EP1069257A2 - Sensor controlled sun protection device - Google Patents

Sensor controlled sun protection device Download PDFInfo

- Publication number

- EP1069257A2 EP1069257A2 EP00114832A EP00114832A EP1069257A2 EP 1069257 A2 EP1069257 A2 EP 1069257A2 EP 00114832 A EP00114832 A EP 00114832A EP 00114832 A EP00114832 A EP 00114832A EP 1069257 A2 EP1069257 A2 EP 1069257A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- sun protection

- protection system

- control

- sensor

- articulated arm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000037072 sun protection Effects 0.000 title claims abstract description 61

- 230000005611 electricity Effects 0.000 claims description 8

- 230000001133 acceleration Effects 0.000 claims description 4

- 238000009429 electrical wiring Methods 0.000 claims 1

- 238000009434 installation Methods 0.000 abstract description 7

- 238000001514 detection method Methods 0.000 abstract description 2

- 239000004744 fabric Substances 0.000 description 7

- 230000010354 integration Effects 0.000 description 2

- 210000001503 joint Anatomy 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 238000010616 electrical installation Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 210000003462 vein Anatomy 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/56—Operating, guiding or securing devices or arrangements for roll-type closures; Spring drums; Tape drums; Counterweighting arrangements therefor

- E06B9/68—Operating devices or mechanisms, e.g. with electric drive

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F10/00—Sunshades, e.g. Florentine blinds or jalousies; Outside screens; Awnings or baldachins

- E04F10/02—Sunshades, e.g. Florentine blinds or jalousies; Outside screens; Awnings or baldachins of flexible canopy materials, e.g. canvas ; Baldachins

- E04F10/06—Sunshades, e.g. Florentine blinds or jalousies; Outside screens; Awnings or baldachins of flexible canopy materials, e.g. canvas ; Baldachins comprising a roller-blind with means for holding the end away from a building

- E04F10/0644—Sunshades, e.g. Florentine blinds or jalousies; Outside screens; Awnings or baldachins of flexible canopy materials, e.g. canvas ; Baldachins comprising a roller-blind with means for holding the end away from a building with mechanisms for unrolling or balancing the blind

- E04F10/0659—Control systems therefor

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/24—Screens or other constructions affording protection against light, especially against sunshine; Similar screens for privacy or appearance; Slat blinds

- E06B9/26—Lamellar or like blinds, e.g. venetian blinds

- E06B9/28—Lamellar or like blinds, e.g. venetian blinds with horizontal lamellae, e.g. non-liftable

- E06B9/30—Lamellar or like blinds, e.g. venetian blinds with horizontal lamellae, e.g. non-liftable liftable

- E06B9/32—Operating, guiding, or securing devices therefor

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/56—Operating, guiding or securing devices or arrangements for roll-type closures; Spring drums; Tape drums; Counterweighting arrangements therefor

- E06B9/68—Operating devices or mechanisms, e.g. with electric drive

- E06B2009/6809—Control

- E06B2009/6818—Control using sensors

Definitions

- the invention relates to a sun protection system a sun protection curtain with at least one electrical Drive that controls the setting of the Sun protection curtain may depend on several Automatically performs input variables.

- the housing of the controls or the Sensors and their electrical connection lines to the Sun protection system also the visual impression for the viewer to disturb.

- the object of the present invention is a To create sun protection system, its installation in particular subsequent installation is simplified.

- the object is achieved in that the Control of the drive wired ready for operation in the sun protection system is integrated and a supply connection preferably for connection to a common household electricity network is provided.

- Such a sun protection system its operation, for example can be done with the help of a radio remote control Receiver is also integrated into the system, only has to mounted in the area of the window opening to be shaded and connected to the household electricity network.

- the electric one Wiring is minimal because it only has to a connection to the nearest distribution point of the Electricity network are produced.

- the one with external controls necessary configurations after interconnection also dropped.

- an intelligent sun protection system can also be used configure ready for connection with automatic blind control, which in turn makes the system particularly simple and is inexpensive to install retrospectively.

- the control is preferably in a housing of the sun protection system installed or in a separate control housing provided that on or in parts of the sun protection system is attached.

- the controller is preferably integrated in the support tube.

- the controller is preferably integrated in the support tube.

- control directly in the support tube to assemble and seal its ends in a suitable manner or the control with a separate control housing in insert the support tube.

- a slot in the support tube or one special sealing cap enables lateral execution the connecting cables to the sensors, the drive and the Power supply network. With such an integrated control this disappears almost invisibly in the support tube.

- the housing can of course with suitable fasteners such.

- B. a clip connection be attached to the support tube.

- the wind load sensor in the form of a vibration or acceleration sensor in a particularly strongly excited by the attacking wind

- the area of the sun protection system With folding arm awnings these areas are close to the failure profile and the articulated arms, an arrangement of the wind load sensor on or in the articulated arm near the drop profile or of the central joint is particularly preferred.

