EP0803002B1 - Process for patterning a web of textile material - Google Patents

Process for patterning a web of textile material Download PDFInfo

- Publication number

- EP0803002B1 EP0803002B1 EP95942649A EP95942649A EP0803002B1 EP 0803002 B1 EP0803002 B1 EP 0803002B1 EP 95942649 A EP95942649 A EP 95942649A EP 95942649 A EP95942649 A EP 95942649A EP 0803002 B1 EP0803002 B1 EP 0803002B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- web

- residues

- thickening agent

- agent

- patterning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B23/00—Component parts, details, or accessories of apparatus or machines, specially adapted for the treating of textile materials, not restricted to a particular kind of apparatus, provided for in groups D06B1/00 - D06B21/00

- D06B23/20—Arrangements of apparatus for treating processing-liquids, -gases or -vapours, e.g. purification, filtration, distillation

Definitions

- the invention relates to a method of Preamble of claim 1 corresponding type and corresponding facility.

- sampling in the sense of the invention comes in primarily a colored sample is considered, whereby not just to think of a real illustration, but also fall under the term a plain color should. On the type of application of the sample it does not matter for the invention. In many cases it is a printing process, but also come Consider processes where the sample agent is dripped on, poured on or sprayed on or in which the web is even put into a sampling fleet is dipped.

- the invention is concerned with methods of this type, where a thickener is present on the web have to be. This is primarily in the case of printing processes Case so that the sample does not run and one clean contour is created, or with it the patterning agent does not penetrate too deeply into the textile material.

- the use of thickeners in textile printing is in the book by M. Peter and H.K. Rouette "Basics of textile finishing" 13th edition (1989), pages 620 to 623 and a number of suitable Listed substances. It is understood that as a thickener also mixtures of several corresponding substances are to be seen.

- the thickening is in the applied Medium, i.e. the printing paste.

- This also applies if in carpet dyeing work with thickening must, so that the applied sample does not increase quickly sinks into the very high pile of carpets and the tips of the fibers do not receive enough dye, so that a gray veil is created.

- the dyeing fleet in Thickening added to these cases keeps the liquor long enough even on the upper areas of the fibers.

- thickeners have to be removed from the web be removed again after steaming. This task is difficult and requires a lot of washing. Many attempts have been made to remove it to facilitate the thickening agent. For example the thickening has only been moistened, after which it Dwelled through the thickening through the To let moisture swell. After that, she should wash out more easily.

- the thickeners form at the end of the damper a real shift on the web, and it is too already been done this layer in the end area to remove the damper mechanically by squeegee, so that at least a substantial part of the thickeners was already off the web without washing and the washing process was relieved accordingly (DE-OS 34 40 948).

- This prior art is the generic term of Claim 1 based.

- the thickener is used not just removed, but recovered for reuse. The removal is done by suction on Exit of the damper, where the color is already on the Fibers is drawn. The extracted thickener is filtered and used to recover the heat sent a heat exchanger.

- the thickener treated in this way will again be the one in front of the order setup application device arranged for the dyeing liquor for the thickener supplied.

- the weight is not just bare Removal of the thickening, but on their recovery and when used again when adding additional sample agents. So the procedure has both ecological aspect, in so far as it is used several times the thickening agent the disposal effort significantly is reduced as well as an economic Aspect, in so far as the multiple use of the expensive thickeners a cost saving that results in the cost the additional equipment in a relatively short time Amortized time.

- the invention has for its object the generic Sample procedures using thickeners to improve.

- “middle remnants” in the sense of the invention the Whole of the unbound on the web and their Fibers are understood, so not only the remains of the applied sample agent, but also the remains of the previous ones Treatment steps applied treatment agents such as Sizes, finishing agents and the like that adhere to the fibers. When mechanically removing the middle remnants these shares are less covered. Most of them remain on the web and are only at the next Washing process removed.

- the mechanically removable parts rather mainly contain the remains of the sample agent, e.g. the printing paste, which is predominantly consist of the thickener, which on this Way of unwanted treatment agents like Finishing, finishing agents, etc. can be separated.

- the accumulation of color in the thickener is counteracted according to the invention by the decolorization treatment, where the mechanically cleaned middle remains with a suitable application device like dyeing on a sheet-like permeable Fabric made of textile fibers applied by the Pattern dye are easy to dye.

- the fabric can be a fabric or a fleece from the Be textile fibers.

- the ones on the fabric Middle remnants are then sucked through the fabric, the dyes still contained therein willingly transition to the fibers of the fabric, which are selected accordingly.

- Those in the middle remnants dyes still contained are made from them so to speak "colored away". It remains practically pure Thickener that can be reused.

- the fabric is either discarded or by appropriate procedures in turn decolorized, if necessary to be reusable.

- An important aspect of the procedure described is that both the removal of the thickener from the web as well as its cleaning without the help of water, so that the recovered thickener as it is, and can be reused without energy-consuming drainage can.

- the mechanical cleaning preceding the decolorization can, as in the prior art, by sieving or filtering be done with the mechanical removal the middle remnants of contaminants such as fluff and the like are removed from the material.

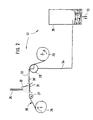

- the textile fabric web designated 1 in FIG. 1 is in the exemplary embodiment, a carpet web, which on a the representation upstream with an order a patterning agent has been provided, which Contained thickener. In the embodiment it is a thickened printing paste.

