EP0952270B2 - Loadbearing sections for mullion-transom-art façades, awnings, canopy roofs or the like - Google Patents

Loadbearing sections for mullion-transom-art façades, awnings, canopy roofs or the like Download PDFInfo

- Publication number

- EP0952270B2 EP0952270B2 EP99105647.4A EP99105647A EP0952270B2 EP 0952270 B2 EP0952270 B2 EP 0952270B2 EP 99105647 A EP99105647 A EP 99105647A EP 0952270 B2 EP0952270 B2 EP 0952270B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- web

- groove

- load

- flange

- profiles according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B2/00—Walls, e.g. partitions, for buildings; Wall construction with regard to insulation; Connections specially adapted to walls

- E04B2/88—Curtain walls

- E04B2/96—Curtain walls comprising panels attached to the structure through mullions or transoms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D39/00—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders

- B21D39/03—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal otherwise than by folding

- B21D39/038—Perpendicular plate connections

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/02—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces

- E04C3/04—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal

- E04C3/06—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal with substantially solid, i.e. unapertured, web

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D3/00—Roof covering by making use of flat or curved slabs or stiff sheets

- E04D3/02—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant

- E04D3/06—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor

- E04D3/08—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor with metal glazing bars

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/02—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces

- E04C3/04—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal

- E04C2003/0404—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects

- E04C2003/0408—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects characterised by assembly or the cross-section

- E04C2003/0413—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects characterised by assembly or the cross-section being built up from several parts

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/02—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces

- E04C3/04—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal

- E04C2003/0404—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects

- E04C2003/0426—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects characterised by material distribution in cross section

- E04C2003/0434—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects characterised by material distribution in cross section the open cross-section free of enclosed cavities

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/02—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces

- E04C3/04—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal

- E04C2003/0404—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects

- E04C2003/0443—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects characterised by substantial shape of the cross-section

- E04C2003/0452—H- or I-shaped

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C3/00—Structural elongated elements designed for load-supporting

- E04C3/02—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces

- E04C3/04—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal

- E04C2003/0404—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects

- E04C2003/0443—Joists; Girders, trusses, or trusslike structures, e.g. prefabricated; Lintels; Transoms; Braces of metal beams, girders, or joists characterised by cross-sectional aspects characterised by substantial shape of the cross-section

- E04C2003/046—L- or T-shaped

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D3/00—Roof covering by making use of flat or curved slabs or stiff sheets

- E04D3/02—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant

- E04D3/06—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor

- E04D3/08—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor with metal glazing bars

- E04D2003/0818—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor with metal glazing bars the supporting section of the glazing bar consisting of several parts, e.g. compound sections

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D3/00—Roof covering by making use of flat or curved slabs or stiff sheets

- E04D3/02—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant

- E04D3/06—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor

- E04D3/08—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor with metal glazing bars

- E04D2003/0818—Roof covering by making use of flat or curved slabs or stiff sheets of plane slabs, slates, or sheets, or in which the cross-section is unimportant of glass or other translucent material; Fixing means therefor with metal glazing bars the supporting section of the glazing bar consisting of several parts, e.g. compound sections

- E04D2003/0837—Sections comprising intermediate parts of insulating material

Definitions

- the invention relates to support profiles in T-shape or in double T-shape for transom post facades, canopies, galleries or the like. with at least one strap and an associated web.

- the DE 25 59 599 shows a thermally insulated composite profile with webs, which are pressed against insulating profiles, which are made of plastic.

- a support profile with the features a to c1 is from the DE 196 22 759 A1 known.

- the support profile known from this document has a belt and a web, wherein a groove or groove in the belt, which serves to receive the web, is created by structure-changing material deformation after the production of the belt itself. This is problematic that the effort to create the groove is relatively high, since after the production of the profile only with another step, the groove must be made.

- the invention has the object over this generic state of the art to further develop the support profile such that it can be manufactured in a simpler manner compared with the prior art, whereby production-related deformations in the region of the material are to be reduced.

- the groove is simply made by extrusion during the extrusion of the belt.

- the belt of the invention further and the like for its use in facade construction. advantageously still a groove for receiving a sealing strip.

