EP0668151B1 - Method for manufacturing a tubular container and container obtained by the method - Google Patents

Method for manufacturing a tubular container and container obtained by the method Download PDFInfo

- Publication number

- EP0668151B1 EP0668151B1 EP95810094A EP95810094A EP0668151B1 EP 0668151 B1 EP0668151 B1 EP 0668151B1 EP 95810094 A EP95810094 A EP 95810094A EP 95810094 A EP95810094 A EP 95810094A EP 0668151 B1 EP0668151 B1 EP 0668151B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tubular body

- lid

- package

- cup

- diaphragm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 22

- 238000004519 manufacturing process Methods 0.000 title claims description 16

- 239000000463 material Substances 0.000 claims abstract description 43

- 239000012528 membrane Substances 0.000 claims description 45

- 238000007789 sealing Methods 0.000 claims description 21

- 239000004033 plastic Substances 0.000 claims description 9

- 238000010438 heat treatment Methods 0.000 claims description 7

- 230000002093 peripheral effect Effects 0.000 claims description 7

- 239000000853 adhesive Substances 0.000 claims description 3

- 238000004026 adhesive bonding Methods 0.000 claims description 3

- 230000001070 adhesive effect Effects 0.000 claims description 3

- 239000011324 bead Substances 0.000 claims description 3

- 238000010410 dusting Methods 0.000 claims description 3

- 238000002604 ultrasonography Methods 0.000 claims description 3

- 238000005304 joining Methods 0.000 claims 3

- 238000005096 rolling process Methods 0.000 abstract 1

- 238000004806 packaging method and process Methods 0.000 description 39

- 208000031968 Cadaver Diseases 0.000 description 14

- 230000001681 protective effect Effects 0.000 description 10

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 8

- 229910052782 aluminium Inorganic materials 0.000 description 8

- 239000011111 cardboard Substances 0.000 description 6

- 239000000123 paper Substances 0.000 description 6

- 239000002985 plastic film Substances 0.000 description 6

- 229920006255 plastic film Polymers 0.000 description 6

- 238000009957 hemming Methods 0.000 description 4

- 238000003466 welding Methods 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- 230000007420 reactivation Effects 0.000 description 3

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 210000000056 organ Anatomy 0.000 description 2

- 239000011087 paperboard Substances 0.000 description 2

- 238000004064 recycling Methods 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 239000003292 glue Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000002991 molded plastic Substances 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 239000011253 protective coating Substances 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000005028 tinplate Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D3/00—Rigid or semi-rigid containers having bodies or peripheral walls of curved or partially-curved cross-section made by winding or bending paper without folding along defined lines

- B65D3/26—Opening arrangements or devices incorporated in, or attached to, containers

- B65D3/261—Opening arrangements or devices incorporated in, or attached to, containers the opening arrangement being located in the container side wall

- B65D3/262—Opening arrangements or devices incorporated in, or attached to, containers the opening arrangement being located in the container side wall forming a circumferential line of weakness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2105/00—Rigid or semi-rigid containers made by assembling separate sheets, blanks or webs

- B31B2105/002—Making boxes characterised by the shape of the blanks from which they are formed

- B31B2105/0022—Making boxes from tubular webs or blanks, e.g. with separate bottoms, including tube or bottom forming operations

Definitions

- the present invention relates to a manufacturing process a tubular package having a tubular body made of rigid material, bottom and cover assembled to the body tightly and made of a material identical or similar to said rigid material, a diaphragm or membrane made of identical or similar material being fixed between the product and the cover.

- the invention also relates to a packaging obtained by the implementation of the process.

- the most common composite tubular packaging used includes a body made of rigid material consisting of one or more layers of cardboard, a exterior label and interior complex intended to ensure by its composition, on the one hand, the tightness of the packaging and, on the other hand, the compatiblity of this complex with the packaged product.

- this complex includes a layer of paper, a layer of aluminum and a protective coating allowing a neutral contact between aluminum and product.

- These packaging often have a metallic background which is crimped on the body after filling. Lid often consists of an aluminum membrane ensuring the inviolability of the box and a cover re-entrant or styling plastic allowing, on the one hand, protect the membrane before use and, on the other hand, the filling of the packaging after extraction of the membrane.

- This type of packaging uses several materials to the manufacture of the main body, the bottom, the protective cover and membrane is cost relatively high and poses problems at the level ecological, especially for waste disposal.

- a body forming device we generally report an aluminum membrane with or without a system easy to open, we place on this membrane a molded plastic cover, of a respectable weight for obtain sufficient rigidity. Closing after filling is of the bottom setting type metallic (steel, tinplate or aluminum) which is also produces on heavy machinery and complex. So you get solid packaging but expensive and making recycling almost impossible because of the different materials composing it.

- Documents DE-A-27 18 574 and FR-A-1 565 609 describe methods of making packaging in cardboard or the like, the lids and bottoms being fixed by gluing, or even by stapling.

- the object of the present invention is to overcome the disadvantages mentioned above by proposing a method of manufacturing of economical and ecological packaging easy to recycle and capable of packaging a very large number of food, chemical, industrial, etc.

- the assembly of the cover and the bottom and any diaphragms or protective membranes on the inner surface of the body tubular is done by gluing by depositing before introduction of these elements a bead of adhesive and subsequently introducing these elements and clamping the body periphery on a tampon and possibly heating depending on the glue chosen

- This procedure allows, on the one hand, to ensure the tightness of the packaging and, on the other hand, to be economical in manufacturing since it is operations that can be done very quickly and simply.

- the internal face of the tube of the tubular body fitted or not of an internal complex is coated with a plastic film sealing which allows an assembly by soldering of the cover and the bottom and as well as any protective membranes by reactivating said film either by conduction heating, or by high frequency either by ultrasound or any other means and in also applying compression.

- the diaphragm or membrane of protection located near the cover also includes a sealing plastic film only on its side face product to prevent it from sticking to the lid while the possible membrane located on the side of the bottom of the package includes a sealing film on its two faces.

- the compression and the reactivation of the sealing plastic film is performed with regard to the assembly of the cover and diaphragm or membrane in two zones spaced in the direction axial to avoid adhesion of the protective membrane on the lid bowl. Besides, the pre-cutting which follows the assembly is done between these two assembly areas.

- the invention also relates to a packaging obtained in means of the method according to the invention.

- the internal complex can be constituted only from a compatible sheet of paper or similar with the product to be packaged or contain a sheet of paper and a thin sheet of aluminum. Even in the latter case, recycling is made more easier than before since the amount of aluminum is weak compared to the rest of the packaging and the sheet of paper and cardboard can be recycled together. However, the use of aluminum will reserved for products for which it is absolutely essential. It should also be noted that the sealing film can easily be recycled with the rest of packaging made of paper and cardboard.

- tubular body of the package whose section can be both tubular and polygonal, may have an external label or of a printed layer, the same label or layer can also on the outside of the cover or even from the bottom.

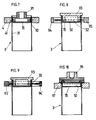

- FIG 1 we have shown a tubular packaging 1 having a tubular body 10 of section rectangular made of rigid material 11 closed by a diaphragm or a protective membrane 12 provided with a tab opening 13 integrated or welded to the membrane 12 and a hinged lid comprising a bowl 14 made of a rigid material at least similar to that of the tubular body 10 and of an entourage 15 coming from the tubular body 10 by precut and hem as will see it later.

