EP0898112B1 - Système de conduites pour la distribution réglée d'un fluide et procédé pour faire fonctionner un tel système - Google Patents

Système de conduites pour la distribution réglée d'un fluide et procédé pour faire fonctionner un tel système Download PDFInfo

- Publication number

- EP0898112B1 EP0898112B1 EP97810570A EP97810570A EP0898112B1 EP 0898112 B1 EP0898112 B1 EP 0898112B1 EP 97810570 A EP97810570 A EP 97810570A EP 97810570 A EP97810570 A EP 97810570A EP 0898112 B1 EP0898112 B1 EP 0898112B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressure

- pressure measuring

- branch lines

- measuring device

- measuring devices

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 7

- 239000012530 fluid Substances 0.000 title 1

- 238000009530 blood pressure measurement Methods 0.000 claims description 24

- 238000005259 measurement Methods 0.000 description 37

- 239000011159 matrix material Substances 0.000 description 7

- 238000009795 derivation Methods 0.000 description 3

- 238000001514 detection method Methods 0.000 description 3

- 239000007789 gas Substances 0.000 description 3

- 238000004364 calculation method Methods 0.000 description 2

- 239000000498 cooling water Substances 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 241001136792 Alle Species 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 239000002737 fuel gas Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- -1 steam Substances 0.000 description 1

- 230000009897 systematic effect Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17D—PIPE-LINE SYSTEMS; PIPE-LINES

- F17D1/00—Pipe-line systems

- F17D1/02—Pipe-line systems for gases or vapours

- F17D1/04—Pipe-line systems for gases or vapours for distribution of gas

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17D—PIPE-LINE SYSTEMS; PIPE-LINES

- F17D3/00—Arrangements for supervising or controlling working operations

- F17D3/18—Arrangements for supervising or controlling working operations for measuring the quantity of conveyed product

Definitions

- the present invention relates to a piping system for Distribution of a flowing medium, comprising a main line, which at a branch point into a plurality branched from branch lines in each of the branch lines a variable throttle, with which the mass flow is adjustable in each of the branch lines, as well as for each Throttle point a first pressure measuring device with which the pressure drop of the flowing medium at the respective Throttle point is measured.

- the invention further relates to a method for operation of such a piping system.

- a compressible or incompressible Medium e.g. cooling water, steam, oil or the like

- the supply system used for this typically exists from a network of pipelines, which itself characterized by branching points (nodes) at which a main line (a main flow of the medium) into two or more branch lines (branch streams) which branch to individual consumers or groups of consumers.

- branching points nodes

- branch streams branch lines

- a control valve is arranged in the branch line whose stroke is set so that the desired one Mass flow flows through the valve.

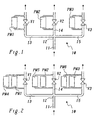

- a piping system as it is in Fig. 1 is shown.

- a main line 11 branches at a branch point 12 in (for example) three branch lines 13, 14 and 15.

- a valve V1 or V2 or V3 provided, by means of which the mass flow can be set (controlled) by the respective branch line can.

- h h (K V ).

- K V ⁇ (dm / dt) [T M / (P M - ⁇ p)] 1 ⁇ 2 [1 / Ap] 1 ⁇ 2 .

- ⁇ the mass flow dm / dt

- the pressure p M the temperature T M at the branch point 12 or in the main line 11, and the pressure drop ⁇ p at the valve.

- the quantity K V can be determined on the basis of the measured quantities T M , p M and ⁇ p according to equation (2).

- the valve lift can be calculated from the specified valve characteristic K V (h). A comparable determination can also be carried out for incompressible media.

- valve stroke The most important variable for the calculation of the valve stroke is the pressure drop measured at valves V1, .., V3. If if this measurement becomes faulty, this leads to an unacceptable one Failure of the supply system (and in the case of one Gas turbine for a quick shutdown) or even (e.g. in Case of a cooling water system) to a security risk. It is therefore desirable in many cases, the measurement of the Pressure drop across valves V1, .., V3 redundant, making an error in a single measurement of the pressure drop ⁇ p not the continuous, safe operation of the system touched or impaired (availability requirement or Availability Requirement AR).

- the purpose of a redundancy concept is twofold: (1) The occurrence of a measurement error should be recognized and the faulty one Measuring device or the faulty measuring channel should be identified. (2) The (not) usable measurement values are to be replaced by redundantly determined measured values.

- Reported errors (Notified Failure NF): This type of error includes all errors that are reported to the control system by the sender or another I / O device using a bad data quality (BDQ) signal. Based on the BDQ signal, the control system knows which ⁇ p measurement is faulty. This typically happens when a measuring line is interrupted or an error occurs in a component in the measuring chain.