- the web is connected to the belt by a slight interference fit and by the web in the region of the free edge of the groove permanently formed belt material.

- connection of the webs with the straps can be made in a continuous process by chiselling with a chisel or by molding by means of rotating rollers. This results from the pressing of belt material on the web under relatively high pressures a Kaltverschweiáung between the belt material and the web.

- a kit of webs of different shapes and straps different to create different support profiles in which the web thickness and the formation of the groove for receiving the longitudinal edges of the webs is designed consistently Dimensions are formed.

- the webs and straps form plate-shaped components that can be processed before their connection to a support profile in a simple and efficient manner.

- the bars are made of light metal.

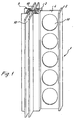

- a supporting profile 1 is shown for a transom-post facade, which is designed as a double-T profile and is composed of straps 2,3 and a web 4.

- the belt 2 is formed as an extruded aluminum profile whose cross-sectional contour in the Fig. 4, 5 and 6 can be seen more clearly.

- the belt 2 has anchoring grooves 5 for fixing glazing gaskets 6 and is provided with a screw groove 7 into which fastening screws for fixing a cover strip 8 are screwed.

- a screw groove 7 into which fastening screws for fixing a cover strip 8 are screwed.

- the screw 7 takes the screw 7 a plastic profile 9, so that the screw extends together with the plastic profile over the entire thickness of the insulating glass 10.

- the web 4 has in the embodiment of the Fig. 1 a series of circular openings 11.

- a support profile 12 is shown, the web 13 is provided with triangular openings 14. These triangular openings are arranged alternately offset from each other.

- a support profile 15 is shown, in which the web 16 is formed trapezoidal.

- the recorded by the belt 3 longitudinal edge of the web 16, which is rectilinear in the exemplary embodiment shown, may also have a deviating from the straight line contour, so that the belt 3 may also be wavy or may have a different geometric course.

- the openings 17 of the web 16 are adapted in size and design of the contour of the side view of the web.

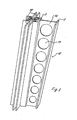

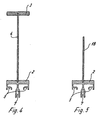

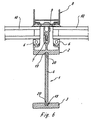

- a support profile is shown in double T-shape

- connection between the web and the straps 2,3 is achieved in that the straps are provided with a groove 19 for receiving the longitudinal edge portion 20 of the web and the web is connected to the belt by a press fit or by a Kaltpreßversch spaung.

- the longitudinal edge portion 20 of the web 4 is inserted with a slight interference fit into the groove 19 of the belt 3.

- a Einstemmvorgang is made by means of a continuously operating tool 21 so that it comes to a Kaltpreßversch spaung between the belt 3 and the web 4 in the region of the Nutlssensrandes.

- the caulking can be done with a chisel in a continuous compression process or by means of rotating rollers.

- the press fit or transition fit a closing engagement of the web and the belt is achieved, which can lead to a cold welding even without a Anstemmvorgang.

- a belt 2,3 is shown, which is provided with a groove 19 for receiving a longitudinal edge region of a web.

- the free edges of the groove 19 are bounded by skirting 22, which are formed by material accumulation.

- the accumulations of material can also serve to guide the Einstemmtechnikmaschine.

- the groove 19 is limited by edge strips 24, which are formed by parallel to the free groove edge grooves 25.

- the grooves 25 serve to guide a Einstemmtechnikmaschinees, by which afford the edge 24 are pressed onto the web inserted into the groove 19.

- the embodiment of the Fig. 10 shows a groove 19 whose walls are equipped with teeth 26.

- these toothing effects tolerance compensation when the web is inserted into the groove 19 and, on the other hand, increases the pressures at the tips which act on the web outer surfaces in the region of the groove engagement.

- the grooves are made with the associated profiles during extrusion.

- the webs 4, 13, 16, 18 are in the region of engagement with the groove of the belt adjacent the groove edge with grooves extending over the web length, as in FIG Fig. 11 or as shown in FIG. 12, with spaced recesses 28 or with a series of holes 29 or stamped channels, as in FIG Fig. 13 be shown, equipped.

- the Fig. 14 shows that the webs 4,13,16,18 be provided in the region of the engagement in the groove 19 with a transverse to the longitudinal direction of the webs roughening 30, knurling, toothing or undulating profiling.

