EP1147018B1 - Method and installation for producing personalized coupons - Google Patents

Method and installation for producing personalized coupons Download PDFInfo

- Publication number

- EP1147018B1 EP1147018B1 EP00901663A EP00901663A EP1147018B1 EP 1147018 B1 EP1147018 B1 EP 1147018B1 EP 00901663 A EP00901663 A EP 00901663A EP 00901663 A EP00901663 A EP 00901663A EP 1147018 B1 EP1147018 B1 EP 1147018B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- coupon

- coupons

- station

- chain

- blank

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000009434 installation Methods 0.000 title claims abstract description 82

- 238000000034 method Methods 0.000 title claims description 31

- 238000004519 manufacturing process Methods 0.000 claims abstract description 60

- 238000005520 cutting process Methods 0.000 claims abstract description 36

- 230000032258 transport Effects 0.000 claims abstract description 20

- 239000011265 semifinished product Substances 0.000 claims abstract description 5

- 238000012546 transfer Methods 0.000 claims description 46

- 239000004033 plastic Substances 0.000 claims description 43

- 229920003023 plastic Polymers 0.000 claims description 43

- 239000000463 material Substances 0.000 claims description 37

- 238000007639 printing Methods 0.000 claims description 32

- 229910052799 carbon Inorganic materials 0.000 claims description 29

- 238000010030 laminating Methods 0.000 claims description 27

- 239000002184 metal Substances 0.000 claims description 20

- 238000004804 winding Methods 0.000 claims description 16

- 238000011161 development Methods 0.000 claims description 11

- 238000010438 heat treatment Methods 0.000 claims description 11

- 238000003860 storage Methods 0.000 claims description 9

- 230000001360 synchronised effect Effects 0.000 claims description 9

- 230000007246 mechanism Effects 0.000 claims description 8

- 238000001816 cooling Methods 0.000 claims description 7

- 238000003825 pressing Methods 0.000 claims description 7

- 238000007789 sealing Methods 0.000 claims description 6

- 125000006850 spacer group Chemical group 0.000 claims description 6

- 239000004698 Polyethylene Substances 0.000 claims description 5

- 239000012190 activator Substances 0.000 claims description 5

- -1 polyethylene Polymers 0.000 claims description 5

- 229920000573 polyethylene Polymers 0.000 claims description 5

- 230000005540 biological transmission Effects 0.000 claims description 4

- 238000005406 washing Methods 0.000 claims description 4

- 238000009736 wetting Methods 0.000 claims description 4

- 239000011247 coating layer Substances 0.000 claims description 3

- 238000001035 drying Methods 0.000 claims description 3

- 230000003287 optical effect Effects 0.000 claims description 3

- 229920000728 polyester Polymers 0.000 claims description 3

- 230000000087 stabilizing effect Effects 0.000 claims description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 3

- 238000012544 monitoring process Methods 0.000 claims description 2

- 238000007598 dipping method Methods 0.000 claims 3

- 230000000712 assembly Effects 0.000 claims 1

- 238000000429 assembly Methods 0.000 claims 1

- 239000003381 stabilizer Substances 0.000 claims 1

- 230000008569 process Effects 0.000 description 13

- 239000000047 product Substances 0.000 description 8

- 238000005096 rolling process Methods 0.000 description 8

- 238000012549 training Methods 0.000 description 8

- 230000009471 action Effects 0.000 description 6

- 230000008878 coupling Effects 0.000 description 5

- 238000010168 coupling process Methods 0.000 description 5

- 238000005859 coupling reaction Methods 0.000 description 5

- 238000002791 soaking Methods 0.000 description 5

- 238000011144 upstream manufacturing Methods 0.000 description 5

- 230000015572 biosynthetic process Effects 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- 239000010410 layer Substances 0.000 description 4

- 238000011084 recovery Methods 0.000 description 4

- 230000001105 regulatory effect Effects 0.000 description 4

- 239000002985 plastic film Substances 0.000 description 3

- 229920006255 plastic film Polymers 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- 238000002360 preparation method Methods 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 238000000926 separation method Methods 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 239000000976 ink Substances 0.000 description 2

- 238000003475 lamination Methods 0.000 description 2

- 210000000056 organ Anatomy 0.000 description 2

- 230000001737 promoting effect Effects 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 238000009987 spinning Methods 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 238000007651 thermal printing Methods 0.000 description 2

- OQCFWECOQNPQCG-UHFFFAOYSA-N 1,3,4,8-tetrahydropyrimido[4,5-c]oxazin-7-one Chemical compound C1CONC2=C1C=NC(=O)N2 OQCFWECOQNPQCG-UHFFFAOYSA-N 0.000 description 1

- 230000004308 accommodation Effects 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000004049 embossing Methods 0.000 description 1

- 229920002457 flexible plastic Polymers 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 230000037452 priming Effects 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000011282 treatment Methods 0.000 description 1

- 239000002966 varnish Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/40—Manufacture

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/20—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof characterised by a particular use or purpose

- B42D25/23—Identity cards

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/20—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof characterised by a particular use or purpose

- B42D25/25—Public transport tickets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/40—Manufacture

- B42D25/475—Cutting cards

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/003—Delivering or advancing articles from machines; Advancing articles to or into piles by grippers

- B65H29/005—Delivering or advancing articles from machines; Advancing articles to or into piles by grippers by chains or bands having mechanical grippers engaging the side edges of articles, e.g. newspaper conveyors

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1052—Methods of surface bonding and/or assembly therefor with cutting, punching, tearing or severing

- Y10T156/1084—Methods of surface bonding and/or assembly therefor with cutting, punching, tearing or severing of continuous or running length bonded web

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/12—Surface bonding means and/or assembly means with cutting, punching, piercing, severing or tearing

Definitions

- the subject of the present invention is a plant for manufacturing personalized coupons including a set of workstations with at least one basic coupon supply station, one post for personalizing basic coupons and a post for cutting of personalized basic coupons, and a system of transport of basic coupons between different work stations.

- the invention also relates to a method of manufacturing by personalized coupon chain comprising at least one step supply of basic coupons to a first work station, a step of personalizing the basic coupons at a second station of work and a step of cutting the basic personalized coupons to a third work station, the basic coupons being transported successively from one workstation to another.

- the document EP-A-0 364 730 describes a facility for manufacturing personalized coupons as described in the preamble of claim 1, and a method of manufacturing these coupons as described in the preamble of claim 29.

- the invention aims to remedy the aforementioned drawbacks and to allow the manufacture of personalized coupons such as cards of excellent quality identification, including secure cards, to a reduced cost and with great flexibility of adaptation to different manufacturing.

- the invention aims in particular to guarantee the operation of a card manufacturing facility without any lags or faults produce during production.

- the invention also aims to allow rapid and without loss of raw material, the production of small series of cards personalized and secure identification.

- the basic coupon transport system includes a carousel comprising at least one link chain driven by pinions indexed motorized, and a set of pliers mounted with a not constant on links in the chain and cooperating with means opening / closing fixed position, to enter each individually a basic coupon, transport this basic coupon between workstations and unload this basic coupon at a workstation recovery of finished or semi-finished product as identification card customized, each clamp having a pair of jaws for enclose a marginal area of a basic coupon at least in two regions thereof which are distant from each other in the direction of displacement of the chain, and external stops integral with one or the other of the jaws to position the base coupon laterally gripped between said jaws.