- damper 3 In the damper 3 is provided with a doctor blade 5 in this area, which unscrews the web 1 and an essential Proportion of the middle remainder on goods web 1, for example 50 to 70% of the web mechanically decreases and collects in a gutter 6, from where it enters one Buffer tank 7 at outlet 4 of the damper merges.

- the Squeegee or other mechanical removal device can also outside the damper close to the outlet 4th be arranged.

- Middle remnants are also the remnants of sizing, finishing agents and the like contained on the fiber and less in Area of the thickener layer on top of the pole to sit. These portions of the middle remainder remain when scraping off predominantly on web 1 and do not get into the buffer container 7 with the doctored Share of the middle remainder.

- the unwanted ingredients like sizing, finishing agents and the like are washed out, if the web 1 after leaving the Damper 3 at the outlet 4 in the direction of arrow 8 in a washing system, not shown, is transferred.

- the scraped off middle residue from the buffer container 7 is by means of a pump 9 in a 10 designated as a whole Cleaning device transferred.

- the cleaning facility 10 comprises two units 11 and 12.

- the doctored The middle remainder first reaches unit 11, which is a sieve and filter unit for removing mechanical contaminants such as fluff and the like which is removed from the web 1 when doctoring become.

- the mechanically pre-cleaned middle residue then arrives into a decolorization unit 12, which the minor Dye shares in the damper 3 not on the web 1 raised, but remained in the middle remnant are getting out of this.

- the decolorization unit 12 will be described in detail with reference to FIG. 2.

- a container 15 provided with thickener stock solution, from which by means of a pump 16 via a line 17 Thickener stock solution in a batch container 18 for the preparation of further sampling materials, for example further printing paste, can be dispensed.

- line 20 can be used Thickener stock solution optionally in one of the storage containers 14 are given to the inside Thickener, its quality in the three storage containers 14 may be different in the required Way to set.

- This setting can be automatic be done by the properties of each Storage containers 14 located amounts of thickener be measured by suitable measuring devices 21. The measured values are each via a line 22 fed to a controller 40 which controls the metering pump 16 controls such that it 14 the amount of thickener stock solution required there feeds.

- the individual storage containers 14 become optional the thickener via a line 23 by means of a Pump 24 removed and the batch container 18 for preparation fed additional sample agent.

- Fig. 2 is a decolorization unit in question 12 reproduced.

- the sieve and filter unit 11 The remaining medium amount is fed via a feed pipe 25 onto a horizontally guided section 30 'of a web-shaped Fabric 30 abandoned, which is a fabric, represents a knitted fabric or a nonwoven made of fibers, the of those contained in the patterning agent for the carpet Dyes are particularly easy to dye.

- the embodiment shown is the fabric of a roll 26 unwound, via a support roller 27 and a effective suction pipe over the width of the fabric 30 28 out in the horizontal section 30 'and then wound up on a roll 29 again.

- the middle remnant is through the feed pipe 25 at one point on top of the fabric 30 delivered on which this the back is supported by a sliding plate 31.

- a doctor blade 32 arranged on the upper side the medium residue applied becomes a uniform one Layer 33 streaked when passing the entrance opening of the suction pipe 28 through the fabric 30 is sucked through into the suction pipe 28.

Description

Die Erfindung bezieht sich auf ein Verfahren der dem Oberbegriff des Anspruchs 1 entsprechenden Art und eine entsprechende Anlage.The invention relates to a method of Preamble of claim 1 corresponding type and corresponding facility.

Als "Bemusterung" im Sinne der Erfindung kommt in erster Linie eine farbige Bemusterung in Betracht, wobei nicht nur an eine regelrechte Bebilderung zu denken ist, sondern auch eine Uni-Färbung unter den Begriff fallen soll. Auf die Art des Auftrags des Bemusterungsmittels kommt es für die Erfindung nicht an. In vielen Fällen wird es sich um einen Druckvorgang handeln, doch kommen auch Verfahren in Betracht, bei denen das Bemusterungsmittel auftropfen gelassen wird, aufgegossen wird oder aufgesprüht wird oder bei denen gar die Warenbahn in eine Bemusterungsflotte getaucht wird.As "sampling" in the sense of the invention comes in primarily a colored sample is considered, whereby not just to think of a real illustration, but also fall under the term a plain color should. On the type of application of the sample it does not matter for the invention. In many cases it is a printing process, but also come Consider processes where the sample agent is dripped on, poured on or sprayed on or in which the web is even put into a sampling fleet is dipped.

Die Erfindung befaßt sich mit Verfahren dieser Art, bei denen auf der Warenbahn ein Verdickungsmittel zugegen sein muß. Dies ist in erster Linie bei Druckverfahren der Fall, damit das Bemusterungsmittel nicht verläuft und eine saubere Kontur entsteht oder damit das Bemusterungsmittel nicht zu schnell in Tiefe des textilen Materials eindringt. Die Verwendung von Verdickungsmitteln beim Textildruck ist in dem Buch von M. Peter und H.K. Rouette "Grundlagen der Textilveredlung" 13. Auflage (1989), Seiten 620 bis 623 beschrieben und eine Reihe geeigneter Stoffe aufgezählt. Es versteht sich, daß als Verdickungsmittel auch Mischungen mehrerer entsprechender Stoffe anzusehen sind.The invention is concerned with methods of this type, where a thickener is present on the web have to be. This is primarily in the case of printing processes Case so that the sample does not run and one clean contour is created, or with it the patterning agent does not penetrate too deeply into the textile material. The use of thickeners in textile printing is in the book by M. Peter and H.K. Rouette "Basics of textile finishing" 13th edition (1989), pages 620 to 623 and a number of suitable Listed substances. It is understood that as a thickener also mixtures of several corresponding substances are to be seen.

