EP0670771B1 - Procede de production de briquettes de fer spongieux a partir de fines de minerai - Google Patents

Procede de production de briquettes de fer spongieux a partir de fines de minerai Download PDFInfo

- Publication number

- EP0670771B1 EP0670771B1 EP93920851A EP93920851A EP0670771B1 EP 0670771 B1 EP0670771 B1 EP 0670771B1 EP 93920851 A EP93920851 A EP 93920851A EP 93920851 A EP93920851 A EP 93920851A EP 0670771 B1 EP0670771 B1 EP 0670771B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- returns

- hot

- briquettes

- fine ore

- briquetting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B11/00—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses

- B30B11/16—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses using pocketed rollers, e.g. two co-operating pocketed rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/0005—Details of, or accessories for, presses; Auxiliary measures in connection with pressing for briquetting presses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/30—Feeding material to presses

- B30B15/302—Feeding material in particulate or plastic state to moulding presses

- B30B15/308—Feeding material in particulate or plastic state to moulding presses in a continuous manner, e.g. for roller presses, screw extrusion presses

Definitions

- the invention relates to a method for producing sponge iron briquettes from fine ore, with a maximum grain size of less than 2 mm, preferably less than 0.5 mm, in which hot fine ore is fed to a roller press and briquetted from opposing briquette troughs of the roller press to form sponge iron briquettes and during the briquetting process, compacted ore and dust-like abrasion occur between the webs separating the briquette troughs, which are separated as return material from the sponge iron briquettes and are fed to the fine ore before the briquetting process, the average grain size of the fine ore being smaller than the average particle size of the returned material.

- the prior art has usually established itself to form fine ore into pellets before hot briquetting.

- the briquetting process then produces spongy iron briquettes and return material, the return material being fed back to the pellets above the roller press.

- This object is achieved in that the return material directly after separation from the sponge iron briquettes is fed to a conveyor system and the still hot return material is fed from the conveyor system substantially uniformly and continuously to the hot ore still to be briquetted.

- the invention offers the advantage that the return material stream fed into the fine ore essentially provides a uniform temperature and a uniform proportion of the quantity.

- the fine ore is then coarsened evenly by the continuously fed return material, which benefits the better briquetting.

- the step of pelleting which is usually considered necessary before the fine ore could be processed, can be completely eliminated by the present invention, since the behavior of the fine ore can be influenced by the continuous supply of return material.

- the returned goods can each be returned at a temperature which can be selected in a specific temperature range and which depends on the speed of the transport system. As a result, thermal fluctuations within the material to be processed, which can lead to excessive loading of the roller presses, are avoided in particular. The service life of the roller press is thus noticeably increased by the invention, which ultimately results in lower costs.

- the sponge iron briquettes and the return material fall into a vibration drum or a rotary drum after briquetting in order to essentially completely separate the return material and sponge iron briquettes from one another.

- a vibration drum or a rotary drum Such a procedure is particularly then of advantage if the sponge iron briquettes are pressed with rigid briquette rollers, which allow a relatively thin briquette seam, as a result of which the briquettes and the returned material can be separated from one another by a relatively simple vibration drum or rotary drum.

- the sponge iron briquettes and the return material are conveyed from the vibratory drum or rotary drum onto a vibrating screen which separates the sponge iron briquettes and return material. After the iron sponge briquettes and the return material are detached from one another by the vibration drum or rotary drum, it is relatively simple to separate these two components from one another by means of a simple vibration sieve.

- the fine ore can be processed in a particularly advantageous manner with the roller press if the fine ore and return material are fed to a screw hopper arranged above the briquetting rollers, the screw of which presses the mixed fine ore and return material into the roller gap of the briquetting rollers.

- This process step has the advantage, on the one hand, that the mixed material is heated again by the pre-pressing with the screw, whereby temperature fluctuations between the returned material and fine ore can essentially be compensated for and, on the other hand, such a screw bunker enables the fine ore to move by moving the mixed material calms and can degas. This is important because the fine ore experiences a strong loosening up to fluidization through its transport. Continuously fed and relatively hot return material does its part to calm the fine ore.

- the hot sponge iron briquettes can then be fed to a briquette cooler after separation from the returned material.

- a briquette cooler In order to cool the sponge briquettes as quickly as possible, they can be cooled in a water bath in the briquette cooler. It has been shown that the reoxidation caused by cooling, should be prevented by cooling in a water bath does not differ significantly from cooling in air.

- the return material separated from the sieve preferably has a maximum grain size of approximately 15 mm. This limit value guarantees that excessively coarse return material has no disruptive influence on the briquetting process.

- the fine ore and return material can be pressed by the roller press in such a way that at least pieces of iron sponge briquette are produced.

- the pressing of sponge iron into briquette strands is generally only known when processing piece ore and / or pellets.

- the roller press has a loose and a fixed roller so that the roller gap can adapt to the amount of material fed.

