EP1024244A2 - Composite section member - Google Patents

Composite section member Download PDFInfo

- Publication number

- EP1024244A2 EP1024244A2 EP00101500A EP00101500A EP1024244A2 EP 1024244 A2 EP1024244 A2 EP 1024244A2 EP 00101500 A EP00101500 A EP 00101500A EP 00101500 A EP00101500 A EP 00101500A EP 1024244 A2 EP1024244 A2 EP 1024244A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- plastic

- composite profile

- profile according

- profiles

- metal profiles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/30—Coverings, e.g. protecting against weather, for decorative purposes

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B3/26301—Frames with special provision for insulation with prefabricated insulating strips between two metal section members

- E06B3/26303—Frames with special provision for insulation with prefabricated insulating strips between two metal section members with thin strips, e.g. defining a hollow space between the metal section members

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/263—Frames with special provision for insulation

- E06B2003/26349—Details of insulating strips

- E06B2003/2635—Specific form characteristics

- E06B2003/26359—Specific form characteristics making flush mounting with neighbouring metal section members possible

Definitions

- Such composite profiles are produced in large quantities and as window, door, balcony or Fence profile used.

- the plastic used for coating is practically exclusive high-impact, plasticizer-free polyvinyl chloride (PVC-u or rigid PVC) is used.

Abstract

Description

Die Erfindung betrifft ein Verbundprofil, ein Verfahren zur Herstellung eines Verbundprofiles und die Verwendung eines Verbundprofiles.The invention relates to a composite profile, a method for producing a composite profile and the use of a composite profile.

Derartige Verbundprofile werden in großen Mengen hergestellt und als Fenster-, Tür-, Balkon- oder Zaunprofil eingesetzt. Derzeit wird als Kunststoff für die Beschichtung praktisch ausschließlich hochschlagfestes, weichmacherfreies Polyvinylchlorid (PVC-u oder Hart-PVC) verwendet.Such composite profiles are produced in large quantities and as window, door, balcony or Fence profile used. Currently, the plastic used for coating is practically exclusive high-impact, plasticizer-free polyvinyl chloride (PVC-u or rigid PVC) is used.

PVC ist insbesondere für kunststoffummantelte Aluminiumprofile hervorragend geeignet, da nach dem Versehen des Aluminiums mit einem Primer aufgrund der Polarität des PVC eine gute Haftung des PVCs auf dem Aluminium gegeben ist (RAL-Gz 716/1, Abschnitt 1: Kunststoff-Fensterprofile, Teil 5: Verbundprofile aus PVC-Hartschaum und Aluminium-Armierung mit Beschichtungen). Dies gilt insbesondere für weiße Profile aus Hart-PVC.PVC is particularly suitable for plastic-coated aluminum profiles, because after good adhesion to the aluminum with a primer due to the polarity of the PVC of PVC on the aluminum (RAL-Gz 716/1, section 1: plastic window profiles, Part 5: Composite profiles made of rigid PVC foam and aluminum reinforcement with coatings). This applies in particular to white profiles made of rigid PVC.

Aufgrund der guten Wärmeleiteigenschaften des Metallprofils ist der Wärmedurchgangskoeffizient bei derartigen Verbundprofilen höher als bei PVC-Profilen.The heat transfer coefficient is due to the good thermal conductivity properties of the metal profile with such composite profiles higher than with PVC profiles.

Aufgabe der Erfindung ist es, Verbundprofile mit einem geringen Wärmedurchgangskoeffizienten (k-Wert) herzustellen.The object of the invention is to provide composite profiles with a low heat transfer coefficient (k-value).

Diese Aufgabe wird erfindungsgemäß dadurch gelöst, daß mindestens zwei Metallprofile, die durch mindestens ein schlecht wärmeleitendes Element miteinander gekoppelt sind, mit Kunststoff ummantelt sind.This object is achieved in that at least two metal profiles through at least one poorly heat-conducting element are coupled together, with plastic are encased.