- the grippers can be actuated mechanically, electromechanically, magnetic or pneumatic.

- each clamp has lateral fasteners on the link chain arranged below the plan for gripping the base coupon by the jaws.

- Each clamp has a central spring arranged between on the one hand a lower plate made integral with the upper jaw, and on the other hand the underside of the lower jaw.

- each clamp comprises external stops vertical directed upwards and integral with the lower jaw.

- the grip width of the jaws of each clamp is between 3 and 5 mm.

- the means clamp opening / closing includes a mechanical push button a rod-crank type mechanism.

- the means clamp opening / closing includes a cylinder generator in rotation.

- the station Basic coupon supply includes transfer-cut station to transfer a section of a strip to a clamp arranged transversely to the chain and having a succession of sections constituting basic coupons.

- the supply station includes means for supporting a reel for storing said tape, a pair of superimposed cylinders between which the strip coming from the reel and which constitute a motorized pulling bridge, a cutter motorized disposed between the motorized pulling bridge and the path of the clamps and an optical cell to control the arrival opposite the clamps of the basic coupons to be cut by the cutter from the sections of the strip and intended to be gripped by grippers actuated by means opening / closing of clamps arranged in the vicinity of the station and synchronized with the indexed advance of the chain with links.

- the supply station can also include a charger pre-cut basic coupons and gripping means, for example example of suction cup type, to supply a basic coupon a clamp located at the supply station for each operational downtime of the cyclic operation of installation.

- a charger pre-cut basic coupons and gripping means for example example of suction cup type

- the installation according to the invention advantageously comprises coding marks on each clamp.

- At least one basic coupon personalization station can be made up of an individualized printing station of at least one face of the basic coupons transported by the pliers.

- the manufacturing installation of cards includes a station for pre-cutting the basic coupons customized, a suction cup mechanism for individual transfer of basic personalized coupons precut to a post lamination fed by upper and lower strips of material plastic introduced parallel to the direction of movement of the coupons basic pre-cut, and a cutting and recovery of finished personalized cards with evacuation and winding in a training station of a skeleton coil residual plastic strips after cutting cards custom finished.

- the laminating station can include a pair heating shoes arranged at the level of the introduction of a custom base precut between said upper bands and lower plastic, two pairs of motorized cylinders and put in pressure to ensure a rolling and sealing of a coupon custom base precut with top and bottom bands plastic, and cooling fans.

- the installation of card manufacturing includes a pre-laminating station with upper and lower rolls for feeding strips of material plastic perpendicular to the direction of travel of the chain links to form a portfolio enveloping an insert consisting of pre-cut personalized base coupon maintained by a clamp, and a plasticizing station acting on the assembly constituted by said wallet and its insert held by a clamp.

- the pre-laminating station includes a feeding device of two strips of plastic material with the passage of a single first longitudinal edge of each of the strips through a heating shoe before the training of the two bands through a pair of rollers motorized which ensure the sealing of the two bands on their first longitudinal edges to form a backing film held open by a shoe tree before receiving said insert and building a portfolio after cutting by a transverse cutting device of the film backing to form a sandwich driven by the central insert held by a clamp to a laminating station.

- the plastic strips are each consisting of a film of a basic material such as polyester provided with a coating layer compatible with the insert and promoting heat sealing, such as polyethylene and upper and lower plastic have their layers of coating facing each other.

- the manufacturing installation of cards includes a laminating station comprising first and second motorized endless perforated and welded metal strips by a set of four cylinders including two non-opposing cylinders are laterally fitted with sprockets, the first and second metal strips having a parallel path portion in which they enclose at least one assembly constituted by said wallet and its insert held by a clamp, this portion of the path parallel successively comprising heating shoes, a pair of rolling rolls and cooling means.

- the motorization of the drive members of the plasticization is synchronized with the indexed motorization of the chain main transport clamps so that the bands of perforated metal and the link chain advance simultaneously the same amount.

- the first and second metal strips endless perforated have tape closure means including the thickness is less than that of the assembly constituted by a wallet and its insert, and which are arranged offset on the first and second metal strips so as to be located in free spaces between two successive sets comprising a wallet and insert.

- the pitch of perforation of the metal strips is identical to the pitch of the link chain fitted with pliers.

- the installation of card manufacturing includes a closed auxiliary link chain driven by indexed motorized gears and equipped with a set of auxiliary clamps mounted with constant pitch on links of the auxiliary chain and a closed main chain with links driven by indexed motorized gears, in synchronism with the auxiliary chain and equipped with a set of main pliers mounted with a constant step on links of the main chain.

- the auxiliary chain moves successively in front of a photosensitive negative coupon supply station, a photographic shooting to transfer personalized data on the negative photosensitive coupon, a development station for the negative coupon by soaking in an activator bath, and a pressure overlay of negative coupon with base coupon positive fed from a coupon supply station positive base, and clamp opening / closing means are arranged at least at the negative coupon supply item level and at the negative coupon overlay station with a coupon basic positive.

- the main chain moves successively in front of at least a positive basic coupon supply item, a pre-wetting, an overlay station under pressure of a coupon negative with a positive base coupon, a transfer-development zone in which the negative coupon is superimposed on the coupon positive base to allow image transfer from negative coupon to the positive base coupon, a negative coupon withdrawal item by mechanized separation of the latter from the basic positive coupon, a positive coupon washing station by soaking in a water bath, a first spinning station, a stabilization station by soaking in a stabilizing bath, a second wringing station and a drying station.

- the pressure stacking station a negative coupon and a positive basic coupon includes a pair motorized gears fitted with spacing cams and integral with the transmission shafts of a pair of cylinders press-transfer between which a superimposed negative coupon and a positive base coupon maintained respectively by clamps driven by the auxiliary chain and the main chain, one of said spacing cams being provided with a light angular position and a spacer boss.

- the station for removing the mechanized peel negative coupon includes a set of three motorized round belts acting on an edge of the negative coupon previously clamped in pliers of the auxiliary chain and making slightly protruding from the positive coupon on the side opposite the clamp keeping the positive coupon.

- the installation according to the present invention makes it possible to introduce personalized data both by photograph and by print and also to combine the two types of technique on the same manufacturing line.

- the manufacturing installation of cards includes a personalized data printing station on a base coupon from a thermal transfer ribbon supplied transversely to the direction of circulation of the chain of transport of the basic coupon, and evacuated after printing of a basic coupon, also transversely to in the direction of movement of the transport link chain of the coupon based.

- the custom data printing station includes a constant tension unwinding device for the transfer ribbon thermal, put in the form of a coil, which device unwinding itself includes a friction support acting on the coil or its mandrel, first and second cylinders set pressure between which the thermal transfer ribbon is introduced unwound, at least one torque generator coupled to one of the shafts of the first and second cylinders and connected to a chassis of the unwinding device by an anti-rotation member.