- the proposed invention makes it possible for the first time that the fine ore can also be handled as a briquette strand by the continuously supplied, hot return material. This has the further advantage that such a type of pressing guarantees a longer service life of the roller presses.

- the briquette strand is then preferably divided by a briquette strand divider into individual sponge iron briquettes and return material. The iron sponge briquettes and the return material then fall onto the vibrating sieve.

- the fine ore has a temperature of substantially 650 to 830 ° C. before the briquetting.

- the return material has a temperature of substantially above 300 ° C. when it is fed into the fine ore. Such a temperature can easily be maintained within a hot briquetting system with a continuous conveyor.

- the separation of returned material and the return material conveyance are carried out essentially under an inert gas atmosphere.

- the hot briquetting system has a roller press which comprises a pair of rollers provided with mold cavities, a separating device arranged below the roller press for separating sponge briquettes and return material and a conveyor system for conveying the return material from the separating device to a bunker arranged above the roller press, in which the return material with the hot fine ore is mixed up.

- the hot briquetting system is characterized in that the conveyor system comprises a continuous conveyor for essentially continuously and uniformly returning the returned material in an essentially hot state.

- An upward-directed downpipe for feeding the return material is preferably arranged on the bunker, the upper end of which is assigned to a continuous conveyor, preferably a bucket elevator, which conveys the upward material and empties it into the upper end.

- a continuous conveyor preferably a bucket elevator

- the bunker is a screw bunker, the pre-press screw of which is essentially at the lower end of the screw bunker and above the roller gap of the pair of rollers for pressing in mixed fine ore and Rear goods are arranged in the nip.

- Such screw bunkers have already proven themselves for feeding finely divided starting material into a roll nip.

- the pair of rollers has a loose roller and a fixed roller, the loose roller adapting itself in accordance with the amount of material supplied and the thickness of the briquette seam being adjustable for the preferred production of a briquette strand.

- Such regulation of the roller press is not yet known when processing fine ore. However, it has the great advantage that the roller press has a significantly longer service life.

- a briquette strand divider is arranged below the pair of rollers as part of the separating device, which divides the briquette strand into individual briquettes and return material.

- the pair of rollers has two rigid rollers for producing briquettes with a briquette seam of relatively small thickness.

- This type of control of the roller press has proven itself quite well with finely divided starting material.

- the briquettes are essentially discharged from the roller press individually or as briquette strand pieces, the briquettes of which are very easy to separate from one another. With this type of regulation, the briquettes have a particularly uniform shape.

- a vibration drum or rotary drum is then advantageously arranged below the roller press as a component of the separating device for releasing briquettes and return material into which the briquettes and the return material fall after the briquetting process. The vibratory drum or rotary drum is completely sufficient to separate the briquettes and to separate the briquettes and the returned goods.

- the vibratory drum or rotary drum can continue to be used as a conveyor if the axis of the vibratory drum or rotary drum is slightly inclined towards the horizontal. The briquettes and the returned goods are then conveyed in the direction of inclination.

- the separating device can also be assigned a sieve for separating briquettes and the return material, the sieve preferably having a mesh size of 8 to 15 mm. Due to the mesh size of the sieve, this arrangement can be used to decide where to draw the line between the returned goods and the briquette.

- the sieve can also be used as a conveying means if the sieve is designed as a slightly inclined vibrating sieve which conveys the sponge iron briquettes into a briquette shaft which extends downward from a discharge end of the sieve.

- the shaking movement of the vibrating sieve also ensures that the briquettes and the returned goods are essentially completely separated from one another.

- a vibrating surface can be arranged below the sieve for receiving and for direct transport of the returned goods, the vibrating surface conveying the returned goods into a return goods shaft which extends downward from a discharge end of the vibrating surface and at its lower end a lower area of the continuous conveyor for delivering the Return goods is assigned.

- the return material thus reaches the continuous conveyor from the sieve as quickly as possible. Excessive heat loss is prevented by the rapid forwarding of the returned goods.

- the lower end of the briquette shaft favorably opens into a briquette cooler. The briquette cooler ensures that the briquettes cool down so that they do not disadvantageously reoxidize too much.

- the briquette cooler is designed as a vibration cooler that cools with a water bath and has a water inflow and outflow and a discharge point for the briquettes.

- the water bath quickly cools down the iron sponge briquettes on the one hand and on the other discharged from the vibration cooler for further transport at the same time.

- the briquette cooler is preferably associated with a heat exchanger connected to the water inflow and outflow for cooling the cooling water back.

- This cooling system can save considerable amounts of cooling water, which is extremely important, especially in countries with water shortages.

- the roller press, the separating device, the briquette cooler and the conveyor system are surrounded by a gas-tight housing which has a gas connection for introducing preferably inert gases.

- the bunker can also have a connection for introducing inert gases, as well as a vent valve. The vent valve is used to discharge gas inclusions stored in the fine ore pores.

