EP0733859A2 - Procédé et dispositif de commande d'un appareil de chauffage - Google Patents

Procédé et dispositif de commande d'un appareil de chauffage Download PDFInfo

- Publication number

- EP0733859A2 EP0733859A2 EP96103437A EP96103437A EP0733859A2 EP 0733859 A2 EP0733859 A2 EP 0733859A2 EP 96103437 A EP96103437 A EP 96103437A EP 96103437 A EP96103437 A EP 96103437A EP 0733859 A2 EP0733859 A2 EP 0733859A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- temperature

- supply air

- fan

- exhaust gas

- blower

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N1/00—Regulating fuel supply

- F23N1/02—Regulating fuel supply conjointly with air supply

- F23N1/022—Regulating fuel supply conjointly with air supply using electronic means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N3/00—Regulating air supply or draught

- F23N3/08—Regulating air supply or draught by power-assisted systems

- F23N3/082—Regulating air supply or draught by power-assisted systems using electronic means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N5/00—Systems for controlling combustion

- F23N5/18—Systems for controlling combustion using detectors sensitive to rate of flow of air or fuel

- F23N5/184—Systems for controlling combustion using detectors sensitive to rate of flow of air or fuel using electronic means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N1/00—Regulating fuel supply

- F23N1/06—Regulating fuel supply conjointly with draught

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2221/00—Pretreatment or prehandling

- F23N2221/08—Preheating the air

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2225/00—Measuring

- F23N2225/08—Measuring temperature

- F23N2225/10—Measuring temperature stack temperature

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2225/00—Measuring

- F23N2225/08—Measuring temperature

- F23N2225/21—Measuring temperature outlet temperature

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2233/00—Ventilators

- F23N2233/02—Ventilators in stacks

- F23N2233/04—Ventilators in stacks with variable speed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2233/00—Ventilators

- F23N2233/06—Ventilators at the air intake

- F23N2233/08—Ventilators at the air intake with variable speed

Definitions

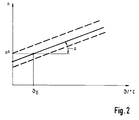

- the allocation of the fan speed depending on the exhaust gas or supply air temperature is determined by a compensation characteristic stored in a control unit. This is composed of empirical values that are supplemented by parameters determined by the heater itself before the start of the first heating process, such as the internal flow resistance. This ensures that a fan speed required in accordance with the compensation is assigned to each exhaust gas or supply air temperature during operation.

- FIG. 1 shows the heating device according to the invention for carrying out the control method according to the invention

- FIG. 2 shows a compensation characteristic from which the fan speed required for a constant supply air mass flow rate can be determined as a function of the exhaust gas temperature or the supply air temperature

- FIG. 3 shows a functional sequence plotted over time After the heater has been switched on, it shows a) the signal for the heat request, b) the fan speed, c) the signal for the ignition, d) the condition of a pressure cell and e) the gas supply.

- the exhaust gas 27 which is produced during combustion is released into the open via the exhaust line 26.

- the supply air line 16 and the exhaust gas line 26 run coaxially to one another and are connected to the environment via an opening 40 in the housing 10.

- the temperature of the fan 24 changes conveyed exhaust gas volume flow.

- the exhaust gas temperature changes as a function of the change in the supply temperature of the heating water in the heat exchanger 38 and as a function of the device state from which the start was made (cold / warm).

- the temperature of the exhaust gas 27 is also influenced by temperature changes in the supply air 17.

- General heating of the heater, as well as the coaxial routing of the supply air line 16 to the exhaust gas line 26 and the fan 24 arranged for cooling in the supply air line 16 bring about a temperature increase in the supply air and thus also an increase in the temperature of the exhaust gas 27 during combustion.

- exhaust gas 27, that is, the fan is running there is combustion.

- the designation nominal speed means that the blower works with 100% output taking into account the necessary compensation of the speed due to the different exhaust gas temperatures.

- the fan 24 is started up first when a heat is requested via the control unit 42.

- the exhaust air volume flow conveyed by the fan 24 corresponds to a specific supply air volume flow.

- the difference in the pressures detected by the control lines 50, 52 in the channel-shaped line 18 is a measure of the delivered supply air volume flow.

- the contacts of the pressure cell 54 attached between the control lines 50, 52 close at a point in time t1.