Beim Druck befindet sich die Verdickung in dem aufgetragenen Medium, d.h. der Druckpaste. Dies gilt auch, wenn bei der Teppichfärberei mit Verdickung gearbeitet werden muß, damit das aufgetragene Bemusterungsmittel nicht zu rasch in den bei Teppichen recht hohen Flor einsinkt und die Spitzen der Fasern nicht genügend Farbstoff erhalten, so daß ein Grauschleier entsteht. Die der Färbeflotte in diesen Fällen zugesetzte Verdickung hält die Flotte lang genug auch an den oberen Bereichen der Fasern fest.When printing, the thickening is in the applied Medium, i.e. the printing paste. This also applies if in carpet dyeing work with thickening must, so that the applied sample does not increase quickly sinks into the very high pile of carpets and the tips of the fibers do not receive enough dye, so that a gray veil is created. The dyeing fleet in Thickening added to these cases keeps the liquor long enough even on the upper areas of the fibers.

Es gibt aber auch Fälle, bei denen Verdickungsmittel nicht mit dem Bemusterungsmittel zusammen, sondern vorher aufgetragen wird. Ein Beispiel hierfür ist der DE 27 08 000 Al zu entnehmen, bei der das Verdickungsmittel (Gum) als Farbrückhaltemittel dient und in einer Schicht auf eine Teppichbahn aufgetragen wird, auf die anschließend ein rapportloses Muster durch Farbflotten aufgetröpfelt wird. Auch hier sind jedoch, wenn die Bemusterung beendet ist und die Ware sich im Dämpfer befindet, Verdickungsmittel zugegeben.But there are also cases where thickeners not together with the sample agent, but beforehand is applied. An example of this is DE 27 08 000 Al in which the thickener (gum) serves as a color retention agent and in one layer a carpet sheet is applied, on which subsequently a repeatless pattern dripped on by fleets of color becomes. Again, however, are when the sampling ends and the goods are in the damper, thickener admitted.

Diese Verdickungsmittel müssen von der Warenbahn nach dem Dämpfen wieder entfernt werden. Diese Aufgabe ist schwierig und erfordert einen erheblichen Waschaufwand. Viele Versuche sind unternommen worden, um das Entfernen der Verdickungsmittel zu erleichtern. Beispielsweise ist die Verdickung erst angefeuchtet worden, worauf sie eine Verweilstrecke durchlief, um die Verdickung durch die Feuchtigkeit quellen zu lassen. Danach sollte sie sich leichter auswaschen lassen.These thickeners have to be removed from the web be removed again after steaming. This task is difficult and requires a lot of washing. Many attempts have been made to remove it to facilitate the thickening agent. For example the thickening has only been moistened, after which it Dwelled through the thickening through the To let moisture swell. After that, she should wash out more easily.

In jedem Fall war bisher der Waschaufwand zur Entfernung der Verdickung wesentlich größer als in der normalen Färberei, wo keine Verdickungsmittel notwendig sind.In any case, the washing effort for removal was previously the thickening much larger than in the normal Dyeing where no thickeners are necessary.

Die Verdickungsmittel bilden am Ende des Dämpfers eine regelrechte Schicht auf der Bahn, und es ist auch bereits unternommen worden, diese Schicht im Endbereich des Dämpfers mechanisch durch Rakeln zu entfernen, so daß wenigstens ein wesentlicher Teil der Verdickungsmittel schon ohne Waschvorgang von der Warenbahn herunter war und der Waschvorgang entsprechend entlastet wurde (DE-OS 34 40 948).The thickeners form at the end of the damper a real shift on the web, and it is too already been done this layer in the end area to remove the damper mechanically by squeegee, so that at least a substantial part of the thickeners was already off the web without washing and the washing process was relieved accordingly (DE-OS 34 40 948).

Alle diese bekannten Maßnahmen standen aber unter dem Aspekt lediglich der Entfernung der Verdickungsmittel, die anschließend aufwendig entsorgt werden mußten.All of these known measures were under the Aspect only of the removal of the thickeners then had to be disposed of at great expense.

Ein Schritt weiter wird in der US-A-4 418 433 getan, die eine Anlage zum kontinuierlichen Färben von Teppichen zeigt. Dieser Stand der Technik liegt dem Oberbegriff des Anspruchs 1 zugrunde. Das Verdickungsmittel wird hierbei nicht nur entfernt, sondern zur erneuten Verwendung wiedergewonnen. Die Entfernung geschieht durch Absaugen am Ausgang des Dämpfers, wo also die Farbe schon auf die Fasern aufgezogen ist. Das abgesaugte Verdickungsmittel wird filtriert und zur Wiedergewinnung der Wärme durch einen Wärmetauscher geschickt. Das so behandelte Verdikkungsmittel wird erneut der vor der Auftragseinrichtung für die Färbeflotte angeordneten Auftragseinrichtung für das Verdickungsmittel zugeleitet.A step further is done in US-A-4,418,433 the one system for the continuous dyeing of carpets shows. This prior art is the generic term of Claim 1 based. The thickener is used not just removed, but recovered for reuse. The removal is done by suction on Exit of the damper, where the color is already on the Fibers is drawn. The extracted thickener is filtered and used to recover the heat sent a heat exchanger. The thickener treated in this way will again be the one in front of the order setup application device arranged for the dyeing liquor for the thickener supplied.