- the shear strength in the longitudinal direction of the support profile between said components is increased after the joining process between web and belt.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mechanical Engineering (AREA)

- Electromagnetism (AREA)

- Physics & Mathematics (AREA)

- Load-Bearing And Curtain Walls (AREA)

- Joining Of Corner Units Of Frames Or Wings (AREA)

- Door And Window Frames Mounted To Openings (AREA)

- Finishing Walls (AREA)

- Special Wing (AREA)

- Connection Of Plates (AREA)

- Wing Frames And Configurations (AREA)

- Rod-Shaped Construction Members (AREA)

Abstract

Description

Die Erfindung bezieht sich auf Tragprofile in T-Form oder in Doppel-T-Form für Riegel-Pfosten-Fassaden, Vordächer, Galerien o.dgl. mit mindestens einem Gurt und einem damit verbundenen Steg.The invention relates to support profiles in T-shape or in double T-shape for transom post facades, canopies, galleries or the like. with at least one strap and an associated web.

Es sind aus einzelnen Bauteilen zusammengesetzte Tragprofile bekannt, bei denen die einzelnen Bauteile insbesondere durch thermische Schweißverfahren miteinander verbunden werden. Hierbei entstehen Schweißnähte, die bei hochwertigen Fassaden nach der Oberflächenbehandlung der Tragprofile störend wirken.There are known from individual components supporting profiles, in which the individual components are connected to each other in particular by thermal welding. This creates welds that interfere with high-quality facades after the surface treatment of the support profiles.

Sofern die einzelnen Bauteile der Tragprofile aus Aluminium gefertigt werden und diese Bauteile eine Eloxaloberflächenbehandlung erfahren haben, kann zur Verbindung der Bauteile ein thermisches Schweißverfahren oder ein sonstiges thermisches Verfahren nicht eingesetzt werden, da sich starke Farbdifferenzen im Bereich der wärmebelasteten Zonen ergeben würden.If the individual components of the support profiles are made of aluminum and these components have undergone anodized surface treatment, a thermal welding method or another thermal method can not be used to connect the components, since there would be strong color differences in the region of the heat-stressed zones.

Die

Ein Tragprofil mit den Merkmalen a bis c1 ist aus der

Die Erfindung hat gegenüber diesem gattungsgemäßen Stand der Technik die Aufgabe, das Tragprofil derart weiterzubilden, daß es gegenüber dem Stand der Technik in einfacherer Weise fertigbar ist, wobei fertigungsbedingte Verformungen im Bereich des Gutes verringert werden sollen.The invention has the object over this generic state of the art to further develop the support profile such that it can be manufactured in a simpler manner compared with the prior art, whereby production-related deformations in the region of the material are to be reduced.

Diese Aufgabe löst die Erfindung durch gegen Gegenstand des Anspruches 1.This object is achieved by the invention by the subject matter of claim 1.

Die Nachteile des Standes der Technik werden mit der Erfindung vermieden, denn die Nut wird einfach beim Strangpressen des Gurtes mit strangpressend gefertigt. Ergänzend weist der Gurt der Erfindung ferner für seinen Einsatz im Fassadenbau u.dgl. in vorteilhafter Weise noch eine Nut zur Aufnahme einer Dichtungsleiste auf.The disadvantages of the prior art are avoided with the invention, because the groove is simply made by extrusion during the extrusion of the belt. In addition, the belt of the invention further and the like for its use in facade construction. advantageously still a groove for receiving a sealing strip.

Bei einer vorteilhaften Ausführungsform wird der Steg mit dem Gurt durch einen leichten Preßsitz und durch an den Steg im Bereich der freien Nutkante bleibend angeformtes Gurtmaterial verbunden.In an advantageous embodiment of the web is connected to the belt by a slight interference fit and by the web in the region of the free edge of the groove permanently formed belt material.

Die Verbindung der Stege mit den Gurten kann in einem kontinuierlichen Verfahren durch Anstemmen mit einem Meißel oder durch Anformen mittels rotierender Rollen vorgenommen werden. Hierbei entsteht durch das Aufpressen von Gurtmaterial auf den Steg unter relativ hohen Drücken eine Kaltverschweiáung zwischen dem Gurt material und dem Steg.The connection of the webs with the straps can be made in a continuous process by chiselling with a chisel or by molding by means of rotating rollers. This results from the pressing of belt material on the web under relatively high pressures a Kaltverschweiáung between the belt material and the web.

