and no core would be a Clipping site included.

- the mold 15a is closed and consists of the mold half 46a, in front of here Not shown spray head is arranged, and the mold half 47a.

- the two Mold halves 46a and 47a are divided in the dividing plane 48 perpendicular to the Longitudinal axis 26 of the rod 14 is, as indicated by the right angle 49.

- the dividing plane 48 simultaneously forms the bottom 66 of the screen 5.

- Die Top 67 of the screen 5 lies in the mold half 46a.

- the shaping of the screen 5 is already completed. In front of the screen 5 extends on the rod 14 of the Sheath 4 of the screen cover 3.

- a ridge formed by the parting line 68 of the two mold halves 46a and 47a is prevented by the following measures: Dosing of the extrudate to form a screen is done so that the Shaping a screen 5 provided molding space 69 of the mold 15 a not to Dividing line 68 is filled. The radial extent R of the mold space 69 is greater than the actually achieved radius r of the screen 5. The parting line 68 is in Edge region 70 of the screen 5 is not closed.

- the parting line 68 between the Both mold halves 46a and 47a can be either on the entire circumference of the mold 15a be open, so that the two mold halves are spaced from each other, or the two mold halves abut each other, but point radially directed, on the Circumferentially distributed grooves, which form channels in closed form to Escape of the air from the mold cavity 69 during molding of the screen. 5

- the shaping surface 72 of the mold half 47 a, the bottom 66 of the Shade forms 5, is smooth in the present embodiment. She can, too concentric be wavy or ribbed. This creates umbrellas with larger Creepage distance. With umbrellas designed in this way, there are fewer compared to smooth umbrellas Umbrellas required per insulator.

- the central opening 73 in the mold half 47 a, with the jacket 4 coated core 102 has a larger diameter than 74 Diameter 75 of the core 102 with jacket 4.

- the difference should be about 0.5 mm be.

- the air poppet valves 77 in the mold halves be provided. They are preferred to be arranged in the areas of the mold, in due to the difficult access to air, the risk of sticking the Screen surface is largest, as in the area of the screen root.

- the present Embodiment is in the mold half 46a a poppet valve in the region of Umbrella root 78 arranged.

- the plate 79 of the valve 77 is flush with the forming surfaces 71 of Mold half 46a from.

- the valve disk 79 is acted upon by a valve stem 80

- Spring 81 is pulled into the valve seat 82.

- the force of the springs 81 is set so that upon reaching a certain negative pressure, which occurs when opening the mold, the plate 79th of the valve 77 lifts off the valve seat 82.

- the negative pressure is set so that a Deformation of the screen 5 is avoided. In addition to the inflow of air presses the plate 79 on the screen surface and lifts them from the forming surfaces 71 off.

- the detachment of the screen 5 from the mold walls can additionally by the supply be supported by compressed air 84 by means of the nozzle 83.

- the nozzle 83 with set their conical mouthpiece 85 in the funnel-shaped adapter 86, the over a channel 87 is connected to the poppet valve 77 and above the valve disk 79 opens. If the compressed air supply 84 is initiated, the valve plate 79 is against the Stressed by the spring 81 from the valve seat 82 and gives the supply of air in the Shaping room 69 free.

- a short-term compressed air supply can also be on the verge of opening the form. This releases the screen surface at the critical points even before opening the two mold halves of the mold walls.

- a mold 15b shown below the longitudinal axis 26 of the rod 14 is another possible embodiment a mold 15b shown. With the shape 15 a matching features are with the same reference numerals.

- the two mold halves 46b and 47b with a heater for thermal treatment the material of the umbrella cover equipped.

- the mold halves 46b and 47b are in at certain distances from each other heating wires 88 inserted, which have connections 89 are connected to a not shown, controllable current source.

- the current and the time can be a predetermined temperature and thus a predetermined state of the material of the shielding shell can be achieved.

- the final thermal treatment would then be in take a continuous furnace.

- the last-described embodiment of a mold may additionally, as here not shown and described, with the previously described embodiment with The valves are combined for the supply of air.

Landscapes

- Insulating Bodies (AREA)

- Insulators (AREA)

Abstract

Description

Die Erfindung betrifft ein Verfahren zur Herstellung von Verbundisolatoren entsprechend dem Oberbegriff des ersten Anspruchs sowie eine Vorrichtung zur Herstellung von Verbundisolatoren entsprechend dem Oberbegriff des neunzehnten Anspruchs.The invention relates to a method for producing composite insulators According to the preamble of the first claim and a device for Production of composite insulators according to the preamble of the nineteenth Claim.

Hochspannungsisolatoren werden außer aus den konventionellen Werkstoffen Porzellan und Glas zunehmend auch als Verbundisolatoren hergestellt. Verbundisolatoren bestehen aus einem stab- oder rohrförmigen Kern, der sich wiederum beispielsweise aus mit Glasfasern verstärktem Epoxidharz zusammensetzt und einer Schirmhülle, gegliedert in einen Mantel um den Kern mit einer Anzahl beabstandeter, tellerförmiger Schirme oder einem oder mehrerer spiralförmiger Schirme, wobei die Schirmhülle aus einem Werkstoff mit Isolationseigenschaften besteht. Zu diesen Werkstoffen zählen elastomere Werkstoffe, beispielsweise polymere Kunststoffe. Mit solchen Werkstoffen läßt sich der Kern leicht ummanteln, bevor mittels einer nachfolgenden thermischen Behandlung der Werkstoff endgültig seine gewünschten mechanischen und elektrischen Eigenschaften erhält.High voltage insulators are out of the conventional materials Porcelain and glass increasingly also manufactured as composite insulators. Composite insulators consist of a rod or tubular core, which is in turn, for example composed of glass fibers reinforced epoxy resin and a screen sheath, divided into a sheath around the core with a number spaced, plate-shaped umbrellas or one or more spiral Umbrellas, wherein the screen cover of a material with insulating properties consists. These materials include elastomeric materials, for example polymeric plastics. With such materials, the core can easily wrap, before by means of a subsequent thermal treatment of the material final obtains its desired mechanical and electrical properties.