- BDQ bad data quality

- the redundant measurement of the pressure drop can be carried out according to FIG. 2 with double redundancy.

- double redundancy is already per valve in addition to that existing pressure measuring device PM1, .., PM3 each one second pressure measuring device PM4, .., PM6 arranged in parallel. If one of the two pressure measurements (per valve) is faulty, can be switched to the other pressure measurement. This is only possible for reported errors where the incorrect measurement can be detected by the BDQ signal can.

- a drift of the measurement can be doubled Redundancy cannot be mastered because only two are independent Measurements per valve cannot be decided which of the two measurements is disturbed (or drifts).

- the redundant measurement can be used to overcome this problem 3 with a triple redundancy be performed.

- pro Valve next to the existing pressure measuring device PM1, .., PM3 each have a second pressure measuring device PM4, .., PM6 and a third pressure measuring device PM7, .., PM9 arranged in parallel.

- the 2-out-of-3 choice principle is used. The 2-out-of-3 choice principle assumes that if 2 out of 3 Measuring channels deliver the same measured values, these measuring channels work correctly while the third measuring channel is faulty is.

- the task is the beginning of a piping system mentioned type in that to achieve redundancy in the pressure measurement at least between two of the branch lines in the direction of flow behind the throttling points second pressure measuring device for measuring the differential pressure is arranged between the respective branch lines.

- second pressure measuring device By adding the second pressure measuring device in the specified Way is used for measuring the pressure drop to the Throttling points of the two affected branch lines one double redundancy achieved.

- the three pressure measuring devices measure the differences between a total of three pressures (the Pressure in the main line and the pressures in the two Branch lines behind the throttling points), each of the three pressures each from two pressure measuring devices as a reference value is taken.

- any pressure reading for a branch line can therefore be divided into two Determine wise (double redundant): First as direct Measured value of the associated first pressure measuring device, and others from the sum of the measured values of the other two pressure measuring devices.

- the invention allows three Pressure measuring devices for two branch lines one double Realize redundancy while using the scheme from Fig. 2 four pressure measuring devices would be necessary.

- the dual redundancy is to be implemented for all branch lines according to a first preferred embodiment the invention between each branch line and each another branch line a second pressure measuring device to measure the differential pressure between the respective Branch lines arranged.

- n branch lines With n branch lines, n-1 Pressure measuring devices required.

- each branch line and two additional branches each have a second one Pressure measuring device for measuring the differential pressure between the respective branch lines is arranged.

- the method according to the invention for operating the pipeline system is characterized in that for each pair of Branch lines the associated first pressure measuring devices and that arranged between the pair of branch lines second pressure measuring device each grouped together be, with the proper functioning of the Pressure measuring devices for each group of pressure measuring devices the sum of the pressure readings is zero, and that if one of the first pressure measuring devices within a group fails, the associated pressure reading from the Pressure measurement values of the other two pressure measuring devices of the Group is determined.

- a preferred embodiment of the method according to the invention is characterized in that every first pressure measuring device each in two groups of pressure measuring devices is represented, and that the pressure readings from the first Pressure measuring device to be treated as faulty if those from the other two pressure gauges each of the the two groups determined associated pressure measurements with each other, but not with those from the first pressure measuring device pressure readings match.

- the pipeline system 10 comprises a main line 11, which is at the branch point 12 in the three branch lines 13, 14 and 15 branches.

- a controllable throttle valve V1, V2 and V3 built-in.

- the pressure drop (pressure loss) at the valves V1, V2, V3 is initially directly through a parallel to the valve arranged first pressure measuring device PM1 or PM2 or PM3 measured. For this - as shown in the figures - on both Sides of the valve from the branch piping to the pressure measuring devices.

- FIG. 4 in the example of FIG. 4 there are three second pressure measuring devices PM10, PM11 and PM12, which are each arranged behind the valves V1, V2 and V3 between the branch lines and the pressure difference between each Measure two of the branch lines 13, 14 and 15.

- the pressure measuring devices PM1, PM2 and PM3 thus measure the pressure drop ⁇ p1, ⁇ p2 and ⁇ p3 at the valves V1, V2 and V2.

- the pressure measuring devices PM10, PM11 and PM12 measure the differential pressures ⁇ p10, ⁇ p11 and ⁇ p12 between the branch line pairs 13/14, 13/15 and 14/15.

- ⁇ pj is the violation of the condition ci by a matrix element "1" is displayed in the jth column and the ith row. Conditions that are not violated are indicated accordingly a matrix element "0" is displayed.

- the Measurement of ⁇ p1 incorrect, the conditions according to the table c1 and c3 violated (matrix elements are "1").