Bei der erfindungsgemäßen Verbindung zwischen den Gurten und den Stegen zur Bildung von Tragprofilen kann zur Erstellung verschiedener Tragprofile, bei denen die Stegdicke und die Ausbildung der Nut zur Aufnahme der Längsränder der Stege übereinstimmend gestaltet ist, ein Bausatz aus Stegen der unterschiedlichsten Formen und aus Gurten unterschiedlicher Abmessungen gebildet werden. Die Stege und Gurte bilden plattenförmige Bauteile, die vor ihrer Verbindung zu einem Tragprofil in einfacher und rationeller Weise bearbeitet werden können. Die Stege sind aus Leichtmetall gefertigt.In the connection between the straps and the webs according to the invention for the formation of support profiles, a kit of webs of different shapes and straps different to create different support profiles, in which the web thickness and the formation of the groove for receiving the longitudinal edges of the webs is designed consistently Dimensions are formed. The webs and straps form plate-shaped components that can be processed before their connection to a support profile in a simple and efficient manner. The bars are made of light metal.

Weitere Merkmale der Erfindung ergeben sich aus den Unteransprüchen.Further features of the invention will become apparent from the dependent claims.

Ausführungsbeispiele der Tragprofile sind in den Zeichnungen dargestellt. Es zeigen:

- Figur 1

- ein aus zwei Gurten und einem Steg zusammengesetztes Tragprofil für eine Fassade, bei dem der Steg mit kreisförmigen Durchbrechungen versehen ist,

Figur 2- eine Abwandlungsform des Tragprofils gegenüber der

Fig. 1 , und zwar ist der Steg mit dreieckförmigen Durchbrechungen ausgestattet, - Figur 3

- eine weitere Ausführungsform eines Tragprofils für eine Fassade, bei dem der Steg in Seitenansicht trapezförmig ausgebildet ist,

Figur 4- ein Doppel-T-förmiges Tragprofil im Querschnitt,

- Figur 5

- ein T-förmiges Tragprofil im Querschnitt,

Figur 6- ein Doppel-T-förmiges, zusammengesetztes Tragprofil im Querschnitt mit zugeordneten Isolierglasscheiben sowie einer sich außenseitig auf den Rändern der Isolierglasscheibe abstützenden Abdeckleiste,

Figur 7- die Verbindung eines Steges mit einem Gurt sowie ein Werkzeug zur Erzielung einer Kaltpreßschweißung zwischen den genannten Bauteilen,

- Figuren 8 bis 10

- Ausführungsformen von in einem Gurt angeordneten Nuten zur Aufnahme eines Längsrandbereiches eines Steges und die

Figuren 11 bis 14- Ausführungsformen von Stegen in perspektivischer Darstellung.

- FIG. 1

- a support profile composed of two straps and a web for a facade in which the web is provided with circular openings,

- FIG. 2

- a modification of the support profile relative to the

Fig. 1 , namely, the bridge is equipped with triangular openings, - FIG. 3

- a further embodiment of a supporting profile for a facade, in which the web is designed trapezoidal in side view,

- FIG. 4

- a double T-shaped support profile in cross section,

- FIG. 5

- a T-shaped support profile in cross section,

- FIG. 6

- a double-T-shaped, composite support profile in cross-section with associated insulating glass panes and a cover strip which is supported on the outside of the edges of the insulating glass pane,

- FIG. 7

- the connection of a web with a belt and a tool for achieving a Kaltpreßschweißung between said components,

- FIGS. 8 to 10

- Embodiments of arranged in a belt grooves for receiving a longitudinal edge region of a web and the

- FIGS. 11 to 14

- Embodiments of webs in perspective view.