Der Kern eines Verbundisolators dient zur Aufnahme der Kräfte, die durch die Aufhängung auf den Isolator einwirken, und trägt deshalb an seinen Enden entsprechend ausgebildete Armaturen, in der Regel aus Metall. Die Schirmhülle soll elektrische Überschläge, in der Regel aufgrund von Witterungseinflüssen, verhindern. Verbundisolatoren haben gegenüber den herkömmlichen Isolatoren aus Glas oder Porzellan den Vorteil, daß sie wesentlich leichter sind. Außerdem haben sie aufgrund des schmutz- und wasserabweisenden Werkstoffs der Schirmhüllen sehr gute Isolationseigenschaften und eignen sich deshalb besonders für Gebiete mit stark verschmutzter Atmosphäre. Diese Eigenschaft wird allerdings nur erreicht, wenn der Überzug des Kerns an keiner Stelle unterbrochen oder vom Kern abgehoben ist, beispielsweise durch Fugen, Nähte oder Spalten. The core of a composite insulator serves to absorb the forces generated by the Suspension acting on the insulator, and therefore carries at its ends appropriately designed fittings, usually made of metal. The screen cover should electrical flashovers, usually due to weather conditions prevent. Composite insulators have compared to the conventional insulators made of glass or Porcelain the advantage that they are much lighter. Besides, they have due the dirt and water-repellent material of the shield covers very good Isolation properties and are therefore particularly suitable for areas with strong polluted atmosphere. This property is only achieved if the Coating of the core is not interrupted at any point or lifted off the core, for example, by joints, seams or columns.

Aus der DE 196 29 796 A1 sind Verbundisolatoren sowie Verfahren zu ihrer Herstellung bekannt. Dabei werden der Mantel und der Schirm gleichzeitig in einem Arbeitsgang kontinuierlich geformt. Nach den bekannten Verfahren sind allerdings nur Verbundisolatoren mit spiralförmigen Schirmen herstellbar. Die Erfahrungen mit solchen Verbundisolatoren werden augenblicklich noch als zu gering angesehen.From DE 196 29 796 A1 are composite insulators and methods for their Production known. At the same time, the mantle and the shade become in one Operation continuously shaped. However, according to the known methods are only Composite insulators with spiral-shaped screens can be produced. The experiences with Such composite insulators are currently considered too low.

Aufgabe der vorliegenden Erfindung ist es, ein Verfahren und eine Vorrichtung vorzustellen, mit denen die Herstellung von Verbundisolatoren mit einer beliebigen Anzahl von ringförmigen Schirmen und einer durchgehenden Schirmhülle möglich ist.The object of the present invention is a method and a device to imagine with which the manufacture of composite insulators with any Number of annular shields and a continuous screen cover is possible.

Die Lösung dieser Aufgabe erfolgt nach dem erfindungsgemäßen Verfahren mit Hilfe der kennzeichnenden Merkmale des ersten Anspruchs. Eine erfindungsgemäße Vorrichtung zur Herstellung der Verbundisolatoren ist gekennzeichnet durch die Merkmale des Anspruchs neunzehn.The solution of this task is carried out by the method according to the invention with the help the characterizing features of the first claim. An inventive Device for producing the composite insulators is characterized by the Features of claim nineteen.

Gegenüber den bekannten Verfahren zur Ummantelung der Kerne von Verbundisolatoren ist es mit dem erfindungsgemäßen Verfahren möglich, Verbundisolatoren mit einer beliebigen Anzahl von ringförmigen Schirmen und in beliebiger Länge nacheinander herzustellen, wobei die Schirmhülle durchgehend ist und keine Fugen, Nähte oder Spalten aufweist. Dazu wird der Kern, wie aus der DE 196 29 796 A1 bekannt ist, mit konstanter Geschwindigkeit mittig durch das Mundstück einer Einrichtung zum Auftragen des Werkstoffs der Schirme, beispielsweise eines Extruders oder einer Kolbenpresse, geführt, wobei der Werkstoff allseitig auf den Kem aufgetragen wird. Die Formgebung der ringförmigen Schirme erfolgt aber im Gegensatz zum bekannten Verfahren so, daß, in Vorschubrichtung des Kerns gesehen, nach der Einrichtung zum Auftragen des Werkstoffs dieser Einrichtung eine Form zugestellt wird. Während der Kern angehalten wird, wird die Form mit dem Werkstoff der Schirmhülle gefüllt und ein Schirm gebildet Wenn der Schirm die vorgesehene Form erreicht hat, wird die Form geöffnet, der Schirm freigegeben und der Vorschub des Kerns wieder eingeleitet. Dabei wird die Zufuhr des Werkstoffs so gesteuert, daß der Auftrag des Werkstoffs nicht unterbrochen wird, bis daß die Schirmhülle vollständig hergestellt ist. Dadurch weist die Schirmhülle an keiner Stelle des Verbundisolators Fugen, Nähte oder Spalten auf.Compared with the known method for sheathing the cores of Composite insulators it is possible with the method according to the invention, Composite insulators with any number of annular shields and in produce any length in succession, the screen cover is continuous and has no joints, seams or gaps. This is the core, as from the DE 196 29 796 A1 is known, with constant speed in the middle of the Mouthpiece of a device for applying the material of the screens, for example, an extruder or a piston press, led, wherein the material applied on all sides on the core. The shape of the ring-shaped umbrellas However, in contrast to the known method so that, in the feed direction of the Kerns seen after the device for applying the material of this device a mold is delivered. While the core is being stopped, the shape is filled with the Material of the screen cover filled and a screen formed When the screen has reached the intended shape, the mold is opened, the screen released and the advance of the core is initiated again. The supply of the material is so controlled that the order of the material is not interrupted until that Umbrella shell is completely made. As a result, the screen cover at any point of the composite insulator joints, seams or columns.

Aus der DE 42 02 653 A1 ist es bekannt, die komplette Schirmhülle mit ringförmigen Schirmen in einer Form um den Kern zu formen. Da die Form in der Ebene teilbar ist, in der der Kern liegt, weist die Schirmhülle auf ihrer gesamten Länge zwei gegenüberliegende Grate auf. Grate müssen weitestgehend entfernt werden, weil sie Störquellen in Bezug auf die Isolation sind, insbesondere wenn sie auf der Oberseite und auf dem Umfang der Schirme liegen. Grate sind Sammelstellen für Schmutz, der die Isolationseigenschaft erheblich herabsetzen kann. In Weiterbildung der Erfindung können insbesondere auf dem Umfang der Schirme Grate dadurch vermieden werden, daß die Form, mit der die Formgebung der Schirme erfolgt, in ihrer radialen Ausdehnung größer ist als der Radius des Schirms und nicht vollständig mit dem Werkstoff der Schirmhülle ausgefüllt wird, so daß die Trennfuge nicht vom Werkstoff erreicht wird. Die Formhälfte zur Formgebung der Oberseite der Schirme sollte zur Vermeidung von Graten einteilig sein. Durch die vorteilhafte Ausgestaltung der Form entfällt ein Arbeitsschritt zur Entfernung der Grate.From DE 42 02 653 A1 it is known, the complete umbrella cover with annular Shield in a form to form the core. Since the shape is divisible in the plane, in which the core is located, the shield shell has two over its entire length opposite ridges on. Burrs have to be removed as far as possible because they are Sources of interference with respect to the insulation are, especially if they are on the top and lie on the perimeter of the umbrellas. Burrs are collection points for dirt, the can significantly reduce the isolation characteristic. In development of the invention can be avoided in particular on the scope of the umbrellas burrs, that the shape with which the shaping of the screens takes place in their radial Extension is greater than the radius of the screen and not completely with the Material of the shield is filled, so that the parting line is not the material is reached. The mold half for shaping the top of the screens should for Avoid burrs in one piece. Due to the advantageous embodiment of the form eliminates a step to remove the burrs.