- the Conditions c2 and c4 are not affected by this error (Matrix elements are "0").

- the three branch lines are sufficient 3 additional pressure measuring devices PM10, PM11 and PM12 from to get largely the same redundancy as one 3. Additional branch lines are added, two additional pressure measuring devices per additional branch line needed between the additional Branch line and any two other branch lines arranged become. The maximum savings on pressure measuring devices compared to the arrangement of Fig. 3 results in the case of three branch lines.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Measuring Fluid Pressure (AREA)

- Pipeline Systems (AREA)

- Flow Control (AREA)

Claims (7)

- Système de conduites tubulaires (10) pour la distribution régulée d'un fluide, comprenant une conduite principale (11) qui se divise en un point de ramification (12) en une pluralité de conduites de ramification (13, 14, 15), dans chacune des conduites de ramification, une zone d'étranglement variable (V1, V2, V3) permettant d'ajuster le débit massique dans chacune des conduites de ramification (13, 14, 15), ainsi qu'à chaque zone d'étranglement (V1, V2, V3), un premier dispositif de mesure de pression (PM1, PM2, PM3) permettant de mesurer la chute de pression du fluide au niveau de la zone d'étranglement respective (V1, V2, V3), caractérisé en ce que pour l'obtention d'une redondance dans la mesure de pression, on dispose au moins entre deux des conduites de ramification (13, 14, ou 13, 15, ou 14, 15) dans le sens de l'écoulement derrière les zones d'étranglement (V1, V2, ou V1, V3, ou V2, V3) un deuxième dispositif de mesure de pression (PM10 ou PM11 ou PM12) pour mesurer la différence de pression entre les conduites de ramification respectives (13, 14 ou 13, 15 ou 14, 15).

- Système de conduites tubulaires selon la revendication 1, caractérisé en ce que l'on dispose, entre chaque conduite de ramification (13, 14, 15) et chaque autre conduite de ramification (14 ou 13 ou 14) un deuxième dispositif de mesure de pression (PM10 ou PM12) pour mesurer la différence de pression entre les conduites de ramification respectives (13, 14 ou 14, 13 ou 15, 14).

- Système de conduites tubulaires selon l'une quelconque des revendications 1 et 2, caractérisé en ce que l'on dispose entre chaque conduite de ramification (13, 14, 15) et à chaque fois deux autres conduites de ramification (14, 15 ou 13, 15 ou 13, 14) à chaque fois un deuxième dispositif de mesure de pression (PM10, PM11 ou PM10, PM12 ou PM11, PM12) pour mesurer la différence de pression entre les conduites de ramification respectives (13, 14, 15).

- Système de conduites tubulaires selon l'une quelconque des revendications 1 à 3, caractérisé en ce que les zones d'étranglement sont réalisées sous la forme de soupapes (V1, V2, V3).

- Système de conduites tubulaires selon l'une quelconque des revendications 1 à 4, caractérisé en ce que l'on utilise trois conduites de ramification (13, 14, 15).

- Procédé pour le fonctionnement d'un système de conduites tubulaires selon la revendication 1, caractérisé en ce que pour chaque paire de conduites de ramification (13, 14 ou 14, 15 ou 13, 15), on rassemble en un groupe les premiers dispositifs de mesure de pression associés (PM1, PM2 ou PM2, PM3 ou PM1, PM3) et le deuxième dispositif de mesure de pression (PM10 ou PM12 ou PM11) disposé entre la paire de conduites de ramification, où, pour un fonctionnement correcte des dispositifs de mesure de pression, pour chaque groupe de dispositifs de mesure de pression la somme des valeurs de mesure de pression est égale à zéro, et en ce que, si à l'intérieur d'un groupe l'un des premiers dispositifs de mesure de pression (PM1 ou PM2, respectivement PM2 ou PM3, respectivement PM1 ou PM3) tombe en panne, la valeur de mesure de pression associée est déterminée à partir des valeurs de mesure de pression des deux autres dispositifs de mesure de pression du groupe.

- Procédé selon la revendication 6, caractérisé en ce que chaque premier dispositif de mesure de pression (PM1, PM2, PM3) est représenté à chaque fois dans deux groupes de dispositifs de mesure de pression, et en ce que les valeurs de mesure de pression sortant du premier dispositif de mesure de pression sont traitées comme erronées lorsque les valeurs de mesure de pression déterminées associées provenant des deux autres dispositifs de mesure de pression de chacun des deux groupes coïncident mutuellement mais pas avec les valeurs de mesure de pression du premier dispositif de mesure de pression.