Das Gewicht liegt hierbei also nicht auf der bloßen Entfernung der Verdickung, sondern auf ihrer Wiedergewinnung und im erneuten Einsatz beim Ansatz weiteren Bemusterungsmittels. Die Verfahrensweise hat also sowohl einen ökologischen Aspekt, insofern durch die mehrmalige Verwendung der Verdickungsmittel der Entsorgungsaufwand wesentlich reduziert wird, als auch einen wirtschaftlichen Aspekt, insofern die Mehrfachverwendung der teuren Verdickungsmittel eine Kostenersparnis ergibt, die die Kosten der zusätzlichen apparativen Ausrüstung in relativ kurzer Zeit amortisiert.The weight is not just bare Removal of the thickening, but on their recovery and when used again when adding additional sample agents. So the procedure has both ecological aspect, in so far as it is used several times the thickening agent the disposal effort significantly is reduced as well as an economic Aspect, in so far as the multiple use of the expensive thickeners a cost saving that results in the cost the additional equipment in a relatively short time Amortized time.

Es ist zwar so, daß bei vielen farblichen Bemusterungen, also Färbungen, die in dem Bemusterungsmittel enthaltenen Farbstoffe bei dosiertem Flottenauftrag zu 99 % und mehr auf die Fasern aufziehen und schon von daher die ganz überwiegend aus dem verbliebenen Verdickungsmittel bestehenden Mittelreste fast farblos übrigbleiben. Da aber diese Farbstoffreste sich bei der Mehrfachverwendung der Verdickungsmittel anreichern können, kann das Verdickungsmittel eine Eigenfarbe bekommen, die sich störend auswirken kann.It is true that with many color samples, that is, dyeings contained in the sample agent Dyes with dosed fleet application to 99% and more on the fibers and therefore the whole consisting mainly of the remaining thickener Middle remnants remain almost colorless. Here but these dye residues are found in the multiple use of Thickeners can accumulate, the thickener get their own color that has a disruptive effect can.

Der Erfindung liegt die Aufgabe zugrunde, das gattungsgemäße mit Verdickungsmitteln arbeitende Bemusterungsverfahren zu verbessern.The invention has for its object the generic Sample procedures using thickeners to improve.

Diese Aufgabe wird durch die in den Ansprüchen 1 und 3 in ihrem verfahrensmäßigen bzw. apparativen Aspekt wiedergegebene Erfindung gelöst.This object is achieved by the in claims 1 and 3 reproduced in its procedural or apparatus aspect Invention solved.

Als "Mittelreste" im Sinne der Erfindung soll die Gesamtheit der ungebundenen auf der Warenbahn und ihren Fasern befindlichen Stoffe verstanden werden, also nicht nur die Reste des aufgetragenen Bemusterungsmittels, sondern auch die verbliebenen Reste von in vorangegangenen Behandlungsschritten aufgetragenen Behandlungsmitteln wie Schlichte, Avivagen und ähnliches, die den Fasern anhaften. Bei der mechanischen Entfernung der Mittelreste werden diese Anteile weniger erfaßt. Sie verbleiben überwiegend auf der Warenbahn und werden erst beim nachfolgenden Waschvorgang entfernt. Die mechanisch entfernbaren Anteile beinhalten vielmehr vorwiegend die Reste des Bemusterungsmittels, z.B. der Druckpaste, die ganz überwiegend aus dem Verdickungsmittel bestehen, welches auf diese Weise von den unerwünschten Behandlungsmitteln wie Schlichten, Avivagen usw. separierbar ist.As "middle remnants" in the sense of the invention, the Whole of the unbound on the web and their Fibers are understood, so not only the remains of the applied sample agent, but also the remains of the previous ones Treatment steps applied treatment agents such as Sizes, finishing agents and the like that adhere to the fibers. When mechanically removing the middle remnants these shares are less covered. Most of them remain on the web and are only at the next Washing process removed. The mechanically removable parts rather mainly contain the remains of the sample agent, e.g. the printing paste, which is predominantly consist of the thickener, which on this Way of unwanted treatment agents like Finishing, finishing agents, etc. can be separated.

Der Anreicherung der Farbe in dem Verdickungsmittel wird erfindungsgemäß durch die Entfärbungsbehandlung entgegengewirkt, bei welcher die mechanisch gereinigten Mittelreste werden mit einer geeigneten Auftragsvorrichtung wie bei einer Färbung auf ein bahnförmiges durchlässiges Flächengebilde aus Textilfasern aufgetragen, die von dem Bemusterungsfarbstoff leicht anfärbbar sind. Das Flächengebilde kann ein Gewebe oder aber auch ein Vlies aus den Textilfasern sein. Die auf dem Flächengebilde befindlichen Mittelreste werden sodann durch das Flächengebilde hindurchgesaugt, wobei die darin noch enthaltenen Farbstoffe bereitwillig auf die Fasern des Flächengebildes übergehen, die ja entsprechend ausgewählt sind. Die in den Mittelresten noch enthaltenen Farbstoffe werden also aus ihnen gewissermaßen "weggefärbt". Es verbleibt praktisch reines Verdickungsmittel, welches wiederverwendet werden kann. Das Flächengebilde wird entweder verworfen oder durch geeignete Verfahren seinerseits entfärbt, um gegebenenfalls wiederverwendbar zu sein.The accumulation of color in the thickener is counteracted according to the invention by the decolorization treatment, where the mechanically cleaned middle remains with a suitable application device like dyeing on a sheet-like permeable Fabric made of textile fibers applied by the Pattern dye are easy to dye. The fabric can be a fabric or a fleece from the Be textile fibers. The ones on the fabric Middle remnants are then sucked through the fabric, the dyes still contained therein willingly transition to the fibers of the fabric, which are selected accordingly. Those in the middle remnants dyes still contained are made from them so to speak "colored away". It remains practically pure Thickener that can be reused. The fabric is either discarded or by appropriate procedures in turn decolorized, if necessary to be reusable.