- the starting product for the present process is finely divided iron sponge 1, which was processed in the fluidized bed and is supplied in reduced form to the hot briquetting system in the hot state.

- the grain size of fine ore 1 is a maximum of 2 mm, but the largest part has a size of less than 0.5 mm.

- the temperature of the fine ore 1 is essentially between 650 and 830 ° C.

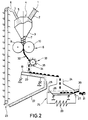

- the fine ore 1 has a bulk density of approx. 2.3 g / cm 3 and is introduced into the hot briquetting system via a feed nozzle 2 which is arranged at an upper end region of a screw bunker 3.

- the fine ore 1 is very loosened up by the transport, which can even lead to fluidization. For this reason, the screw bunker 3 is not completely filled with bulk material, so that gas inclusions in the fine ore 1 escape upwards and can be discharged via a vent valve 4. Furthermore, a down pipe 5 is provided at the upper end region of the screw bunker 3 for feeding back material 6 into the screw bunker 3.

- the backing material 6 is composed of compacted fine ore 1, which has a grain size of less than 15 mm, preferably less than 0.5 mm.

- a pre-press screw 7 is also arranged, which presses mixed back 6 and fine ore 1 into the nip of a roller press 8.

- the worm shaft is driven by a hydraulic drive, not shown, which has a high torque when the worm 7 is clamped and is able to adapt elastically to all fluctuations.

- the screw bunker 3 is made of highly heat-resistant steel and is surrounded by an insulation (not shown) against heat radiation.

- the roller press 8 has a first press roller 9 and a second press roller 10.

- the rollers are equipped with briquette depressions 11 made of segments or with rings.

- a roller body 12 on which the molds are placed is mounted in, preferably spherical roller bearings 13 and provided with a corresponding cooling, not shown.

- the press roll 8 is designed as a rigid roll, as a result of which bearing housings 14 are arranged immovably.

- the second press roll 10 has displaceable bearing housings 15, as a result of which the roll gap between the first and second press rolls 9 and 10 can be adjusted.

- the necessary adjustment path and the necessary contact pressure of the two press rollers 9 and 10 is achieved by hydraulic cylinders 16 which act on the displaceable bearing housing 15.

- the pressure in the hydraulic cylinders 16 is set so that the press roll 10 also becomes a fixed roll.

- the hydraulic pressure goes through the bearing housings 14 and 15 to spacers, not shown.

- Pressure transducers are located in the spacers between the bearing blocks. These first measure the full pressure without material. By introducing mixed fine ore 1 and return material 6, the pressure load cells are now partially relieved. This signal change can then be used to regulate the screw speed.

- Such a control has the advantage that material is pressed by the roller press 8 to sponge iron briquettes 17, which have a relatively small briquette seam thickness, which means that the briquettes 17 are already isolated directly after the briquetting process, or can be separated relatively easily by this small briquette seam thickness .

- the briquettes 17 or briquette strand pieces fall into a funnel-shaped introduction of a vibratory drum 18 or rotary drum which, depending on the design, can rotate about its own axis and a shaking movement executes.

- rollers 9 and 10 of the roller press 8 Since the rollers 9 and 10 of the roller press 8 always have a certain roller gap, material is also pressed through the web areas between the briquette troughs 11, which material is then discharged as fragments from the roller press 8 and is likewise introduced into the vibration drum 18 or rotary drum. These compacted fine ore fragments and any fine ore abrasion are referred to as return material 6 because they are later fed back into the process.

- the return material 6 and the briquettes 17 are now essentially completely separated from one another by the vibration drum 18 or rotary drum. Due to the possibly simultaneous rotational movement, a slight grinding process is also carried out, as a result of which the return material is partially reduced.

- the vibration drum 18 or rotary drum has a slight inclination with respect to the horizontal, so that the return material 6 and the briquettes 17 are conveyed further in the direction of inclination.

- the return material 6 and the briquettes 17 then fall onto a vibrating screen 19, which preferably has a mesh size of 8 to 15 mm. Due to the shaking movement of the vibrating screen 19, which is also slightly inclined, all pieces of return goods that fall below a certain size fall through the screen 19 and reach a vibrating surface 20 which is arranged essentially parallel to the screen 19. If the vibrating screen 19 is chosen long enough , After a certain distance, the entire return goods are separated from the briquettes 17 below a certain size.

- the vibration surface 20 has a discharge end 21, below which there is a downward chute 22.

- the return goods chute 22 picks up the return goods 6 and forwards them to a lower area of a continuous conveyor 23, which immediately picks up the return goods 6 and conveys them upwards.

- the continuous conveyor 23 is preferred trained as bucket elevator. At its upper end, the continuous conveyor 23 delivers the return material 6 to the conveying pipe 5, as a result of which it gets back into the screw bunker 3.