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE59710962T DE59710962D1 (de) | 1997-08-15 | 1997-08-15 | Rohrleitungssystem zur gesteuerten Verteilung eines strömenden Mediums sowie Verfahren zum Betrieb eines solchen Rohrleitungssystems |

| EP97810570A EP0898112B1 (fr) | 1997-08-15 | 1997-08-15 | Système de conduites pour la distribution réglée d'un fluide et procédé pour faire fonctionner un tel système |

| US09/133,668 US6021677A (en) | 1997-08-15 | 1998-08-12 | Pipeline system for the controlled distribution of a flowing medium and method for operating such a pipeline system |

| JP10228868A JPH11132400A (ja) | 1997-08-15 | 1998-08-13 | 流動媒体を制御分配するための管路系並びに該管路系の運転法 |

| CN98118369A CN1084863C (zh) | 1997-08-15 | 1998-08-17 | 用于控制流动介质分配的管道系统及其操作方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP97810570A EP0898112B1 (fr) | 1997-08-15 | 1997-08-15 | Système de conduites pour la distribution réglée d'un fluide et procédé pour faire fonctionner un tel système |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0898112A1 EP0898112A1 (fr) | 1999-02-24 |

| EP0898112B1 true EP0898112B1 (fr) | 2003-11-05 |

Family

ID=8230342

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97810570A Expired - Lifetime EP0898112B1 (fr) | 1997-08-15 | 1997-08-15 | Système de conduites pour la distribution réglée d'un fluide et procédé pour faire fonctionner un tel système |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6021677A (fr) |

| EP (1) | EP0898112B1 (fr) |

| JP (1) | JPH11132400A (fr) |

| CN (1) | CN1084863C (fr) |

| DE (1) | DE59710962D1 (fr) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10115750B4 (de) * | 2001-03-20 | 2017-05-24 | Robert Bosch Gmbh | Verfahren und Vorrichtung zur Steuerung und/oder Diagnose eines einen Massenstrom beeinflussenden Steuersystems |

| US6904386B2 (en) * | 2002-10-07 | 2005-06-07 | Honeywell International Inc. | Control system and method for detecting plugging in differential pressure cells |

| US6813588B1 (en) * | 2003-03-31 | 2004-11-02 | Honeywell International Inc. | Control system and method for detecting plugging in differential pressure cells |

| JP5223555B2 (ja) * | 2008-02-19 | 2013-06-26 | 株式会社デンソー | 燃料噴射装置及び蓄圧式燃料噴射装置システム |

| US8024161B2 (en) * | 2008-08-19 | 2011-09-20 | Honeywell International Inc. | Method and system for model-based multivariable balancing for distributed hydronic networks |

| KR101534209B1 (ko) * | 2014-04-16 | 2015-07-07 | 한국에너지기술연구원 | 압축성 유체 공급 시스템 |

| CN105576268B (zh) * | 2014-10-08 | 2019-02-15 | 通用电气公司 | 用于控制流量比的系统和方法 |

| EP3405764B1 (fr) | 2016-06-20 | 2019-10-23 | Siemens Aktiengesellschaft | Procédé de mesure du débit de fluide pour zone discrète de réseau d'alimentation en fluide |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3821897A (en) * | 1972-10-17 | 1974-07-02 | Gen Signal Corp | Pressure sensing probe |

| DE3225449C2 (de) * | 1982-07-07 | 1988-09-29 | Klöckner Stahlforschung GmbH, 8458 Sulzbach-Rosenberg | Verfahren und Vorrichtung zum Messen und/oder Regeln des Massestromes von Feststoffteilchen |

| US4839571A (en) * | 1987-03-17 | 1989-06-13 | Barber-Greene Company | Safety back-up for metering pump control |

| US4900445A (en) * | 1988-06-29 | 1990-02-13 | Conoco Inc. | Low pressure hydrocyclone separator |

| DE59301530D1 (de) * | 1992-06-30 | 1996-03-14 | Landis & Gyr Business Support | Verfahren und Vorrichtung zur Begrenzung eines Flusses durch eine Leitung |

| US5307668A (en) * | 1992-10-05 | 1994-05-03 | Badger Meter, Inc. | Gas density meter and method |

| JP2959947B2 (ja) * | 1994-02-28 | 1999-10-06 | 信越石英株式会社 | 原料ガス供給方法及び装置 |

| FR2721999B1 (fr) * | 1994-06-30 | 1996-08-09 | Contruction De Moteurs D Aviat | Debimetre massique redondant |

