EP0640418B2 - Herstellung von Gussstahlgegenständen mit inneren Hohlräumen - Google Patents

Herstellung von Gussstahlgegenständen mit inneren Hohlräumen Download PDFInfo

- Publication number

- EP0640418B2 EP0640418B2 EP93500118A EP93500118A EP0640418B2 EP 0640418 B2 EP0640418 B2 EP 0640418B2 EP 93500118 A EP93500118 A EP 93500118A EP 93500118 A EP93500118 A EP 93500118A EP 0640418 B2 EP0640418 B2 EP 0640418B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- parts

- casting

- production

- projection

- core

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 9

- 229910001208 Crucible steel Inorganic materials 0.000 title claims description 7

- 238000005266 casting Methods 0.000 claims description 19

- 239000007789 gas Substances 0.000 claims description 3

- 239000000463 material Substances 0.000 claims description 2

- 229910000831 Steel Inorganic materials 0.000 description 10

- 239000010959 steel Substances 0.000 description 10

- 230000004807 localization Effects 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 3

- 239000004576 sand Substances 0.000 description 3

- 238000000034 method Methods 0.000 description 2

- 230000007935 neutral effect Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22C—FOUNDRY MOULDING

- B22C9/00—Moulds or cores; Moulding processes

- B22C9/10—Cores; Manufacture or installation of cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22C—FOUNDRY MOULDING

- B22C9/00—Moulds or cores; Moulding processes

- B22C9/20—Stack moulds, i.e. arrangement of multiple moulds or flasks

Definitions

- the present invention relates to improvements introduced in the production of cast steel parts provided with inner cavities, particularly concerning a mould assembly therefor, which permit substantial advantages to be obtained relative to the present state of the art.

- the steel parts to be produced according to the present invention are preferably wear-resistant cast steel parts, in particular the teeth of excavators and other earth-moving machines, in which the part has a generally pointed structure with an inner cavity, which is open at one end of the part, thus permitting it to be connected to an acceptance or male part of the machine, and therefore enabling it to be replaced when it is worn.

- the improvements which constitute the basis of the present invention are based substantially on the production of parts by means of a filling system using moulds comprising successive stacking of compartments or casting boxes, each of which has a set of parts supplied from a collector or central casting block, which facilitates successive filling of each of the levels of the mould formed by the various compartments, in association with specific means of designing the inner cavity of the part, in order to obtain controlled localisation of its recess, thus making it compatible with correct resistance of the part.

- improved quality of the part is obtained by using moulds which are more highly resistant, thus enabling defects caused by inclusions of sand to be avoided, and providing improvements in the surface appearance of the product, as well as providing improved dimensional accuracy thereof.

- An additional advantage consists of reducing the burr on the parts, thus reducing the finishing time necessary.

- Another feature of the present improvements consists of the reduced consumption of sand for a specific quantity of steel cast, thus constituting an additional cost-reduction factor.

- the present invention is based on the preparation of multiple boxes such as 1, 2, 3, 4, 5 and 6, with their corresponding cores, forming a mould assembly in which there are distributed multiple levels of individual parts as indicated by number 7 in Figure 1, of a variable number and arrangement, which in the example shown is radial, but which could be of another type, originating in a common axial filling duct 8, without any sinkheads whatsoever.

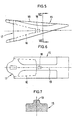

- each of the individual components produced such as a tooth for an earth-moving machine, designated 15 in Figure 5, consists of a cast steel part provided with an inner cavity 16, which is open at the end connection surface 17 of the tooth, and which, according to the present invention, has a projection 18, which is constituted in a specific manner at the time of casting, in order to obtain localisation of the recess in an inner area of the tooth, preferably in an area which corresponds to the neutral line of the part, and in conditions of separation relative to the outer surface of the part, in order to avoid fragile areas.

- the present invention also includes the optional arrangement of thickened parts such as 19, which are designed to provide a larger cross-section of the material in the area in which the inner recess will be provided.