- the temperature loss of the return material 6 is relatively low.

- the entire return period from sieve 19 to screw 7 is approximately only 30 seconds. This means that the existing temperature of the return material 6 when filling the screw bunker is still at least 300 ° C.

- a briquette shaft 24 which is designed as a vibration cooler that cools with a water bath 26.

- the water bath 26 ensures rapid cooling of the briquettes 17 and at the same time prevents their reoxidation in the warm state.

- a water inlet 27 for supplying fresh water for the water bath 26 and a water outlet 28 for discharging from the heated water bath 26 are arranged on the briquette cooler 25.

- the cooling water is transported in a cooling circuit from the water outlet 28 via a heat exchanger 29 to the water inlet 27 and is passed through the cooler 25 within the briquette cooler 25 in counterflow to the transport direction of the briquettes 17.

- the briquettes 17 are cooled from approx. 700 ° C. to approx. 80 ° C.

- the discharge temperature of the briquettes 17 can be varied by regulating the amount of water circulated and the residence time of the briquettes 17 in the water bath 26. If the briquettes 17 are discharged at approximately 80 ° C. at a discharge point 30 of the briquette cooler 25, the residual heat of the briquettes 17 is sufficient to dry the surface of the briquettes 17.

- the vibration cooler 25 is preferably equipped with a controllable drive which enables the dwell time of the briquettes 17 to be set. The briquettes 17 then pass from the discharge point 30 onto a briquette conveyor belt 31.

- Sponge iron has a great tendency to reoxidize, especially when its temperature is still relatively high.

- a certain proportion of fine material passes unpressed the roller press 8.

- the separating device and the space around the continuous conveyor 23 must be kept low in oxygen.

- it is preferably flushed with inert gas or an inert gas atmosphere is created.

- the individual units are equipped with appropriate connections for inert gas.

- the screw bunker 3 and the briquette cooler 25 can each have a connection for inert gas.

- the units have gas-tight housings which are essentially not shown.

- the relatively fine starting material is also particularly taken into account in the roller diameters and in the peripheral speed with which the press rollers 9 and 10 can briquette. Because of the poor intake of fine ore 1, a roll diameter of approximately 1400 mm has proven to be favorable.

- the peripheral speed is a maximum of 0.36 m / s, which corresponds to a speed of 5 revolutions / min. If fine ore 1 is to be processed with a particularly small grain size, there is a need to reduce the roller speed considerably. Therefore, in such systems, the speed is regulated not only according to the desired discharge amount, but also according to the briquetting ability of the fine ore 1. This means that the finer the starting product, the slower the press rolls 1 and 10 must rotate.

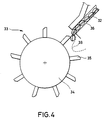

- FIGS. 2 to 4 A second exemplary embodiment of the present invention is explained in more detail below with reference to FIGS. 2 to 4. In the following, only the differences from the above method and the above system will be discussed. The same reference numbers are used for the same and similar components.

- the press rolls 9 and 10 of the roll press 8 are operated with a different control concept.

- the press roll 10 is operated as a loose roll and the press roll 9 as a fixed roll.

- the hydraulic pressure in the hydraulic cylinders 16 is selected so that they shift accordingly at a higher pressure in the nip of the press rolls 9 and 10.

- the loose roller 10 can adapt to the amount of material that is pressed into the nip by the screw 7.

- This operation can be clearly seen in the operation of the roller press 8 from the movement of the bearing housing 15.

- This displacement of the bearing housing 15 serves as an indication of the size of the roll gap, and thus of the seam thickness between the individual briquettes 17.

- the movement of the roll 10 also changes the hydraulic pressure and the torque or the current consumption of the press rolls 9, 10, which also can be used as a control variable.

- the present invention can now also be used to briquette fine ore. This is because due to the more specific coarsening of the briquette material by the return material 6, fluidization of the briquette material in the roller gap is prevented. It is now also possible to produce a briquette strand 32 with fine ore 1 as the starting product. Due to the relatively large roller gap, the individual briquettes now adhere to one another at the briquette seams.

- This strand of briquette must then be divided into individual briquettes 17 and return material 6 by a separating device.

- the separating device is assigned a briquette strand divider 33 which, as can be seen in particular in FIG. 4, comprises a rotor 34 which has rotor blades 35 which protrude radially on its outer casing.

- the peripheral speed of the rotor 34 is adjusted according to the speed of the roller press 8, so that a briquette with a rotor blade 35 is knocked off.

- the briquette strand is guided on a guide rail 36, over the free end of which a hold-down 37 is provided for depressing the briquette strand 32 that bulges out during the knock-off process. Since, as can be seen from FIG.

- the briquette strand 32 is also formed from two adjacent briquettes 17, a nose 38 is also provided, which is shown in broken lines in FIG. 4.

- the nose 38 then cuts through the central web of the briquette strand 32.

- the rotor 34 is preferably shaped accordingly.