Ein wichtiger Aspekt der geschilderten Verfahrensweise liegt darin, daß sowohl die Entfernung des Verdikkungsmittels von der Warenbahn als auch seine Reinigung ohne die Zuhilfenahme von Wasser vonstatten gehen, so daß das wiedergewonnene Verdickungsmittel so, wie es ist, und ohne energieaufwendige Entwässerung wiederverwendet werden kann.An important aspect of the procedure described is that both the removal of the thickener from the web as well as its cleaning without the help of water, so that the recovered thickener as it is, and can be reused without energy-consuming drainage can.

Die der Entfärbung vorgeschaltete mechanische Reinigung kann wie im Stand der Technik durch Sieben oder Filtern erfolgen, wobei die bei der mechanischen Entfernung der Mittelreste mitgenommenen Verunreinigungen wie Flusen und dergleichen aus dem Material entfernt werden.The mechanical cleaning preceding the decolorization can, as in the prior art, by sieving or filtering be done with the mechanical removal the middle remnants of contaminants such as fluff and the like are removed from the material.

Die Ansprüche 3 bis 8 geben die Erfindung in ihrer apparativen Ausgestaltung wieder.Claims 3 to 8 give the invention in its apparatus design again.

In der Zeichnung ist die Erfindung schematisch dargestellt.

Die in Fig. 1 mit 1 bezeichnete textile Warenbahn ist in dem Ausführungsbeispiel eine Teppichbahn, die an einer der Darstellung vorgeschalteten Stelle mit einem Auftrag eines Bemusterungsmittels versehen worden ist, welches Verdickungsmittel enthielt. In dem Ausführungsbeispiel handelt es sich um eine verdickte Druckpaste.The textile fabric web designated 1 in FIG. 1 is in the exemplary embodiment, a carpet web, which on a the representation upstream with an order a patterning agent has been provided, which Contained thickener. In the embodiment it is a thickened printing paste.

Nach dem Auftrag des Bemusterungsmittels sind also

auf der Warenbahn 1 das Bemusterungsmittel und das Verdickungsmittel

zugleich zugegeben. Die Warenbahn 1 läuft so

im Sinne des Pfeiles 2 in einen Dämpfer 3 ein, in welchem

die Farbstoffe aus dem Bemusterungsmittel auf die Fasern

der Warenbahn 1 aufziehen. Am Ende des Durchlaufs ist

dieser Vorgang beendet und bleibt auf der Warenbahn ein

Mittelrest zurück, der aus geringen Farbstoffresten, etwaigen

geringen Rückständen sonstiger Art und dem gesamten

Verdickungsmittel besteht. Letzteres findet sich als eine

Art Schicht auf der Polseite der Warenbahn, wenn diese

dabei ist, den Dämpfer 3 an dem Auslaß 4 zu verlassen. In

dem Dämpfer 3 ist in diesem Bereich eine Rakel 5 vorgesehen,

die die Warenbahn 1 abrakelt und einen wesentlichen

Anteil des auf der Warenbahn 1 befindlichen Mittelrestes,

beispielsweise 50 bis 70 %, von der Warenbahn mechanisch

abnimmt und in einer Rinne 6 sammelt, von wo er in einen

Pufferbehälter 7 am Auslaß 4 des Dämpfers übergeht. Die

Rakel oder eine sonstige mechanische Entfernungseinrichtung

können auch außerhalb des Dämpfers dicht am Auslaß 4

angeordnet sein.So after applying the sample agent

on the material web 1 the patterning agent and the thickening agent

admitted at the same time. The web 1 runs like this

in the direction of arrow 2 in a damper 3, in which

the dyes from the patterning agent on the fibers

of web 1. At the end of the run is

this process ends and remains on the web

Middle residue back, that of small dye residues, any

small residues of any other kind and the whole

There is a thickener. The latter is found as one

Kind of layer on the pole side of the web, if this

is about to leave the damper 3 at the outlet 4. In

the damper 3 is provided with a

Es ist nicht erwünscht, den auf der Warenbahn verbliebenen

Mittelrest durchgreifend zu entfernen. In dem

Mittelrest sind nämlich auch Rest von Schlichte, Avivagen

und dergleichen enthalten, die an der Faser und weniger im

Bereich der oben auf dem Pol befindlichen Verdickungsmittelschicht

sitzen. Diese Anteile des Mittelrestes verbleiben

bei der Abrakelung überwiegend auf der Warenbahn 1 und

gelangen nicht in den Pufferbehälter 7 mit dem abgerakelten

Anteil des Mittelrestes. Die unerwünschten Bestandteile

wie Schlichte, Avivagen und dergleichen werden ausgewaschen,

wenn die Warenbahn 1 nach dem Verlassen des

Dämpfers 3 an dem Auslaß 4 im Sinne des Pfeiles 8 in eine

nicht dargestellte Waschanlage überführt wird.It is not desirable to leave the one remaining on the web