- the bottom of the packaging which is not visible in Figure 1, also present a bowl similar to bowl 14 assembled on the internal face of the body 10 the lower end of the body 10 also being folded (hemmed).

- Figure 1A shows a partial view of a package including the same elements as the packaging of Figure 1, the only difference being that it is of circular section.

- the same reference numbers with an accent (') denote the same elements.

- FIG 2 we have shown a package 2 of circular section comprising a tubular body 20 also made of a rigid material such as cardboard, closed by a cover 21 comprising a bowl 22 formed by stamping at least similar material to that of the tubular body 20, an entourage 23 obtained by folding (hemming) the upper part of the tubular body 20 and precut 25.

- a cover 21 comprising a bowl 22 formed by stamping at least similar material to that of the tubular body 20, an entourage 23 obtained by folding (hemming) the upper part of the tubular body 20 and precut 25.

- there are 24 discontinuity points in the pre-cut 25 of the lateral surface of the main body 20 which ensure the apparent inviolability of the packaging.

- we can obtain the spacing of the cover 21 of the packaging which is preferably fitted with a diaphragm or a protective membrane similar to that of figure 1.

- the bottom of the package not shown in Figure 2 is obtained from similar to that in Figure 1.

- FIG. 3 we have shown a tubular body 3 made of a rigid material 30 and coated on its surface interior of a complex 31 consisting of at least one sealing plastic film.

- the tubular body 30 is manufactured using known methods and means not being the subject of the present invention. It is held around and near one of its ends by two jaws 4 ensuring the holding and centering of the body 3 while a piece 5 cut from a coil of a material at least similar to the rigid material 30 is placed on a die 6.

- Another part 7 made thinner material such as cut paper also in a reel is provided with a tear-off tab 72 glued or welded or coming from a part with element 7, is arranged above a second matrix 8.

- a male drawing member 9 provided possibly a heating means we proceed to the successive stamping of the part 5 to form a bowl 50 (FIG. 4) and of part 7 while crossing the matrix 8 to form a second bowl 70 (figure 5) and we just place these two superimposed bowls 50, 70 inside the body 3 facing the jaws 4 (figure 6).

- the dimensions pieces 5 and 7 are chosen so that the lateral surface 51 of the bowl 50 formed by the part 5 is higher than the lateral surface 71 of the bowl 70 formed by part 7. This characteristic facilitates as we will see later the separation between the cover and the protective membrane.

- the die 4 is provided with a groove 41 and the buffer 91 of a groove 92 intended to prevent the pressure is exerted along these grooves on the surfaces in contact and also prevent the film 31 bottom in this place to avoid possible assembly from bowl 70 to bowl 50. It should be noted that the assembly of the bowl 50 on the internal wall of the body is preferably done along the third superior of its lateral surface to avoid in particular the welding of the two bowls 50 and 70 between them and make pre-cutting easier.

- the part 7 is provided on its inner surface also wrapped in film sealing plastic which allows during reactivation to obtain an assembly and sealing of better quality between part 70 and the internal surface of the tubular body 3.

- this precut is also done with certain discontinuities ensuring inviolability of the box and to prevent inadvertent opening of the cover.

- this grooving can be avoided, the hinge is formed during the opening of the box, for example for the packaging of Figure 1A.

- Figure 9 we proceed by means of an organ 94 'similar to member 94 when creating a groove 33 on the tubular body 3 intended to act as hinge for the cover.

- organ 94 similar to member 94 when creating a groove 33 on the tubular body 3 intended to act as hinge for the cover.

- the hinge is formed during the first opening of the box and grooving is not necessary.

- the packaging may have a bottom which is assembled to the body by other means.

- FIG 11 we presented a sectional packaging showing in detail the different elements of the packaging constructed according to the method of the present invention.

- the tubular body 3 having a rigid body 30, an interior complex 31 with a sealing film, the diaphragm or the protective membrane of the bowl 70 with the tear-off tab 72, welded by its lateral surface 71 on the internal face of the body tubular 3 while the lateral surface 51 of the bowl 50 of rigid material is welded along the part exceeding the lateral surface of the bowl 70 also on the inner surface of the body 3.

- the part upper body 3 is folded inwards forming a hem 35 constituting after the precut along line 32, the packaging lid.

- the grooving 33 intended to form the opening hinge here being a packaging hinged.

- the lower part of the box includes a bowl 50 ', made of rigid material at least similar to that of the bowl 50 and a bowl 70 'forming the diaphragm or membrane of protection similar to bowl 70 except that this bowl 70 'has the same dimensions as the bowl 50 'and are formed simultaneously before introduction in the body.

- the tongue 13, or 72 when the tongue 13, or 72 is integrated into part 7, its side folded towards the cover is lined with paper to prevent the tab adheres during the welding operation to the cover and that it has a sealing film on a single side. 35 'hem also provides finishing of the packaging. To avoid laying a covering paper, the tongue may be longer and will be folded in on itself to prevent adhesion of the coated side of the film on the cover.

- the manufacturing process is the same, except that the bowl diaphragm or membrane is perforated and made of a material more rigid.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

- Closures For Containers (AREA)

- Packging For Living Organisms, Food Or Medicinal Products That Are Sensitive To Environmental Conditiond (AREA)

- Making Paper Articles (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

Abstract

Description

La présente invention concerne un procédé de fabrication d'un emballage tubulaire présentant un corps tubulaire fait d'un matériau rigide, un fond et un couvercle assemblés au corps de manière étanche et faits d'un matériau identique ou similaire audit matériau rigide, un diaphragme ou membrane fait d'un matériau identique ou similaire étant fixé entre le produit et le couvercle.The present invention relates to a manufacturing process a tubular package having a tubular body made of rigid material, bottom and cover assembled to the body tightly and made of a material identical or similar to said rigid material, a diaphragm or membrane made of identical or similar material being fixed between the product and the cover.

L'invention concerne également un emballage obtenu par la mise en oeuvre du procédé.The invention also relates to a packaging obtained by the implementation of the process.

Actuellement les produits de grande consommation concernant notamment le domaine alimentaire et chimique sont conditionnés dans des emballages constitués d'une pluralité de matériaux et de composants.Currently consumer products concerning especially food and chemical are packaged in packages consisting of plurality of materials and components.

L'emballage tubulaire composite le plus fréquemment utilisé comprend un corps formé d'un matériau rigide constitué d'une ou plusieurs couches de carton, d'une étiquette extérieure et d'un complexe intérieur destiné à assurer par sa composition, d'une part, l'étanchéité de l'emballage et, d'autre part, la compatiblité de ce complexe avec le produit conditionné. Très souvent ce complexe comprend une couche de papier, une couche d'aluminium et un revêtement de protection permettant un contact neutre entre l'aluminium et le produit. Ces emballages possèdent souvent un fond métallique qui est serti sur le corps après le remplissage. Le couvercle est constitué souvent d'une membrane d'aluminium assurant l'inviolabilité de la boíte et d'un couvercle en plastique rentrant ou coiffant permettant, d'une part, d'assurer la protection de la membrane avant l'utilisation et, d'autre part, le rebouchage de l'emballage après l'extraction de la membrane. The most common composite tubular packaging used includes a body made of rigid material consisting of one or more layers of cardboard, a exterior label and interior complex intended to ensure by its composition, on the one hand, the tightness of the packaging and, on the other hand, the compatiblity of this complex with the packaged product. Very often this complex includes a layer of paper, a layer of aluminum and a protective coating allowing a neutral contact between aluminum and product. These packaging often have a metallic background which is crimped on the body after filling. Lid often consists of an aluminum membrane ensuring the inviolability of the box and a cover re-entrant or styling plastic allowing, on the one hand, protect the membrane before use and, on the other hand, the filling of the packaging after extraction of the membrane.