- the custom data printing station includes a constant tension winding device, which device comprises first and second superimposed cylinders ensuring a draft of the thermal transfer ribbon after passing in front of a print head, at least one torque generator associated with the at least one drive shaft minus one of the first and second cylinders and a gear motor group rotational drive of both the torque generator and a ribbon take-up reel in the form of a reel around said mandrel after drawing by passage between said first and second cylinder.

- a constant tension winding device which device comprises first and second superimposed cylinders ensuring a draft of the thermal transfer ribbon after passing in front of a print head, at least one torque generator associated with the at least one drive shaft minus one of the first and second cylinders and a gear motor group rotational drive of both the torque generator and a ribbon take-up reel in the form of a reel around said mandrel after drawing by passage between said first and second cylinder.

- the data printing station custom includes reel storage ribbon transfer and a coil for receiving thermal transfer ribbon, full diameters are not more than about three times the diameter in the empty state, the storage and receiving coils being located on either side of a print head, a torque generator is coupled directly to the storage reel support mandrel and is connected to the support frame of said mandrel by an anti-rotation member, and a torque generator associated with a motorization member is directly coupled to the spool support mandrel reception.

- the basic coupons can be made of paper or material plastic. However, these basic coupons can also be produced in the form of plates comprising, where appropriate, electronic circuit elements, such as an integrated circuit and a coil antenna for example.

- the invention also relates to a method of manufacturing by personalized coupon chain such as identification cards comprising at least one step of supplying coupons base to a first workstation, a step of personalization of basic coupons at a second workstation and a cutting stage basic personalized coupons at a third workstation, basic coupons being transported successively from work station to the other, characterized in that the transport of the basic coupons from one station work to another, is carried out individually using mounted pliers with a constant pitch on the links of a driven link chain closed-indexed and in that each basic coupon transported and pinched is seized along one of its marginal zones at less in two regions thereof which are distant from each other in the direction of movement of the chain, while cooperating with the same clamp.

- the basic coupon procurement step may include transfer and cutting, at a clamp brought to a station supply, a section of strip arranged transversely with respect to the link chain and comprising a succession of sections constituting basic coupons.

- the supply stage can also be carried out from a stack of pre-cut basic coupons.

- the step of personalization of a basic coupon includes the opposite supply of a print head of a tension transfer thermal transfer ribbon constant from a storage reel, data carryover customized, by printing using the print head, on a basic coupon superimposed on the thermal transfer ribbon, and the evacuation thermal transfer ribbon by pulling it at constant tension before winding on a receiving coil.

- the method comprises a laminating step of a basic coupon and prior to the step of lamination, each basic coupon held by a clamp is inserted in a portfolio made up of a film film format made from of two sections of plastic strips brought perpendicular to the direction of travel of the link chain and sealed together on only one of their longitudinal edges, located at the front the corresponding basic coupon in the direction of transport of this coupon.

- the method includes a step of laminating a basic coupon and before the laminating step, each basic coupon held by a clamp is released from the clamp by cutting and gripped by a mobile suction cup to be transported individually to a workstation plastic fed plastic by upper bands and lower introduced parallel to the direction of movement of the movable suction cups.

- the method of manufacturing identification cards includes a training stage and transport of negative coupons each seized in a marginal area at least in two regions thereof which are distant from each other, in the direction of movement of an auxiliary chain in a closed circuit, using pliers transported by the auxiliary chain with indexed advance, a stage of training and transport of positive basic coupons seized each in a marginal area at least in two regions thereof which are distant from each other, in the direction of movement of a chain main in closed circuit, using pliers transported by the chain main with indexed advance, a step of overlapping and pressure of a negative coupon and a positive basic coupon, a step of transport of a positive coupon and a negative coupon superimposed using the only clamp transported by the main chain, a step of removing the negative coupon by mechanized detachment and a stage of transport and processing of the only positive coupon using the forceps carried by the main chain.

- the invention allows the production of personalized coupons such as identification cards and more particularly cards secure identification such as identity documents which include, in addition to any security elements present on different cards of the same type, personalized data that differs from card to card the other.

- personalized data can include a suite alphanumeric information, such as information concerning civil status, and graphic elements such as ID photograph or signature.

- This custom data can be stored in a file computer or a manual file, from which they are transferred, by a process of printing or photographic transfer, on coupons basic, during the process of making identification cards.

- the present invention thus makes it possible to ensure personalization basic coupons using a printing process, a process photographic or a combination of the two, graphic elements which can for example be transferred to a basic coupon by a process photographic, while alphanumeric data is reported by a printing process.

- the installation according to the invention allows great flexibility of implemented thanks to its modular design and a system of individual transport of basic coupons between the different job.

- a first conforming example will be described with reference to FIG. 1 to the invention of an installation for manufacturing identification cards.

- the installation 100 comprises a vertical panel 101 serving as support for all the functional elements defining the different installation workstations.

- the vertical panel 101 can itself be mounted on any type of mobile or fixed chassis.

- the space located on one side of the panel 101 for example the space located in back of the plan of Figure 1, can serve as accommodation for different electric drive or control components while the space located in front of the plan in Figure 1 can serve as housing for different organs of the production chain through which circulate the basic coupons leading to the formation of finished or semi-finished products.

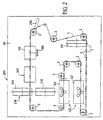

- FIG. 1 comprises a carousel comprising a closed-link chain 1 driven by motorized sprockets 2 indexed.

- a set of pliers 5 are mounted with a constant pitch on links of chain 1 and cooperate with opening / closing means, such as 37 ( Figure 3) or 343 (figure 21) placed at a fixed post, to enter each individually a basic coupon C, transport this basic coupon C between workstations and release a card as a finished product or semi-finished when the basic coupon C has undergone all the treatments desired.

- opening / closing means such as 37 ( Figure 3) or 343 (figure 21) placed at a fixed post

- the link chain 1 successively serves a station 110 for supplying basic coupons C 1 , a station 120 for personalizing basic coupons C 1 which is constituted in the example considered by a station of two-sided printing 121, 122 of the thermal transfer type, and a station 130 for cutting basic coupons C 2 .

- a coupon C 3 which constitutes an individualized semi-finished product, is collected by a movable suction cup 131 which ensures the transfer of the coupon C 3 to a work station 140 which in the example considered constitutes a plasticizing station.

- the movement of the movable suction cups 131, 132 intended to grip the cut coupons C 3 is synchronized with that of the chain 1 but takes place along a path independent of the closed circuit path of the chain 1.

- the plasticizing station 140 is supplied by upper 152 and lower 162 strips of plastic material coming from coils 150, 160 mounted on mandrels 151, 161, which strips 152, 162 are introduced parallel to the direction of movement of a basic coupon pre-cut custom C 3 , on either side thereof, between two successive pairs 142, 143 of motorized cylinders and pressurized to ensure rolling and sealing of a coupon with sections of the upper and lower strips 152 , 162 of plastic.

- the upper and lower strips 152, 162 of plastic material are brought into contact with heating shoes 141 and after the exit of the second pair of cylinders 143, the plastic card C 4 comprising the personalized coupon C 3 sandwiched between the strips of plastic material C 4 is subjected to the action of cooling fans.