In der

Der Gurt 2 weist Verankerungsnuten 5 zur Festlegung von Verglasungsdichtungen 6 auf und ist mit einer Schraubnut 7 ausgestattet, in die Befestigungsschrauben zur Festlegung einer Deckleiste 8 eingeschraubt werden. Bei dem Ausführungsbeispiel nach der

Der Steg 4 weist bei dem Ausführungsbeispiel nach der

In der

In der

Während in der

Die Verbindung zwischen dem Steg und den Gurten 2,3 wird dadurch erreicht, daß die Gurte mit einer Nut 19 zur Aufnahme des Längsrandbereiches 20 des Steges versehen sind und der Steg mit dem Gurt durch einen Preßsitz oder durch eine Kaltpreßverschweißung verbunden ist.The connection between the web and the

Bei dem Ausführungsbeispiel nach der

Durch die Preßpassung bzw. Übergangspassung wird ein schließendes Ineinandergreifen des Steges und des Gurtes erreicht, das auch ohne einen Anstemmvorgang zu einer Kaltverschweißung führen kann.The press fit or transition fit a closing engagement of the web and the belt is achieved, which can lead to a cold welding even without a Anstemmvorgang.

In der

Die Materialanhäufungen können auch dazu dienen, das Einstemmwerkzeug zu führen.The accumulations of material can also serve to guide the Einstemmwerkzeug.

Bei dem Ausführungsbeispiel nach der

Die Rillen 25 dienen der Führung eines Einstemmwerkzeuges, durch das die Rand leisten 24 auf den in die Nut 19 eingesetzten Steg gepreßt werden.The

Das Ausführungsbeispiel nach der

Bei der Herstellung der Gurte 2,3 im Strangpreßverfahren werden die Nuten mit den zugeordneten Profilierungen beim Strangpressen gefertigt.In the production of the

Zur Intensivierung der Steg-Gurt-Verbindung können, wie in den

Die

Bei den Stegausführungsformen nach den

Als Durchbrechungen der Stege sind in den Zeichnungen runde und dreieckförmige dargestellt. Die Durchbrechungen können aber auch eine beliebige andere geometrische Kontur aufeisen.As perforations of the webs round and triangular are shown in the drawings. The breakthroughs can also iron on any other geometric contour.

- 11

- Tragprofilsupport section

- 22

- Gurtbelt

- 33

- Gurtbelt

- 44

- Stegweb

- 55

- Verankerungsnutanchoring groove

- 66

- Verglasungsdichtungglazing gasket

- 77

- Schraubnutscrew groove

- 88th

- Deckleistecover strip

- 99

- KunststoffprofilPlastic profile

- 1010

- Isolierverglasungglazing

- 1111

- Durchbrechungperforation

- 1212

- Tragprofilsupport section

- 1313

- Stegweb

- 1414

- Durchbrechungperforation

- 1515

- Tragprofilsupport section

- 1616

- Stegweb

- 1717

- Durchbrechungperforation

- 1818

- Stegweb

- 1919

- Nutgroove

- 2020

- LängsrandbereichLongitudinal edge area

- 2121

- WerkzeugTool

- 2222

- Randleistesidebar

- 2323

- Flächearea

- 2424

- Randleistesidebar

- 2525

- Rillegroove

- 2626

- Verzahnunggearing

- 2727

- Ausnehmungrecess

- 2828

- Vertiefungdeepening

- 2929

- Bohrungdrilling

- 3030

- Aufrauhungroughening

Claims (10)

- Load-bearing profiles in T form or in double T form for mullion-transom facades, canopy roofs, galleries or the like, comprisinga) at least one flange (2, 3) and a web (4, 13, 16, 18) connected thereto;b) wherein the flange (2, 3) comprises a groove (19) for accommodating the longitudinal boundary region of the web (4, 13, 16, 18), in which the longitudinal boundary region of the web engages with closing action, and whereinc) the web (4, 13, 16, 18) is connected to the flange (2, 3) byc1) a press fit which leads to cold welding, orc2) a cold pressure welding;d) wherein the at least one flange (2, 3) is made of an extruded aluminium profile whose grooves (19) for accommodating the longitudinal boundary region of the web (4, 13, 16, 18) are produced by a continuous casting process during extrusion of the flange (2, 3), ande) wherein the flange (2, 3) is provided with anchoring grooves (5) for sealing strips (6), andf) wherein the web (4, 13, 16, 18) is produced as an extruded profile made of light metal.