Ce type d'emballage utilisant plusieurs matériaux pour la fabrication du corps principal, du fond, du couvercle et de la membrane de protection est d'un coût relativement élevé et pose des problèmes au niveau écologique, notamment pour l'élimination des déchets. En effet, pour fabriquer ces emballages on utilise un dispositif de formage du corps, on rapporte en général une membrane en aluminium pourvue ou non d'un système d'ouverture facile, on place sur cette membrane un couvercle plastique moulé, d'un poids respectable pour obtenir une rigidité suffisante. La fermeture après remplissage est du type à sertissage d'un fond métallique (acier, fer blanc ou aluminium) qui est produit également sur des machines lourdes et complexes. Ainsi, on obtient un emballage solide mais coûteux et rendant quasi impossible son recyclage à cause des différents matériaux le composant.This type of packaging uses several materials to the manufacture of the main body, the bottom, the protective cover and membrane is cost relatively high and poses problems at the level ecological, especially for waste disposal. In fact, to manufacture these packages, a body forming device, we generally report an aluminum membrane with or without a system easy to open, we place on this membrane a molded plastic cover, of a respectable weight for obtain sufficient rigidity. Closing after filling is of the bottom setting type metallic (steel, tinplate or aluminum) which is also produces on heavy machinery and complex. So you get solid packaging but expensive and making recycling almost impossible because of the different materials composing it.

Les documents DE-A-27 18 574 et FR-A-1 565 609 décrivent des procédés de fabrication d'emballages en carton ou similaire, les couvercles et les fonds étant fixés par collage, voire par agrafage.Documents DE-A-27 18 574 and FR-A-1 565 609 describe methods of making packaging in cardboard or the like, the lids and bottoms being fixed by gluing, or even by stapling.

La présente invention a pour but de pallier les inconvénients susmentionnés en proposant un procédé de fabrication d'un emballage économique et écologique facile à recycler et capable de conditionner un très grand nombre de produits alimentaires, chimiques, industriels, etc. The object of the present invention is to overcome the disadvantages mentioned above by proposing a method of manufacturing of economical and ecological packaging easy to recycle and capable of packaging a very large number of food, chemical, industrial, etc.

Le procédé selon l'invention est caractérisé en ce

qu'après le formage du corps tubulaire, on procède

selon les étapes suivantes :

Les avantages du procédé selon l'invention sont les

suivants :

L'avantage de cette d'exécution est le fait que le diaphragme ou membrane, quelque soit sa fonction, est situé juste à la suite du couvercle et il est réalisé, en ce qui concerne son formage, pratiquement simultanément avec la cuvette du couvercle et que sa fixation se fait également en même temps que celle de la cuvette du couvercle ce qui élimine une opération supplémentaire, puisque actuellement un tel diaphragme ou membrane est d'abord fixé et par la suite on met en place le couvercle plastique.The advantage of this execution is the fact that the diaphragm or membrane, whatever its function, is located just at the continuation of the cover and it is made, as far as its formation, practically simultaneously with the cover bowl and that it is also fixed together with that of the lid bowl which eliminates an additional operation, since currently such a diaphragm or membrane is first fixed and by next we put in place the plastic cover.

Selon une autre variante du procédé selon l'invention l'assemblage du couvercle et du fond et des éventuel diaphragmes ou membranes de protection sur la surface interne du corps tubulaire se fait par collage en déposant avant l'introduction de ces éléments un cordon d'adhésif et en procédant par la suite à l'introduction de ces éléments et le serrage de la périphérie de corps sur un tampon et éventuellement au chauffage en fonction de la colle choisieAccording to another variant of the method according to the invention the assembly of the cover and the bottom and any diaphragms or protective membranes on the inner surface of the body tubular is done by gluing by depositing before introduction of these elements a bead of adhesive and subsequently introducing these elements and clamping the body periphery on a tampon and possibly heating depending on the glue chosen

Cette manière de procéder permet, d'une part, d'assurer l'étanchéité de l'emballage et, d'autre part, d'être économique au niveau de la fabrication puisqu'il s'agit d'opérations qui peuvent se faire très rapidement et simplement.This procedure allows, on the one hand, to ensure the tightness of the packaging and, on the other hand, to be economical in manufacturing since it is operations that can be done very quickly and simply.

Selon une autre variante d'exécution de l'invention, la face interne du tube du corps tubulaire munie ou pas d'un complexe interne, est revêtue d'un film plastique de scellage ce qui permet d'obtenir un assemblage par soudure du couvercle et du fond et ainsi que des éventuelles membranes de protection en réactivant ledit film soit par chauffage par conduction, ou par haute fréquence, soit par ultrasons ou tout autre moyen et en appliquant également une compression. According to another variant of the invention, the internal face of the tube of the tubular body fitted or not of an internal complex, is coated with a plastic film sealing which allows an assembly by soldering of the cover and the bottom and as well as any protective membranes by reactivating said film either by conduction heating, or by high frequency either by ultrasound or any other means and in also applying compression.

Selon d'autres variantes d'exécution le diaphragme ou membrane de protection situé près du couvercle comprend également un film plastique de scellage seulement sur sa face côté produit afin d'éviter qu'il adhère sur le couvercle tandis que l'éventuelle membrane se trouvant du côté du fond de l'emballage comprend un film de scellage sur ses deux faces.According to other variant embodiments, the diaphragm or membrane of protection located near the cover also includes a sealing plastic film only on its side face product to prevent it from sticking to the lid while the possible membrane located on the side of the bottom of the package includes a sealing film on its two faces.

Selon une variante d'exécution préférée, la compression et la réactivation du film plastique de scellage est réalisée en ce qui concerne l'assemblage du couvercle et du diaphragme ou membrane selon deux zones espacées dans le sens axial afin d'éviter l'adhésion de la membrane de protection sur la cuvette du couvercle. D'ailleurs, le prédécoupage qui suit l'assemblage se fait entre ces deux zones d'assemblage.According to a preferred embodiment, the compression and the reactivation of the sealing plastic film is performed with regard to the assembly of the cover and diaphragm or membrane in two zones spaced in the direction axial to avoid adhesion of the protective membrane on the lid bowl. Besides, the pre-cutting which follows the assembly is done between these two assembly areas.

L'invention concerne également un emballage obtenu au moyen du procédé selon l'invention.The invention also relates to a packaging obtained in means of the method according to the invention.