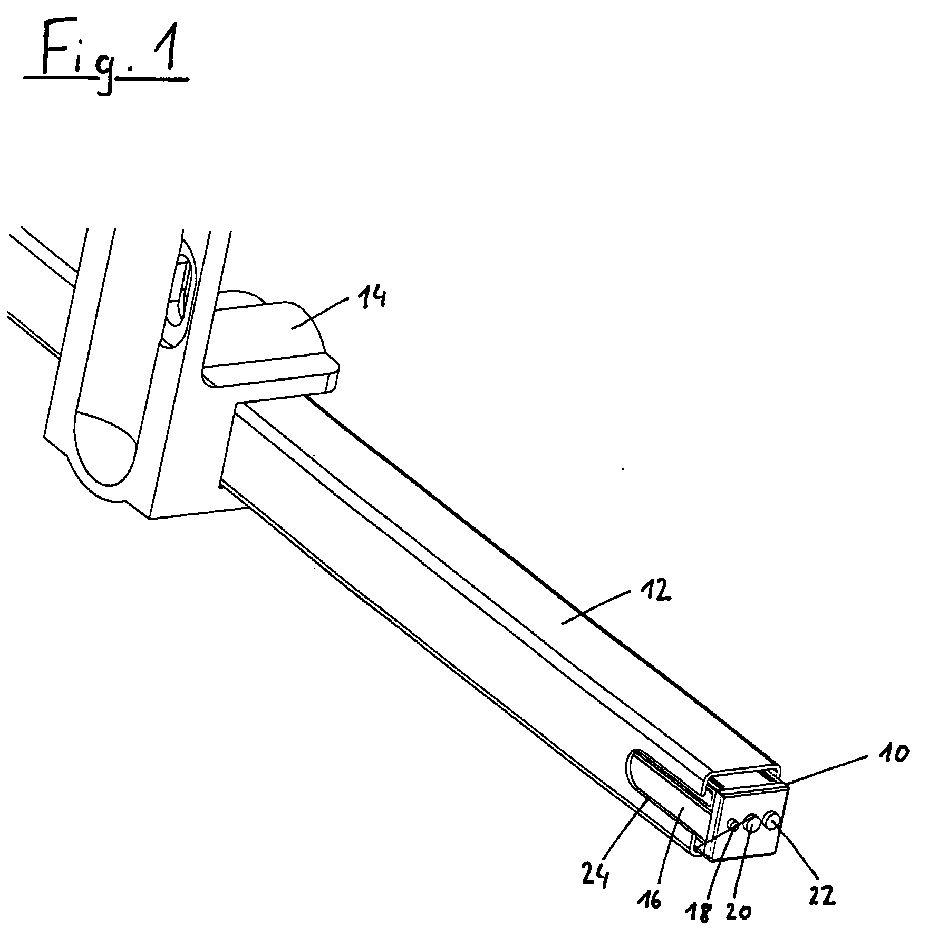

- FIG. 1 shows the possible integration of a controller 10 in an articulated arm awning is shown, of which for illustration only a support tube designed as a square tube 12 and a support bracket 14 for mounting the awning on one Wall or a ceiling projection is shown.

- the control 10 is in the inner cross section of the support tube 12 arranged in cross section adapted control housing 16, which can be inserted laterally into the support tube 12.

- On the front of the housing are three connection options provided, with a first connection 18 for connection to one or more sensors, a second connection 20 for Connection with an electric drive of the folding arm awning and a third connector 22 for connection to a Power supply network, for example a household power network, is provided.

- a side slot 24 allows the lateral execution of those connected to the controller 10 Connection lines to the sensor, the drive and the power supply.

- the support tube 12 is after placing a side Cloth shaft bracket 26 with a side plastic cover 28 shown.

- the bracket 30 of an articulated arm (see Fig. 4 and 5) is attached to the support tube 12 and screwed (Screws not shown).

- the cloth shaft bracket 26 and the plastic cap 28 is that Housing 16 invisibly hidden inside the support tube 12.

- Controller 10 with a sensor line 32 on the support tube 12 is guided along to the articulated arm 30.

- a drive line 34 leads to that in the cloth shaft (not shown) which in the Cloth shaft console 26 can be used, arranged electrical Drive motor (also not shown).

- a supply line 36 will be sent to the nearest distributor connected to the household electricity network. Because the sensor that Drive and control are already wired ready for operation and configured, the articulated arm awning can be Assembly and connecting the supply line 36 with the Household electricity network can be put into operation immediately.

- Fig. 3 is an alternative placement of a controller 110 shown on a support tube 112 of an articulated arm awning, in which the housing 116 of the controller 110 is limited Space can not be installed. There are therefore mounting brackets 124 provided the support tube Wrap 112 and in grooves provided in the housing 116 125 intervene. At the front of the controller 110 are again Connections 118, 120, 122 for the electrical lines intended. A support tube bracket 114 and a cloth shaft bracket 126 are also shown.

- the controller leading electrical cables can be used in the usual way Help of known fastening aids from the field of electrical installation, e.g. B. with the help of self-adhesive cable tie loops, be made.

- an articulated arm half 38 is shown with Using a drop joint 40 on a drop profile (not shown) and via a central joint (not shown) on one upper articulated arm is pivotally fixed, the upper articulated arm halves with the articulated arm holder 30 (see FIG. 2) is articulated. Near the joint 40 is a Vibration sensor 42 is provided which through a bore 44 in Profile of the lower articulated arm half 38 into the articulated arm interior can be introduced. The sensor 42 is via the connecting line 32 (see also Fig. 2), which leads past the articulated arm profiles on the outside is connected to the controller 10.

- a cover strip 46 protects the connecting line 32 and the sensor 42 Damage, the cover strip 46 on its long sides has locking lugs 48 which in corresponding grooves 50 engage in the longitudinal direction on the articulated arm half 38 are provided.

- the location of the sensor 42 nearby the failure profile has proven to be advantageous since in particularly strong vibrations and accelerations in this area can occur under the influence of wind load.

- a wind load sensor Vibration sensor 142 protected by a plastic receptacle 144 near the articulated arm center joint 146 on the upper articulated arm half 148 attached.

- a Cover bar 150 is provided, which is not shown in FIG. 5 Connection line to the controller 10 covers.

- the Sensor 142 is installed in plastic receptacle 144 pressed in and the latter is with retaining lugs 152 in grooves 154 engaged on the upper half of the articulated arm 148, in which the cover strip 150 is also attached.

- the advantage of this Arrangement is that with the connecting line to Control only one joint must be bridged, too the sensor position due to the pronounced movement of the middle joint Also particularly suitable in the event of a wind attack on the cloth is.

- a wire is also preferably in the connecting line 32 integrated as a receiving antenna for a radio remote control the sun protection system can be used.