- the plasticized card C 5 includes the personalized coupon C 3 sandwiched between the two strips of plastic material 152, 162 sealed together around the entire periphery of the coupon C 3 , for example in a frame 3 mm wide.

- the card C 5 is introduced into a station 170, 180 for cutting and recovering the finished personalized cards C 6 with evacuation and winding around a mandrel 191 in a station for forming a coil 190, of the residual skeleton C 7 of the plastic strips after cutting finished personalized cards C 6 .

- FIG. 28 shows the successive states of coupons C 1 to C 6 between the supply station 110 and the recovery station for finished products.

- FIG. 1 The installation in FIG. 1 is particularly suitable for the case where the base coupon C is made of paper and must be protected by a plastic envelope sealed in a sealed manner over the entire periphery of the personalized and precut base coupon C 3 .

- Figure 2 shows another example installation 200 of manufacture of identification cards according to the invention using works a closed link chain 1 driven by sprockets indexed motorized and comprising a set of pliers 5 mounted with a constant pitch on links of chain 1.

- the clamps 5 can be mounted at a constant pitch which can correspond for example to ten links and constitutes the indexing step.

- FIG. 2 the various useful members can be mounted on a vertical panel 101 in a similar manner to installation 100 of the figure 1.

- the installation 200 of FIG. 2 comprises a station 110 supply of basic coupons C, a set 120 of personalization of basic coupons C including an extension 121 printing the front of a coupon and a station 122 printing the back of the coupon, a pre-plasticization station 230 for bringing a basic coupon personalized at a laminating station 240 remaining transported by the same clamp 5, a station 170 for cutting a card finished laminated, a 180 recovery mat for finished cards and a post 290 for the evacuation of the residual parts of the resulting basic coupons of the cutting operation at work station 170.

- Each clamp 5 includes a pair of jaws 54, 55 for grip the edge of a base coupon C essentially over the entire length of the latter in the direction of movement of the chain 1.

- Des vertical outer stops 52 directed upwards and integral with the lower jaw 54 ensure correct positioning of a coupon base which is gripped by a clamp 5 over a length L and a width l.

- the grip width prise of the jaws 54, 55 of each clamp 5 is between 3 and 5 mm.

- the length L of the jaws 54, 55 may for example be 70 mm for a coupon base with dimension in the direction of movement of the clamps of the order of 100 mm.

- the clamps 5 thus enclose a base coupon C over a length L which constitutes more than half the dimension of the coupon in the direction of movement of the clamps.

- Each clamp 5 has lateral fasteners 51 allowing a fixing, for example by a system of quick couplings, on the chain links 1.

- Fasteners 51 are arranged below the gripping plane of a basic coupon by the jaws 54, 55.

- Each clamp 5 which can for example be made of stainless steel, comprises a central spring 59 disposed between on the one hand a plate lower 56 made integral with the upper jaw 55 by lateral uprights 57 and on the other hand the underside of the jaw lower 54.

- the spring 59 can be held in the central position by a centering stud 53 secured to the underside of the lower jaw 54.

- the lateral fasteners 51 are connected to the lower jaw 54 by a connecting piece 50.

- FIG. 6A shows a clamp 5 in the closed position while the FIG. 6B shows a clamp 56 in the open position under the action of a thrust member 37 comprising for example a spherical head.

- the clamps 5 are actuated mechanically but they could also be actuated so magnetic, electromechanical or pneumatic.

- the means elastic return of the jaws 54, 55 included in the clamp 5 could be different from spring 59.

- the grip length L of a coupon C by the jaws 54, 55 constitutes a substantial portion of the length of the coupon C and it is essential that the pressure of the jaws 54, 55 be distributed over a marginal area of a coupon C in at least two regions distant from each other in the direction of scrolling of the coupons so that the times to avoid distortions of the basic coupons and to guarantee a safe keeping of these coupons.

- the internal bearing faces of the jaws 54, 55 can be provided with a coating promoting adhesion, for example under the form of a set of points distributed over the entire surface and made up for example with diamond powder.

- the jaws 54, 55 may however undergo a slight calibration so that the pressure exerted by the clamp on the card entered slightly stronger at both front and rear ends of the clamp.

- clamps 5 can be installed every ten links of a chain with a pitch of 12.7 mm or every 127 mm. Not constant between clamps 5, which corresponds to a constant whole number of links naturally depends on the size of the cards to be produced.

- the card manufacturing installations according to the invention can typically include for example between 20 and 80 clamps. It is so easy to quickly make small series of cards. The course complete with a clamp of all the workstations being lower at 3 minutes, the waiting time for a card of a new type is very reduced. In a stabilized production regime, the production rate can be in the order of 1,200 cards manufactured per hour.

- the clamps 5 can advantageously be provided with a set of coding marks, such as a barcode, which allows monitoring with precision the evolution of the clamp within the installation.

- Figure 3 shows an example of supply station 110 in basic coupons C from a strip of material B wound under the form of a coil 30 around a mandrel 31.

- the strip B can be in paper, plastic, photosensitive material of negative type or positive.

- the band B can in particular be formed by a material with a safety bottom.

- FIG. 3 it can be seen that the reel 30 for storing the tape B is supported by rollers 32.

- the support rollers could however also act directly on the mandrel 31, on both sides of the coil 30.

- the strip B from the coil 30 is pinched between a pair of superimposed cylinders 33 which constitute a pulling bridge motorized 33.

- a motorized cutter 34 is disposed between the pulling bridge motorized 33 and the path of the clamps 5 to ensure the cutting of a section of strip B which will constitute a basic coupon C seized by a clamp 5 whose opening is effected by a mechanism 36 opening / closing comprising a pusher head 37 acting on the clamp 5 and integral with a rod-crank system 38 driven by a motor 39 controlled synchronously with the advance of chain 1 and clamps 5 so as to allow the opening of a clamp 5 when it is temporarily stopped in front of supply station 110 to receive a basic coupon C cut by the cutter 34 of which the action is also synchronized with that of the advance of the clamps 5 and takes into account the information of an optical cell 35, for example a fiber optic reading cell, intended to control the position, with respect to pliers 5, of the base coupon C to be cut from the band B.

- an optical cell 35 for example a fiber optic reading cell

- band B already has information must be located at a specific location on each base coupon C

- multiple fiber optic reading cells can be used to detect not only a coupon length, but also the location of printed marks. In this case several operations of cutting can be provided if necessary.

- a supply station has been described with reference to FIG. 3 as a base coupon from a strip of material wound under the in the form of a coil 30.

- the supply station 110 could also, alternatively, include a basic coupon loader precut and destacking and / or gripping means such as suction cups to supply basic coupons from this charger, synchronized with the stop movements of the chain 1, each clamp located at the supply station 110.

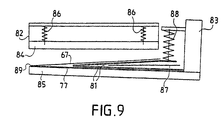

- the post 230 for pre-plasticization or preparation of a film wrapped in plastic material in the form of a wallet comprises upper rollers 60 and lower 70 for feeding strips of plastic material P 11 , P 12 perpendicular to the direction of travel of the link chain 1 fitted with clamps 5.

- the coils 60, 70 wound around mandrels 61, 71 are supported by rollers 62, 72 respectively which, according to a variant could act on the mandrels 61, 71 rather than on the coils 60,70.