- Load-bearing profiles according to claim 1, characterized in that the web (4) is connected to the flange by a light press fit and by flange material integrally formed on the web remaining in the region of the free groove edge.

- Load-bearing profiles according to claim 1 or 2, characterized in that the edges of the longitudinal groove are formed by strips which can be deformed in the direction of the web (4, 3, 6, 8) inserted into the groove (19).

- Load-bearing profiles according to claim 3, characterized in that the edge strips (22, 4) are formed by accumulations of material or by scores (25) extending parallel to the groove.

- Load-bearing profiles according to one of the preceding claims, characterized in that the groove walls are provided with denticulations (26) or other profilings or structurings.

- Load-bearing profiles according to one of the claims 1 to 5, characterized in that the webs (4, 13, 16, 18) are provided in the region of the engagement of the groove (19), to be precise adjacent to the groove edge, with scores (27) extending over the length of the web and having depressions (28) arranged at a distance from each other, or with a row of boreholes or a row of punched channels.

- Load-bearing profiles according to one of the preceding claims, characterized in that the webs (4, 13, 16, 18) are provided in the region of engagement in the groove (19) with a roughening formation (30), knurling, denticulation or corrugated profiling extending transversally to the longitudinal direction of the webs.

- Load-bearing profiles according to one of the preceding claims, characterized in that a screw-connection groove for the fastening screws of a cover strip (8) resting on the panel edges is provided between the anchoring grooves (5) for the sealing strips (6).

- Load-bearing profiles according to claim 9, characterized in that the webs are provided with triangular or circular breakthroughs, or with breakthroughs of any other geometrical shape.

- Load-bearing profiles according to one of the preceding claims, characterized in that the one longitudinal boundary edge of the web extends rectilinearly and the other longitudinal boundary edge extends parallel to the first one or with rectilinear inclination or with any other geometrical contour.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DK99105647T DK0952270T3 (en) | 1998-04-21 | 1999-03-19 | Support profile for pole-and-wall facades, canopies, galleries and the like |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19817708 | 1998-04-21 | ||

| DE19817708A DE19817708A1 (en) | 1998-04-21 | 1998-04-21 | Support profiles for transom-mullion facades, canopies, galleries or the like |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP0952270A2 EP0952270A2 (en) | 1999-10-27 |

| EP0952270A3 EP0952270A3 (en) | 2000-12-27 |

| EP0952270B1 EP0952270B1 (en) | 2004-10-13 |

| EP0952270B2 true EP0952270B2 (en) | 2013-09-11 |

Family

ID=7865268

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99105647.4A Expired - Lifetime EP0952270B2 (en) | 1998-04-21 | 1999-03-19 | Loadbearing sections for mullion-transom-art façades, awnings, canopy roofs or the like |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0952270B2 (en) |

| AT (1) | ATE279606T1 (en) |

| DE (3) | DE19817708A1 (en) |

| DK (1) | DK0952270T3 (en) |

| ES (1) | ES2227919T3 (en) |

| PL (1) | PL201509B1 (en) |

| RU (1) | RU2237788C2 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10030076B4 (en) * | 2000-06-19 | 2010-01-28 | Sommer Metallbau-Stahlbau Gmbh & Co. Kg | Device for holding facade parts |

| DE10200754B4 (en) * | 2002-01-10 | 2021-06-24 | Gudrun Woschko | Two-part metal profile |

| EP1653022A1 (en) * | 2004-10-18 | 2006-05-03 | Renovision, Ingenieurgesellschaft für Fenster und Fassade mbh | Profiled element for structural framework |

| DE102005048243A1 (en) * | 2005-10-07 | 2007-04-19 | Thyssenkrupp Steel Ag | Profile element and uses of such a profile element |

| DE102008031553A1 (en) * | 2008-07-07 | 2010-01-14 | Thyssenkrupp Steel Ag | Profile for building high rack warehouse, has bar and belt which is connected with bar in form-fit or force-fit manner, where groove is molded in central section of belt having additional section extending along central section |

| DE202015105071U1 (en) * | 2015-09-25 | 2016-12-28 | Raico Bautechnik Gmbh | Support profile and supporting structures with such a support profile |