- sun protection systems such as B. with venetian blinds or drop arm awnings, conceivable, Integrate sensors and control in a form that that described above using the example of an articulated arm awning The arrangement is similar, but the particularities are adjusted.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Structural Engineering (AREA)

- Civil Engineering (AREA)

- Blinds (AREA)

- Building Awnings And Sunshades (AREA)

- Wind Motors (AREA)

- Power-Operated Mechanisms For Wings (AREA)

- Operating, Guiding And Securing Of Roll- Type Closing Members (AREA)

- Transmission And Conversion Of Sensor Element Output (AREA)

- Train Traffic Observation, Control, And Security (AREA)

Abstract

Eine Sonnenschutzanlage mit einem Sonnenschutzbehang besitzt wenigstens einen elektrischen Antrieb, der mit Hilfe einer Steuerung (10) die Einstellung des Sonnenschutzbehangs ggf. in Abhängigkeit von Eingangsgrößen vorzugsweise selbsttätig vornimmt. Bei bekannten Sonnenschutzanlagen ist eine aufwendige Verdrahtung der externen Steuerung und der Sensoren und eine aufwendige Konfiguration der Anlage notwendig. Um dies zu vermeiden ist vorgesehen, daß die Steuerung (10) und/oder wenigstens ein eine Eingangsgröße erfassender Sensor (42) betriebsfertig verdrahtet in die Sonnenschutzanlage integriert ist und ein Versorgungsanschluß (36) vorzugsweise zur Verbindung mit einem üblichen Haushaltsstromnetz vorgesehen ist. Eine derartige Sonnenschutzanlage muß nur noch in der gewünschten Einbaulage montiert und mit dem nächstliegenden Verteiler des Stromnetzes verbunden werden. Sie ist sodann unmittelbar einsatzbereit. Ein Vorteil eines beispielsweise integrierten Windlastsensors besteht in der exakten Erfassung der Windlast im Bereich der Sonnenschutzanlage. A sun protection system with a sun protection curtain has at least one electric drive which, with the aid of a controller (10), preferably performs the setting of the sun protection curtain automatically, depending on input variables. In known sun protection systems, complex wiring of the external control and sensors and complex configuration of the system are necessary. In order to avoid this, it is provided that the control (10) and / or at least one sensor (42) detecting an input variable is wired ready for operation in the sun protection system and that a supply connection (36) is preferably provided for connection to a conventional household power supply system. Such a sun protection system only has to be installed in the desired installation position and connected to the nearest distributor in the power grid. It is then immediately ready for use. One advantage of an integrated wind load sensor, for example, is the exact detection of the wind load in the area of the sun protection system.

Description

Die Erfindung befaßt sich mit einer Sonnenschutzanlage mit einem Sonnenschutzbehang mit wenigstens einem elektrischen Antrieb, der mit Hilfe einer Steuerung die Einstellung des Sonnenschutzbehangs unter Umständen in Abhängigkeit von mehreren Eingangsgrößen selbsttätig vornimmt.The invention relates to a sun protection system a sun protection curtain with at least one electrical Drive that controls the setting of the Sun protection curtain may depend on several Automatically performs input variables.

Bisher üblich sind Lösungen, bei welchen die Steuerung und Sensoren zur Erfassung der Eingangsgrößen extern, getrennt von der Sonnenschutzanlage angeordnet sind. Diese Anordnung, bei welcher die zentralen Sensoren oft auf dem Dach eines Gebäudes angeordnet sind und eine Zentralsteuerung für alle Sonnenschutzanlagen vorgesehen ist, bedingt eine Reihe von Nachteilen. Die externe Anordnung der Sensoren führt durch den räumlichen Abstand zur Sonnenschutzanlage zu zum Teil erheblichen Abweichungen der gemessenen kritischen Umgebungseinflüsse, wie z. B. Wind, im Vergleich zur Istbelastung der Sonnenschutzanlage. Diese schwer vorhersehbaren Abweichungen müssen im Steuerprogramm durch Sicherheiten ausgeglichen werden, die bei einer Windüberwachung grundsätzlich dazu führen, daß der Sonnenschutz früher eingefahren wird, als es von der tatsächlichen Istbelastung der Sonnenschutzanlage her gesehen notwendig wäre.Solutions in which the control and External sensors for recording the input variables, separately are arranged by the sun protection system. This arrangement, where the central sensors are often on the roof of a building are arranged and a central control for everyone A number of sun protection systems is provided Disadvantages. The external arrangement of the sensors carries out the spatial distance to the sun protection system is sometimes considerable Deviations of the measured critical environmental influences, such as B. wind, compared to the actual load of the Sun protection system. These hard-to-predict deviations must be offset by collateral in the tax program, which generally lead to wind monitoring that the sun protection is retracted earlier than that of the Actual actual load of the sun protection system seen here would be necessary.

Die externe Anordnung der Steuerung bedingt ihrerseits einen erheblichen Verdrahtungsaufwand, wobei neben dem erschwerten Anschluß der einzelnen Sonnenschutzanlagen vor allem die gebäudeseitige Verlegung der Steuer- und Versorgungsleitungen einen erheblichen Aufwand nach sich zieht. The external arrangement of the control in turn requires one considerable wiring effort, in addition to the more difficult Connection of the individual sun protection systems, especially the building side Laying the control and supply lines involves considerable effort.

Je nach Einbauart können die Gehäuse der Steuerungen oder der Sensoren sowie ihre elektrischen Verbindungsleitungen zu der Sonnenschutzanlage auch den optischen Eindruck für den Betrachter stören.Depending on the type of installation, the housing of the controls or the Sensors and their electrical connection lines to the Sun protection system also the visual impression for the viewer to disturb.