To completely remove the middle remainder. By doing

Middle remnants are also the remnants of sizing, finishing agents

and the like contained on the fiber and less in

Area of the thickener layer on top of the pole

to sit. These portions of the middle remainder remain

when scraping off predominantly on web 1 and

do not get into the buffer container 7 with the doctored

Share of the middle remainder. The unwanted ingredients

like sizing, finishing agents and the like are washed out,

if the web 1 after leaving the

Damper 3 at the outlet 4 in the direction of

Der abgerakelte Mittelrest aus dem Pufferbehälter 7

wird mittels einer Pumpe 9 in eine als Ganzes mit 10 bezeichnete

Reinigungseinrichtung überführt. Die Reinigungseinrichtung

10 umfaßt zwei Aggregate 11 und 12. Der abgerakelte

Mittelrest gelangt zunächst in das Aggregat 11,

welches eine Sieb- und Filtereinheit zum Entfernen von

mechanischen Verunreinigungen wie Flusen und dergleichen

ist, die beim Abrakeln von der Warenbahn 1 abgenommen

werden.The scraped off middle residue from the buffer container 7

is by means of a pump 9 in a 10 designated as a whole

Cleaning device transferred. The

Der mechanisch vorgereinigte Mittelrest gelangt sodann

in eine Entfärbungseinheit 12, die die geringfügigen

Farbstoffanteile, die in dem Dämpfer 3 nicht auf die Warenbahn

1 aufgezogen, sondern in dem Mittelrest verblieben

sind, aus diesem herausholt. Die Entfärbungseinheit 12

wird anhand von Fig. 2 noch im einzelnen beschrieben. The mechanically pre-cleaned middle residue then arrives

into a

Das die Entfärbungseinheit 12 in der Leitung 13 verlassende

Medium ist nicht mehr als "Mittelrest" anzusprechen,

sondern besteht aus praktisch reinem Verdickungsmittel,

welches in Vorratsbehälter 14 abgegeben werden

kann. An sich wäre nur ein Vorratsbehälter 14 erforderlich.

Die Qualität des auf der Leitung 13 anstehenden

Verdickungsmittels kann jedoch von Metrage zu Metrage der

Warenbahn 1 schwanken. Es empfiehlt sich daher, das Verdickungsmittel

bei jeder Metrage separat aufzufangen. Aus

diesem Grund sind in dem Ausführungsbeispiel drei Vorratsbehälter

14 vorgesehen, in die das auf der Leitung 13

geförderte Verdickungsmittel wahlweise abgegeben werden

kann.The one that leaves the

Außer den drei Vorratsbehältern 14 ist noch ein Behälter

15 mit Verdickungsmittel-Stammlösung vorgesehen,

aus welchem mittels einer Pumpe 16 über eine Leitung 17

Verdickungsmittel-Stammlösung in einen Ansatzbehälter 18

zur Bereitung weiteren Bemusterungsmittels, zum Beispiel

weiterer Druckpaste, abgegeben werden kann.In addition to the three storage containers 14, there is also a

Alternativ oder zusätzlich kann über die Leitung 20

Verdickungsmittel-Stammlösung wahlweise in einen der Vorratsbehälter

14 gegeben werden, um das darin befindliche

Verdickungsmittel, dessen Qualität in den drei Vorratsbehältern

14 unterschiedlich sein kann, in der erforderlichen

Weise einzustellen. Diese Einstellung kann automatisch

erfolgen, indem die Eigenschaften der in den einzelnen

Vorratsbehältern 14 befindlichen Verdickungsmittelmengen

durch geeignete Meßeinrichtungen 21 gemessen werden.

Die Meßwerte werden jeweils über eine Leitung 22

einem Regler 40 zugeführt, der die dosierende Pumpe 16

derart steuert, daß sie den einzelnen Vorratsbehältern 14

die dort jeweils benötigte Menge an VerdickungsmittelStammlösung

zuführt.Alternatively or additionally,

Aus den einzelnen Vorratsbehältern 14 wird wahlweise

das Verdickungsmittel über eine Leitung 23 mittels einer

Pumpe 24 entnommen und dem Ansatzbehälter 18 zur Bereitung

weiteren Bemusterungsmittels zugeführt. The individual storage containers 14 become optional

the thickener via a

In Fig. 2 ist eine in Betracht kommende Entfärbeeinheit

12 wiedergegeben. Die die Sieb- und Filtereinheit 11

verlassende Mittelrestmenge wird über ein Zuführrohr 25

auf einen horizontal geführten Abschnitt 30' eines bahnförmigen

Flächengebildes 30 aufgegeben, welches ein Gewebe,

eine Gewirke oder ein Vlies aus Fasern darstellt, die

von den in dem Bemusterungsmittel für den Teppich enthaltenen

Farbstoffen besonders leicht anfärbbar sind. In dem

gezeigten Ausführungsbeispiel wird das Flächengebilde von

einer Rolle 26 abgewickelt, über eine Tragwalze 27 und ein

über die Breite des Flächengebildes 30 wirksames Saugrohr

28 in dem horizontalen Abschnitt 30' geführt und anschließend

auf eine Rolle 29 wieder aufgewickelt. Der Mittelrest

wird durch das Zuführrohr 25 an einer Stelle auf die Oberseite

des Flächengebildes 30 abgegeben, an der dieses auf

der Rückseite durch eine Gleitplatte 31 unterstützt ist.