Durch diese Maßnahme werden die Wärmedämmeigenschaften des Fensters verbessert, da das ummantelte Aluminiumprofil zweiteilig ausgeführt ist und somit vermieden wird, daß es als Kältebrücke zwischen der Außen- und der Innenseite des Fensters wirkt. Auf diese Weise werden die günstigen Stabilitätseigenschaften des Fensters aufgrund der Metallarmierung mit den günstigen Wärmedämmeigenschaften des Kunststoffs kombiniert.This measure improves the thermal insulation properties of the window, because that coated aluminum profile is made in two parts and thus it is avoided that it Cold bridge between the outside and the inside of the window acts. That way the favorable stability properties of the window due to the metal reinforcement with the favorable Combined thermal insulation properties of the plastic.

Eine Weiterbildung der Erfindung besteht darin, die Metallprofile mit aufgeschäumtem Kunststoff ummantelt sind.A further development of the invention consists in the metal profiles with foamed plastic are encased.

Geschäumte Kunststoffe bringen in der Regel bessere Wärmedämmungseigenschaften mit sich als ungeschäumte.Foamed plastics generally have better thermal insulation properties than unfoamed.

Eine andere Ausbildung der Erfindung besteht darin, daß die Metallprofile mit einem Kunststoff aus der Gruppe bestehend aus PVC, ABS, ASA, PMMA und PP oder mehreren dieser Kunststoffe ummantelt sind.Another embodiment of the invention is that the metal profiles with a plastic the group consisting of PVC, ABS, ASA, PMMA and PP or several of these plastics are encased.

Es hat sich im Rahmen von Untersuchungen gezeigt, daß diese Kunststoffe im Bereich der Fenster- und Türenproduktion als Alternative zu PVC geeignet sindStudies have shown that these plastics are used in the window and door production are suitable as an alternative to PVC

Es liegt im Rahmen der Erfindung, daß das schlecht wärmeleitende Element aus Kunststoff, insbesondere aus PA, besteht.It is within the scope of the invention that the poorly heat-conducting element made of plastic, in particular PA.

Ein aus Kunststoff bestehendes schlecht wärmeleitendes Element erleichtert eine Ummantelung mit Kunststoff.A poorly heat-conducting element made of plastic also facilitates sheathing Plastic.

Es ist zweckmäßig, daß der aufgeschäumte Kunststoff in allen Bereichen des Verbundprofils eine gleichmäßige Wandstärke aufweist.It is expedient that the foamed plastic has one in all areas of the composite profile has uniform wall thickness.

Hierdurch wird die Tendenz zum Verziehen des Verbundprofils minimiert und es kann mit einer höheren Geschwindigkeit extrudiert werden.This minimizes the tendency to warp the composite profile and it can be used with a extruded at higher speed.

Eine Weiterbildung der Erfindung besteht darin, daß der aufgeschäumte Kunststoff mit einer Schicht aus Hart-PVC ummantelt ist.A further development of the invention is that the foamed plastic with a Layer of hard PVC is covered.

Hierdurch wird der Neigung des aufgeschäumten Kunststoffs, beim Sägen zu splittern entgegengewirkt. Da Hart-PVC weniger als der aufgeschäumte Kunststoff schrumpft, wird ein Verziehen des Profils bei Wärmeaufnahme durch diese Maßnahme vermieden.This increases the tendency of the foamed plastic to splinter when sawing counteracted. Since hard PVC shrinks less than the foamed plastic, a Warping of the profile when absorbing heat is avoided by this measure.

Weiterhin liegt es im Rahmen der Erfindung, daß an der Außenseite des Verbundprofils Rastelemente aus Hart-PVC vorgesehen sind. Diese Rastelemente (Rastnasen bzw. entsprechende Vertiefungen) sind stabiler als solche aus aufgeschäumtem Kunststoff und splittern nicht beim Sägen oder Einbringen von Rastelementen wie z.B. Glasleisten oder Verbreiterungsprofile.Furthermore, it is within the scope of the invention that on the outside of the composite profile Locking elements made of hard PVC are provided. These locking elements (locking lugs or corresponding Depressions) are more stable than those made of foamed plastic and do not splinter when Sawing or inserting locking elements such as Glazing beads or widening profiles.