Dans certains cas le complexe interne peut être constitué seulement d'une feuille de papier ou similaire compatible avec le produit à conditionner soit contenir une feuille de papier et une mince feuille d'aluminium. Même dans ce dernier cas, le recyclage est rendu plus facile qu'auparavant puisque la quantité d'aluminium est faible par rapport au reste de l'emballage et la feuille de papier et le carton peuvent être recyclés ensemble. Néanmoins, l'utilisation de l'aluminium sera réservé aux produits pour lesquels elle s'avère absolument indispensable. Il est également à relever que le film de scellage peut facilement être recyclé avec le reste de l'emballage fait en papier et en carton. In some cases the internal complex can be constituted only from a compatible sheet of paper or similar with the product to be packaged or contain a sheet of paper and a thin sheet of aluminum. Even in the latter case, recycling is made more easier than before since the amount of aluminum is weak compared to the rest of the packaging and the sheet of paper and cardboard can be recycled together. However, the use of aluminum will reserved for products for which it is absolutely essential. It should also be noted that the sealing film can easily be recycled with the rest of packaging made of paper and cardboard.

Il est évident que si le corps tubulaire de l'emballage, dont la section peut être aussi bien tubulaire que polygonale, peut être muni d'une étiquette externe ou d'une couche imprimée, la même étiquette ou couche peut également se trouver sur la face extérieure du couvercle voire même du fond.Obviously if the tubular body of the package, whose section can be both tubular and polygonal, may have an external label or of a printed layer, the same label or layer can also on the outside of the cover or even from the bottom.

L'invention sera décrite plus en détail à l'aide du

dessin annexé.

Nous allons décrire maintenant le prodécé de fabrication d'un emballage tubulaire selon l'invention comprenant un diaphragme à l'aide du dessin annexé.We will now describe the manufacturing process a tubular packaging according to the invention comprising a diaphragm using the attached drawing.

A la figure 1 nous avons représenté un emballage tubulaire

1 présentant un corps tubulaire 10 de section

rectangulaire fait d'un matériau rigide 11 fermé par un

diaphragme ou une membrane de protection 12 muni d'une languette

d'ouverture 13 intégrée ou soudée sur la membrane 12 et

d'un couvercle à charnière comprenant une cuvette 14

faite d'un matériau rigide au moins similaire à celui

du corps tubulaire 10 et d'un entourage 15 venant du

corps tubulaire 10 par prédécoupage et ourlage comme on

le verra par la suite. Le fond de l'emballage, qui

n'est pas visible sur la figure 1, présente également

une cuvette similaire à la cuvette 14 assemblée sur la

face interne du corps 10 l'extrémité inférieure du

corps 10 étant également repliée (ourlée).In Figure 1 we have shown a

La figure 1A représente une vue partielle d'un emballage comprenant les mêmes éléments que l'emballage de la figure 1, la seule différence étant le fait qu'il est de section circulaire. Les mêmes références numériques avec un accent (') désignent les mêmes éléments. Figure 1A shows a partial view of a package including the same elements as the packaging of Figure 1, the only difference being that it is of circular section. The same reference numbers with an accent (') denote the same elements.

A la figure 2 nous avons représenté un emballage 2 de

section circulaire comprenant un corps tubulaire 20

fait également d'un matériau rigide tel que du carton,

fermé par un couvercle 21 comprenant une cuvette 22

formée par emboutissage d'un matériau au moins similaire

à celui du corps tubulaire 20, un entourage 23 obtenu

par pliage (ourlage) de la partie supérieure du

corps tubulaire 20 et prédécoupage 25. Sur la figure 2

on distingue les points de discontinuité 24 dans le

prédécoupage 25 de la surface latérale du corps principal

20 qui assurent l'inviolabilité apparente de l'emballage.

En rompant ces points de discontinuité, on

peut obtenir l'écartement du couvercle 21 de l'emballage

qui est de préférence muni d'un diaphragme ou une membrane de protection

similaire à celle de la figure 1. Le fond de l'emballage

non représenté sur la figure 2 est obtenu de

manière similaire à celui de la figure 1.In Figure 2 we have shown a package 2 of

circular section comprising a

Ces deux formes d'emballage ne sont pas limitatives, néanmoins ce sont les formes que l'on trouve le plus souvent dans le commerce.These two forms of packaging are not limiting, nevertheless these are the forms that are found the most often in trade.

A la figure 3 nous avons représenté un corps tubulaire

3 fait d'un matériau rigide 30 et revêtu sur sa surface

intérieure d'un complexe 31 consituté d'au moins un

film plastique de scellage. Le corps tubulaire 30 est

fabriqué en utilisant des procédés et des moyens connus

ne faisant pas l'objet de la présente invention. Il est

tenu autour et à proximité d'une de ses extrémités par

deux mâchoires 4 assurant la tenue et le centrage du

corps 3 tandis qu'une pièce 5 découpée dans une bobine

d'un matériau au moins similaire au matériau rigide 30

est disposée sur une matrice 6. Une autre pièce 7 faite

d'un matériau plus fin tel que du papier découpée également

dans une bobine est munie d'une languette d'arrachage

72 collée ou soudée ou venant d'une pièce avec

l'élément 7, est disposée au-dessus d'une deuxième matrice

8. Au moyen d'un organe mâle d'emboutissage 9 muni

éventuellement d'un moyen de chauffage on procéde à

l'emboutissage successif de la pièce 5 pour former une

cuvette 50 (figure 4) et de la pièce 7 en traversant la

matrice 8 pour former une deuxième cuvette 70 (figure

5) et on vient placer ces deux cuvettes 50, 70 superposées

à l'intérieur du corps 3 face aux mâchoires 4 (figure

6).In Figure 3 we have shown a

Il est important de relever à ce stade que les dimensions

des pièces 5 et 7 sont choisies de sorte que la

surface latérale 51 de la cuvette 50 formée par la pièce

5 est plus haute que la surface latérale 71 de la

cuvette 70 formée par la pièce 7. Cette caractéristique

facilite comme on le verra par la suite la séparation

entre le couvercle et la membrane de protection.It is important to note at this stage that the

Par la suite on procède à l'assemblage des deux cuvettes

50, 70 sur la surface latérale interne du corps 3

(figure 7) au moyen d'un tampon 91 contre lequel les

mâchoires 4 serrent l'ensemble corps tubulaire 3 et cuvettes

50, 70 et en réactivant le film plastique de

scellage soit par chauffage par convection soit par

chauffage à haute fréquence soit par ultrasons ou tout

autre moyen connu. Pendant cette période de réactivation,

le film plastique 31 fond ce qui permet la soudure

de la surface latérale de la cuvette 50 sur la

surface latérale interne du corps 3 ainsi que la soudure

de la surface latérale 71 de la cuvette 70 sur la

surface interne du corps 3. Il est important de souligner

que la matrice 4 est munie d'une gorge 41 et le

tampon 91 d'une gorge 92 ayant pour but d'éviter que la

pression soit exercée le long de ces gorges sur les

surfaces en contact et empêcher également que le film

31 fond à cet endroit afin d'éviter l'éventuel assemblage

de la cuvette 70 sur la cuvette 50. Il est à noter

que l'assemblage de la cuvette 50 sur la paroi interne

du corps se fait de préférence le long du tiers

supérieur de sa surface latérale pour éviter notamment

la soudure des deux cuvettes 50 et 70 entre-elles et

rendre plus facile le prédécoupage.Then we proceed to the assembly of the two

Selon une variante préférée, la pièce 7 est munie sur

sa surface intérieure à l'emballage également d'un film

plastique de scellage ce qui permet lors de la réactivation

d'obtenir un assemblage et une étanchéité de

meilleure qualité entre la pièce 70 et la surface interne

du corps tubulaire 3.According to a preferred variant, the

Après l'opération d'assemblage des deux cuvettes 70 et

50 sur la face interne du corps 3 on doit procéder au

prédécoupage de la surface latérale du corps 3 selon

une ligne périphérique 32 (figure 8) située à l'emplacement

des deux gorges 41 et 92 citées précédemment.