Beim Öffnen der Form kann die Oberfläche der Schirme an den Formwänden haften bleiben. Dadurch lassen sich die Schirme schwer ausformen und es besteht die Gefahr, daß ihre Oberfläche beschädigt wird. Die Haftneigung kann werkstoffbedingt sein, kann aber auch durch die Adhäsion der Schirmoberfläche an den formgebenden Oberflächen der Form, den Formwänden, hervorgerufen werden, wenn die Zufuhr von Luft an die Stellen erschwert ist, wo sich die Schirmoberfläche von den Formwänden lösen soll. Um das Ausformen der Schirme zu erleichtem ist es vorteilhaft, einen Werkstoff mit einer hohen Williams-Plastizität zu verwenden. Die Neigung, auf Oberflächen zu haften, nimmt mit steigender Williams-Plastizität ab. Dem Werkstoff kann auch ein Antihaftadditiv beigemischt werden, um seine Haftneigung herabzusetzen. When opening the mold, the surface of the screens can adhere to the mold walls stay. This makes the umbrellas difficult to shape and it is the Risk of their surface being damaged. The tendency to stick may be due to the material can be, but also by the adhesion of the screen surface to the shaping Surfaces of the mold, the mold walls, are caused when the supply of Air is difficult to the places where the screen surface of the mold walls should solve. To facilitate the shaping of the umbrellas, it is advantageous to have a To use material with a high Williams plasticity. The inclination, up Surface sticking decreases with increasing Williams plasticity. The material Also, a non-stick additive can be added to its sticking tendency decrease.

Die Gefahr des Haftens des Werkstoffs der Schirmhülle an den Formwänden kann weiterhin dadurch herabgesetzt werden, daß die Formwände aus einem Werkstoff bestehen, der sogenannte Antihafteigenschaften aufweist, wie beispielsweise Polytetrafluorethylen.The risk of sticking the material of the screen cover to the mold walls can continue to be reduced by the fact that the mold walls made of a material exist, which has so-called non-stick properties, such as Polytetrafluoroethylene.

Bei zum Haften neigenden Werkstoffen, insbesondere beispielsweise Silikonen, sind folgende Verfahrensschritte beim Ausformen der Schirme vorteilhaft: Das Füllen der Form wird mit mindestens einem Drücksensor an oder in der Form überwacht. Bei einem bestimmten, den Grad der gewünschten Füllung entsprechenden Druck wird die Form einen vorgegebenen Spalt geöffnet. Dazu wird zunächst die in Vorschubrichtung des Kerns vornliegende Formhälfte in Vorschubrichtung des Kerns verschoben, beispielsweise um etwa einen Millimeter, um den Druck auf den Werkstoff zu verringern und seine Haftung an den Formwänden zu lösen. Erst danach wird die Form zur Freigabe des Schirms vollständig geöffnet.When prone to sticking materials, especially for example silicones, are following steps in forming the umbrellas advantageous: filling the Shape is monitored with at least one pressure sensor on or in the mold. at a certain, the degree of desired filling corresponding pressure the mold opens a given gap. For this purpose, first in Feed direction of the core forward mold half in the feed direction of the core shifted, for example, by about a millimeter to the pressure on the Reduce material and solve its adhesion to the mold walls. Only after the mold is fully opened to release the screen.

Die Adhäsion an den formgebenden Oberflächen der Form kann allerdings so groß sein, daß ihre Überwindung durch weitere Verfahrensschritte unterstützt werden muß. Um ein beschädigungsfreies Ausformen der Schirme zu gewährleisten, kann das Ablösen der Schirmoberfläche durch Luftzufuhr zur Schirmoberfläche, insbesondere an besonders gefährdete Stellen des Schirms wie die Schirmwurzel, unterstützt werden. Dazu sind in den Formwänden Kanäle vorgesehen, die auf den formgebenden Oberflächen enden. Die Kanäle sind zu den formgebenden Oberflächen hin durch Ventile verschlossen die sich dann öffnen, wenn beim Ablösen der Schirmoberflächen von den Formwänden ein Unterdruck entsteht. Die Ablösung kann mit Druckluft unterstützt werden, die durch die Ventile eingeblasen wird.However, the adhesion to the shaping surfaces of the mold can be so great be that their overcoming must be supported by further process steps. To ensure a damage-free shaping of the umbrellas, the Detachment of the screen surface by air supply to the screen surface, in particular at particularly endangered areas of the screen such as the umbrella root, supported become. For this purpose, channels are provided in the mold walls, which on the forming surfaces finish. The channels are shaping Surface closed by valves which then open when peeling the screen surfaces of the mold walls creates a negative pressure. The replacement can be assisted with compressed air injected through the valves.

Das Ablösen der Schirmoberflächen von den Formwänden kann auch mechanisch durch Drehen mindestens einer Formhälfte gegenüber der anderen um die Längsachse des Kerns unterstützt werden, wobei eventuell an den Formwänden anhaftender Werkstoff aufgrund der Scherbewegung gelöst wird. The detachment of the screen surfaces from the mold walls can also be mechanical by rotating at least one mold half opposite the other around the Longitudinal axis of the core are supported, possibly on the mold walls adhering material is released due to the shearing motion.