Es ist vorteilhaft, daß das schlecht wärmeleitende Element mit den Metallprofilen formschlüssig verbunden ist.It is advantageous that the poorly thermally conductive element with the metal profiles connected is.

Eine Weiterbildung der Erfindung besteht darin, daß zwischen den Metallprofilen und zwei diese koppelnden schlecht wärmeleitenden Elementen eine Kammer angeordnet ist.A further development of the invention is that between the metal profiles and two of them coupling poorly heat-conducting elements, a chamber is arranged.

Diese Kammer kann mit Entwässerungsbohrungen zum Abführen von Regenwasser versehen sein und hat zudem eine wärmedämmende Wirkung.This chamber can be provided with drainage holes for removing rainwater and also has a heat-insulating effect.

Es ist zweckmäßig, daß das Metallprofil aus einer Aluminiumverbindung oder aus Baustahl besteht.It is expedient that the metal profile consists of an aluminum compound or of structural steel.

Weiterhin liegt im Rahmen der Erfindung ein Verfahren zur Herstellung eines erfindungsgemäßen Verbundprofiles, wobei mindestens zwei mit Klebstoff beschichtetes Metallprofile in ein Extrusionswerkzeug eingeschoben werden, der Klebstoff erhitzt wird, dem Extrusionwerkzeug Kunststoff zugeführt wird und der Kunststoff die Metallprofile ummantelt.Furthermore, within the scope of the invention is a method for producing an inventive Composite profile, with at least two metal profiles coated with adhesive in one Extrusion tool are inserted, the adhesive is heated, the extrusion tool Plastic is supplied and the plastic encases the metal profiles.

Hierbei ist es vorteilhaft, daß der Kunststoff im Extrusionswerkzeug aufgeschäumt wird.It is advantageous here that the plastic is foamed in the extrusion die.

Eine Weiterbildung der Erfindung besteht darin, daß um den aufgeschäumten Kunststoff eine Schicht aus Hart-PVC im Coextrusionsverfahren aufgebracht wird.A further development of the invention consists in that around the foamed plastic Layer of hard PVC is applied in a coextrusion process.

Weiterhin ist die Verwendung eines erfindungsgemäßen Verbundprofiles als Fenster-, Tür-, Zaun- oder Balkonprofil erfindungsgemäß.Furthermore, the use of a composite profile according to the invention as a window, door, fence or balcony profile according to the invention.

Im folgenden werden Ausführungsbeispiele der Erfindung anhand von Zeichnungen erläutert.Exemplary embodiments of the invention are explained below with reference to drawings.

Es zeigen

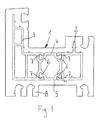

- Fig. 1

- ein Verbundprofil gemäß der Erfindung,

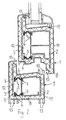

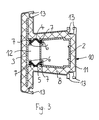

- Fig. 2

- ein Rahmenprofil mit dem entsprechenden Flügelprofil, Fig. 3 ein Kämpferprofil gemäß der Erfindung.

- Fig. 1

- a composite profile according to the invention,

- Fig. 2

- a frame profile with the corresponding wing profile, Fig. 3 is a fighter profile according to the invention.

Das in Fig. 1 dargestellte Flügelprofil 1 besteht aus zwei Aluminiumprofilen 2, 3, die über zwei

Kunststoffstege 4, 5 miteinander verbunden sind. Die Enden 6 der Kunststoffstege 4, 5 greifen

formschlüssig in entsprechende Ausbuchtungen 7 der Aluminiumprofile 1 und durch die

aneinanderliegenden Schultern der Aluminiumprofile 2, 3 und der Kunststoffstege 4, 5 wird eine

lagefeste Verbindung der beiden Aluminiumprofile 2, 3 sichergestellt. Aufgrund der schlechten

Wärmeleiteigenschaften der aus PVC, ABS, ASA, PMMA oder PP bestehenden Kunststoffstege 4,

5 wird eine Wärmebrücke zwischen der Außen- und der Innenseite des Fensters vermieden.