- the lower strip P 12 is superimposed with the upper strip P 11 at the level of a roller 74. Only one of the longitudinal edges of the superimposed strips P 11 , P 12 passes through a heating shoe 65 before the superimposed strips are pinched and entrained in common by a pair of motorized rollers 66 which seal the two strips P 11 , P 12 on their first longitudinal edges so as to form a film film comprising upper faces 67 and lower 77 connected by an edge 89.

- the backing film 67, 77 is kept open by a shoe tree 81 and defines a free space into which a base coupon 87 held by a clamp 5 can be introduced from the rear.

- FIG. 29 shows a basic coupon P 1 held by a clamp 5 and inserted between the two sheets of a coated plastic film P 2 , the connecting edge D of which is located at the front, in the direction of scrolling of the coupons, so that the drive of the coupon P 1 by the clamp 5 secured to the chain 1 with indexed movement also causes the wallet or case P 2 enclosing the coupon P 1 , to a post next work consisting of a laminating station.

- the backing film 67, 77 enclosing a base coupon 87 held by a clamp 5 was released from the bands P 11 , P 12 using a shear-shaped cutting device acting transversely to the bands P 11 , P 12 .

- the cutting device may include a cutting counter blade 85 disposed under the shoe tree 81, a cutting blade 82 cooperating with the counter blade 85, and a plate 84 cooperating with springs 86 and coming to play the role of press film on film 67 during the operation of chopped off. Also seen in Figure 9 a spring 88 serving as a spring of the shoe tree 81 consisting of a V-shaped piece. counter blade 85 is mounted on a support 83 and provides space under the shoe tree 81 for the passage of the film 77.

- the face upper of shoe tree 81 descends with the shears under the action of the plate 84, which avoids deforming the upper film 67 relative to the film lower 77 when cutting with blade 85 and allows two sections of film cut 67, 77 of the same dimensions perfectly Bunk.

- the spring 88 makes it possible to raise the upper face of the shoe tree 81 between two cutting operations.

- the two plastic films P 11 , P 12 are advantageously made of polyester with a layer of polyethylene.

- the polyethylene layers are opposite.

- the heating shoe 65 is regulated in such a way that only the polyethylene is melted in order to then seal between the first longitudinal edges of the two films at the level of the cylinders 66.

- base coupon 87 can be paper or flexible plastic, but can also be rigid and made of any other material which may undergo plasticization.

- coupon 87 can consist of a rigid or semi-rigid card equipped with a chip integrated circuit and, where applicable, a wound antenna.

- the 240 laminator basically consists of two strips of perforated metal 528 which are welded or closed in zones of junction 529 (figure 20) so as to form endless bands indexed training.

- the 528 perforated endless belts are driven by four motorized cylinders 522, 523 arranged in pairs of which two non-opposing 522 cylinders are fitted laterally with sprockets (or “Caroll” wheels).

- the metal strips 528 are in contact, in their part upstream, with two regulated heating shoes 541, 542.

- a couple of rolling rollers 524, 525 is arranged after the shoes heaters 541, 542.

- Cooling shoes 551, 552 are in contact with metal strips 528 downstream of the cylinders rolling 524, 525.

- the metal strips 528 thus have a parallel path portion in which they enclose at least one card constituted by a wallet P 2 made of plastic material and its insert held by a clamp 515.

- Perforations of metal bands 528 and spiked wheels 522 allow to locate perfectly the 529 junctions of the bands 528 and thus ensure that these 529 junctions are localized, in the indexed motor movement, in space intermap. It can be noted that if the strips 528 were not perforated and controlled in their positioning by the 522 sprockets, the bands 528 would have junctions 529 which would be positioned randomly on the card to be laminated and would cause a fault in laminating making a mark.

- junctions 529 can be rigorously located in inter-card spaces (figure 18).

- the junctions 529 of the two endless metal strips 528 are preferably offset from each other by a distance d corresponding to one step or a whole number of steps of the clamps 515 ( Figure 20).

- the connecting elements of junctions 529 must themselves have a thickness less than that of a card (i.e. wallet and its insert) driven by a pair of bands metallic 528. In this way, one can obtain an icing and a very good flatness of the plastic card, thanks to the constant and rigorous maintenance between the two metal strips 528.

- the motorization of the laminator 240 is linked to the motorization of the main chain 1 with clamps 515, so that there is simultaneous advance and of the same amount of the roller chain 1 and the metal strips perforated 528.

- the pitch of the perforations of the bands 528 is advantageously the same as that of the drive chain of pliers 515.

- FIG. 17 shows the diagram of the general motorization 510 of the laminator 240 with a chain 501 driven by sprockets of motorization 502 associated with counter-rollers 503 and a roller reference 504.

- the reference 538 furthermore designates one of the motor gears of the rolling cylinders 524, 525.

- the references 526 and 527 in FIG. 18 also denote a spring and a adjusting screw of the pressure exerted on the cylinders of rolling 524, 525.

- Figures 18 and 19 show clogs as an example 541, 542 heating and 551, 552 cooling whose length roughly corresponds to that of two lengths of coupons, so as to double the length of stay coupons at these heating 541, 542 and cooling 551, 552.

- FIGS. 1 and 2 methods and identification card manufacturing facilities whereby the card personalization is carried out in a 120 station essentially using a printer to print before laminating data on the front and / or back of a card from files.

- a method and an installation for manufacturing cards secure identification according to which part of the personalization is transferred to the cards by a type process photographic and another part of the data is carried over to cards by a printing process. It is therefore essential to obtain good quality identification cards, regardless of the printing step done with care.

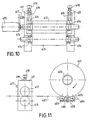

- systems are proposed to maintain constant or almost constant tension on the unwinding of a tape without the need to monitor the diameter of the reel to be unwound.

- a friction support comprising rollers 403 mounted on a support 404 and resting on a braking plate 405, acts on the coil 401 to simply avoid an untimely and random unfolding of the inertia coil.

- a similar system is applied, not directly to the coil 401, but to the mandrel 402 of it.

- the unwound 407 tape then passes between two rolls 412, 413 pressurized using a set screw system 418 and spring 419 acting relative to a support frame 411, in such a way that the pressure between the cylinders 412, 413 is necessary and sufficient to allow the rolling of these cylinders by the pulling action carried out on the strip 407 downstream of the cylinders 412, 413.

- At least one of the cylinders 412, 413 (cylinder 412) is equipped with a torque generator 415, which is connected to the shaft of the cylinder 412 by a coupling 416 and is connected to the chassis 411 by an anti-rotation support.

- the pulling torque at the cylinders 412, 413 is relatively zero and the tension of the belt at unwinding is almost zero.

- the efficiency of the constant web tension on unwinding is given by the presence of a 415 torque generator installed on the minus one of the shafts of cylinders 412, 413. It is possible the case install a torque generator on each of the shafts cylinders 412, 413, mounted using bearings 414 on the chassis 411.

- the torque generator 415 can be of the electromechanical type such as a powder coupler or a hysteresis brake. Such a type of torque generator, at a constant regulated voltage, delivers a constant output current determining a constant pulling torque. This type of torque generator can be adjusted by potentiometer on its control circuit, according to a sampling of value corresponding to his type.