Die in Transportrichtung gesehen vornliegende Formhälfte muß mindestens zweiteilig ausgebildet sein, um durch Öffnen in einer im wesentlichen radialen Richtung, durch Auseinanderziehen oder Aufklappen, den Weg für den Schirm freigeben zu können. Es können auch beide Formhälften zweiteilig ausgebildet sein. Beim Öffnen der Form können die Teilhälften der einen Formhälfte zeitversetzt zu den Teilhälften der anderen Formhälfte geöffnet werden, wobei die Teilhälften wiederum in einer im wesentlichen radialen Richtung vom Kern hinwegbewegt werden. Durch diese Verfahrensweise wird eine Deformation des Schirms in Öffnungsrichtung vermieden, wie sie beim gleichzeitigen Öffnen der Teilhälften auftreten könnte.The seen in the transport direction forward mold half must be at least two parts be formed to by opening in a substantially radial direction, through Pull apart or open, to clear the way for the screen. Both mold halves can also be designed in two parts. When opening the mold the halves of one half of the mold can be offset in time from the halves of the mold other half of the mold to be opened, the part halves turn in a in the substantially radial direction away from the core. Through this Procedure, a deformation of the screen in the opening direction is avoided as they might occur when opening the halves of the part at the same time.

Eine weitere Möglichkeit, die Haftneigung des Werkstoffs der Schirmhülle an den Formwänden zu überwinden besteht darin, die Form zu beheizen. Die Wärmebehandlung kann auf die Aushärtung der Oberfläche beschränkt sein, so daß sich der Schirm leicht ausformen läßt. Die abschließende Wärmebehandlung würde dann in einem weiteren Verfahrensschritt erfolgen. Die Wärmebehandlung kann aber auch den gesamten erforderlichen Prozeß zur Aushärtung des Werkstoffs der Schirmhülle umfassen.Another way, the sticking tendency of the material of the shielding shell to the To overcome mold walls is to heat the mold. The Heat treatment may be limited to the curing of the surface, so that The umbrella can be easily shaped. The final heat treatment would then take place in a further process step. But the heat treatment can also the entire required process for curing the material of the Cover screen.

An den Enden eines Kerns werden die Armaturen befestigt, mit denen an der einen Seite der Isolator selbst und auf der anderen Seite der elektrische Leiter befestigt ist. Zur Befestigung der Armaturen auf dem Kern müssen die Enden des Kerns frei vom Werkstoff der Schirmhülle sein. Bei der Herstellung eines erfindungsgemäßen Verbundisolators wird zunächst dann, wenn der Anfang des Kerns aus der Vorrichtung zum Auftragen des Werkstoffs der Schirmhülle austritt, der Auftrag des Werkstoffs so lange ausgesetzt, bis daß die für die Befestigung der Armatur vorgesehene Länge die Vorrichtung verlassen hat. Wenn am Ende des Kerns der Punkt erreicht wird, ab dem er die Armatur tragen soll, wird die Zufuhr des Werkstoffs unterbrochen. Der Mantel reißt dann beim weiteren Vorschub des Kerns an der Einrichtung zum Auftragen des Werkstoffs ab und der Kern bleibt nackt. At the ends of a core, the faucets are attached, with those at the one Side of the insulator itself and on the other side the electrical conductor is attached. To attach the fittings to the core, the ends of the core must be free from Be the material of the screen cover. In the manufacture of an inventive Composite insulator is first used when the beginning of the core from the Device for applying the material of the screen sheath emerges, the order of the Material exposed as long as that for the attachment of the fitting provided length has left the device. If at the end of the core of the Point is reached, from which he should wear the fitting, the supply of the material interrupted. The coat then tears at the further advancement of the core at the Device for applying the material from and the core remains naked.

Eine weitere Möglichkeit, ein mantelfreies Ende des Kerns zu erhalten besteht darin, den Stab bei kontinuierlicher Förderung des Mantelwerkstoffs ruckartig um das Stück vorzuschieben, das freibleiben soll. Aufgrund seiner Viskosität reißt der Mantelwerkstoff beim Vorschieben ab und wird erst dann wieder aufgetragen, wenn der Kern mit der üblichen Vorschubgeschwindigkeit durch die Einrichtung zum Auftragen der Schirmhülle transportiert wird.Another way to obtain a sheath-free end of the core is to the rod with continuous promotion of the shell material jerkily around the piece to advance, which should remain free. Due to its viscosity ruptures the Sheath material from advancing and is only reapplied when the core with the usual feed rate through the device for Applying the screen cover is transported.

Durch die zuvor beschriebenen Verfahrensschritte wird ein Arbeitsgang zur nachträglichen Entfernung des Mantels an den Enden des Kerns, wo er die Armaturen tragen soll, eingespart. Zusätzlich wird dadurch Werkstoff eingespart, der sonst verlorenging.By the method steps described above, a single operation for subsequent removal of the jacket at the ends of the core, where he has the fittings should carry, saved. In addition, this material is saved, the otherwise got lost.

Eine Vereinfachung des Arbeitsablaufs zur Produktion eines Verbundisolators wird erreicht, wenn nicht jeder Kern einzeln der Einrichtung zum Auftragen des Werkstoffs der Schirmhülle zugeführt werden muß. Wenn der für die Kerne vorgesehene Stab oder das Rohr aus glasfaserverstärktem Kunststoff so lang ist, daß mindestens zwei Verbundisolatoren nacheinander hergestellt werden können, kann ein fertig geformter Verbundisolator oder zumindest der bereits fertig geformte Teil des Verbundisolators durch eine Heizeinrichtung geführt werden, ohne daß eine Abstützung auf dem noch nicht ausgehärteten Werkstoff der Schirmhülle erforderlich ist. Anschließend kann der Verbundisolator oder zumindest der Teil des Verbundisolators, der bereits der Wärmebehandlung unterzogen wurde, den noch die Wärmebehandlung zu unterziehenden Teil unterstützungslos tragen, der die Einrichtung zum Auftragen des Werkstoffs der Schirmhülle bereits verlassen hat.A simplification of the workflow for the production of a composite insulator is achieved, if not each core individually of the device for applying the material the screen cover must be supplied. If provided for the cores rod or the tube of glass fiber reinforced plastic is so long that at least two Composite insulators can be made one after another, can be a finished molded Composite insulator or at least the already finished molded part of the composite insulator be guided by a heater without a support on the still uncured material of the shielding is required. Then the Composite insulator or at least the part of the composite insulator, already the Heat treatment was subjected to the heat treatment Unaiding wearing part, which is the device for applying the Material of the shield has already left.