- the speed of the fan 24 which in this case corresponds to 80% of the nominal speed of the fan 24 and the temperature by the Sensor 46 detected exhaust air 27 stored in the control unit 42.

- the speed of the fan 24 is detected with the aid of a sensor 44 attached to the fan 24.

- the sensor 46 is arranged on the inside of the housing 25 of the fan 24. He is thus directly exposed to the temperature of the exhaust gas 27 being conveyed.

- PTC resistors, thermocouples or NTC resistors can be used as temperature sensors. The latter have the advantage that they have a relatively large linear characteristic range.

- the sensor 46 consists of two NTC resistors with different resistance values, preferably 10 k ⁇ for a temperature range from 0 ° to 90 ° C and 100 k ⁇ for a temperature range from 90 ° C to 200 ° C.

- the fan 24 ' is arranged in the supply air duct 18, the combustion chamber 36 and the exhaust gas-carrying parts must be designed to be tight.

- the control procedure is just as little on Restricted gas heaters, but can in principle also be used for heaters with other energy sources, such as oil.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Regulation And Control Of Combustion (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19510425A DE19510425C2 (de) | 1995-03-24 | 1995-03-24 | Verfahren und Vorrichtung zur Regelung eines Heizgerätes |

| DE19510425 | 1995-03-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0733859A2 true EP0733859A2 (fr) | 1996-09-25 |

| EP0733859A3 EP0733859A3 (fr) | 1996-12-11 |

Family

ID=7757392

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96103437A Ceased EP0733859A3 (fr) | 1995-03-24 | 1996-03-06 | Procédé et dispositif de commande d'un appareil de chauffage |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0733859A3 (fr) |

| DE (1) | DE19510425C2 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0855556A1 (fr) * | 1997-01-23 | 1998-07-29 | Truma Gerätetechnik GmbH & Co. | Dispositif et procédé de régulation de la vitesse angulaire d'un moteur |

| EP1333227A3 (fr) * | 2002-01-31 | 2004-07-07 | Robert Bosch Gmbh | Procédé d'ajustement d'un appareil de chauffage incorporant un brûleur à son système d'échappement et/ou de tirage en air |

| EP1450102A1 (fr) * | 2003-02-20 | 2004-08-25 | Robert Bosch Gmbh | Appareil de chauffage et procédé de fonctionnement correspondant |

| EP1475580A1 (fr) * | 2003-05-07 | 2004-11-10 | Robert Bosch Gmbh | Dispositif ou procédé pour adapter à la géométrie d'un système d'échappement ou d'un système d'air la puissance d'un ventilateur d'un dispositif de chauffage ou d'un dispositif de ventilation |

| EP1260766A3 (fr) * | 2001-05-21 | 2004-12-08 | Vaillant GmbH | Procédé d'adaptation d' un appareil de chauffage à brûleur à la cheminée d'air/fumée |

| EP2455660A3 (fr) * | 2010-11-18 | 2016-08-17 | Reznor Manufacturing Company, LLC | Réchauffeur d'air à prémélange |

| EP3438528A4 (fr) * | 2016-03-30 | 2020-02-26 | Kazuo Miyatani | Dispositif de combustion de combustible solide, procédé de combustion de combustible solide, dispositif de chauffage au gaz, dispositif de chauffage de liquide, système de production d'énergie et système de refroidissement |

| EP4033147A3 (fr) * | 2021-01-25 | 2022-08-03 | Vaillant GmbH | Agencement et procédé de fonctionnement d'un appareil de chauffage |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010054807B4 (de) * | 2010-12-16 | 2015-07-02 | Honeywell Technologies Sarl | Verfahren zum Betreiben einer Gasbrennervorrichtung |

| DE102021206320A1 (de) * | 2021-06-21 | 2022-12-22 | Robert Bosch Gesellschaft mit beschränkter Haftung | Verfahren zum Bestimmen und/oder Optimieren einer Wärmeleistung eines Heizgeräts sowie Heizgerät und Steuergerät |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63318417A (ja) * | 1987-06-19 | 1988-12-27 | Matsushita Electric Ind Co Ltd | 強制給排気式暖房機の制御装置 |

| JPH01212817A (ja) * | 1988-02-19 | 1989-08-25 | Toto Ltd | 強制排気式ガス燃焼装置 |

| JPH02192512A (ja) * | 1989-01-17 | 1990-07-30 | Noritz Corp | 強制給排気式燃焼装置 |

| NL9200825A (nl) * | 1992-05-08 | 1993-12-01 | Fasto Nefit Bv | Ventilatorbesturing. |