Auf die miteinander verbundenen Aluminiumprofile 2, 3 wird anschließend ein Klebstoff

aufgebracht, der es ermöglicht, die Aluminiumprofile 2, 3 mit einer Kunststoffummantelung 8 aus

vorzugsweise geschäumtem PVC, ABS, ASA, PMMA oder PP zu versehen.The

Wie in Fig. 2 und 3 dargestellt, können neben Flügelprofilen 1 auch Rahmenprofile 9 und

Kämpferprofile 10 gemäß der Erfindung hergestellt werden. Die in den Fig. 2 und 3 gezeigten

Ausführungsformen unterscheiden sich von der in Fig. 1 dargestellten unter anderem dadurch, daß

die Schichtdicke der geschäumten Kunststoffummantelung 8 an allen Stellen der Profile im

wesentlichen konstant ist, was gleichmäßigere Drücke im Werkzeug, einen geringeren Verzug und

eine schnellere Extrusion ermöglicht. Weiterhin ist hier die Kunststoffummantelung 8 mit einer

coextrudierten Schicht 11 aus Hart-PVC umgeben, durch die das Splittern beim Sägen der Profile

und das Verziehen bei Wärmeaufnahme deutlich reduziert werden können. Des weiteren besteht

durch die Deckschicht aus Hart-PVC die Möglichkeit, einen höheren Glanz der Profiloberfläche zu

erreichen. Auch die Rastelemente 13 sind aus den gleichen Gründen aus Hart-PVC hergestellt.As shown in FIGS. 2 and 3, in addition to

Weiterhin ist bei den Ausführungsformen gemäß den Fig. 2 und 3 zwischen den beiden

Aluminiumprofilen 2, 3 und dem schlecht wärmeleitenden Element 4, 5 eine luftgefüllte Kammer

12 angeordnet, durch die mittels Entwässerungsbohrungen (nicht dargestellt) Regenwasser

abgeführt werden kann. Zudem wirkt diese Kammer 12 wärmedämmend. Durch das gegenüber Fig.

1 größere geschlossene Aluminiumprofil 2 wird eine höhere Steifigkeit des Profils erreicht.Furthermore, in the embodiments according to FIGS. 2 and 3 between the two

Claims (14)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19903234A DE19903234A1 (en) | 1999-01-27 | 1999-01-27 | Metal profile |

| DE19903234 | 1999-01-27 |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP1024244A2 true EP1024244A2 (en) | 2000-08-02 |

| EP1024244A3 EP1024244A3 (en) | 2002-07-03 |

| EP1024244B1 EP1024244B1 (en) | 2007-01-24 |

| EP1024244B2 EP1024244B2 (en) | 2010-01-27 |

Family

ID=7895570

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00101500A Expired - Lifetime EP1024244B2 (en) | 1999-01-27 | 2000-01-26 | Composite section member |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1024244B2 (en) |

| AT (1) | ATE352696T1 (en) |

| DE (2) | DE19903234A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102619439A (en) * | 2011-01-28 | 2012-08-01 | 上海金河实业有限公司 | Composite sectional material provided with heat insulated bridge structure and used for doors and windows |

| CN102628333A (en) * | 2012-04-26 | 2012-08-08 | 山西华鹏新型建筑材料科技研发有限公司 | Heat insulating bridge-cut-off aluminum-plastic co-extrusion profile |

| DE102014004430A1 (en) * | 2014-03-27 | 2015-10-01 | Alanod Gmbh & Co. Kg | Self-adhesive plastic for the insulation of metal surfaces |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4130976A (en) * | 1977-03-07 | 1978-12-26 | Gerbruder Kommerling Kunststoffwerke G.M.B.H. | Frame for doors, windows and the like |

| DE2833738A1 (en) † | 1978-08-01 | 1980-02-21 | Koemmerling Kunststoff | PVC (foam)-coated profiled metal strip for mfr. of doors, windows - has undercut edge and longitudinal groove or rib shaped to ensure tight fit for assembly |