Pour cela on utilise, d'une part, un tampon interne 93

ayant la forme et les dimensions de la cuvette 50 et,

d'autre part, un couteau 94. Néanmoins, le prédécoupage

n'est pas réalisé sur la totalité de cette ligne lorsqu'il

s'agit d'un couvercle à charnière, l'ensemble 95

assurant la tenue de l'ensemble.After the assembly operation of the two

Il est évident que ce prédécoupage est fait également avec certaines discontinuités assurant l'inviolabilité de la boíte et pour empêcher l'ouverture intempestive du couvercle. En fonction du matériau rigide utilisé, on peut éviter ce rainurage, la charnière se forme lors de l'ouverture de la boíte, comme par exemple pour l'emballage de la figure 1A. It is obvious that this precut is also done with certain discontinuities ensuring inviolability of the box and to prevent inadvertent opening of the cover. Depending on the rigid material used, this grooving can be avoided, the hinge is formed during the opening of the box, for example for the packaging of Figure 1A.

Par la suite (figure 9) on procède au moyen d'un organe

94' similaire à l'organe 94 à la création d'une rainure

33 sur le corps tubulaire 3 destiné à faire office de

charnière pour le couvercle. En fonction du matériau

rigide utilisé on peut éviter le rainurage, la charnière

se forme lors de la première ouverture de la boíte

et un rainurage n'est pas nécessaire.Thereafter (Figure 9) we proceed by means of an organ

94 'similar to

A l'étape suivante, on procède au moyen d'un organe 96

au repliage de l'extrémité supérieure du corps tubulaire

3, cette opération étant appelée communément ourlage.

L'organe 96 est également de préférence chauffé pour

assurer une bonne qualité de l'ourlage. Le corps 3 est

maintenu en place par des mâchoires 97. A la suite de

cette opération le couvercle de l'emballage est formé

par la cuvette 50 fixée par soudure contre la face interne

du tube 3 par la partie repliée, tandis que la

cuvette 70 fixée de manière indépendante sur la face

intérieure du corps tubulaire 3 forme le diaphragme ou la membrane de

protection. En cassant les points de discontinuité, on

peut ouvrir le couvercle et obtenir une situation comme

celle de la figure 1, ou s'il s'agit d'un couvercle

sans charnière obtenir la situation de la figure 2.In the next step, we proceed by means of an

Après avoir terminé l'une des extrémités de l'emballage, on procède sur place ou à un autre endroit au remplissage avec le produit à conditionner de la boíte à travers l'autre extrémité, donc en retournant la boíte. Par la suite on procède à la mise en place du fond de l'emballage en répétant les opérations des figures 3, 4, 5 et 6 sauf que le fond peut être fixé directement sans cuvette correspondant à la cuvette 70 lorsque le matériau du fond est compatible avec le produit à conditionner. Dans le cas où une cuvette de protection est nécessaire pour assurer l'étanchéité et la compatibilité avec le produit à conditionner la pièce qui formera la cuvette est munie d'un film de scellage sur ses deux faces afin de permettre d'assurer son adhésion aussi bien contre la face latérale de la cuvette du fond et de la face interne du corps 3 (voir figure 11). Dans ce cas les deux cuvettes celle en matériau rigide et celle munie avec le film de scellage ont exactement les mêmes dimensions.After you finish one end of the package, filling is carried out on site or at another location with the product to be packaged from the box through the other end, so turning the box over. Thereafter we proceed to the establishment of the bottom of the packaging by repeating the operations of FIGS. 3, 4, 5 and 6 except that the bottom can be attached directly without bowl corresponding to bowl 70 when the bottom material is compatible with the product to be packaged. In the event that a protective bowl is necessary to ensure watertightness and compatibility with the product to be packaged the part which will form the bowl has a sealing film on both faces in order to ensure its adhesion also well against the side face of the bottom bowl and of the internal face of the body 3 (see Figure 11). In this case the two bowls the one in rigid material and the one fitted with the sealing film have exactly the same dimensions.

L'emballage peut avoir un fond qui est assemblé au corps par d'autres moyens.The packaging may have a bottom which is assembled to the body by other means.

Dans le cas de l'assemblage de différentes cuvettes sur

la face interne du corps tubulaire 3 par collage, on

procède avant l'introduction de cuvettes dans le corps

à la mise en place d'un cordon adhésif qui est laminé

lors de l'introduction de cuvettes et assure l'adhésion

des cuvettes respectives par pression et éventuellement

chauffage. Dans ce cas il est entendu que le diaphragme ou la membrane

de protection peut adhérer par le bord supérieur de sa

surface latérale 71 sur la cuvette 50 formant le couvercle

et dans ce cas le prédécoupage doit être fait

avec plus de précision afin d'obtenir la séparation de

la partie collée contre la surface 51 la cuvette 50

pour éviter lors de l'ouverture de l'emballage que la

membrane de protection soit déchirée.In the case of the assembly of different bowls on

the inner face of the

A la figure 11 nous avons présenté un emballage en coupe

montrant en détail les différents éléments de l'emballage

construit selon le procédé de la présente invention.

Ainsi, nous retrouvons le corps tubulaire 3

présentant un corps rigide 30, un complexe intérieur 31

avec un film de scellage, le diaphragme ou la membrane de protection de

la cuvette 70 avec la languette d'arrachage 72, soudée

par sa surface latérale 71 sur la face interne du corps

tubulaire 3 tandis que la surface latérale 51 de la cuvette

50 en matériau rigide est soudée le long de la

partie dépassant la surface latérale de la cuvette 70

également sur la surface intérieure du corps 3. La partie

supérieure du corps 3 est repliée vers l'intérieur

formant un ourlage 35 constituant après le prédécoupage

selon la ligne 32, le couvercle de l'emballage. On distingue

sur cette figure le rainurage 33 destiné à former

la charnière d'ouverture s'agissant ici d'un emballage

à charnière.In figure 11 we presented a sectional packaging

showing in detail the different elements of the packaging

constructed according to the method of the present invention.