Statt einzelne Verbundisolatoren herzustellen kann der Herstellungsprozeß auch kontinuierlich durchgeführt werden, wenn jeweils ein nachfolgender Kern mit dem vorhergehenden Kern zu einem durchgehenden Stab oder Rohr großer Länge verbunden wird. Bei einer entsprechenden Qualität der Verbindung der Stäbe oder Rohre miteinander besteht die Möglichkeit, Verbundisolatoren unterschiedlicher Länge nacheinander zu fertigen. Die Länge der Verbundisolatoren wird also nicht mehr durch die Länge der einzeln zugeführten Kerne festgelegt, sondern durch die vorgegebene Anzahl der Schirme. Die Kerne werden dann getrennt, wenn die vorgegebene Anzahl der Schirme und damit die vorgegebene Länge eines Verbundisolators erreicht ist. Die Verbindung kann beispielsweise durch ein Aneinanderkleben der Stäbe oder Rohre oder ein thermisches Verbinden erfolgen. Sollte die Verbindung der Stäbe oder Rohre allerdings nur dazu genutzt werden, um einen durchgehenden Stab oder ein durchgehendes Rohr großer Länge zu erzeugen und die Verbindungsstellen nicht den mechanischen Anforderungen an den Kern eines Verbundisolators genügen, kann eine solche Verbindungsstelle als Stelle zum Abtrennen fertiger Verbundisolatoren festgelegt werden.Instead of producing individual composite insulators, the manufacturing process can also be carried out continuously, if in each case a following core with the previous core to a continuous rod or tube of great length is connected. With a corresponding quality of connection of the rods or Tubes together there is the possibility of composite insulators of different Length to manufacture one after the other. The length of the composite insulators will not more determined by the length of the individually supplied cores, but by the predetermined number of screens. The cores are then separated when the given number of screens and thus the given length of a Composite insulator is achieved. The connection can for example by a Sticking together of the rods or pipes or a thermal bonding done. However, the connection of the rods or tubes should only be used to To produce a continuous rod or a continuous pipe of great length and the joints do not meet the mechanical requirements for the core meet a composite insulator, such a junction as a body for Separating finished composite insulators are set.

Bei der Herstellung der Verbundisolatoren kann vorteilhaft so verfahren werden, daß die nach dem Auftragen des Werkstoffs der Schirmhülle bereits ausgeformten Teile des Verbundisolators zur Erzeugung der geforderten Werkstoffeigenschaften der fertigen Schirmhülle thermisch behandelt werden, während der Werkstoff zur Ausformung des noch restlichen Teils des Verbundisolators oder bereits zur Ausformung des nachfolgenden Verbundisolators auf dem durchgehenden Kern aufgetragen wird, wenn aufgrund der Zufuhr langer Stäbe oder Rohre zur individuellen Abtrennung von Kernen eine kontinuierliche Fertigung von Verbundisolatoren vorgesehen ist. Bei diesen Verfahrensvarianten muß, im Gegensatz zum Stand der Technik, nicht mehr auf die vollständige Fertigstellung eines Verbundisolators gewartet werden, bevor die erforderliche thermische Behandlung erfolgen kann.In the manufacture of the composite insulators can advantageously be moved so that after the application of the material of the shielding shell already formed parts of the composite insulator to produce the required material properties of finished screen sheath are thermally treated, while the material for Forming of the remaining part of the composite insulator or already for Forming the subsequent composite insulator on the continuous core is applied when due to the supply of long rods or tubes for individual separation of cores continuous production of Composite insulators is provided. In these process variants must, in Contrary to the state of the art, no longer on the complete completion a composite insulator to be serviced before the required thermal Treatment can be done.

Bei der thermischen Behandlung von Verbundisolatoren mit Wärmestrahlungsquellen, die vom äußeren Umfang her auf die Verbundisolatoren einwirken, besteht die Gefahr einer Überhitzung der dünnen Schirmränder. Eine gleichmäßige Erwärmung des Mantels und insbesondere der Schirme wird vorteilhaft dadurch erreicht, daß zur Erwärmung heiße Luft verwendet wird. Die Heizstrecke, die der Verbundisolator durchläuft, ist mit einem Heißluftgebläse ausgestattet, das für eine gleichmäßige Temperaturverteilung und damit für eine gleichmäßige Erwärmung der Schirmhülle sorgt.In the thermal treatment of composite insulators with heat radiation sources, which act on the composite insulators from the outer periphery, there is a risk Overheating of the thin screen edges. A uniform heating of the Mantels and in particular the umbrellas is advantageously achieved in that the Heating hot air is used. The heating section, which is the composite insulator is equipped with a hot air blower, which ensures a uniform Temperature distribution and thus for a uniform heating of the screen cover provides.

Wenn der Werkstoff der Schirmhülle ein entsprechend hohes Dipolmoment aufweist, beispielsweise Silikonkautschuk (HTV) oder Ethylen-Propylen-Copolymer (EPM), ist auch eine Vulkanisation mit energiereicher Strahlung, beispielsweise mit Mikrowelle, möglich.If the material of the shielding shell has a correspondingly high dipole moment, for example, silicone rubber (HTV) or ethylene-propylene copolymer (EPM) also a vulcanization with high-energy radiation, for example with a microwave, possible.

Die Handhabung der Verbundisolatoren während ihrer Herstellung wird insbesondere dadurch erleichtert, daß mindestens ein bereits fertiger Verbundisolator, der noch über den Kern mit dem nachfolgenden, noch nicht fertigen Verbundisolator verbunden ist, durch eine Fördereinrichtung abgestützt wird. Die Fördereinrichtung ist der Heizeinrichtung nachgeschaltet. Der durchgehende Stab oder das durchgehende Rohr, von dem die fertigen Verbundisolatoren abgeschnitten werden, ist auf der einen Seite in den Antriebsrollen der Vorschubeinrichtung für den Stab oder das Rohr gelagert und wird auf der anderen Seite durch einen fertigen Verbundisolator abgestützt. Dadurch ist es möglich, einen noch nicht fertigen Verbundisolator ohne Unterstützung seiner noch weichen Schirmhülle während seiner Formgebung und anschließenden thermischen Behandlung zu transportieren. Eine Verformung oder Beschädigung der Schirmhülle wird so vermieden. Die Fördereinrichtung kann beispielsweise ein nicht angetriebenes Förderband sein, auf dem die bereits fertigen Verbundisolatoren mit dem äußeren Umfang ihrer Schirme aufliegen. Die Verbundisolatoren werden allein durch den Vorschub des Kerns bewegt. Der Vorschub erfolgt mittels einer Vorschubeinrichtung durch die Einrichtung zum Auftragen des Werkstoffs der Schirmhülle hindurch. Das Förderband bewegt sich allein durch die auf ihm aufliegenden Verbundisolatoren vorwärts. Die Fördereinrichtung kann aber auch angetrieben sein. Dabei muß ihr Antrieb mit dem Antrieb des Stabs oder Rohrs synchron erfolgen.The handling of the composite insulators during their manufacture becomes particular facilitated by the fact that at least one already finished composite insulator that still connected via the core with the following, not yet finished composite insulator is supported by a conveyor. The conveyor is the Heating device downstream. The continuous bar or the continuous one Pipe from which the finished composite insulators are cut off is on one side Side in the drive rollers of the feed device for the rod or tube stored and on the other side by a finished composite insulator supported. This makes it possible, a not yet ready composite insulator without Supporting his still soft umbrella case during its shaping and subsequent thermal treatment to transport. A deformation or Damage to the screen cover is avoided. The conveyor can for example, be a non-driven conveyor belt on which already finished Composite insulators rest with the outer circumference of their screens. The Composite insulators are moved solely by the advance of the core. Of the Feed takes place by means of a feed device through the device for Applying the material of the screen cover through. The conveyor belt is moving only by the composite insulators resting on it. The Conveyor can also be driven. Their drive with the Drive the rod or tube synchronously done.