- a torque generator can still be integrated inside the cylinder 412 or two torque generators can be integrated into the interior of the two cylinders 412, 413.

- a pair of cylinders 412, 413 equipped with at least one generator torque 415.

- the coating material of the cylinders 412, 413 is determined by the nature of the product to be unrolled.

- the diameter of the cylinders 412, 413 is itself determined by the tensile force to be obtained for the constant voltage and by the torque given by the generator 415.

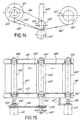

- Figures 12 and 13 show the implementation of a principle similar to the level of the winding of a product in strip 427 on a take-up mandrel 422 to form a coil 421, obtaining a constant voltage winding.

- the mandrel 422 of the coil 421 is driven from of a geared motor unit 425, for example by friction using a belt 424.

- the band 427 to be wound passes through a couple of cylinders 432, 433 mounted in a frame 431 in a manner analogous to cylinders 412, 413 of the unwinding device of FIGS. 10 and 11.

- the cylinder shafts 432, 433 are thus mounted using bearings 434 in the frame 431 and adjustment screws 438 associated with springs 439 for adjusting the pressure exerted by the cylinder 432 on the cylinder 433.

- a torque generator 435 is linked by a coupling 436 to the cylinder shaft 433.

- the torque generator 435 is rotated, for example using a pulley 428, by the belt 434 from the gearmotor group 425.

- the coil 421 is thus rotated by a transmission like that of the torque generator 425, from the same geared motor group 425.

- torque generator 435 in Figure 12 can be chosen according to the same criteria as for the 415 torque generator Figure 10.

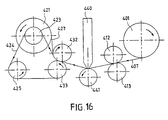

- FIG. 16 There is shown in Figure 16, by way of example, so schematic, a printer with a 440 print head acting on a printing ribbon comprising an upstream portion 407 unwound from a reel 401 to be introduced on a counter-roller 441 in front of the print head 440 and a downstream portion 427 which, after being passed in front of the print head 440 is wound on a spool 421.

- a tension is maintained constant for strip sections 407 and 427 thanks to a combination of the devices described above with reference to Figures 10 to 13.

- the device of FIG. 16 is adapted to the case where for the coils 401 and 421 there is a big difference between the diameter of the coils and the diameter of the empty coils.

- a winding device can be used and simplified procedure (Figures 14 and 15) which contributes to reducing the voltage variations of sections 407 ′, 427 ′ of the printing ribbon situated upstream and downstream of the printhead 440 ', while using a less complex mechanism than that represented on the whole of the Figure 16 and Figures 10 to 13.

- the print ribbon passes between the print head 440 'and a counter roller 441' in the same way as in the device of figure 16, but the pairs of rollers 412, 413 and 432, 433 of the Figure 16 are deleted.

- the associated 415 'and 435' torque generators to the unwinding and winding devices are then installed directly respectively on the mandrels 402 ', 422' of the coils 401 ', 421 'mounted using bearings 414', 434 'on the support frame 411'.

- the torque generator 415 ' is connected by a coupling 416 'to the shaft 402' and comprises a member anti-rotation 417 'cooperating with the frame 411'.

- the torque generator 435 ' is connected by a coupling 436 'to the shaft 422' and further comprises a pulley 423 'allowing motorization via a belt 424 'and a pulley 428' driven by a motorisation member 425 'which also contributes to driving the counter-roller shaft 441', mounted on the support frame 411 'using bearings 434'.

- these torque generators could be incorporated inside the shafts of the affected cylinders or coils.

- the installation 300 of FIG. 21 is remarkable in particular in that it includes an auxiliary chain closed with links 11 driven by motorized pinions 12 indexed and equipped with a set of auxiliary clamps 15 mounted with a constant pitch on links of the auxiliary chain 11.

- the auxiliary clamps 15 can have a configuration completely similar to that of the clamps 5 described in reference to Figures 4, 5 and 6A, 6B.

- the length L of jaws of the pliers 15 may be different from that of the jaws of the clamps 5 mounted on the main chain 1.

- the length L of the jaws clamps 5, 15 is in fact adapted to the size of the coupons base to be gripped by these pliers.

- the main closed chain with links 1, equipped with a set of main pliers 5 mounted with a constant pitch on links the main chain 1 is analogous to the description which has been made previously with reference to Figures 1 and 2.

- the main chain 1 is however driven by motorized pinions 2 indexed, in synchronism with the auxiliary chain 11.

- the auxiliary chain 11 which in the installation described is intended to ensure the transport of a basic coupon N consisting of a photosensitive element such as a film or negative paper, consists of a roller chain equipped with 20 clamps 15 mounted at regular intervals of 127 mm corresponding to a constant step of 10 links of a chain with a step of 12.7 mm.

- the main chain 1, which in the installation described is intended for ensure the transport of positive basic coupons P of paper or material plastic on which information must be reported personalized, in particular from basic negative coupons N, can be constituted by a roller chain equipped with 60 clamps 5 mounted at regular 127 mm intervals corresponding to one step constant of 10 links in a chain with a pitch of 12.7 mm. It is naturally possible to modify these values according to envisaged applications, and in particular depending on the size of the basic coupons and the number of workstations, as soon as one keeps advances indexed and synchronized in constant steps with temporary stops for processing coupons at the various level personal work places.

- an installation implement two chains 1.11 and the set of workstations which will described with reference to FIG. 21, may include a means of general motorization constituted by a motor-reduction unit - indexer relatively reduced power, for example 0.18 kW.

- the cost operating a machine such as installation 300 with a single electrical energy can be reduced and correspond to consumption of electrical energy not exceeding 2 to 3 kWh.

- the production rate of cards can be for example of around 1200 cards / hour with a compact installation 300 of which all the organs of the different workstations can be mounted on a same chassis 101 constituted for example essentially by a plate vertical with a thickness of about 15 mm and the length and height may be of the order of 1800 mm.

- the chassis 101 is thus compact and can be mounted if necessary on a mobile frame which allows easy movement of the machine 300.

- the auxiliary chain equipped with pliers 15 moves in front of a 310 supply station photosensitive negative coupon N, which may have a structure similar to that of supply station 110 already described in reference to figure 1 and allows entry of an individual negative coupon N by pliers 15.

- the auxiliary chain 11 then passes in front of a station 320 photographic shooting to transfer data personalized, in particular graphic data such as ID photograph, on the photosensitive negative coupon N from of information available in a database.

- this negative coupon N is brought to a post 330 of development where the negative coupon N is developed by dipping in an activator or developer bath.

- the length of the development 330 is adapted to the time required to reveal the negative coupon N. So this development station 330 can be extended if necessary on several steps ahead of the auxiliary chain 11 to keep the negative coupon N in contact with the activator bath for several successive steps in advance of the clamps 15.

- the auxiliary chain 11 then arrives at a station 342 of pressure overlay of negative coupon N with base coupon positive P supplied from a coupon supply station 110 positive base P where the positive basic coupons are entered by clamps 5 mounted on the main chain 1.