Die Aufgabe der vorliegenden Erfindung besteht darin, eine Sonnenschutzanlage zu schaffen, deren Einbau insbesondere bei nachträglicher Installation vereinfacht ist.The object of the present invention is a To create sun protection system, its installation in particular subsequent installation is simplified.

Erfindungsgemäß wird die Aufgabe dadurch gelöst, daß die Steuerung des Antriebes betriebsfertig verdrahtet in die Sonnenschutzanlage integriert ist und ein Versorgungsanschluß vorzugsweise zur Verbindung mit einem üblichen Haushaltsstromnetz vorgesehen ist.According to the invention the object is achieved in that the Control of the drive wired ready for operation in the sun protection system is integrated and a supply connection preferably for connection to a common household electricity network is provided.

Eine derartige Sonnenschutzanlage, deren Bedienung beispielsweise mit Hilfe einer Funkfernbedienung erfolgen kann, deren Empfänger ebenfalls in die Anlage integriert ist, muß lediglich im Bereich der zu verschattenden Fensteröffnung montiert und an das Haushaltsstromnetz angeschlossen werden. Der elektrische Verdrahtungsaufwand ist minimal, denn es muß lediglich eine Verbindung zum nächstliegenden Verteilerpunkt des Stromnetzes hergestellt werden. Die bei externen Steuerungen notwendige Konfigurationen nach dem Zusammenschalten können ebenfalls entfallen.Such a sun protection system, its operation, for example can be done with the help of a radio remote control Receiver is also integrated into the system, only has to mounted in the area of the window opening to be shaded and connected to the household electricity network. The electric one Wiring is minimal because it only has to a connection to the nearest distribution point of the Electricity network are produced. The one with external controls necessary configurations after interconnection also dropped.

Bei einer Sonnenschutzanlage, bei welcher mit Hilfe einer Steuerung die Einstellung des Sonnenschutzbehangs in Abhängigkeit von mehreren Eingangsgrößen selbständig erfolgt, kann eine alternative Lösung zur Verminderung des Einbauaufwandes vorsehen, daß wenigstens ein Teil von Sensoren zur Erfassung der Eingangsgrößen betriebsfertig verdrahtet in die Sonnenschutzanlage integriert sind und ebenfalls ein Versorgungsanschluß vorzugsweise zur Verbindung mit einem üblichen Haushaltsstromnetz vorgesehen ist.In a sun protection system, with the help of a Control the setting of the sun protection curtain depending independently of several input variables, can an alternative solution to reduce the installation effort provide that at least a portion of sensors for detection of the input variables wired ready for operation into the sun protection system are integrated and also a supply connection preferably for connection with a conventional one Household electricity network is provided.

Bei einer derartigen Sonnenschutzanlage entfällt die ansonsten notwendige Verdrahtung durch die Integration bisher extern angeordneter Sensoren. Ein weiterer wesentlicher Vorteil integrierter Sensoren zur Erfassung bestimmter Eingangsgrößen, beispielsweise der Windlast, besteht darin, daß die Eingangsgröße unmittelbar im Bereich der Sonnenschutzanlage erfaßt wird und dadurch Sicherheiten im Sinne einer optimalen automatischen Steuerung auf ein Minimum reduziert werden können. Insbesondere bei der Windüberwachung ergeben sich dabei erhebliche Funktionsvorteile.With such a sun protection system, this is otherwise not necessary necessary wiring through integration so far external arranged sensors. Another major advantage integrated sensors for recording certain input variables, for example the wind load, is that the input variable recorded directly in the area of the sun protection system and thereby guarantees in the sense of an optimal automatic control can be reduced to a minimum. This results in particular in wind monitoring considerable functional advantages.

Ist bei einer solchen Sonnenschutzanlage entsprechend der zuvor beschriebenen erfindungsgemäßen Lösung auch die Steuerung integriert, läßt sich auch eine intelligente Sonnenschutzanlage mit automatischer Behangsteuerung anschlußfertig konfigurieren, wodurch die Anlage wiederum besonders einfach und kostengünstig auch nachträglich zu installieren ist.In such a sun protection system is the same as before described solution according to the invention also the control integrated, an intelligent sun protection system can also be used configure ready for connection with automatic blind control, which in turn makes the system particularly simple and is inexpensive to install retrospectively.

Vorzugsweise ist die Steuerung in einem Gehäuse der Sonnenschutzanlage eingebaut oder in einem separaten Steuerungsgehäuse vorgesehen, das an oder in Teilen der Sonnenschutzanlage befestigt ist.The control is preferably in a housing of the sun protection system installed or in a separate control housing provided that on or in parts of the sun protection system is attached.

Je nach Beschaffenheit der Sonnenschutzanlage verfügt diese bereits über ein Gehäuse, das zur Aufnahme der unter Umständen in bezug auf beispielsweise Feuchtigkeit und Staub empfindlichen Steuerung geeignet ist. In anderen Fällen ist es zweckmäßig, die Steuerung mit einem Gehäuse zu versehen, daß einerseits den geforderten Schutz für die Steuerung bietet und sich andererseits leicht in die Sonnenschutzanlage integrieren läßt.Depending on the nature of the sun protection system, this has already have a housing that can accommodate the circumstances sensitive to, for example, moisture and dust Control is suitable. In other cases it is expedient to provide the controller with a housing that on the one hand offers the required protection for the control and easily integrate into the sun protection system leaves.