Durch eine auf der Oberseite angeordnete Streichrakel 32

wird die aufgebrachte Mittelrestmenge zu einer gleichmäßigen

Schicht 33 ausgestrichen, die beim Passieren der Eingangsöffnung

des Saugrohrs 28 durch das Flächengebilde 30

hindurch in das Saugrohr 28 hineingesaugt wird.In Fig. 2 is a decolorization unit in

Die in dem Mittelrest noch enthaltenen geringen Farbstoffmengen

gehen dabei auf das Flächengebilde 30 über, so

daß in der Leitung 34 praktisch farbloses Verdickungsmittel

herauskommt, welches in dem Abscheider 35 von dem

Saugluftstrom getrennt wird, so daß luftfreies Verdikkungsmittel

in die Leitung 13 gelangt, aus der es in der

im Zusammenhang mit Fig. 1 beschriebenen Weise weiterverarbeitet

wird.The small amounts of dye still contained in the middle residue

go over to the

Claims (8)

- A method of patterning textile webs, particularly carpet webs,characterised in thatwherein a patterning agent is applied to the web and a thickening agent is added to the web,wherein the web provided with the patterning agent is conveyed through a steamer,wherein residues of agents on the web are at least partly removed mechanically from the entire web or from the parts of the web still substantially at the steamer temperature, andwherein the removed residues are purified without being diluted with water and the remaining practically pure thickening agent is re-used when more patterning agent is added,

purification is followed by decolorising treatment wherein the mechanically removed residues are applied to a permeable flat web of textile fibres which can readily be coloured by the patterning dye and then sucked through the flat structure, wherein dyes remaining in the thickening agent are deposited on the structure. - A method according to claim 1, characterised in that purification comprises mechanical purification by screening and filtering for removing fluff and the like.

- An installation for working the method according to claim 1 or 2,characterised in thatcomprising means for continuously conveying a textile web (1), particularly a carpet web, in the longitudinal direction thereof, along a processing zone,comprising an applicator for applying patterning agent and thickening agent together or separately to the advancing web (1),comprising a steamer (3) disposed downstream of the applicator in the processing zone,comprising a means (5, 6, 7) disposed in the neighbourhood of the steamer outlet (4) for mechanical removal of a substantial part of the residues containing thickening agent from the web (1) and for collecting and disposing of the removed residues,comprising a means (10) for purifying the residues without diluting them with water in order to recover practically pure thickening agent, andcomprising a means (13, 14, 23, 24) for recycling the recovered thickening agent for reuse thereof when additional patterning agent is added,

the means (10) for purifying the removed residues comprises a decolorising means (12) containing an applicator (25, 32) by means of which the mechanically purified residues are applied to an advancing flat structure (30) of textile fibres which can be readily coloured by the dyes in the patterning agent, a suction device (28) downstream of the applicator region for sucking the applied residues through the flat structure (30) and a separator (35) for separating the thickening agent from the sucked away air stream. - An installation according to claim 3,

characterised in that the flat web (30) is spread out and guided from a delivery roller (26) over a zone (30') to a take-up roller (29) and the applicator (25, 32) and the suction device (28) are disposed one behind the other in the zone (30'). - An installation according to claim 3 or 4,

characterised in that a device (21) for measuring properties of the recovered thickening agent and a storage container (15) for a stock solution of thickening agent are provided, and when further patterning agent is added, stock solution for adjusting the properties of the thickening agent as required can be drawn in controlled manner from the storage container. - An installation according to any of claims 3 to 5,

characterised in that the means for mechanically removing the residues comprises a scraper arrangement (5) operative across the width of the web (1) and engaging the web (1) on the side to which agents are applied. - An installation according to any of claims 3 to 5,

characterised in that the means for mechanically removing the residues comprises a suction device operative across the width of the web (1) and engaging the web (1) on the side to which agents are applied. - An installation according to any of claims 3 to 7,

characterised in that the means (10) for purifying the removed residues comprises a fluff screen and/or filter.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19503520A DE19503520C1 (en) | 1995-02-03 | 1995-02-03 | Pattern dyeing of carpetings, allowing repeated use of thickening agent |

| DE19503520 | 1995-02-03 | ||

| PCT/DE1995/001867 WO1996023923A1 (en) | 1995-02-03 | 1995-12-28 | Process for patterning a web of textile material |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0803002A1 EP0803002A1 (en) | 1997-10-29 |

| EP0803002B1 true EP0803002B1 (en) | 1999-03-10 |

Family

ID=7753091

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95942649A Expired - Lifetime EP0803002B1 (en) | 1995-02-03 | 1995-12-28 | Process for patterning a web of textile material |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5968205A (en) |

| EP (1) | EP0803002B1 (en) |

| JP (1) | JP2816599B2 (en) |

| CA (1) | CA2211751C (en) |

| DE (2) | DE19503520C1 (en) |

| WO (1) | WO1996023923A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1288365A1 (en) * | 2001-08-22 | 2003-03-05 | Halbmond Teppichwerke GmbH | Method for recycling printing paste thickener used in printing textile webs |

| CN107503061A (en) * | 2017-08-31 | 2017-12-22 | 杭州依翰丝绸文化创意有限公司 | A kind of energy-conserving and environment-protective rapid steamer |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20010070871A (en) * | 2001-06-15 | 2001-07-27 | 이석수 | Method for spray dyeing a fiber using an oil and water repellent |

| KR100921983B1 (en) | 2008-03-05 | 2009-10-14 | 송용문 | The decolorization device and decolorization method fabric |

| CN108867011B (en) * | 2018-09-04 | 2023-07-14 | 浙江工业职业技术学院 | Waste cloth recycling device |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1070405B (en) * | 1976-02-25 | 1985-03-29 | Rca Corp | METHOD AND APPARATUS FOR DYEING TEXTILE MATERIALS |

| US4418433A (en) * | 1981-08-07 | 1983-12-06 | Diamond Carpet Mills, Incorporated | Method and system for reclaiming and recycling gum and water in a carpet dyeing process |

| DE3440948A1 (en) * | 1984-11-09 | 1986-05-15 | Vepa AG, Riehen, Basel | Process and apparatus for washing printed material webs |