- roller press 8 Above the roller press 8 and below the briquette strand divider 33, the system and its mode of operation is the same as that described above.

- the method according to the invention thus also provides the possibility that fine ore can be processed independently of the control concept of the roller press 8. This is particularly the case with the control concept described last positively noticeable in that the service life of the molds with the briquette troughs 11 can be increased significantly. This can also significantly reduce the segment or ring costs in hot briquetting systems for fine ore.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Manufacture Of Iron (AREA)

Abstract

Claims (28)

- Procédé pour la production de briquettes de fer spongieux (17) à partir de fines de minerai (1) d'une granulométrie maximale inférieure à 2 mm, de préférence inférieure à 0,5 mm, dans lequel les fines de minerai chaudes (1) sont alimentées sur une presse à cylindre (8) et transformées par des cavités de briquettes opposées (11) de la presse à cylindre (8) en briquettes de fer spongieux (17) et dans lequel, lors du processus d'agglomération, il est produit entre les nervures séparant les cavités de briquettes (11) des fines de minerai compactées ainsi que des fines de minerai raclées pulvérulentes qui sont séparées comme produit de retour (6) des briquettes de fer spongieux (17) et qui sont retournées aux fines de minerai chaudes (1) avant le processus d'agglomération en briquettes, la granulométrie moyenne des fines de minerai (1) étant plus petite que la taille moyenne de particules du produit de retour (6),

caractérisé en ce que

le produit de retour (6) après la séparation des briquettes de fer spongieux (17) est retourné directement au système de transport (23) et en ce que le produit de retour encore chaud (6) est ramené par le système de transport (23) pour l'essentiel d'une manière régulière et continue aux fines de minerai encore chaudes restant à agglomérer en briquettes. - Procédé selon la revendication 1, caractérisé en ce que les briquettes de fer spongieux (17) et le produit de retour (6) après l'agglomération en briquettes tombent dans un tambour vibrant (18) ou un tambour rotatif pour séparer complètement pour l'essentiel d'une part le produit de retour (6) et les briquettes de fer spongieux (17).

- Procédé selon la revendication 1 ou 2, caractérisé en ce que les briquettes de fer spongieux (17) et le produit de retour (6) sont transportés par le tambour vibrant (18) ou le tambour rotatif sur un crible vibrant (19) qui sépare les briquettes de fer spongieux (17) et le produit de retour (6).

- Procédé selon l'une des revendications 1 à 3, caractérisé en ce que les fines de minerai (1) et le produit de retour (6) sont alimentés sur une trémie à vis (3) disposée au-dessus des cylindres d'agglomération de briquettes (9, 10) dont la vis (7) comprime les fines de minerai mélangées (1) et le produit de retour (6) dans l'emprise des cylindres d'agglomération de briquettes (9, 10).

- Procédé selon l'une des revendications 1 à 4, caractérisé en ce que les briquettes de fer spongieux chaudes (17) sont alimentées après la séparation du produit de retour (6) sur un refroidisseur de briquettes (25).

- Procédé selon l'une des revendications 1 à 5, caractérisé en ce que les briquettes de fer spongieux (17) sont refroidies dans un bain d'eau (26) dans le refroidisseur de briquettes (25).

- Procédé selon l'une des revendications 1 à 6, caractérisé en ce que le produit de retour (6) séparé dans le crible (19) présente une granulométrie maximale d'environ 15 mm.

- Procédé selon l'une des revendications 1 à 7, caractérisé en ce que les fines de minerai (1) et le produit de retour (6) sont comprimés par la presse à cylindre (8) de telle manière qu'il en résulte au moins des morceaux de chapelet de briquettes de fer spongieux.

- Procédé selon l'une des revendications 1 à 8, caractérisé en ce que le chapelet de briquettes (32) est partagé par un dispositif de partage de chapelet de briquettes (33) en briquettes de fer spongieux individuelles (17) et en produit de retour (6) et en ce que les briquettes de fer spongieux (17) et le produit de retour (6) sont ensuite transportés sur le crible vibrant (19).

- Procédé selon l'une des revendications 1 à 9, caractérisé en ce que les fines de minerai (1), avant l'agglomération en briquettes, présentent une température pour l'essentiel de 650 à 830°C.

- Procédé selon l'une des revendications 1 à 10, caractérisé en ce que le produit de retour (6) dans son alimentation sur les fines de minerai (2) présente une température pour l'essentiel au-dessus de 300°C.

- Procédé selon l'une des revendications 1 à 11, caractérisé en ce qu'au moins le processus d'agglomération en briquettes, la séparation du produit de retour et le transport du produit de retour sont exécutés pour l'essentiel sous une atmosphère de gaz inerte.