Bei einer Gelenkarmmarkise, die unter Umständen gar kein Gehäuse besitzt sondern nur offene Rahmenteile aufweist, ist die Steuerung vorzugsweise in das Tragrohr integriert. Hierbei ist es denkbar, die Steuerung unmittelbar in dem Tragrohr zu montieren und dessen Enden in geeigneter Weise abzudichten oder die Steuerung mit einem gesonderten Steuerungsgehäuse in das Tragrohr einzuschieben. Ein Schlitz im Tragrohr oder eine spezielle Verschlußkappe ermöglicht eine seitliche Ausführung der Anschlußleitungen zu den Sensoren, dem Antrieb und zum Stromversorgungsnetz. Bei einer derartig integrierten Steuerung verschwindet diese nahezu unsichtbar in dem Tragrohr.With an articulated arm awning, which may not have a housing at all has but only has open frame parts, is the controller is preferably integrated in the support tube. Here it is conceivable to control directly in the support tube to assemble and seal its ends in a suitable manner or the control with a separate control housing in insert the support tube. A slot in the support tube or one special sealing cap enables lateral execution the connecting cables to the sensors, the drive and the Power supply network. With such an integrated control this disappears almost invisibly in the support tube.

Sofern der Einbau in das Tragrohr oder auch in die Tragkonsole nicht möglich ist, kann das Gehäuse selbstverständlich mit geeigneten Befestigungselementen, wie z. B. einer Clipverbindung, am Tragrohr befestigt sein.If the installation in the support tube or in the support bracket is not possible, the housing can of course with suitable fasteners such. B. a clip connection, be attached to the support tube.

Wie bereits erwähnt, ist vorzugsweise wenigstens ein Sensor zur Erfassung der auf die Sonnenschutzanlage wirkenden Windlast in die Sonnenschutzanlage integriert, um die Windlast für jede einzelne Sonnenschutzanlage mit großer Genauigkeit messen zu können. Besonders bevorzugt ist es dabei, den Windlastsensor in Form eines Vibrations- oder Beschleunigungssensors in einem vom angreifenden Wind besonders stark erregten Bereich der Sonnenschutzanlage anzuordnen. Bei Gelenkarmmarkisen liegen diese Bereiche in der Nähe des Ausfallprofils und der Gelenkarme, wobei eine Anordnung des Windlastsensors an oder in dem Gelenkarm in der Nähe des Ausfallprofils oder des Mittelgelenkes besonders bevorzugt ist.As already mentioned, there is preferably at least one sensor for recording the wind load acting on the sun protection system integrated in the sun protection system to the wind load for each individual sun protection system with great accuracy to be able to measure. It is particularly preferred to use the wind load sensor in the form of a vibration or acceleration sensor in a particularly strongly excited by the attacking wind To arrange the area of the sun protection system. With folding arm awnings these areas are close to the failure profile and the articulated arms, an arrangement of the wind load sensor on or in the articulated arm near the drop profile or of the central joint is particularly preferred.

Soll die Sonnenschutzanlage mit Hilfe einer Fernbedienung verstellbar sein, so ist es besonders zweckmäßig, die hierzu notwendige Antenne in eine freiliegende Verdrahtung als zusätzliche Ader zu integrieren.Should the sun protection system with the help of a remote control be adjustable, it is particularly useful to do this necessary antenna in an exposed wiring as additional Integrating vein.

Nachfolgend wird anhand der beigefügten Zeichnungen näher auf ein Ausführungsbeispiel der Erfindung eingegangen. Es zeigen:

- Fig. 1

- Eine Schrägansicht eines Tragrohrs einer Gelenkarmmarkise;

- Fig. 2

- das Tragrohr gemäß Fig. 1 mit angebrachter Tuchwellenkonsole;

- Fig. 3

- eine alternative Anordnung des Steuerungsgehäuses an dem Tragrohr;

- Fig. 4

- eine schematische Ansicht der Anordnung eines Sensors in einer Gelenkarmhälfte;

- Fig. 5

- eine schematische Ansicht eines Gelenkarmes einer Markise mit außenseitig montiertem Sensor.

- Fig. 1

- An oblique view of a support tube of an articulated arm awning;

- Fig. 2

- the support tube of Figure 1 with attached cloth shaft bracket.

- Fig. 3

- an alternative arrangement of the control housing on the support tube;

- Fig. 4

- a schematic view of the arrangement of a sensor in a joint arm half;

- Fig. 5

- is a schematic view of an articulated arm of an awning with sensor mounted on the outside.

In Fig. 1 ist die mögliche Integration einer Steuerung 10 in

einer Gelenkarmmarkise dargestellt, von welcher zur Veranschaulichung

nur ein als Vierkantrohr ausgebildetes Tragrohr

12 und eine Tragkonsole 14 zur Montage der Markise an einer

Wand oder einem Deckenvorsprung dargestellt ist. Die Steuerung

10 ist dabei in einem dem Innenquerschnitt des Tragrohres

12 im Querschnitt angepaßten Steuerungsgehäuse 16 angeordnet,

das seitlich in das Tragrohr 12 einschiebbar ist. Auf

der Stirnseite des Gehäuses sind drei Anschlußmöglichkeiten

vorgesehen, wobei ein erster Anschluß 18 zur Verbindung mit

einem oder mehreren Sensoren, ein zweiter Anschluß 20 zur

Verbindung mit einem elektrischen Antrieb der Gelenkarmmarkise

und ein dritter Anschluß 22 zur Verbindung mit einem

Stromversorgungsnetz, beispielsweise einem Haushaltsstromnetz,

vorgesehen ist. Ein seitlicher Schlitz 24 ermöglicht

das seitliche Ausführen der mit der Steuerung 10 verbundenen

Anschlußleitungen zu dem Sensor, dem Antrieb und der Stromversorgung.1 shows the possible integration of a

In Fig. 2 ist das Tragrohr 12 nach dem Aufsetzen einer seitlichen

Tuchwellenkonsole 26 mit einer seitlichen Kunststoffabdeckung

28 dargestellt. Die Halterung 30 eines Gelenkarmes

(s. Fig. 4 und 5) ist an das Tragrohr 12 angesetzt und verschraubt

(Schrauben nicht dargestellt). Nach dem Aufsetzen

der Tuchwellenkonsole 26 und der Kunststoffkappe 28 ist das

Gehäuse 16 unsichtbar im Innneren des Tragrohres 12 verborgen.