- the main chain 1 moves itself successively in front of post 110 for the supply of a positive basic coupon P (which can be carried out in accordance with the description previously given in reference to Figure 3 but could also include a charger pre-cut basic coupons), the 342 overlay item under pressure of a negative coupon N with a positive basic coupon P (which will be described in more detail with reference to FIGS. 22 to 24), a station 343 automatic opening of the gripper 15 carrying a coupon negative N in order to release this negative coupon N superimposed on a coupon positive P and a 350 transfer-development zone in which the negative coupon N is held in position by capillary adhesion on the positive coupon P itself transported by pliers 5 of the chain main 1, so that an image transfer is performed photo of the negative coupon N on the positive coupon P.

- a positive basic coupon P which can be carried out in accordance with the description previously given in reference to Figure 3 but could also include a charger pre-cut basic coupons

- the 342 overlay item under pressure of a negative coupon N with a positive basic coupon P (which will be described in

- the chain 1 then arrives at a 360 post to withdraw the negative coupon N by mechanized detachment of this negative coupon N compared to the coupon positive P and evacuation of the negative coupon N in a base 361.

- the chain main 1 then goes past a coupon washing station 370 positive P by soaking in a water bath, a first station 371 spinning through a pair of motorized cylinders, a station 372 of stabilization by soaking in a stabilizing bath, a second station 373 spin through a pair of motorized cylinders and a 380 station for example through a heated and ventilated tunnel.

- the positive coupon P personalized by the presence of an image photographic which may only fill a limited area of the positive coupon P, intended for example for an identity photograph, or which can contain all alphanumeric and graphic information necessary for personalization, can then be processed in a way similar to what has been described above with reference to FIG. 2.

- a station printing device 120 comprising a first printing device 121 on the front of a coupon P and a second printing device 122 on the back of a coupon P, a station 230 for training a case in plastic from stocks 231, 232 of upper and lower bands plastic material, a plasticizing station 240, a station 170 of card cutting, a mat 180 for receiving finished cards can be associated with a stacker, and a skeleton receiving tray 290 consisting of the remnants of coupon P after cutting at the cutting station 170, the opening of the clamp 5 holding this skeleton can be done automatically in front of bin 290 to release this skeleton.

- This way automatic clamp opening can be achieved simply by generator of a rotating cylinder which raises the bottom plate 56 of the clamp for example at the level of a sprocket for returning the chain 1 to the first workstation 110.

- FIG. 21 A more specific representation of this is shown in FIG. 21.

- the peripheral part of the rotating cylinder 343 synchronized with the advance of the chain 11 acts on a clamp 15 to open the latter after the step of superimposing the negative coupon N with the positive coupon P for allow training, by a single clamp 5 of the main chain 1, of the positive coupon P to which is superimposed, while slightly overflowing laterally, the negative coupon N.

- the reference 341 designates a coating roller the front of the positive coupon P in activator product taken for example in the tank used for wetting the negative coupon N in the development 330.

- the wetting device 341 is located just in upstream of the station 342 at the level of which the chains 1 and 11 become neighbors to allow the superimposition of a positive coupon P and a negative coupon N.

- FIG. 29 illustrates the layering of a negative coupon N with a positive receiving coupon P, then the release of the negative coupon N by the clamp 15, the negative coupon N remaining superimposed on the positive coupon P and only the part previously held by the clamp 15 projecting laterally.

- FIG. 29 shows the separation of the negative N after transfer of the photographic image to the positive coupon P 1 , then the combination of a plastic wallet P 2 and a personalized positive coupon P 1 for a plasticization operation before cutting a P 3 card and discarding the residual P 4 skeleton.

- the cost of the films constituting the negative coupons N is generally higher than the cost of the materials constituting the positive coupons P. It is thus possible to use negative coupons N small corresponding to the dimensions necessary for the reproduction of a graphic image such as an identity photograph, and to reproduce by photographic transfer on a positive coupon only this identity photograph occupying only a fraction of the surface of the P positive coupon, and complete the personalization of the P positive coupon on the parts not occupied by photography exclusively by a printing means in a station such as station 120 which can be constituted for example by a thermal or jet type printer ink.

- FIGS 22 to 24 illustrate an example of station 342 of pressure superimposition of a negative coupon N maintained by a clamp 15 of the auxiliary chain 11 and a positive coupon P maintained by a clamp 5 of the main chain 1 equipped with a motorized pinion 42.

- This stacking station essentially comprises two cylinders of transfer-press 41,45 superimposed mounted on shafts 41A, 45A respectively.

- the shaft 45A is mounted on a bearing box 47 which is set pressure, against the support 46 of the shaft 41A secured to the frame 101 of the machine, by a tension spring 69.

- the cylinder 41 integral with the pinion 42 forming a motorization socket and a motorization gear 43, is rotated around the fixed shaft 41A on which the cylinder 41 and the gear 43 are mounted by means of bearings 68.

- the cylinder 45 is itself driven in rotation by its integral shaft 45A a motorization gear 44 in engagement with the gear 43.

- the pressure exerted between the two cylinders 41, 45 by the spring 69 is relatively consistent and can cause a slightly offset positioning of the negative coupon N on the positive coupon P.

- This opening is achieved for example thanks to the setting work of cams 48, 49 mounted on the motorization gears 43, 44 and at least one of which has a spacer boss 64 (FIG. 23).

- a light 63 is formed on the cam 48 to ensure an adjustment of the angular position.

- the cycled ratio of the motorized gears 43, 44 allows to synchronize the synchronism of the opening of the rollers 41, 45 with the arrival of a negative coupon N.

- a similar device can be used at the level a printer, such as those illustrated in FIGS. 14, 15 and 16, to let a basic coupon enter under the print head 440, 440 'which comes to apply by pressure a thermal printing ribbon on a basic coupon moving on a counter roller 441, 441 '.

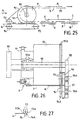

- the mechanical detachment of the negative coupon N at item 360 can be realized for example from the as illustrated in Figures 25 to 27, using a set of three small motorized belts 93A, 94A with circular section acting on the edge of the negative coupon N previously clamped in pliers 15 of the chain auxiliary 11 and projecting slightly from the positive coupon P on the side opposite to the clamp 5 for holding the positive coupon P.

- Figure 25 shows the path 99 of the links of the main chain 1 carrying pliers (symbolized by a vertical line), separated by one step E, supporting positive coupons P.

- a pinion 91 for driving the chain 1 serving as motorization socket for a pulley 92 is mounted at using bearings 90A on a shaft 90 secured to the frame 101 of the machine.

- Pulley 92 has two adjacent grooves having a diameter corresponding to the original diameter of the grippers 5 driven around the pinion 91.

- the shaft 90 carries on the side opposite to the frame 101, a plate 98 on which are fixed (by means of bearings 98A), a small pulley 93 with two grooves and two small upstream pulleys 95 and downstream 94 at a gorge.

- a pair of gears 96, 97, coaxial with small pulleys 93, 94 ensures the motorization of the small pulley 94 to from the movement of the small pulley 93 itself driven by the main pulley 92 of large diameter.

- the different pulleys 92, 93, 94, 95 have grooves for receiving belts 93A, 94A having a circular section whose diameter can be for example of the order of 3 mm.