-

1997

- 1997-08-15 EP EP97810570A patent/EP0898112B1/fr not_active Expired - Lifetime

- 1997-08-15 DE DE59710962T patent/DE59710962D1/de not_active Expired - Lifetime

-

1998

- 1998-08-12 US US09/133,668 patent/US6021677A/en not_active Expired - Lifetime

- 1998-08-13 JP JP10228868A patent/JPH11132400A/ja active Pending

- 1998-08-17 CN CN98118369A patent/CN1084863C/zh not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| CN1208831A (zh) | 1999-02-24 |

| EP0898112A1 (fr) | 1999-02-24 |

| US6021677A (en) | 2000-02-08 |

| JPH11132400A (ja) | 1999-05-21 |

| DE59710962D1 (de) | 2003-12-11 |

| CN1084863C (zh) | 2002-05-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60206405T2 (de) | Überdruckschutzsystem | |

| DE10393433B4 (de) | Bürstendichtungen verwendende Dichtungsanordnung | |

| DE19983825B4 (de) | Vorrichtung zum thermischen Messen eines Massenflusses eines Gasstromes und Verwendung eines Laminar-Flusselements | |

| DE102007023541A1 (de) | Rohrleitungsschutzsystem | |

| EP0898112B1 (fr) | Système de conduites pour la distribution réglée d'un fluide et procédé pour faire fonctionner un tel système | |

| EP1695055B1 (fr) | Dispositif de mesure, en particulier convertisseur de mesure de temperature | |

| EP1092177B1 (fr) | Regulateur ou regulateur de propulseur, propulseur et procede pour reguler un systeme de reglage ou d'entrainement ou un propulseur | |

| DE19916452A1 (de) | Vorrichtung für einen Powerring | |

| DE69119523T2 (de) | Fehlererkennung in Relaisansteuerungsschaltungen | |

| EP2085707A2 (fr) | Installation de chauffage et procédé destiné au fonctionnement d'une installation de chauffage | |

| EP2217983B1 (fr) | Procédé de fonctionnement d'un système de conduites de transport de fluide | |

| EP1315060A1 (fr) | Procédé de régulation continue de la position d'une soupape de régulation | |

| DE102011082599B4 (de) | Ventilanordnung, Verwendung, Turbine und Kraftwerk | |

| EP1757817B1 (fr) | Arrangement de valve pour contrôler une soupape à fermeture rapide de turbine à gaz ou à vapeur | |

| EP3338189A2 (fr) | Procédé de fonctionnement d'un processeur multicoeur | |

| EP0817953B1 (fr) | Appareil a determiner le sens de rotation et a controler la vraisemblance, utilise dans les capteurs de la position angulaire absolue, avec notamment la transmission en serie des positions reelles detectees | |

| DE102019211372B4 (de) | Verfahren zum Überwachen eines Brennstoffzufuhrsystems einer Brennkraftmaschine und Brennkraftmaschine zur Durchführung eines solchen Verfahrens | |

| DE19518634A1 (de) | Verfahren und Gerät zur Kraftstoffzumessung und -verteilung | |

| DE102008054303B4 (de) | Sensoreinheit zum Überwachen eines Hydrauliksystems | |

| DE2730738A1 (de) | Steuerung fuer eine druckmittelbetaetigte stellgliedanordnung sowie druckmittelbetaetigte stellgliedanordnung mit einer steuerung dieser art | |

| EP2169644A1 (fr) | Contrôle des lignes d'alerte d'une installation d'alerte au danger | |

| DE102021204617A1 (de) | Schmiersystem | |

| DE1751809C3 (de) | Anordnung zur elektrohydraulischen Steuerung eines hydraulischen Tandem-Stellmotors | |

| DE69702143T2 (de) | Messverstärker | |

| DE2146196C3 (de) | Auswahlschaltung für eine dreikanalige redundante Vorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE GB |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19990714 |

|

| AKX | Designation fees paid |

Free format text: DE GB |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALSTOM |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALSTOM (SWITZERLAND) LTD |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE GB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 59710962 Country of ref document: DE Date of ref document: 20031211 Kind code of ref document: P |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: ALSTOM TECHNOLOGY LTD |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040120 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040806 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59710962 Country of ref document: DE Representative=s name: ROESLER, UWE, DIPL.-PHYS.UNIV., DE Ref country code: DE Ref legal event code: R081 Ref document number: 59710962 Country of ref document: DE Owner name: GENERAL ELECTRIC TECHNOLOGY GMBH, CH Free format text: FORMER OWNER: ALSTOM TECHNOLOGY LTD., BADEN, CH |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160822 Year of fee payment: 20 Ref country code: GB Payment date: 20160819 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59710962 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20170814 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20170824 AND 20170830 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170814 |