So, we find the

La partie inférieure de la boíte comprend une cuvette

50', en matériau rigide au moins similaire à celui de

la cuvette 50 et une cuvette 70' formant le diaphragme ou membrane de

protection similaire à la cuvette 70 à l'exception que

cette cuvette 70' a les mêmes dimensions que la cuvette

50' et sont formées simultanément avant introduction

dans le corps.The lower part of the box includes a bowl

50 ', made of rigid material at least similar to that of

the

Il est à noter que lorsque la languette 13, ou 72 est

intégrée à la pièce 7, sa face repliée vers le couvercle

est revêtie d'un papier pour éviter que la languette

adhère lors de l'opération de soudure au couvercle

et qu'elle est munie d'un film de scellage sur une

seule face. Un ourlage 35' assure également la finition

de l'emballage. Pour éviter la pose d'un papier de revêtement,

la languette peut être plus longue et sera

repliée sur elle-même pour empêcher l'adhésion de la

face enduite du film au couvercle.It should be noted that when the

Si le diaphragme ou membrane est un opercule perforé pour permettre le poudrage avec le produit contenu dans l'emballage, le procédé de fabrication est le même, sauf que la cuvette du diaphragme ou membrane est perforée et est fait d'un matériau plus rigide.If the diaphragm or membrane is a perforated seal to allow dusting with the product contained in the packaging, the manufacturing process is the same, except that the bowl diaphragm or membrane is perforated and made of a material more rigid.

Claims (13)

- A process for manufacturing a tubular package having a tubular body made of a rigid material, and joined to the body, in an impermeable manner, are a bottom and a lid which are made of a material which is identical or similar to said rigid material, a diaphragm or membrane made of an identical or similar material being attached between the product and the lid, wherein after forming the body, the following steps are carried out :a) a first cup, which is the lid cup, is formed from a piece, cut out from a reel of a rigid material, by drawing by means of a male forming tool and an external die,b) a second piece, cut out from a reel, is formed by drawing by means of the drawing tool for the lid cup and a second external die located on the path of said drawing tool between the external die used for drawing the lid cup and the tubular body, thus forming a second cup which is in contact with the lower face of the lid cup and at least over part of the height of the lateral surface of said lid cup,c) the combination of the two cups is simultaneously inserted by means of the same male tool via one of the ends of the tubular body held from the outside, near said end, by jaws,d) at least the upper third of the said walls of the two cups are joined in an impermeable manner to the inner side wall of the body,e) the lateral surface of the tubular body is prescored along a peripheral line located between a first joint area for joining the first cup to the inner wall of the tubular body and a joint area for joining the second cup, the one forming said diaphragm or membrane, to the inner wall of the tubular body, thus providing for the opening of the lid without tearing the diaphragm, the prescoring being produced either along part of the peripheral line, if it is a package with a hinged lid, or right along it, if it is a package with a detachable lid,f) then the folding-over of the end of the tubular body is carried out by means of a folding-over plug, thus completing the manufacture of the lid,g) after turning the body over, it is filled with the product to be packaged,h) the second end of the tubular body is closed.

- The process as claimed in claim 1, wherein, for packages with a hinged lid, the non-prescored part is notched in order to make the lid easier to pivot.

- The process as claimed in one of claims 1 or 2, wherein the elements providing the closure of the tubular body are joined to the inner surface of the body by adhesion, by arranging, before inserting the respective elements, an adhesive bead on the inner periphery of the tubular body and, after inserting said elements, clamping the body, from the outside, against an internal plug and, if necessary, heating.

- The process as claimed in one of claims 1 or 2, wherein the tubular body is equipped on its inner face with a plastic sealing film and wherein the elements providing the closure of the tubular body are joined by clamping the body, from the outside, against an internal plug and making said sealing film react.

- The process as claimed in claim 4, wherein the diaphragm is also equipped with a sealing film on its surface lying on the inside of the package and wherein the bottom of the package is similar to the lid, and wherein the diaphragm or membrane located at the bottom of the package is equipped with a plastic sealing film on both its surfaces, thus permitting adhesion both to the bottom and to the inner lateral surface of the tubular body.

- The process as claimed in one of claims 4 or 5, wherein the plastic sealing film is made to react by application of high-frequency or ultrasound.

- The process as claimed in one of claims 4 or 5, wherein the plastic sealing film is made to react by conduction of heat by means of an element heating through the elements to be assembled.

- The process as claimed in one of claims 4 to 7, wherein the plastic sealing film is pressed and made to react along two peripheral areas spaced apart in the axial direction of the tubular body relating to the region of the lid so as to prevent the upper surface of the diaphragm from being joined to the lid cup.

- The process as claimed in one of claims 1 to 8, wherein the bottom is closed by repeating steps a, c, d, g.

- A package obtained by the implementation of the process according to any one of claims 1 to 9, comprising a tubular body (3, 10, 10', 20) made of a rigid material (11, 11', 30), a bottom (50') and a lid (14, 14', 22, 50) which are cup shaped joined to the tubular body (3, 10, 10', 20) in an impermeable manner and which are made of a material which is identical or similar to said rigid material (11, 11', 30), a diaphragm or membrane cup shaped (12, 12', 70) made of a material identical or similar to the rigid material, joined to the tubular body between the product and the lid (14, 14', 22, 50), wherein the raised wall (51) of the cup forming the lid (50) is higher than the raised wall (71) of the cup (70) forming the diaphragm or membrane so that after the joining by adhesive bonding of both cups (50, 70) to the inner wall of the tubular body (3, 10, 10', 20), the joint areas of both cups do not overlap one another in order to prevent, when opening the lid of the package, the diaphragm or membrane from tearing, wherein the upper and lower ends of the tubular body (3, 10, 10', 20) are provided with a seam (35, 35') to ensure the rigidity of the package ends, and wherein the tubular body is prescored according at least a part of a peripheral line lying between said joint areas.

- The package according to claim 10, wherein the rigid material (3, 10, 10', 20) is board and wherein the diaphragm or membrane (12, 12', 70) is equipped with perforations for permitting dusting with the product contained.

- The package according to claim 10, wherein the rigid material (3, 10, 10', 20) is board and wherein an inner complex (31) comprising at least one sheet of paper makes it possible to provide the impermeability of the package and the compatibility with the product packaged.

- The package as claimed in claim 11, wherein the inner complex (31) comprises a plastic sealing film arranged on the inner face of said complex.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9402003A FR2716408B1 (en) | 1994-02-22 | 1994-02-22 | Method for manufacturing tubular packaging and packaging obtained by implementing the method. |

| FR9402003 | 1994-02-22 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0668151A1 EP0668151A1 (en) | 1995-08-23 |

| EP0668151B1 true EP0668151B1 (en) | 1999-04-14 |

Family

ID=9460313

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95810094A Expired - Lifetime EP0668151B1 (en) | 1994-02-22 | 1995-02-14 | Method for manufacturing a tubular container and container obtained by the method |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5566529A (en) |

| EP (1) | EP0668151B1 (en) |

| JP (1) | JP3340580B2 (en) |

| AT (1) | ATE178836T1 (en) |

| DE (1) | DE69508986T2 (en) |

| ES (1) | ES2132577T3 (en) |

| FR (1) | FR2716408B1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013057392A1 (en) | 2011-10-18 | 2013-04-25 | Pakea Sasu | Method of producing a packaging box and a box obtained according to this method |

| WO2013072737A1 (en) | 2011-11-14 | 2013-05-23 | Pakea | Sealed packaging container, in particular for a food product |