- the edge of the negative coupon N is effectively pinched without sliding between the two upper round belts 93A engaged on pulleys 92 and 93 and the lower round belt 94A engaged on pulleys 94 and 95.

- the coupon negative is then automatically removed by pinching between the three belts 93A, 94A while the positive coupon P which is indented by compared to the pulleys 92, 93, 94, 95, continues its journey with the clamp 5 the along chain 1.

- the grippers 5, 15 for gripping the coupons or formats C, P, N involved in the card manufacturing process can be provided with a code, such as a bar code, which allows, by reading the code of each clamp at the level of the different work stations, to locate at any time in the machine, the card being produced.

- a code such as a bar code

- reading the code of pliers 5, 15 at a customization 120, 320 allows to control during production the applications of personalized identification data and avoids any error even when various personalization data (for example example postponement of identity photograph, printing of the front of a card, printing the back of a card) are inserted on a card different workstations 320, 121, 122 from file different data.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Credit Cards Or The Like (AREA)

- Making Paper Articles (AREA)

- Cash Registers Or Receiving Machines (AREA)

- Telephonic Communication Services (AREA)

- Perforating, Stamping-Out Or Severing By Means Other Than Cutting (AREA)

- Electrophonic Musical Instruments (AREA)

- Punching Or Piercing (AREA)

- Reverberation, Karaoke And Other Acoustics (AREA)

- Devices For Checking Fares Or Tickets At Control Points (AREA)

- Bakery Products And Manufacturing Methods Therefor (AREA)

- Breeding Of Plants And Reproduction By Means Of Culturing (AREA)

- Control Of Metal Rolling (AREA)

Abstract

Description

La présente invention a pour objet une installation de fabrication de coupons personnalisés comprenant un ensemble de postes de travail avec au moins un poste d'approvisionnement en coupons de base, un poste de personnalisation des coupons de base et un poste de découpage des coupons de base personnalisés, et un système de transport des coupons de base entre les différents postes de travail.The subject of the present invention is a plant for manufacturing personalized coupons including a set of workstations with at least one basic coupon supply station, one post for personalizing basic coupons and a post for cutting of personalized basic coupons, and a system of transport of basic coupons between different work stations.

L'invention concerne également un procédé de fabrication à la chaíne de coupons personnalisés comprenant au moins une étape d'approvisionnement en coupons de base à un premier poste de travail, une étape de personnalisation des coupons de base à un deuxième poste de travail et une étape de découpe des coupons de base personnalisés à un troisième poste de travail, les coupons de base étant transportés successivement d'un poste de travail à l'autre.The invention also relates to a method of manufacturing by personalized coupon chain comprising at least one step supply of basic coupons to a first work station, a step of personalizing the basic coupons at a second station of work and a step of cutting the basic personalized coupons to a third work station, the basic coupons being transported successively from one workstation to another.

On a déjà proposé différents types de procédés et d'installations de fabrication de documents personnalisés tels que des cartes d'identification, notamment de cartes d'identification sécurisées, telles que des cartes d'identité, des permis de conduire, des cartes bancaires, des cartes de sécurité sociale, des badges. De telles cartes d'identification comportent un support ou coupon de base, par exemple en papier ou en matière plastique, sur lequel sont reportées différentes informations de personnalisation, telles que des informations utilisant des caractères alphanumériques ou des informations utilisant des images photographiques. Les informations de personnalisation diffèrent d'une carte à l'autre. Des éléments sécuritaires peuvent être en outre adjoints aux coupons de base, ou à des feuilles additionnelles combinées aux coupons de base, par exemple à l'aide d'encres chimiques, de vernis UV, de luminophores, d'embossages. Enfin, les coupons de base personnalisés et sécurisés font souvent l'objet d'une plastification.Various types of processes and installations have already been proposed. manufacture of personalized documents such as cards identification, including secure identification cards, such as identity cards, driver's licenses, bank cards, social security cards, badges. Such identification cards have a basic support or coupon, for example made of paper or plastic material, on which various information of personalization, such as information using characters alphanumeric or information using images Photographic. Personalization information differs from card to another. Security elements can also be added basic coupons, or additional sheets combined with basic coupons, for example using chemical inks, UV varnish, phosphors, embossing. Finally, the basic coupons Personalized and secure are often subject to laminating.

Les installations existantes présentent généralement une grande complexité, notamment du fait des problèmes de synchronisation des différentes opérations successives conduisant à des cartes finies. Il convient en effet d'éviter tout décalage dans les opérations successives notamment d'impression ou découpe des différentes cartes fabriquées successivement sur une même installation.Existing installations generally have a large complexity, especially due to synchronization problems different successive operations leading to finished cards. he indeed, avoid any delay in successive operations especially printing or cutting of the different cards produced successively on the same installation.

Les procédés connus de fabrïcation de cartes d'identification impliquent par ailleurs des pertes importantes de produits consommables (bandes de papier ou matière plastique devant recevoir les informations personnalisées, bandes de matière plastique pour l'opération de plastification), notamment du fait des longueurs d'amorçage nécessaires pour assurer le réglage des Installations. Il s'ensuit que ces installations connues ne sont pas adaptées à la fabrication de petites séries de cartes, dès lors qu'elles impliquent pour chaque série de fabrication des pertes de produits significatives et un temps de traitement relativement long.Known methods of manufacturing identification cards also involve significant losses of consumables (strips of paper or plastic to receive information customized, plastic bands for the operation of plasticization), in particular because of the necessary lengths of priming to ensure the adjustment of the Installations. It follows that these installations known are not suitable for the manufacture of small series of cards, since they involve for each production series losses of significant products and a relatively long processing time.

Les installations existantes ne se prêtent pas non plus facilement à une modification de leurs caractéristiques du fait d'un manque de caractère modulaire.Nor do existing facilities lend themselves easily to a change in their characteristics due to a lack of modular character.

Le document EP-A-0 364 730 décrit

une installation de fabrication de coupons peronnalisés

telle que décrite dans le préambule de la revendication 1,

et un procédé de fabrication de ces coupons

tel que decrit dans le préambule de la revendication 29.The document EP-A-0 364 730 describes

a facility for manufacturing personalized coupons

as described in the preamble of

L'invention vise à remédier aux inconvénients précités et à permettre la fabrication de coupons personnalisés tels que des cartes d'identification d'excellente qualité, notamment de cartes sécurisées, à un coût réduit et avec une grande souplesse d'adaptation à des procédés de fabrication différents.The invention aims to remedy the aforementioned drawbacks and to allow the manufacture of personalized coupons such as cards of excellent quality identification, including secure cards, to a reduced cost and with great flexibility of adaptation to different manufacturing.

L'invention vise en particulier à garantir le fonctionnement d'une installation de fabrication de cartes sans que des décalages ou défauts se produisent en cours de production.The invention aims in particular to guarantee the operation of a card manufacturing facility without any lags or faults produce during production.

L'invention vise également à permettre de réaliser rapidement et sans pertes de matière première, la fabrication de petites séries de cartes d'identification personnalisées et sécurisées.The invention also aims to allow rapid and without loss of raw material, the production of small series of cards personalized and secure identification.