Im folgenden wird das erfindungsgemäße Verfahren zur Herstellung von Verbundisolatoren auf einer dazu vorgesehenen Vorrichtung erläutert. In the following, the inventive method for the production of Composite insulators explained on a device provided for this purpose.

Es zeigen:

Figur 1- schematisch den Aufbau eines Verbundisolators,

Figur 2- eine Vorrichtung zur Herstellung von erfindungsgemäßen Verbundisolatoren,

Figur 3- als Detail eine Einrichtung zur Bildung eines durchgehenden Stabs, von dem die Kerne der Verbundisolatoren abgeschnitten werden, und

Figur 4- als Detail weitere Ausführungsbeispiele einer Form zur Formgebung eines Schirms.

- FIG. 1

- schematically the structure of a composite insulator,

- FIG. 2

- a device for producing composite insulators according to the invention,

- FIG. 3

- as a detail, means for forming a continuous rod from which the cores of the composite insulators are cut, and

- FIG. 4

- as a detail, further embodiments of a mold for shaping a screen.

In Figur 1 ist der Aufbau eines erfindungsgemäßen Verbundisolators dargestellt, wie er die erfindungsgemäße Vorrichtung zur Herstellung von Verbundisolatoren vor dem Abtrennen vom Kern des nachfolgenden Verbundisolators verläßt.FIG. 1 shows the construction of a composite insulator according to the invention, such as FIG he the inventive device for the production of composite insulators before Separating from the core of the subsequent composite insulator leaves.

Der Verbundisolator 1 besteht aus einem Kern 2, der mit einer Schirmhülle 3

überzogen ist. Die Schirmhülle 3 gliedert sich in einen Mantel 4 und ringförmige

Schirme 5. Der Übersichtlichkeit halber ist hier nur ein Schirm 5 dargestellt. Ein

Verbundisolator weist fünf Abschnitte auf. Der Abschnitt A stellt das erste Ende 6 dar.

Es weist keinen Mantel 4 auf. Dieses freie Ende 6 hat eine Abmessung 8, die zur

Befestigung einer hier nicht dargestellten Armatur erforderlich ist. In Abschnitt B ist

der Kern 2 mit einem Mantel 4 überzogen. In Abschnitt C befindet sich der ringförmige

Schirm 5 und im Abschnitt D ist der Kern 2 ebenfalls mit einem Mantel 4 überzogen.

Der Bereich E umfaßt das zweite Ende 7 des Isolators 1 und hat die Abmessung 9,

die zur Befestigung der weiteren, hier nicht dargestellten Armatur erforderlich ist. An

den Bereich E schließt sich wiederum ein Bereich A des nachfolgenden Isolators 101

an, der hier nicht vollständig dargestellt ist und auch noch nicht vollständig

fertiggestellt sein soll. The

Wie aus Figur 1 weiter ersichtlich ist, bilden der Kern 2 und der Kern 102 des

nachfolgenden Verbundisolators 101 im vorliegenden Ausführungsbeispiel einen

durchgehenden Stab 14. Der Kem kann auch aus Rohre gebildet werden. An der

Stelle 10 wird der bereits fertiggestellte Verbundisolator 1 vom Verbundisolator 101

abgetrennt. Wie aus Figur 1 weiter ersichtlich ist, schließt sich an das mantelfreie

Ende 7 des Kerns 2 des Verbundisolators 1, an die Trennstelle 10, das erste Ende

106 des Kerns 102 des Verbundisolators 101 an, auf dem ebenfalls eine Armatur

befestigt werden soll. Dieses Ende 106 ist deshalb in einer Länge 108 ebenfalls frei

von dem Mantel 4.As can be further seen from FIG. 1, the

Figur 2 zeigt schematisch ein Ausführungsbeispiel für eine erfindungsgemäße

Vorrichtung 11 zur Herstellung von Verbundisolatoren. Es sind nur die zur Erfindung

beitragenden Merkmale dargestellt und beschrieben.Figure 2 shows schematically an embodiment of an

Die Vorrichtung 11 zur Herstellung von Verbundisolatoren umfaßt im vorliegenden

Ausführungsbeispiel im wesentlichen eine Einrichtung 12 zum Auftragen des

Werkstoffs der Schirmhüllen 3, der über eine Vorschubeinrichtung 13 ein langer Stab

14 aus glasfaserverstärktem Kunststoff zugeführt wird, aus dem die Kerne 2, 102 der

Verbundisolatoren 1, 101 gebildet werden. Weiterhin gehört zur Vorrichtung 11 eine

Form 15 zur Formgebung der Schirme 5, die vor der Einrichtung 12 zum Auftragen

des Werkstoffs der Schirmhüllen 3 angeordnet ist. An die Einrichtung 12 schließen

sich im vorliegenden Ausführungsbeispiel eine Heizstrecke 16 zur thermischen

Behandlung des Werkstoffs der Schirmhülle, eine Transporteinrichtung 17 und eine

Trenneinrichtung 18 zum Abtrennen der fertigen Verbundisolatoren 1 von dem Stab

14 an. Der Stab 14 wird dadurch hergestellt, daß er aus kürzeren Teilstücken 19

zusammengesetzt wird. Während die Kerne 2 der fertigen Verbundisolatoren 1 von

dem Stab 14 abgetrennt werden, werden vor seinem Eintritt in die Einrichtung 12 zum