| DE2903730A1 (en) * | 1979-02-01 | 1980-08-07 | Phoenix Ag | Double glazed window frame - prevents condensn. by metal profiles embedded in plastics foam profiles |

| EP0028775A1 (en) * | 1979-11-12 | 1981-05-20 | Gebrüder Kömmerling Kunststoffwerke GmbH | Frame or leaf of outside windows or doors, and profile member therefor |

| US4341831A (en) * | 1981-05-04 | 1982-07-27 | Fulgeritwerke Seelze Und Eichriede In Luthe Bei Hannover Adolf Oesterheld Gmbh & Co. Kommanditgesellschaft | Shapes for windows or doors |

| GB2143270A (en) * | 1983-07-14 | 1985-02-06 | Bkl Extrusions Ltd | Window or door frame |

| EP0150025A2 (en) † | 1984-01-24 | 1985-07-31 | Fulgurit GmbH & Co. Kommanditgesellschaft | Fixed and opening frame for windows or glazed doors |

| DE3407639A1 (en) † | 1984-03-01 | 1985-09-12 | Gebrüder Kömmerling Kunststoffwerke GmbH, 6780 Pirmasens | CONNECTING ROD, ESPECIALLY FOR WINDOW FRAMES, DOOR FRAMES AND ROLLER SHUTTERS |

| DE8313480U1 (en) † | 1983-05-06 | 1988-11-17 | Schueco Heinz Schuermann Gmbh & Co, 4800 Bielefeld, De | |

| DE19504601A1 (en) * | 1995-01-11 | 1996-07-25 | Wicona Bausysteme Gmbh | Thermally insulated composite profile for mfr. of building components |

-

1999

- 1999-01-27 DE DE19903234A patent/DE19903234A1/en not_active Withdrawn

-

2000

- 2000-01-26 EP EP00101500A patent/EP1024244B2/en not_active Expired - Lifetime

- 2000-01-26 AT AT00101500T patent/ATE352696T1/en not_active IP Right Cessation

- 2000-01-26 DE DE50013991T patent/DE50013991D1/en not_active Expired - Fee Related

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4130976A (en) * | 1977-03-07 | 1978-12-26 | Gerbruder Kommerling Kunststoffwerke G.M.B.H. | Frame for doors, windows and the like |

| DE2833738A1 (en) † | 1978-08-01 | 1980-02-21 | Koemmerling Kunststoff | PVC (foam)-coated profiled metal strip for mfr. of doors, windows - has undercut edge and longitudinal groove or rib shaped to ensure tight fit for assembly |

| DE2903730A1 (en) * | 1979-02-01 | 1980-08-07 | Phoenix Ag | Double glazed window frame - prevents condensn. by metal profiles embedded in plastics foam profiles |

| EP0028775A1 (en) * | 1979-11-12 | 1981-05-20 | Gebrüder Kömmerling Kunststoffwerke GmbH | Frame or leaf of outside windows or doors, and profile member therefor |

| US4341831A (en) * | 1981-05-04 | 1982-07-27 | Fulgeritwerke Seelze Und Eichriede In Luthe Bei Hannover Adolf Oesterheld Gmbh & Co. Kommanditgesellschaft | Shapes for windows or doors |

| DE8313480U1 (en) † | 1983-05-06 | 1988-11-17 | Schueco Heinz Schuermann Gmbh & Co, 4800 Bielefeld, De | |

| GB2143270A (en) * | 1983-07-14 | 1985-02-06 | Bkl Extrusions Ltd | Window or door frame |

| EP0150025A2 (en) † | 1984-01-24 | 1985-07-31 | Fulgurit GmbH & Co. Kommanditgesellschaft | Fixed and opening frame for windows or glazed doors |

| DE3407639A1 (en) † | 1984-03-01 | 1985-09-12 | Gebrüder Kömmerling Kunststoffwerke GmbH, 6780 Pirmasens | CONNECTING ROD, ESPECIALLY FOR WINDOW FRAMES, DOOR FRAMES AND ROLLER SHUTTERS |