- Installation d'agglomération en briquettes à chaud pour la fabrication de briquettes de fer spongieux (17) à partir de fines de minerai (1) en particulier d'après un procédé selon les revendications 1 à 12, avec une presse à cylindre (8) qui comporte une paire de cylindres (9, 10) munis de cavités de formage (11) avec un dispositif de séparation disposé sous la presse à cylindre (8) pour la séparation des briquettes de fer spongieux (17) et du produit de retour (6) et avec un système de transport (23) pour le transport du produit de retour (6) depuis le dispositif de séparation jusqu'à une trémie (3) disposée au-dessus de la presse à cylindre (8), dans laquelle le produit de retour (6) est mélangé avec les fines de minerai (1), caractérisé en ce que le système de transport comporte un dispositif de manutention continu (23) pour le retour pour l'essentiel continu et régulier du produit de retour (6) à l'état chaud.

- Installation d'agglomération en briquettes selon la revendication 13, caractérisée en ce qu'une colonne de chute (5) orientée vers le haut est disposée sur la trémie (3) pour l'alimentation du produit de retour (6) dont l'extrémité supérieure est associée à un dispositif de manutention continu (23), de préférence un système à godets, assurant le transport du produit de retour (6) vers le haut et le vidant à l'extrémité supérieure (23).

- Installation d'agglomération de briquettes à chaud selon la revendication 13 ou 14, caractérisée en ce que la trémie (3) est une trémie à vis dont la vis de pré-pressage (7) est disposée pour l'essentiel à l'extrémité inférieure de la trémie à vis (3) et au-dessus de l'emprise de la paire de cylindres (9, 10) pour le pressage de fines de minerai (1) et de produit de retour (6) mélangés dans l'emprise des cylindres.

- Installation d'agglomération de briquettes à chaud selon l'une des revendicationf 13 à 15, caractérisée en ce que la paire de cylindres (9, 10) comporte un cylindre libre (10) et un cylindre fixe (9), le cylindre libre (10) étant adapté à la quantité de matériau alimenté et l'épaisseur du joint de briquette étant réglable pour la production préférée d'un chapelet continu de briquettes (32).

- Installation d'agglomération de briquettes à chaud selon la revendication 16, caractérisée en ce que sous la paire de cylindres (9, 10) est disposé un diviseur de chapelet de briquettes (33) comme partie du dispositif de séparation qui partage le chapelet continu de briquettes (32) en briquettes individuelles (17) et en produit de retour (6).

- Installation d'agglomération de briquettes à chaud selon l'une des revendications 13 à 17, caractérisée en ce que la paire de cylindres (9, 10) présente deux cylindres fixes pour la fabrication de briquettes (17) avec un joint de briquette d'une épaisseur relativement petite.

- Installation d'agglomération de briquettes à chaud selon la revendication 18, caractérisée en ce que sous la presse à cylindre (8) est disposé un tambour vibrant (18) ou un tambour rotatif comme partie du dispositif de séparation pour la séparation des briquettes (17) et du produit de retour (6), dans lequel les briquettes (17) et le produit de retour (6) tombent après le processus d'agglomération des briquettes.

- Installation d'agglomération de briquettes à chaud selon la revendication 19, caractérisée en ce que l'axe du tambour vibrant (18) ou du tambour rotatif présente une légère inclinaison par rapport à l'horizontale pour le transport des briquettes (17) et du produit de retour (6) dans le sens de l'inclinaison.

- Installation d'agglomération de briquettes à chaud selon l'une des revendications 13 à 20, caractérisée en ce que un crible (19) pour la séparation des briquettes (17) et du produit de retour (6) est associé au dispositif de séparation, le crible présentant de préférence une largeur de mailles de 8 à 15 mm.

- Installation d'agglomération de briquettes à chaud selon la revendication 21, caractérisée en ce que le crible (19) est conçu sous la forme d'un crible vibrant légèrement incliné qui transporte les briquettes de fer spongieux (17) dans un puits de briquettes (24) qui s'étend vers le bas en partant de l'extrémité de décharge (21) du crible (19).

- Installation d'agglomération de briquettes à chaud selon la revendication 21 ou 22, caractérisée en ce que sous le crible 19 est disposée une surface vibrante (20) pour la réception et pour la poursuite directe du transport du produit de retour (6), la surface vibrante (20) assurant le transport du produit de retour (6) dans un puits de produit de retour (22) s'étendant vers le bas depuis une extrémité de décharge (21) de la surface de vibration (20), puits qui, à son extrémité inférieure, est asocié à une région inférieure du dispositif de manutention continue (23) pour le dépôt du produit de retour (6).

- Installation d'agglomération de briquettes à chaud selon l'une des revendications 13 à 23, caractérisée en ce que l'extrémité inférieure du puits de briquettes (24) débouche dans un refroidisseur de briquettes (25).

- Installation d'agglomération de briquettes à chaud selon l'une des revendications 14 à 24, caractérisée en ce que le refroidisseur de briquettes (25) est conçu comme un refroidisseur vibrant à refroidissement par bain d'eau (26) qui présente une arrivée d'eau (27), un écoulement d'eau (28) et un emplacement de décharge (30) pour les briquettes (17).