Auftragen des Werkstoffs der Schirmhüllen 3 neue Teilstücke 19 ergänzt, so daß eine

kontinuierliche Produktion von Verbundisolatoren möglich ist. The

Die Art der Verbindung zweier Teilstücke, Stäbe oder Rohre, richtet sich nach dem vorgesehenen Verfahren. Sollen nur Verbundisolatoren hergestellt werden, die genau so lang sind wie die miteinander verbundenen Stäbe oder Rohre, bildet jeder Stab oder jedes Rohr einen Kern. Diese Kerne brauchen nur insoweit miteinander verbunden zu werden, daß ein gemeinsamer Transport möglich ist. Dazu genügt beispielsweise bereits die Verbindung zweier an den Stirnflächen aneinanderstoßender Stäbe oder Rohre mittels Klebeband.The type of connection of two sections, rods or tubes, depends on the envisaged procedures. If only composite insulators are to be produced exactly As long as the interconnected bars or tubes, each bar forms or every tube a core. These cores only need each other so far to be connected, that a common transport is possible. That's enough For example, already the connection of two at the end faces abutting rods or pipes by means of adhesive tape.

Sollen aber die Teilstücke dauerhaft und belastbar verbunden werden, sind andere Verbindungsverfahren erforderlich, beispielsweise Kleben, thermisches Verbinden, Reibschweiße oder mittels Zapfen.But if the sections are to be connected permanently and resiliently, there are others Connection method required, for example, bonding, thermal bonding, Friction welding or by means of pins.

Von den möglichen Verbindungsverfahren wird hier nur ein Beispiel beschrieben. Das

Verbinden der Teilstücke 19 mit dem Ende des Stabs 14 erfolgt dauerhaft durch

Kleben in einer Klebeeinrichtung 21, die in Figur 3 dargestellt ist. Sie ist der

Einrichtung 12 zum Auftragen des Werkstoffs der Schirmhüllen 3 vorgeschaltet. Die

Klebeeinrichtung 21 kann beispielsweise mittels Laufrollen 22 an einer Hängeschiene

23 verschiebbar aufgehängt sein, um während des Klebevorgangs die

Vorschubbewegung des Stabs 14 mitmachen zu können. Die Klebeeinrichtung 21 hält

mit einem fest angeordneten Greifer 24 den Stab 14 während des Klebevorgangs fest.

Ein Greifer 25, der in Richtung der Längsachse 26 des Stabs 14 hin- und

herverschiebbar ist, wie durch den Doppelpfeil 27 angedeutet wird, hält ein Teilstück

19 zur Ergänzung des Stabs 14. Das Teilstück 19 wird über Stützrollen 28 zugeführt,

deren Abstand zueinander auf den Durchmesser der Teilstücke einstellbar ist.

Beispielsweise mittels einer Düse 29 wird Klebstoff auf die Stirnfläche 20 des Stabs

14 aufgetragen. Dann wird das Teilstück 19 mittels des Greifers 25 in Pfeilrichtung 30

mit seiner Stirnfläche 20 gegen die mit Kleber benetzte Stimfläche 20 des Stabs 14

gepreßt und so lange gehalten, bis daß die Klebverbindung belastbar ist. Während

dieser Zeit wandert die Klebeeinrichtung 21 in Vorschubrichtung 31 des Stabs 14 mit,

was durch das Mitlaufen auf der Hängeschiene 23 möglich ist. Nach Beendigung des

Klebevorgangs werden die Greifer 24 und 25 geöffnet und die Klebeeinrichtung 12 an

das noch freie Ende des gerade angeklebten Teilstücks 19 gefahren, um dort das

nächste Teilstück anzukleben.Of the possible connection methods, only one example will be described here. The

Connecting the

Nachfolgend wird die Herstellung von Verbundisolatoren mit der in Figur 2 dargestellten erfindungsgemäßen Vorrichtung beschrieben.Hereinafter, the production of composite insulators with the in Figure 2 described inventive device described.

Die Herstellung von Verbundisolatoren kann vollautomatisch erfolgen, wobei die

Verfahrensabläufe in den einzelnen Einrichtungen mittels einer Steuereinrichtung 32

aufeinander abgestimmt werden. Die einzelnen Einrichtungen sind über Signal- und

Steuerleitungen 33 mit der Steuereinrichtung 32 verbunden.The production of composite insulators can be fully automatic, with the

Processes in the individual devices by means of a control device 32nd

be coordinated with each other. The individual facilities are via signal and

Beim Start der Vorrichtung 11 zu Herstellung von Verbundisolatoren 1 wird ein Stab

14 in Vorschubrichtung 31 durch die geöffneten Antriebsrollen 34 der

Vorschubeinrichtung 13 in den Spritzkopf 35 der Einrichtung 12 zum Auftragen des

Werkstoffs der Schirmhülle eingeführt. Die Einrichtung 12 ist im vorliegenden

Ausführungsbeispiel ein Extruder. Der Werkstoff 36, aus dem die Schirmhüllen 3

geformt werden, ist im vorliegenden Ausführungsbeispiel ein HTV-Silikonkautschuk.

Er wird als Band von einer Vorratsrolle in bekannter Weise durch eine rotierende

Schnecke 37 in den Extruder 39 eingezogen und durch eine den Stab 14 ringförmig

umgebende Düse im Spritzkopf 35 ausgedrückt und in gleichmäßig dicker Schicht auf

den Stab 14 aufgetragen. Damit das Auftragen des Werkstoffs 36 für die Schirmhülle

3 gleichmäßig erfolgt, ist der Antrieb 40 der Schnecke 37 über einen Gleichlaufregler

41 mit der Vorschubeinrichtung 13 des Stabs 14 verbunden.When starting the

Damit die Schirmhülle 3 gut auf dem Kern 102 des noch herzustellenden

Verbundisolators 101 haftet, wird in einer Einrichtung 42, die im vorliegenden

Ausführungsbeispiel der Vorschubeinrichtung 13 vorgeschaltet ist und die der Stab 14

durchläuft, ein Haftmittel aufgetragen. Weiterhin ist ein Längenmeßgerät 43

vorgesehen, das mit einem Tastrad 44 auf der Oberfläche des Stabs 14 aufliegt. Mit

dem Längenmeßgerät 43 wird der Vorschub des Stabs 14 überwacht, die Länge der

Kerne 2 und 102 und die Abstände der Schirme voneinander abgemessen sowie die

Trenneinrichtung 18 und der Auftrag des Werkstoffs der Schirmhüllen 3 gesteuert.Thus, the