| RU186147U1 (en) * | 2018-08-06 | 2019-01-11 | Валерий Иванович Шуляк | MOUNTING UNIT FOR DECORATIVE HINGED FACADE |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE448116C (en) † | 1926-02-17 | 1927-08-05 | Eisen U Stahlwerk Hoesch Akt G | Production of wide-flanged I, T and similar profiles |

| DE2559599A1 (en) † | 1975-11-25 | 1977-08-25 | Fuchs Kg Otto | Composite heat insulating profiled section - has insulating bar secured by distorted ribs on metal shells |

| DE3501233A1 (en) † | 1985-01-16 | 1986-07-17 | IsKoAl Firmengruppe für Fenster- und Türsysteme GmbH, 3167 Burgdorf | Method for manufacturing a multipart profiled frame |

| EP0260224A1 (en) † | 1986-09-04 | 1988-03-16 | Alusuisse-Lonza Services Ag | Apparatus for rolling the connecting part of a composite profile |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE893858C (en) * | 1949-01-31 | 1953-10-19 | Hans Twerenbold | Putty-free roof glazing |

| US3256671A (en) * | 1962-09-13 | 1966-06-21 | Mc Graw Edison Co | Elongated rigid structure |

| DE3222773A1 (en) * | 1982-06-18 | 1984-04-05 | Rummer & Co -GmbH & Co KG-, 8000 München | Profile system for putty-free fastening of glass panes for roofs |

| NO156505C (en) * | 1985-01-31 | 1987-09-30 | Johannes Gunnarshaug | HEATING SYSTEM FOR BUILDINGS, WITH A PLATFORM solar collector. |

| DE19622759A1 (en) * | 1995-12-14 | 1997-06-19 | Niemeier Ralf | Metal profile |

-

1998

- 1998-04-21 DE DE19817708A patent/DE19817708A1/en not_active Withdrawn

- 1998-04-21 DE DE29825152U patent/DE29825152U1/en not_active Expired - Lifetime

-

1999

- 1999-03-19 AT AT99105647T patent/ATE279606T1/en not_active IP Right Cessation

- 1999-03-19 EP EP99105647.4A patent/EP0952270B2/en not_active Expired - Lifetime

- 1999-03-19 DK DK99105647T patent/DK0952270T3/en active

- 1999-03-19 DE DE1999510795 patent/DE59910795D1/en not_active Expired - Lifetime

- 1999-03-19 ES ES99105647T patent/ES2227919T3/en not_active Expired - Lifetime

- 1999-04-20 RU RU99109098A patent/RU2237788C2/en not_active IP Right Cessation

- 1999-04-20 PL PL332615A patent/PL201509B1/en unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE448116C (en) † | 1926-02-17 | 1927-08-05 | Eisen U Stahlwerk Hoesch Akt G | Production of wide-flanged I, T and similar profiles |

| DE2559599A1 (en) † | 1975-11-25 | 1977-08-25 | Fuchs Kg Otto | Composite heat insulating profiled section - has insulating bar secured by distorted ribs on metal shells |

| DE3501233A1 (en) † | 1985-01-16 | 1986-07-17 | IsKoAl Firmengruppe für Fenster- und Türsysteme GmbH, 3167 Burgdorf | Method for manufacturing a multipart profiled frame |

| EP0260224A1 (en) † | 1986-09-04 | 1988-03-16 | Alusuisse-Lonza Services Ag | Apparatus for rolling the connecting part of a composite profile |

Also Published As

| Publication number | Publication date |

|---|---|

| DK0952270T3 (en) | 2005-01-03 |

| EP0952270A2 (en) | 1999-10-27 |

| DE29825152U1 (en) | 2005-08-04 |

| EP0952270A3 (en) | 2000-12-27 |

| DE19817708A1 (en) | 1999-10-28 |

| EP0952270B1 (en) | 2004-10-13 |

| ATE279606T1 (en) | 2004-10-15 |

| ES2227919T3 (en) | 2005-04-01 |

| RU2237788C2 (en) | 2004-10-10 |

| PL201509B1 (en) | 2009-04-30 |

| PL332615A1 (en) | 1999-10-25 |

| DE59910795D1 (en) | 2004-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0006431A1 (en) | Hollow building panel of extruded plastics | |