- Installation d'agglomération de briquettes à chaud selon la revendication 25, caractérisée en ce que un échangeur de chaleur (29) relié à l'arrivée d'eau (27) et à l'écoulement d'eau (28) pour le refroidissement de l'eau de refroidissement est associé au refroidisseur de briquettes (25).

- Installation d'agglomération de briquettes à chaud selon l'une des revendications 13 à 26, caractérisée en ce que la presse à cylindre (8), le dispositif de séparation, le refroidisseur de briquettes (25) et le système de transport (23) sont entourés d'une enceinte pour l'essentiel étanche aux gaz qui présente au moins un raccord de gaz pour l'introduction, de préférence, de gaz inertes.

- Installation d'agglomération de briquettes à chaud selon l'une des revendications 13 à 27, caractérisée en ce que la trémie (3) présente un raccord pour l'introduction de gaz inertes ainsi qu'une soupape d'évacuation d'air (4).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP1993/002681 WO1995009079A1 (fr) | 1993-09-30 | 1993-09-30 | Procede de production de briquettes de fer spongieux a partir de fines de minerai |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0670771A1 EP0670771A1 (fr) | 1995-09-13 |

| EP0670771B1 true EP0670771B1 (fr) | 1997-03-19 |

Family

ID=8165770

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93920851A Expired - Lifetime EP0670771B1 (fr) | 1993-09-30 | 1993-09-30 | Procede de production de briquettes de fer spongieux a partir de fines de minerai |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5630202A (fr) |

| EP (1) | EP0670771B1 (fr) |

| AU (1) | AU674615B2 (fr) |

| DE (1) | DE59305903D1 (fr) |

| WO (1) | WO1995009079A1 (fr) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2216326C (fr) * | 1997-10-14 | 2007-09-18 | Companhia Vale Do Rio Doce | Procede de production de boulettes de minerai de fer |

| US6340378B1 (en) * | 1999-08-25 | 2002-01-22 | Kvaerner Metals | Method for screening hot briquetted direct reduced iron |

| AU7646400A (en) | 1999-10-13 | 2001-04-23 | Novo Nordisk A/S | Method for producing an elongated drug formulation |

| GB2367030B (en) * | 2000-09-20 | 2002-12-31 | Reckitt Benckiser Nv | Method and apparatus for manufacturing multi-layer press molded bodies |

| KR100797843B1 (ko) * | 2006-12-27 | 2008-01-24 | 주식회사 포스코 | 괴성체 제조 장치 및 이를 이용한 용철제조장치 |

| DE102013109405A1 (de) * | 2013-08-29 | 2015-03-05 | Rwe Power Ag | Verfahren zur Formung von Formkörpern aus einem granularen Material und entsprechende Walzenpresse |

| DE102014111906A1 (de) * | 2014-08-20 | 2016-02-25 | Maschinenfabrik Köppern Gmbh & Co. Kg | Anlage zum Heißbrikettieren |

| MX2014014746A (es) * | 2014-12-03 | 2015-10-02 | D R &D Labs And Engineering S De R L De C V | Proceso para la obtencion de briquetas a partir de finos de pellet, lodos de dri, finos de dri y polvos de sistemas de desempolvado de dri para su uso industrial en procesos de producción de hierro de reducción directa. |

| US10042613B2 (en) * | 2016-08-19 | 2018-08-07 | International Business Machines Corporation | System, method, and recording medium for validating computer documentation |

| SE545339C2 (en) * | 2021-11-11 | 2023-07-11 | Hybrit Dev Ab | An apparatus for producing hot briquetted iron |

| DE102022101419A1 (de) | 2022-01-21 | 2023-07-27 | Maschinenfabrik Köppern Gmbh & Co. Kg | Vorrichtung zum Zerteilen eines Brikettstrangs |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2799573A (en) * | 1953-04-07 | 1957-07-16 | Monsanto Chemicals | Method of sintering ores |

| DE1758951C3 (de) * | 1968-09-07 | 1978-04-27 | Fried. Krupp Gmbh, 4300 Essen | Verfahren zur Herstellung von Eisenschwamm |

| US3627288A (en) * | 1970-02-24 | 1971-12-14 | Michigan Foundry Supply Appara | Deoiling and briquetting apparatus |

| US3932169A (en) * | 1973-06-28 | 1976-01-13 | United States Steel Corporation | Method of making briquettes with machine having an inert gas seal |

| US4033559A (en) * | 1975-06-05 | 1977-07-05 | Midrex Corporation | Apparatus for continuous passivation of sponge iron material |

| JPS56160900A (en) * | 1980-05-16 | 1981-12-10 | Mitsubishi Heavy Ind Ltd | Briquette machine |

| JPS59153599A (ja) * | 1983-02-22 | 1984-09-01 | Mitsubishi Heavy Ind Ltd | ブリケツトマシン |

| DE3507166A1 (de) * | 1985-03-01 | 1986-09-04 | Dr. Küttner GmbH & Co KG, 4300 Essen | Brikettierung von eisenschwamm |