Der Stab 14 wird so weit in den Spritzkopf 35 eingeschoben, daß seine Stirnseite mit

der Austrittsöffnung der hier nicht dargestellten Ringdüse übereinstimmt. Dann wird

die Vorschubeinrichtung 13 eingeschaltet, der Extruder 12, die Einrichtung zum

Auftragen des Werkstoffs 36 der Schirmhüllen 3, aber noch nicht. Erst wenn der Stab

14, der ab jetzt der zukünftige Kern eines neuen Verbundisolators ist, um die der

durch die Befestigung der Armatur vorgegebenen Länge 8, Abschnitt A in Figur 1, aus

dem Spritzkopf 35 ausgetreten ist, wird der Extruder 12 eingeschaltet und der

Werkstoff 36 zur Bildung einer Schirmhülle 3 aufgetragen. Dabei wird der erste Mantel

4 gebildet. Nachdem die durch die Steuereinrichtung 32 vorgegebene Länge durch

das Längenmeßgerät 43 festgestellt worden ist, wird der Vorschub des Stabs 14

gestoppt. Der Abschnitt B des Verbundisolators ist damit hergestellt. Für eine durch

die Steuereinrichtung 32 vorgegebene Zeit fördert die Schnecke 37 weiterhin den

Werkstoff 36 zur Bildung der Schirmhülle 3 im Bereich C. Dadurch quillt das Extrudat

45 aus der Auftragsdüse konzentrisch um den Stab 14. Nach Ablauf der Zeit wird die

Förderung des Extrudats 45 gestoppt und daraus ein Schirm 5 geformt.The

Zur Formgebung eines Schirms 5 wird eine Form 15 eingesetzt. Sie besteht aus zwei

Hälften 46 und 47, wobei die erste Hälfte 46 unmittelbar an der Stirnseite des

Spritzkopfs 35 angeordnet ist, an der der Stab 14 austritt. Die zweite Formhälfte 47

ist, in Transportrichtung 31 des Stabs 14 gesehen, hinter der ersten Formhälfte 46

angeordnet. Die beiden Formhälften 46 und 47 sind in einer Ebene 48 geteilt, die im

wesentlichen senkrecht auf der Längsachse 26 des Stabs 14 steht, wie durch den

rechten Winkel 49 angedeutet wird. Während die erste Formhälfte 46 fest mit dem

Spritzkopf 35 verbunden ist, kann die zweite Formhälfte 47 entlang der Längsachse

26 des Stabs 14 zum Schließen in Richtung auf die erste Formhälfte 46 hin und zum

Öffnen von ihr wegbewegt werden, wie durch den Doppelpfeil 50 angedeutet wird. For shaping a

Um den frischgeformten Schirmen den Weg freizugeben, ist die zweite Formhälfte 47

mindestens noch einmal in zwei Teilhälften 51 und 52 geteilt, wobei die

Teilungsebene 53 senkrecht zur ersten Teilungsebene 48 steht und durch die

Längsachse 26 des Stabs 14 geht. Die Teilung der Formhälfte 47 ermöglicht es, ihre

Teilhälften 51 und 52 im wesentlichen radial zur Längsachse 26 des Stabs 14, also im

wesentlichen in der Teilungsebene 48 zu bewegen, wie durch den Doppelpfeil 54

angedeutet wird. Die beiden Teilhälften 51 und 52 der Formhälfte 47 können mittels

einer Einrichtung 55 geöffnet und geschlossen werden, wie mit dem Doppelpfeil 54

ebenfalls angedeutet wird. Möglich, hier aber nicht dargestellt, ist auch ein Aufklappen

der beiden Teilhälften wie zwei Torflügel. Außerdem übernimmt die Einrichtung 55

auch noch das Öffnen und Schließen der beiden Formhälften 46 und 47 zur

Formgebung der Schirme. Die Einrichtung 55 ist über eine Steuerleitung 33 mit der

Steuereinrichtung 32 verbunden.To clear the way for the newly formed screens, the

Zur Formgebung eines Schirms 5 werden die Teilhälften 51 und 52 der Formhälfte 47

zusammengeführt und dann die Formhälfte 47 auf die Formhälfte 46 zubewegt. Dabei

wird das für die Formung eines Schirms vorgesehene Extrudat 45 von der Form 15

eingeschlossen und ein Schirm 5 geformt. Da die Menge des Extrudats 45 so

bemessen ist, daß es die Form 15 nicht bis zur Trennfuge ausfüllt, entsteht kein Grat

auf dem Umfang eines Schirms 5 an der Stelle, wo die beiden Formhälften 46 und 47

zusammenstoßen.For shaping a

Die Formgebung eines Schirms 5 kann auch so erfolgen, daß die Form 15 bereits

geschlossen wird, wenn der Vorschub des Stabs 14 gestoppt wird. Das für die

Formgebung eines Schirms vorgesehene Extrudat 45 wird dann in die geschlossene

Form gefördert. Auch hier kann die Fördermenge des Extrudats von der

Steuereinrichtung 32 über die Zeit vorgegeben werden. Möglich ist auch die

Steuerung der Füllmenge über Drucksensoren in der Form 15 oder an den Wänden

der Formhälften 46 und 47, wie hier nicht dargestellt ist. The shape of a

Da die Formhälfte 47 nochmals in zwei Teilhälften 51 und 52 aufgeteilt ist, kann an

deren Trennfuge ein Grat entstehen. Um das weitestgehend zu vermeiden, kann

durch eine entsprechende Formgebung der Kanten der Teilhälften, beispielsweise

durch Abrunden, die Bildung eines spitzen und dadurch störenden Grats vermieden

werden. Außerdem kann die Formhälfte 47 zur Formgebung der Unterseite der

Schirme vorgesehen sein, so daß mit der einteiligen Formhälfte 46 die Oberseite der

Schirme völlig gratfrei geformt werden kann.Since the

Nach der Formgebung eines Schirms 5 muß die Form 15 den Schirm ohne

Beschädigung seiner Oberfläche freigeben. Bei Werkstoffen, die zum Haften an den

formgebenden Oberflächen der Form 15 neigen, beispielsweise insbesondere

Silikonkautschuk, müssen die Formhälften 46 und 47 vorsichtig geöffnet werden,

damit die Schirmoberfläche nicht beschädigt wird. Dabei kann so vorgegangen

werden, daß das Füllen der Form 15 mittels hier nicht dargestellter Drucksensoren