| EP1119468B1 (en) | Conductor rail for supplying power and a production method therefor | |

| DE29712058U1 (en) | Heat sinks for mounting on semiconductor components and partial profiles for the production of such heat sinks | |

| EP1020579B1 (en) | Fassade or a glazed roof having a sealing | |

| EP0952270B2 (en) | Loadbearing sections for mullion-transom-art façades, awnings, canopy roofs or the like | |

| DE202011101654U1 (en) | Thermally separated profile | |

| EP2743421A1 (en) | Facade or skylight, insulating bar and method for producing an insulating bar | |

| EP1510643B1 (en) | Profile and method of its manufacture | |

| EP1138864B1 (en) | Compound section member for windows, facades, doors or glazed roof | |

| AT9079U1 (en) | CONSTRUCTION AND USE OF A CARRIER AND METHOD FOR PRODUCING A FAÇADE ELEMENT | |

| DE10223038B4 (en) | Facade construction with a transom-side insulating profile sealed by a sealing element | |

| EP0235493B1 (en) | Thermally insulating composite profile member | |

| EP3879043B1 (en) | Sealing piece for sealing a t-connection between a post and latch profile and a post-latch structure with such a sealing piece | |

| EP1577455B1 (en) | Building facade or roof with framework for supporting facade panels | |

| AT393859B (en) | REINFORCEMENT OR SUPPORT PLATE | |

| DE19953675B4 (en) | Cross butt joint | |

| EP3626900B1 (en) | Insulating element for a facade, window or door structure and facade structure comprising such a insulating element | |

| DE29509856U1 (en) | T-connector for an outer shell made of metal of a thermally insulated frame profile for windows, doors or facades | |

| EP1837095A2 (en) | Metal profile for frame constructions for window, door or façade elements and method for manufacturing the same | |

| DE19804925A1 (en) | Bracket used for mounting panels in facade cladding or conservatory glazing construction | |

| DE102020101068A1 (en) | Composite profile, frame and element facade | |

| DE20106147U1 (en) | Facade component | |

| EP2248982B1 (en) | Coupling element for window frames, facades or similar | |

| EP3748115A1 (en) | Threshold for a sliding door | |

| DE20205731U1 (en) | Fastening system for light band hollow chamber panels |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FI FR GB IT LI NL |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT PAYMENT 19990319;LV PAYMENT 19990319;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991224 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT PAYMENT 19990319;LV PAYMENT 19990319;MK;RO;SI |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE DK ES FI FR GB IT LI NL |

|

| AXX | Extension fees paid |

Free format text: LT PAYMENT 19990319;LV PAYMENT 19990319 |

|

| 17Q | First examination report despatched |

Effective date: 20030310 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB IT LI NL |

|

| AX | Request for extension of the european patent |

Extension state: LT LV |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59910795 Country of ref document: DE Date of ref document: 20041118 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20041129 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20050323 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20050331 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2227919 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: NORSK HYDRO ASA Effective date: 20050713 |

|

| ET | Fr: translation filed | ||

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: NORSK HYDRO ASA |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20060331 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: WD Ref document number: 1021396 Country of ref document: HK |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| LTLA | Lt: lapse of european patent or patent extension |

Effective date: 20060319 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PLAH | Information related to despatch of examination report in opposition + time limit modified |

Free format text: ORIGINAL CODE: EPIDOSCORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20090325 Year of fee payment: 11 Ref country code: AT Payment date: 20090323 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20090324 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090324 Year of fee payment: 11 Ref country code: CH Payment date: 20090325 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20090330 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070319 |

|

| BERE | Be: lapsed |

Owner name: *SCHUCO INTERNATIONAL K.G. Effective date: 20100331 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20101001 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100319 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20111118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100320 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: NORSK HYDRO ASA Effective date: 20050713 |

|

| PLAH | Information related to despatch of examination report in opposition + time limit modified |

Free format text: ORIGINAL CODE: EPIDOSCORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: NORSK HYDRO ASA Effective date: 20050713 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20130911 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE DK ES FI FR GB IT LI NL |

|

| AX | Request for extension of the european patent |

Extension state: LT LV |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 59910795 Country of ref document: DE Effective date: 20130911 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20140319 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140401 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59910795 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20151130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150331 |