Zu erkennen sind lediglich die Anschlußleitungen der

Steuerung 10, wobei eine Sensorleitung 32 an dem Tragrohr 12

entlang zu dem Gelenkarm 30 geführt ist. Eine Antriebsleitung

34 führt zu dem in der Tuchwelle (nicht gezeigt), die in die

Tuchwellenkonsole 26 einsetzbar ist, angeordneten elektrischen

Antriebsmotor (ebenfalls nicht dargestellt). Eine Versorgungsleitung

36 wird an die nächstliegende Verteilerstelle

des Haushaltsstromnetzes angeschlossen. Da der Sensor, der

Antrieb und die Steuerung bereits betriebsfertig verdrahtet

und konfiguriert sind, kann die Gelenkarmmarkise nach der

Montage und dem Verbinden der Versorgungsleitung 36 mit dem

Haushaltsstromnetz unmittelbar in Betrieb genommen werden.In Fig. 2, the

In Fig. 3 ist eine alternative Unterbringung einer Steuerung

110 an einem Tragrohr 112 einer Gelenkarmmarkise dargestellt,

in welchem sich das Gehäuse 116 der Steuerung 110 wegen beschränkter

Platzverhältnisse nicht montieren läßt. Es sind

daher Befestigungsklammern 124 vorgesehen, die das Tragrohr

112 umschlingen und in in dem Gehäuse 116 vorgesehene Nuten

125 eingreifen. An der Stirnseite der Steuerung 110 sind wiederum

Anschlüsse 118, 120, 122 für die elektrischen Leitungen

vorgesehen. Eine Tragrohrkonsole 114 und eine Tuchwellenkonsole

126 sind ebenfalls dargestellt. Die zu der Steuerung

führenden elektrischen Leitungen können in üblicher Weise mit

Hilfe bekannter Befestigungshilfen aus dem Gebiet der Elektroinstallation,

z. B. mit Hilfe selbstklebender Kabelbinderschlaufen,

vorgenommen werden.In Fig. 3 is an alternative placement of a

In Fig. 4 ist eine Gelenkarmhälfte 38 dargestellt, die mit

Hilfe eines Ausfallgelenks 40 an einem Ausfallprofil (nicht

gezeigt) und über ein Mittelgelenk (nicht gezeigt) an einer

oberen Gelenkarmhälfte schwenkbar festgelegt ist, wobei die

obere Gelenkarmhälte mit der Gelenkarmhalterung 30 (s. Fig.

2) gelenkig verbunden ist. In der Nähe des Gelenks 40 ist ein

Vibrationssensor 42 vorgesehen, der durch eine Bohrung 44 im

Profil der unteren Gelenkarmhälfte 38 in das Gelenkarminnere

einführbar ist. Der Sensor 42 ist über die Anschlußleitung 32

(s. auch Fig. 2), die außen an den Gelenkarmprofilen vorbeigeführt

ist, mit der Steuerung 10 verbunden. Eine Abdeckleiste

46 schützt die Anschlußleitung 32 und den Sensor 42 vor

Beschädigungen, wobei die Abdeckleiste 46 an ihren Längsseiten

über Rastnasen 48 verfügt, die in entsprechende Nuten 50

eingreifen, die in Längsrichtung an der Gelenkarmhälfte 38

vorgesehen sind. Die Anbringung des Sensors 42 in der Nähe

des Ausfallprofils hat sich als vorteilhaft erwiesen, da in

diesem Bereich besonders starke Vibrationen und Beschleunigungen

unter dem Einfluß von Windlast auftreten können.In Fig. 4, an articulated

Bei Gelenkarmmarkisen, bei welchen der Einbau im Inneren des

Armprofils nicht möglich ist, kann eine Einbausituation gemäß

Fig. 5 vorgesehen sein. Hierbei ist als Windlastsensor ein

Vibrationssensor 142 von einer Kunststoffaufnahme 144 geschützt

in der Nähe des Gelenkarmmittelgelenks 146 an der

oberen Gelenkarmhälfte 148 angebracht. Es ist wiederum eine

Abdeckleiste 150 vorgesehen, welche die in Fig. 5 nicht dargestellte

Verbindungsleitung zur Steuerung 10 abdeckt. Der

Sensor 142 wird bei der Montage in die Kunststoffaufnahme 144

eingedrückt und letztere ist mit Haltenasen 152 in Nuten 154

an der oberen Gelenkarmhälfte 148 eingerastet, in welchen

auch die Abdeckleiste 150 befestigt ist. Der Vorteil dieser

Anordnung besteht darin, daß mit der Verbindungsleitung zur

Steuerung nur ein Gelenk überbrückt werden muß, wobei auch

die Sensorposition wegen der ausgeprägten Bewegung des Mittelgelenks

bei Windangriff am Tuch ebenfalls besonders geeignet

ist.For articulated arm awnings where the installation inside the

Arm profile is not possible, can be installed according to

5 may be provided. Here is a wind load

Selbstverständlich sind weitere Lageanordnungen des Vibrations- bzw. Beschleunigungssensors denkbar, beispielsweise

auch an dem Ausfallprofil der Gelenkarmmarkise, wobei als

Nachteil allerdings das Führen der Verbindungsleitung über

insgesamt drei Gelenke bis zur Steuerung zu erwähnen ist.

Weitere Sensoren, die über die Steuerung 10 Einfluß auf die

Behangstellung nehmen, beispielsweise Regen-, Lichteinfall- oder

Temperatursensoren, können ebenfalls an einer geeigneten

exponierten Stelle der Gelenkarmmarkise vorgesehen sein.Of course, further position arrangements of the vibration or acceleration sensor are conceivable, for example

also on the drop profile of the folding arm awning, being as

Disadvantage, however, is the routing of the connecting line

a total of three joints to control should be mentioned.