| GB2271443A (en) * | 1992-10-12 | 1994-04-13 | Vaillant Joh Gmbh & Co | Method of maintaining constant the maximum power and/or the minimum power of a water heater that comprises a gas burner |

| EP0615095A1 (fr) * | 1993-03-11 | 1994-09-14 | Landis & Gyr Technology Innovation AG | Automate à brûleur |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3125513A1 (de) * | 1981-06-29 | 1983-01-13 | Siemens AG, 1000 Berlin und 8000 München | "verfahren zum betrieb einer vergasungsbrenner/heinzkesselanlage" |

| DE3812697A1 (de) * | 1988-04-16 | 1989-12-28 | Programmelectronic Eng Ag | Verfahren zur reduzierung der stoergroessenwirkung bei geblaesebrenneranlagen und geblaesebrenneranlage |

| DE4109841C2 (de) * | 1991-03-26 | 1994-06-09 | Bosch Gmbh Robert | Regelvorrichtung für Gasbrenner mit einem Gebläse zum Zuführen von Verbrennungsluft |

| DE9310451U1 (de) * | 1993-03-05 | 1994-06-30 | Landis & Gyr Business Support Ag, Zug | Steuer- bzw. Regeleinrichtung für Gas-Feuerungsautomaten von Heizungsanlagen |

-

1995

- 1995-03-24 DE DE19510425A patent/DE19510425C2/de not_active Expired - Fee Related

-

1996

- 1996-03-06 EP EP96103437A patent/EP0733859A3/fr not_active Ceased

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS63318417A (ja) * | 1987-06-19 | 1988-12-27 | Matsushita Electric Ind Co Ltd | 強制給排気式暖房機の制御装置 |

| JPH01212817A (ja) * | 1988-02-19 | 1989-08-25 | Toto Ltd | 強制排気式ガス燃焼装置 |

| JPH02192512A (ja) * | 1989-01-17 | 1990-07-30 | Noritz Corp | 強制給排気式燃焼装置 |

| NL9200825A (nl) * | 1992-05-08 | 1993-12-01 | Fasto Nefit Bv | Ventilatorbesturing. |

| GB2271443A (en) * | 1992-10-12 | 1994-04-13 | Vaillant Joh Gmbh & Co | Method of maintaining constant the maximum power and/or the minimum power of a water heater that comprises a gas burner |

| EP0615095A1 (fr) * | 1993-03-11 | 1994-09-14 | Landis & Gyr Technology Innovation AG | Automate à brûleur |

Non-Patent Citations (3)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 013, no. 161 (M-815), 18.April 1989 & JP-A-63 318417 (MATSUSHITA ELECTRIC IND CO LTD), 27.Dezember 1988, * |

| PATENT ABSTRACTS OF JAPAN vol. 013, no. 521 (M-896), 21.November 1989 & JP-A-01 212817 (TOTO LTD;OTHERS: 02), 25.August 1989, * |

| PATENT ABSTRACTS OF JAPAN vol. 014, no. 478 (M-1036), 18.Oktober 1990 & JP-A-02 192512 (NORITZ CORP), 30.Juli 1990, * |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0855556A1 (fr) * | 1997-01-23 | 1998-07-29 | Truma Gerätetechnik GmbH & Co. | Dispositif et procédé de régulation de la vitesse angulaire d'un moteur |

| EP1260766A3 (fr) * | 2001-05-21 | 2004-12-08 | Vaillant GmbH | Procédé d'adaptation d' un appareil de chauffage à brûleur à la cheminée d'air/fumée |

| EP1333227A3 (fr) * | 2002-01-31 | 2004-07-07 | Robert Bosch Gmbh | Procédé d'ajustement d'un appareil de chauffage incorporant un brûleur à son système d'échappement et/ou de tirage en air |

| EP1450102A1 (fr) * | 2003-02-20 | 2004-08-25 | Robert Bosch Gmbh | Appareil de chauffage et procédé de fonctionnement correspondant |

| EP1475580A1 (fr) * | 2003-05-07 | 2004-11-10 | Robert Bosch Gmbh | Dispositif ou procédé pour adapter à la géométrie d'un système d'échappement ou d'un système d'air la puissance d'un ventilateur d'un dispositif de chauffage ou d'un dispositif de ventilation |