Families Citing this family (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE502434C2 (en) * | 1994-02-10 | 1995-10-16 | Lars Olof Andersson | Method and apparatus for sealing at least one end of a pipe and sealing plug |

| JPH09509915A (en) * | 1994-03-07 | 1997-10-07 | ザ ピルズベリイ カンパニー | Container sealing equipment |

| US6524230B1 (en) * | 1994-07-22 | 2003-02-25 | Ranpak Corp. | Packing material product and method and apparatus for making, monitoring and controlling the same |

| US5913798A (en) * | 1995-04-02 | 1999-06-22 | Grabher; Werner | Can and closure diaphragm, as well as process and apparatus for tightly connecting a can wall with the closure diaphragm |

| US6244020B1 (en) * | 1997-07-18 | 2001-06-12 | Effem Gmbh | Process for producing a filled container and filled container |

| US6325232B1 (en) | 1996-07-19 | 2001-12-04 | Effem Gmbh | Process for producing a filled container and filled container |

| DE19731654C2 (en) * | 1997-07-23 | 2001-05-17 | Effem Gmbh | Process for producing a container sterile sealed with a film |

| EP0911272B1 (en) * | 1997-10-25 | 2001-04-11 | Werner Grabher | Container and closure as well as method of manufacturing the closure |

| EP0915024A1 (en) * | 1997-10-25 | 1999-05-12 | Werner Grabher | Closure lid and method of manufacture |

| US6047878A (en) * | 1999-03-11 | 2000-04-11 | Sonoco Development, Inc. | Substantially paper container |

| US6510981B1 (en) * | 1999-06-09 | 2003-01-28 | General Mills, Inc. | Canister with paper and plastic layers and a plastic lid for containing a particulate-type product, such as a ready-to-eat cereal |

| US6267243B1 (en) | 1999-07-01 | 2001-07-31 | General Mills, Inc. | Canister with detachable premium for containing a particulate-type product |

| US6355286B2 (en) | 1999-07-01 | 2002-03-12 | General Mills, Inc. | Perforated air-tight seal membrane for a canister containing a particulate-type product |

| US6338864B1 (en) | 1999-07-01 | 2002-01-15 | General Mills, Inc. | Canister with adhered paper layers for a particulate-type product |

| US6261615B1 (en) | 1999-07-01 | 2001-07-17 | General Mills, Inc. | Canister with venting holes for containing a particulate-type product |

| US6173833B1 (en) | 1999-11-12 | 2001-01-16 | General Mills, Inc. | Package including a separately formed premium tray |

| US6460759B1 (en) | 2000-05-02 | 2002-10-08 | Sonoco Development, Inc. | Multi-ply composite container with regions of weakened strength and method for manufacturing same |

| US6395318B1 (en) | 2000-06-15 | 2002-05-28 | General Mills, Inc. | Delaminating membrane lid for a canister containing a particulate-type product |

| FR2842170B1 (en) * | 2002-07-15 | 2004-09-24 | Georges Sireix | METHOD FOR MANUFACTURING A TUBULAR PACKAGING AND INSTALLATION FOR IMPLEMENTING THE METHOD |

| JP4352166B2 (en) * | 2003-04-17 | 2009-10-28 | 四国化工機株式会社 | Container sealing device |

| DE602005009518D1 (en) * | 2004-04-20 | 2008-10-16 | Joergen Henriksen | |

| GB2438924A (en) * | 2006-06-07 | 2007-12-12 | Robinson Paperboard Packaging | Concentric cylindrical container with tamper evident line of weakness |

| KR20090026782A (en) * | 2006-07-05 | 2009-03-13 | 네스텍 소시에테아노님 | Packaged food product |

| US20090100805A1 (en) * | 2007-10-19 | 2009-04-23 | Schneider Wayne F | Sealed plastic closure and method for making the same |

| DE102008031379B4 (en) * | 2008-07-04 | 2011-07-28 | F.W. Schmitt GmbH, 55435 | Method and apparatus for ultrasonic welding a closure device on the spout of a container |

| TWI570024B (en) * | 2009-05-13 | 2017-02-11 | 四國化工機股份有限公司 | Method for manufacturing food - filled sealed containers |

| FR2986514B1 (en) | 2012-02-06 | 2015-05-22 | Georges Sireix | METHODS OF MANUFACTURING SHUTTLE STRUCTURE FOR TUBULAR PACKAGING AND PACKAGING, SHUTTER STRUCTURE, AND PACKAGING |

| FR2998503B1 (en) | 2012-11-29 | 2014-11-14 | Guillaume Sireix | METHOD AND MACHINE FOR ASSEMBLING RIGID TUBULAR BODIES OF CARDBOARD MATERIAL WITH SHUTTER STRUCTURE |

| FR3013628B1 (en) | 2013-11-27 | 2016-07-01 | Guillaume Sireix | METHOD FOR ASSEMBLING TUBULAR BODIES OF CARDBOARD MATERIAL WITH AN SHUTTER STRUCTURE |

| FR3019538B1 (en) * | 2014-04-02 | 2017-02-17 | Sidel Participations | METHOD OF CLOSING A HOLLOW CONTAINER, RECIPIENT MOUTH OBTAINED BY SUCH A METHOD AND USE OF SUCH A MOUTH CONTAINER |

| FR3043069B1 (en) * | 2015-10-28 | 2017-12-22 | Georges Sireix | PACKAGING |

| ITUA20161903A1 (en) * | 2016-03-22 | 2017-09-22 | Aroma System Srl | CAPSULE TO GET DRINKS AND THE SAME PRODUCTION METHOD |

| SE539899C2 (en) * | 2016-04-15 | 2018-01-02 | A & R Carton Lund Ab | Paperboard packaging container with a lid and a method for producing such a container |

| SE543005C2 (en) * | 2016-07-06 | 2020-09-22 | A & R Carton Lund Ab | Method of producing and filling a packaging container. |

| FR3073827B1 (en) | 2017-11-20 | 2022-08-05 | Georges Sireix | DEVICE FOR SEALING THE BOTTOM OR LID OF AN ECOLOGICALLY DESIGNED CARDBOARD PACKAGING USING AN EXTENDABLE SUPPORT ELEMENT |

| SE542898C2 (en) | 2018-08-31 | 2020-08-18 | Å&R Carton Lund Ab | A composite container with separable top, a body blank, and a method of separating a top end portion from a main body of the container |

| SE544358C2 (en) | 2019-07-02 | 2022-04-19 | A & R Carton Lund Ab | Method of producing a packaging container and a packaging container |

| SE544445C2 (en) * | 2019-12-12 | 2022-05-31 | Ar Packaging Systems Ab | Method of producing a packaging container, a packaging container and a curling tool |

| SE543911C2 (en) * | 2020-01-14 | 2021-09-21 | A & R Carton Lund Ab | An expansible press plunger, an attachment unit for attaching a container element in a container body and a method for attaching a container element in a container body |

| USD980055S1 (en) | 2020-06-01 | 2023-03-07 | Gpi Systems Ab | Fastener for packaging |

| USD980056S1 (en) | 2020-06-01 | 2023-03-07 | Gpi Systems Ab | Fastener for packaging |

| DE102022202764A1 (en) | 2022-03-21 | 2023-09-21 | Sig Combibloc Services Ag | LIQUID-TIGHT CONTAINER WITH WEDGE-SHAPED BOTTOM OR TOP SEAM |

| SE2250951A1 (en) * | 2022-08-05 | 2024-02-06 | Gpi Systems Ab | A packaging container and a method of producing such a packaging container |