Other sensors that influence the

Vorzugsweise ist in die Verbindungsleitung 32 auch eine Ader

integriert, die als Empfangsantenne für eine Funkfernbedienung

der Sonnenschutzanlage nutzbar ist.A wire is also preferably in the connecting

Grundsätzlich ist es auch bei anderen Arten von Sonnenschutzanlagen, wie z. B. bei Raffstoren oder Fallarmmarkisen, denkbar, Sensoren und Steuerung in einer Form zu integrieren, die der vorstehend am Beispiel einer Gelenkarmmarkise beschriebenen Anordnung ähneln, jedoch den jeweiligen Besonderheiten angepaßt sind.Basically, it is also with other types of sun protection systems, such as B. with venetian blinds or drop arm awnings, conceivable, Integrate sensors and control in a form that that described above using the example of an articulated arm awning The arrangement is similar, but the particularities are adjusted.

Claims (12)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19932731 | 1999-07-14 | ||

| DE19932731A DE19932731A1 (en) | 1999-07-14 | 1999-07-14 | Sun protection system with curtain adjustment that adapts to the incidence of light |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1069257A2 true EP1069257A2 (en) | 2001-01-17 |

| EP1069257A3 EP1069257A3 (en) | 2003-05-02 |

| EP1069257B1 EP1069257B1 (en) | 2004-09-29 |

Family

ID=7914629

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00114832A Expired - Lifetime EP1069257B1 (en) | 1999-07-14 | 2000-07-11 | Sensor controlled sun protection device |

| EP00114880A Withdrawn EP1069275A3 (en) | 1999-07-14 | 2000-07-12 | Sun protection device with position adapting depending on the incidence of light |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00114880A Withdrawn EP1069275A3 (en) | 1999-07-14 | 2000-07-12 | Sun protection device with position adapting depending on the incidence of light |

Country Status (3)

| Country | Link |

|---|---|

| EP (2) | EP1069257B1 (en) |

| AT (1) | ATE278081T1 (en) |

| DE (2) | DE19932731A1 (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10204469B4 (en) * | 2002-02-05 | 2004-02-12 | Warema Renkhoff Gmbh | Sun protection system with integrated rain sensor |

| US6732018B2 (en) | 2000-01-31 | 2004-05-04 | Turnils Ab | Awning assembly and control system |

| EP1712882A1 (en) | 2005-04-13 | 2006-10-18 | Somfy SAS | Autonomous home sensor and installation comprising said sensor |

| US7242162B2 (en) | 2004-11-22 | 2007-07-10 | Carefree/Scott Fetzer Company | Apparatus and method for retracting awning |

| WO2009049827A1 (en) | 2007-10-19 | 2009-04-23 | Somfy Sas | Solar protection installation provided with a wind sensor |

| EP1666681A3 (en) * | 2004-11-29 | 2010-03-24 | Dometic, LLC | Wind sensing awning control having armmounted sensor |

| US8620475B2 (en) | 2008-01-10 | 2013-12-31 | Nice S.P.A. | Operating system for roller blinds with protection against excessive wind |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10202830A1 (en) * | 2002-01-24 | 2003-08-14 | Colt Internat Holdings Ag Baar | Device for adjusting a technical light element uses difference sensor between solar position sensor and light adjustment device sensor |

| US7111952B2 (en) * | 2003-03-24 | 2006-09-26 | Lutron Electronics Co., Inc. | System to control daylight and artificial illumination and sun glare in a space |

| DE102006005408B4 (en) | 2006-02-03 | 2008-04-03 | Roma Rolladensysteme Gmbh | Device for shading building openings |

| DE102007029622A1 (en) * | 2007-06-26 | 2009-01-08 | Weinor Dieter Weiermann Gmbh & Co. | Sunscreen shield device, particularly awning, has control device for manipulation of electric drive of sunscreen shield unit, where control device has units, which evaluates raw signal supplied by wind force sensor |

| FR2999304B1 (en) * | 2012-12-11 | 2016-08-26 | Somfy Sas | METHOD FOR OPERATING A DOMOTIC DEVICE FOR IMPLEMENTING A PERIOD OF INHIBITING DETECTION OF CANDY |

| FR3013859B1 (en) * | 2013-11-22 | 2017-11-03 | Somfy Sas | METHOD FOR CONTROLLING A FACILITY EXPOSED TO INTEMPERIES, AND ASSOCIATED DOMOTIC INSTALLATION |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE755183R (en) * | 1969-08-28 | 1971-02-01 | Hueppe Justin | MOTOR-DRIVEN SUN VISOR INSTALLATION CONTROL DEVICE |

| GB1573104A (en) * | 1977-04-28 | 1980-08-13 | Colt Ltd W | Control system for external louvres on a building |

| DE2800968A1 (en) * | 1978-01-11 | 1979-07-12 | Trietex Antriebstechnik Gmbh | Photoelectric vertically-slatted sunblind angle control - has sensor for switches swinging slats back from half circle turn |

| DE3304962C2 (en) * | 1983-02-12 | 1986-04-10 | Willi 4292 Rhede Rademacher | Blackout device |

| DE3640241A1 (en) * | 1986-11-25 | 1988-05-26 | Ind Elektronik Und Feinmechani | Process and apparatus for protection from the sun |

| DE4032221A1 (en) * | 1990-10-11 | 1992-04-16 | Warema Renkhoff Gmbh & Co Kg | METHOD AND DEVICE FOR CONTROLLING RAFFSTORES |

| DE4106033A1 (en) * | 1991-02-27 | 1992-09-03 | Warema Renkhoff Gmbh & Co Kg | Control unit for sun protection system in office or home - has controlled shapes in which values are displayed and using front panel switches allow reference points to be set |

| DE4201971A1 (en) * | 1992-01-22 | 1993-08-05 | Wilhelm Rademacher | DARKENING DEVICE |