-

1993

- 1993-09-30 EP EP93920851A patent/EP0670771B1/fr not_active Expired - Lifetime

- 1993-09-30 DE DE59305903T patent/DE59305903D1/de not_active Expired - Fee Related

- 1993-09-30 WO PCT/EP1993/002681 patent/WO1995009079A1/fr active IP Right Grant

- 1993-09-30 US US08/446,707 patent/US5630202A/en not_active Expired - Fee Related

- 1993-09-30 AU AU78023/94A patent/AU674615B2/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| AU674615B2 (en) | 1997-01-02 |

| US5630202A (en) | 1997-05-13 |

| AU7802394A (en) | 1995-04-18 |

| WO1995009079A1 (fr) | 1995-04-06 |

| DE59305903D1 (de) | 1997-04-24 |

| EP0670771A1 (fr) | 1995-09-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69610703T2 (de) | Verfahren und Rollenmühle zum Trocknen und Mahlen von feuchtem Mahlgut | |

| WO1995009080A1 (fr) | Procede de production de briquettes de fer spongieux a partir de fines de minerai | |

| DE102005040519A1 (de) | Verfahren und Vorrichtung zur Vermahlung von heißem und feuchtem Rohmaterial | |

| EP0670771B1 (fr) | Procede de production de briquettes de fer spongieux a partir de fines de minerai | |

| DE8916267U1 (de) | Sichter zum Sichten von körnigem Gut und Mahlanlage mit Einschaltung eines solchen Sichters | |

| DE102007045373A1 (de) | Verfahren und Vorrichtung zur Vor- und Fertigmahlung von mineralischen und nichtmineralischen Materialien | |

| EP1721019B1 (fr) | Procede de fabrication d'un melange brut de frittage | |

| DE7620411U1 (de) | Schneckenfoerderer zur rueckgewinnung feinstverteilter feststoffe aus schlaemmen | |

| DE10141414A1 (de) | Wälzmühle, insbesondere Luftstrom-Wälzmühle, und Verfahren zur Vermahlung von Stoffen mit magnetisierbaren, insbesondere eisenhaltigen Bestandteilen, beispielsweise Schlacken | |

| DE69215751T3 (de) | Vorrichtung und Verfahren zur Zerkleinerung | |

| EP0292739B1 (fr) | Procédé et installation pour le broyage de matière à broyer | |

| DE69807268T2 (de) | Verfahren und Vorrichtung zum Mahlen von Zementklinker mittels einer vertikalen Walzenmühle | |

| EP0447669A1 (fr) | Procédé et dispositif de broyage en deux étapes de matériaux friables | |

| EP0403778B1 (fr) | Procédé d'exploitation d'une installation de broyage pour matériau friable | |

| DE3686720T2 (de) | Schlacken-austragesystem fuer einen vergasungsreaktor fuer feste brennstoffe. | |

| DE3015250C2 (de) | Verfahren und Einrichtung zur Aufbereitung von Mineralfaserschrott unterschiedlicher Beschaffenheit, insbesondere hinsichtlich seiner organischen Bestandteile | |

| DE3024541C2 (de) | Verfahren und Vorrichtung zur Kühlung von heißem, stückigem Material | |

| DE3215140C2 (de) | Verfahren und Vorrichtung zur Herstellung ungebrannter eisenhaltiger Pellets | |

| EP0887106B1 (fr) | Dispositif de broyage en circuit fermé avec une presse à rouleaux à haute pression et un séparateur | |

| EP2241434A2 (fr) | Procédé et installation de fabrication de granulés de bois à partir de biomasse dans une masse à granulés destinés à être utilisés comme matériaux combustibles dans des foyers | |

| DE69332973T2 (de) | Verfahren zur herstellung von gesinterterm erz | |

| DE2046977C3 (de) | Verfahren zum Verdichten und Stückigmachen von feinkörnigen Kohlen ohne zusätzliche Bindemittel | |

| EP1646731B1 (fr) | Procede pour produire du minerai avec des agglomerats verts contenant des fines | |

| DE3123856A1 (de) | Verfahren und vorrichtung zur wiederverwendung der pressmasse aus einer presse kommender ausschussformlinge, insbesondere ausschusssteine | |

| WO2011009636A1 (fr) | Procédé et installation de production à partir de biomasse, dans une presse à granulés, de granulés destinés à être utilisés comme matériau combustible dans des chaudières |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19950517 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19960805 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE |

|

| REF | Corresponds to: |

Ref document number: 59305903 Country of ref document: DE Date of ref document: 19970424 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20031030 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050401 |