| EP2455660A3 (fr) * | 2010-11-18 | 2016-08-17 | Reznor Manufacturing Company, LLC | Réchauffeur d'air à prémélange |

| EP3438528A4 (fr) * | 2016-03-30 | 2020-02-26 | Kazuo Miyatani | Dispositif de combustion de combustible solide, procédé de combustion de combustible solide, dispositif de chauffage au gaz, dispositif de chauffage de liquide, système de production d'énergie et système de refroidissement |

| EP4033147A3 (fr) * | 2021-01-25 | 2022-08-03 | Vaillant GmbH | Agencement et procédé de fonctionnement d'un appareil de chauffage |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0733859A3 (fr) | 1996-12-11 |

| DE19510425A1 (de) | 1996-09-26 |

| DE19510425C2 (de) | 1999-05-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102004055716B4 (de) | Verfahren zur Regelung einer Feuerungseinrichtung und Feuerungseinrichtung (Elektronischer Verbund I) | |

| DE3888327T2 (de) | Brennstoffbrennereinrichtung und ein Kontrollverfahren. | |

| DE3422866C3 (de) | Verfahren und vorrichtung zur steuerung eines hitzdraht-luftmengenmessers fuer brennkraftmaschinen | |

| WO2006000367A1 (fr) | Procede de reglage du coefficient d'air sur un dispositif de chauffage et dispositif de chauffage | |

| DE19510425C2 (de) | Verfahren und Vorrichtung zur Regelung eines Heizgerätes | |

| EP3824366B1 (fr) | Dispositif de réglage d'un mélange gazeux au moyen d'un capteur de gaz, d'un capteur de gaz combustible et d'un capteur de mélange gazeux | |

| EP3593047B1 (fr) | Procédé d'identification de types de gaz combustibles lors du processus de démarrage d'un appareil de chauffage fonctionnant au gaz combustible et appareil de chauffage fonctionnant au gaz combustible | |

| DE3707258C2 (de) | Brennervorrichtung | |

| EP1236957B1 (fr) | Procédé et dispositif d'adaptation d'un appareil de chauffage à brûleur à un système d'évacuation d'air-de gaz brûlés | |

| EP0505714A2 (fr) | Dispositif de commande pour un brûleur de gaz avec un ventilateur pour l'alimentation d'air de combustion | |

| AT408033B (de) | Verfahren zur anpassung eines brennerbeheizten heizgerätes | |

| DE10140388C2 (de) | Heizgerät für mobile Anwendungen | |

| DE4334625A1 (de) | Verfahren zum Konstanthalten der Leistung eines Wassererwärmers | |

| DE102004055715C5 (de) | Verfahren zur Einstellung von Betriebsparametern an einer Feuerungseinrichtung und Feuerungseinrichtung | |

| EP1333227B1 (fr) | Procédé d'ajustement d'un appareil de chauffage incorporant un brûleur à son système d'échappement et/ou de tirage en air | |

| DE69113959T2 (de) | Trocknungsvorrichtung und ihre Steuervorrichtung für Rotationsdruckmaschine. | |

| DE10144406C1 (de) | Heizgerät, insbesondere Zusatzheizgerät für mobile Anwendungen | |

| DE3419891A1 (de) | Einrichtung zur anpassung eines gasbrenners an unterschiedliche brenngasheizwerte | |

| DE10340194B4 (de) | Verfahren zur Anpassung der Gebläsedrehzahl eines gebläseunterstützten Heizgerätes | |

| EP0158842B1 (fr) | Dispositif de régulation du rapport carburant/air d'une source de chaleur chauffée au carburant | |

| DE102004063992B4 (de) | Verfahren zur Steuerung einer Feuerungseinrichtung und Feuerungseinrichtung | |

| DE60027582T2 (de) | Steuersystem für eine Verbrennugsanlage | |

| DE202004017851U1 (de) | Feuerungseinrichtung | |

| DE202004017850U1 (de) | Feuerungseinrichtung | |

| DE102004030299A1 (de) | Verfahren zur Regelung und Steuerung einer Feuerungseinrichtung und Feuerungseinrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19970611 |

|

| 17Q | First examination report despatched |

Effective date: 19980223 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 19980917 |