| DE9306368U1 (en) * | 1993-04-27 | 1993-07-08 | Rademacher, Wilhelm, 4292 Rhede | Blackout device with an awning, an external blind or similar. |

| DE4315406C1 (en) * | 1993-05-08 | 1994-11-10 | Wilhelm Dipl Ing Brabender | Device for the automatic control of drives for roller shutters, blinds or the like in particular. |

| US5663621A (en) * | 1996-01-24 | 1997-09-02 | Popat; Pradeep P. | Autonomous, low-cost, automatic window covering system for daylighting applications |

| DE19630496A1 (en) * | 1996-07-29 | 1998-02-12 | Selve Ernst Gmbh Co Kg | Device for recording measured values, for implementing motor controls for electromotive drives for windings that can be wound up and unwound |

| ATE288526T1 (en) * | 1998-05-28 | 2005-02-15 | Hermann-Frank Mueller | AWNING WITH FLEXIBLE SOLAR MODULES |

| DE20000682U1 (en) * | 2000-01-17 | 2000-03-30 | Helmut Beyers GmbH, 41066 Mönchengladbach | Device for controlling the movement of a shading device |

-

1999

- 1999-07-14 DE DE19932731A patent/DE19932731A1/en not_active Withdrawn

-

2000

- 2000-07-11 EP EP00114832A patent/EP1069257B1/en not_active Expired - Lifetime

- 2000-07-11 AT AT00114832T patent/ATE278081T1/en not_active IP Right Cessation

- 2000-07-11 DE DE50007964T patent/DE50007964D1/en not_active Expired - Fee Related

- 2000-07-12 EP EP00114880A patent/EP1069275A3/en not_active Withdrawn

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6732018B2 (en) | 2000-01-31 | 2004-05-04 | Turnils Ab | Awning assembly and control system |

| DE10204469B4 (en) * | 2002-02-05 | 2004-02-12 | Warema Renkhoff Gmbh | Sun protection system with integrated rain sensor |

| US7242162B2 (en) | 2004-11-22 | 2007-07-10 | Carefree/Scott Fetzer Company | Apparatus and method for retracting awning |

| EP1666681A3 (en) * | 2004-11-29 | 2010-03-24 | Dometic, LLC | Wind sensing awning control having armmounted sensor |

| US7828036B2 (en) | 2004-11-29 | 2010-11-09 | Dometic, LLC | Wind sensing awning control having arm-mounted sensor |

| AU2005239637B2 (en) * | 2004-11-29 | 2010-12-16 | Dometic, LLC | Wind sensing awning control |

| EP1712882A1 (en) | 2005-04-13 | 2006-10-18 | Somfy SAS | Autonomous home sensor and installation comprising said sensor |

| WO2009049827A1 (en) | 2007-10-19 | 2009-04-23 | Somfy Sas | Solar protection installation provided with a wind sensor |

| US8261608B2 (en) | 2007-10-19 | 2012-09-11 | Somfy Sas | Solar protection installation equipped with a wind sensor |

| US8620475B2 (en) | 2008-01-10 | 2013-12-31 | Nice S.P.A. | Operating system for roller blinds with protection against excessive wind |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE278081T1 (en) | 2004-10-15 |

| EP1069275A2 (en) | 2001-01-17 |

| EP1069257B1 (en) | 2004-09-29 |

| DE19932731A1 (en) | 2001-03-22 |

| EP1069275A3 (en) | 2003-01-22 |

| DE50007964D1 (en) | 2004-11-04 |

| EP1069257A3 (en) | 2003-05-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1069257B1 (en) | Sensor controlled sun protection device | |

| EP1666291B1 (en) | Window roller blind with simplified assembly | |

| DE69807438T3 (en) | UNIVERSAL MOUNTING AND PARALLEL GUIDE FOR WINDOW SHIELDING | |

| EP1936105B1 (en) | Vertical shading | |

| DE202019103794U1 (en) | End bar with side guide | |

| DE19513954C2 (en) | Additional roller blind | |

| EP3173569B1 (en) | Protection device | |

| EP1686232A2 (en) | Mounting device for a light barrier | |

| DE29621563U1 (en) | Roller blind, in particular side window roller blind for motor vehicles | |

| EP3957815B1 (en) | Device for shading windows or door openings extending over a corner | |

| DE10127070B4 (en) | Interior mirror arrangement | |

| DE202012001975U1 (en) | Panel curtain system | |

| EP2436848B1 (en) | Support structure | |

| EP3043018B1 (en) | Building opening shading device with a lateral guide rail | |

| WO2013079127A1 (en) | Cassette awning with concealed fastenings | |

| DE19809025C2 (en) | Facade roller blind and guide rail for a facade roller blind | |

| DE19544894C1 (en) | Awning with spring-loaded slewing arm | |

| DE10014144A1 (en) | Sleeve awning | |

| DE19936377B4 (en) | fastening device | |

| EP3604705B1 (en) | Device for limiting the displacement of drives | |

| EP3348740A1 (en) | Awning made from two separate mounting modules | |

| EP3486421B1 (en) | Vertical awning | |

| DE202006021144U1 (en) | vertical awnings | |

| DE202007005567U1 (en) | Awning e.g. joint arm awning, for e.g. window, has solar drive with drive unit, where storage unit and drive unit are integrated in inner space of awning support tube, which is hollow profile and consists of access opening at front side | |

| EP4567246A1 (en) | Shading device and method for mounting a shading device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| 17P | Request for examination filed |

Effective date: 20031030 |

|

| AKX | Designation fees paid |

Designated state(s): AT CH DE LI |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE LI |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50007964 Country of ref document: DE Date of ref document: 20041104 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20090727 Year of fee payment: 10 Ref country code: AT Payment date: 20090723 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090923 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110201 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100731 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50007964 Country of ref document: DE Effective date: 20110201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100711 |