| DE19504601A1 (en) * | 1995-01-11 | 1996-07-25 | Wicona Bausysteme Gmbh | Thermally insulated composite profile for mfr. of building components |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102619439A (en) * | 2011-01-28 | 2012-08-01 | 上海金河实业有限公司 | Composite sectional material provided with heat insulated bridge structure and used for doors and windows |

| CN102628333A (en) * | 2012-04-26 | 2012-08-08 | 山西华鹏新型建筑材料科技研发有限公司 | Heat insulating bridge-cut-off aluminum-plastic co-extrusion profile |

| DE102014004430A1 (en) * | 2014-03-27 | 2015-10-01 | Alanod Gmbh & Co. Kg | Self-adhesive plastic for the insulation of metal surfaces |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE352696T1 (en) | 2007-02-15 |

| EP1024244A3 (en) | 2002-07-03 |

| EP1024244B2 (en) | 2010-01-27 |

| DE19903234A1 (en) | 2000-08-03 |

| EP1024244B1 (en) | 2007-01-24 |

| DE50013991D1 (en) | 2007-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3529062B1 (en) | Method for producing a thermoplastic window or door hollow chamber profile | |

| DE2945664C2 (en) | Profile rod for blind and / or casement frames for external windows or doors | |

| DE102013100588A1 (en) | Hollow chamber profile for windows or doors | |

| EP1019607A1 (en) | Frame profiles for producing window or door frames and a method for producing the same | |

| DE102020115821A1 (en) | Hollow chamber profile for a window or door and this comprehensive frame assembly | |

| EP2045431A2 (en) | Covering with integrated heat insulation | |

| WO2018108268A1 (en) | Heat-insulated metal-plastic composite profiled section | |

| DE102010049097A1 (en) | Method for introducing foam material into hollow chamber profiles and hollow chamber profile | |

| EP3825502A1 (en) | Hollow chamber profile for a window or door and frame assembly comprising same | |

| EP1024244B1 (en) | Composite section member | |

| EP1812675B1 (en) | Hollow chamber profile made of plastic | |

| DE19736393A1 (en) | Profile system for manufacturing windows and doors | |

| DE10212452A1 (en) | Process for producing a heat-insulating insulating and connecting web and insulating and connecting web produced according to this process | |

| DE202018101565U1 (en) | Hollow profile for a window or door and this comprehensive frame assembly | |

| DE19741787A1 (en) | Insulated door or window frame | |

| EP3768489A1 (en) | Method for producing a hollow-chamber profile for a window or a door, as well as a hollow-chamber profile produced according to this method | |

| EP3670808A1 (en) | Frame assembly for a door or window | |

| EP3721040B1 (en) | Hollow profile, in particular window profile or door profile | |

| DE202013103305U1 (en) | Wing-covering door | |

| DE2919437C2 (en) | ||

| DE2943593C2 (en) | Method of making a frame | |

| DE102021122153A1 (en) | Process for the production of a polymeric, in particular thermoplastic, window or door hollow chamber profile | |

| EP4183949A1 (en) | Profile for façade covering | |

| WO2009129825A1 (en) | Construction elements | |

| DE2128441A1 (en) | Door or window frame - with pvc profiles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KOEMMERLING KUNSTSTOFF GMBH |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 7E 06B 3/30 A, 7E 06B 3/263 B, 7E 06B 3/00 B, 7E 06B 3/26 B |

|

| 17P | Request for examination filed |

Effective date: 20021219 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20030723 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: PROFINE GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070131 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070131 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50013991 Country of ref document: DE Date of ref document: 20070315 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070424 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070505 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070625 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20070124 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| EN | Fr: translation not filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 |

|

| 26 | Opposition filed |

Opponent name: SCHUECO INTERNATIONAL KG Effective date: 20071019 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| BERE | Be: lapsed |

Owner name: PROFINE G.M.B.H. Effective date: 20070131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070131 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070425 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070914 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20090115 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070126 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090711 Year of fee payment: 10 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20100127 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20070127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100126 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100803 |