| US20240166403A1 (en) * | 2022-11-22 | 2024-05-23 | Graphic Packaging International, Llc | Container with Reinforcement Features, Related Systems and Methods |

| DE102023200841A1 (en) * | 2023-02-02 | 2024-08-08 | Optima consumer GmbH | Resealable container |

| DE102023201643A1 (en) | 2023-02-23 | 2024-08-29 | Weyhmüller Verpackungstechnik GmbH | Method and device for closing a packaging body and packaging |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT46092B (en) * | 1909-09-04 | 1911-01-25 | Jesse Caldwell Thompson | Punching and forming machine. |

| FR1565609A (en) * | 1968-03-15 | 1969-05-02 | ||

| DE2718574A1 (en) * | 1977-04-26 | 1978-11-02 | Honshu Paper Co Ltd | Heat sealed liq. container - with flanged end seal bonded to body along part of flanged area only |

| GB2073156A (en) * | 1980-04-02 | 1981-10-14 | Ferry Pickering Sales Ltd | Dispensing Containers |

| FR2523073A1 (en) * | 1982-03-12 | 1983-09-16 | Cazas Ets | Support for food receptacle - has lid welded on by ultrasonic head against rigid support plate |

| US4599123A (en) * | 1982-09-02 | 1986-07-08 | Esselte Pac Aktiebolag | Method and apparatus for manufacturing a container having an inner end closure |

| US4888935A (en) * | 1988-07-25 | 1989-12-26 | Campbell Soup Company | Method for sealing a lid to a container |

| SE9000410L (en) * | 1990-02-06 | 1991-08-07 | Duma Ab | CONTAINER DEVICE AND PROCEDURES FOR PREPARING THEREOF |

| US5080233A (en) * | 1990-11-21 | 1992-01-14 | Minnesota Mining And Manufacturing Company | Gable top container having reduced opening force and method for construction therefor |

-

1994

- 1994-02-22 FR FR9402003A patent/FR2716408B1/en not_active Expired - Lifetime

-

1995

- 1995-02-14 DE DE69508986T patent/DE69508986T2/en not_active Expired - Lifetime

- 1995-02-14 AT AT95810094T patent/ATE178836T1/en not_active IP Right Cessation

- 1995-02-14 EP EP95810094A patent/EP0668151B1/en not_active Expired - Lifetime

- 1995-02-14 ES ES95810094T patent/ES2132577T3/en not_active Expired - Lifetime

- 1995-02-17 JP JP05344695A patent/JP3340580B2/en not_active Expired - Fee Related

- 1995-02-21 US US08/391,540 patent/US5566529A/en not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2013057392A1 (en) | 2011-10-18 | 2013-04-25 | Pakea Sasu | Method of producing a packaging box and a box obtained according to this method |

| WO2013072737A1 (en) | 2011-11-14 | 2013-05-23 | Pakea | Sealed packaging container, in particular for a food product |

Also Published As

| Publication number | Publication date |

|---|---|

| DE69508986T2 (en) | 1999-10-28 |

| FR2716408B1 (en) | 1996-05-15 |

| ES2132577T3 (en) | 1999-08-16 |

| EP0668151A1 (en) | 1995-08-23 |

| JPH07257543A (en) | 1995-10-09 |

| ATE178836T1 (en) | 1999-04-15 |

| DE69508986D1 (en) | 1999-05-20 |

| FR2716408A1 (en) | 1995-08-25 |

| JP3340580B2 (en) | 2002-11-05 |

| US5566529A (en) | 1996-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0668151B1 (en) | Method for manufacturing a tubular container and container obtained by the method | |

| EP0524897B1 (en) | Plastic tube head with barrier effect inner layer and part forming this layer | |

| EP0746506B1 (en) | Box or lid made of a rigid sheet material, blank, and method for making same | |

| EP2021263B1 (en) | Stopper member, fluid product dispenser comprising such a member and method of producing such a dispenser | |

| FR2727091A1 (en) | PACKAGING BAG | |

| FR2614278A1 (en) | PACKAGING WITH REFERMABLE PATCH AND METHOD OF MANUFACTURING THE SAME | |

| EP0197073A1 (en) | Sealed package, method for manufacturing and utilization of said package. | |

| FR2691952A1 (en) | Sealed composite package - uses case and base attached at edges by ultra sound technique separated by tearing at solder line | |

| WO2013057392A1 (en) | Method of producing a packaging box and a box obtained according to this method | |

| FR2490183A2 (en) | BLANK FOR FOLDABLE SHEET CONTAINERS AND CONTAINER OBTAINED FROM THE BLANK | |

| EP0631941A1 (en) | Plastic container comprising a rigid receptacle and a lid | |

| EP1836110B1 (en) | Plastic packaging and production and packaging method | |

| FR2502119A1 (en) | PACKAGING CONTAINER HAVING A SLEEVE-SHAPED BODY AND TWO LIDS FOR LIQUID AND SOLID FOOD PRODUCTS | |

| EP0094888B1 (en) | Method for the airtight closing of packages made of multilayer material | |

| EP0442770B1 (en) | Metallic package with heat-sealed cover and method of making such a package | |

| WO2004007186A1 (en) | Method and installation for making a tubular package | |

| FR2578510A1 (en) | Double thickness container or carton | |

| FR2571338A1 (en) | Sealed packaging, method of manufacture, and use of this packaging | |

| FR2535684A1 (en) | CONTAINER SUBSTANDED AND / OR COVERED AND METHOD OF MANUFACTURING | |

| FR2578783A1 (en) | Process for manufacturing a leaktight package and leaktight package produced according to this process | |

| FR2714891A1 (en) | Rigid food packaging dish with integral hinged lid | |

| EP1283806B2 (en) | Airtight closed container or package | |

| WO2004022326A1 (en) | Method of producing a package by forming and fixing a semi-rigid blank | |

| FR2802464A1 (en) | Manufacturing procedure, for packaging box comprising ring, has internal thermoplastic lining impervious to liquid placed in it and pneumatically pressurized | |

| FR2633870A1 (en) | Method for producing a bag and bag obtained |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES GB IT LI LU NL |

|

| 17P | Request for examination filed |

Effective date: 19951125 |

|

| 17Q | First examination report despatched |

Effective date: 19970122 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PLI Owner name: SIREIX, GEORGES TRANSFER- SONOCO CONSUMER PRODUCTS |

|

| 111L | Licence recorded |

Free format text: 971014 0100 SONOCO CONSUMER PRODUCTS LTD. |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES GB IT LI LU NL |

|

| REF | Corresponds to: |

Ref document number: 178836 Country of ref document: AT Date of ref document: 19990415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BUGNION S.A. |

|

| REF | Corresponds to: |

Ref document number: 69508986 Country of ref document: DE Date of ref document: 19990520 |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990622 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2132577 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20030212 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20030226 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20030227 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20030331 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20030429 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040214 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040229 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040229 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20040312 Year of fee payment: 10 |

|

| BERE | Be: lapsed |

Owner name: *SIREIX GEORGES Effective date: 20040228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040901 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20040901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050214 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050215 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20050215 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140224 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20140219 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69508986 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20150213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20150213 |