-

1995

- 1995-02-03 DE DE19503520A patent/DE19503520C1/en not_active Expired - Lifetime

- 1995-12-28 EP EP95942649A patent/EP0803002B1/en not_active Expired - Lifetime

- 1995-12-28 DE DE59505337T patent/DE59505337D1/en not_active Expired - Fee Related

- 1995-12-28 CA CA002211751A patent/CA2211751C/en not_active Expired - Fee Related

- 1995-12-28 US US08/894,894 patent/US5968205A/en not_active Expired - Fee Related

- 1995-12-28 JP JP8523147A patent/JP2816599B2/en not_active Expired - Fee Related

- 1995-12-28 WO PCT/DE1995/001867 patent/WO1996023923A1/en active IP Right Grant

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1288365A1 (en) * | 2001-08-22 | 2003-03-05 | Halbmond Teppichwerke GmbH | Method for recycling printing paste thickener used in printing textile webs |

| CN107503061A (en) * | 2017-08-31 | 2017-12-22 | 杭州依翰丝绸文化创意有限公司 | A kind of energy-conserving and environment-protective rapid steamer |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2816599B2 (en) | 1998-10-27 |

| EP0803002A1 (en) | 1997-10-29 |

| CA2211751A1 (en) | 1996-08-08 |

| US5968205A (en) | 1999-10-19 |

| WO1996023923A1 (en) | 1996-08-08 |

| DE19503520C1 (en) | 1996-04-25 |

| JPH10500742A (en) | 1998-01-20 |

| DE59505337D1 (en) | 1999-04-15 |

| CA2211751C (en) | 2000-06-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2362109A1 (en) | PROCEDURE FOR TREATMENT, IN PARTICULAR, INKING AND PRINTING GOODS AND DEVICE FOR CARRYING OUT THIS PROCESS | |

| DE4419540C2 (en) | Method and device for cleaning a rotating screen or felt web | |

| DE2403815A1 (en) | METHOD FOR TREATMENT OF TEXTILE, FLEECE AND SIMILAR WEBS | |

| EP0803002B1 (en) | Process for patterning a web of textile material | |

| DE2853242A1 (en) | DEVICE FOR WET TREATMENT OF FIBER MATERIAL | |

| DE2256427A1 (en) | DEVICE FOR PRINTING AND / OR INKING HIGH-PILE ROLLS | |

| DE2921102A1 (en) | METHOD AND DEVICE FOR REINFORCING TEXTILE SURFACES BY COATING THE SAME WITH PLASTIC | |

| DE2459781C2 (en) | Device for separating fiber cracks, fiber adhesions, foreign matter particles (strips) and short fibers when carding or carding fiber materials | |

| EP0030670B1 (en) | Method for scouring chemical fibres subsequent to the spinning thereof | |

| DE305379C (en) | ||

| DD256735A5 (en) | DEVICE FOR REMOVING FROM THE SURFACE OF ROLLERS OR BZW. CYLINDER PENDING INCIDENTS | |

| DE2166719A1 (en) | CLEANING DEVICE FOR THE PRINTING CYLINDER OF AN OFFSET PRINTING MACHINE | |

| DE19511231B4 (en) | Process for washing rollers of an inking unit of printing machines | |

| DE3428388A1 (en) | Process for eliminating so-called stain rings on the rolls of a calender and corresponding paper-refining unit | |

| DE126156C (en) | ||

| DE3503974A1 (en) | Device for continuous washing-out of printing blocks | |

| DE3311707A1 (en) | DEVICE AND METHOD FOR CHEMICAL TREATING A CLOTH | |

| DE2613844A1 (en) | Transporter for the web in a tandem carding engine - includes wire clothed cylinders with waste suction housings | |

| DE3233061C2 (en) | Device for printing flexible surface parts | |

| DE3032742C2 (en) | ||

| DE3013738A1 (en) | DEVICE FOR DRAINING A POROUS FABRIC, IN PARTICULAR A CARPET | |

| AT503488A2 (en) | APPARATUS AND METHOD FOR CONDITIONING THE LOAD IN MATERIAL RAIL MAKING MACHINES | |

| DE2204751A1 (en) | Cleaning of nozzles - esp of slotted suction nozzles used in impregnating appts for fibrous widths, eg widths of glass wool | |

| AT152295B (en) | Process for washing and post-treatment of freshly spun and cut staple fibers (rayon). | |

| DE10163341C2 (en) | Device and method for cleaning dirty cleaning agent from printing presses |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19970507 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE CH DE FR IT LI |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: EDUARD KUESTERS MASCHINENFABRIK GMBH & CO. KG |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19980526 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE FR IT LI |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: R. A. EGLI & CO. PATENTANWAELTE Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59505337 Country of ref document: DE Date of ref document: 19990415 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19991217 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19991220 Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001231 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010831 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20041231 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20050629 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060701 |

|

| BERE | Be: lapsed |

Owner name: EDUARD *KUSTERS MASCHINENFABRIK G.M.B.H. & CO. K.G Effective date: 20051231 |