- the cross-section of the projection 20 will be variable according to the needs of each case, for example it can be circular, as shown in Figures 8 and 9, or it can be a truncated pyramid, as in the projection 22 in Figures 10 and 11, or it can be lobar, as in the projection 23 in Figures 12 and 13, which has a head 24 consisting of a series of projecting lobes, which may be pointed.

- the projection can also be of the detachable type, as shown in Figure 14, in which the male part 25 has an aperture in which there is mounted the projection 26, which, in the case shown, is a lobar head 27.

- the area of the projection, indicated 28 is disposed in a preferably neutral area of the part 29, such that the recess which is formed in this area 28 does not have any functional consequences on the finished part.

- the communication with the atmosphere via the sand 30 of the core enables the pressures to be equalised in the recess area, thus avoiding local depressions, such as those which would occur in an inner recess without the control provided according to the present invention.

- the nature of the projection 28 is such that it facilitates communication with the atmosphere, as previously described, without also facilitating the addition of heat and gases, by which means the recess formed is controlled.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Molds, Cores, And Manufacturing Methods Thereof (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

Claims (2)

- Formanordnung zum Herstellen von Gussstahlteilen mit inneren Hohlräumen, bei der die Formen zu einem Stapel um einen gemeinsamen Füllkanal herum radial angeordnet sind, wobei jede Form einen Kern zur Herstellung von Teilen mit einem hohlen Ende aufweist und der Kern am äußeren Ende mit der Atmosphäre in Verbindung steht, dadurch gekennzeichnet, dass an demjenigen Kernende, das dem inneren Hohlraum jedes der zu formenden Teile entspricht, ein Vorsprung aus einem Werkstoff angeordnet ist, der beim Gießen Wärme und Gase erzeugen kann, um die Ausnehmung nach dem Gießen so zu kontrollieren, dass sie in einem von den Außenfächen des Gussstücks entfernten Bereich liegt, und dass die Formen so angeordnet sind, dass sie ohne Speiser aus dem gemeinsamen Füllkanal vollständig gefüllt werden.

- Formanordnung nach Anspruch 1, dadurch gekennzeichnet, dass der Vorsprung des Kerns abnehmbar ist.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES09101593A ES2046078B1 (es) | 1991-07-08 | 1991-07-08 | Perfeccionamientos en la fabricacion de piezas moldeadas de acero, dotadas de cavidades interiores. |

| EP93500118A EP0640418B2 (de) | 1991-07-08 | 1993-08-02 | Herstellung von Gussstahlgegenständen mit inneren Hohlräumen |

| DE1993623740 DE69323740T3 (de) | 1993-08-02 | 1993-08-02 | Production of cast steel parts provided with inner cavities |

| GR990401342T GR3030249T3 (en) | 1991-07-08 | 1999-05-19 | Improvements in the production of cast steel parts provided with inner cavities. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES09101593A ES2046078B1 (es) | 1991-07-08 | 1991-07-08 | Perfeccionamientos en la fabricacion de piezas moldeadas de acero, dotadas de cavidades interiores. |

| EP93500118A EP0640418B2 (de) | 1991-07-08 | 1993-08-02 | Herstellung von Gussstahlgegenständen mit inneren Hohlräumen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0640418A1 EP0640418A1 (de) | 1995-03-01 |

| EP0640418B1 EP0640418B1 (de) | 1999-03-03 |

| EP0640418B2 true EP0640418B2 (de) | 2004-12-01 |

Family

ID=26134801

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93500118A Expired - Lifetime EP0640418B2 (de) | 1991-07-08 | 1993-08-02 | Herstellung von Gussstahlgegenständen mit inneren Hohlräumen |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0640418B2 (de) |

| ES (1) | ES2046078B1 (de) |

| GR (1) | GR3030249T3 (de) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH09141391A (ja) * | 1995-11-17 | 1997-06-03 | Riken Kiyasutetsuku:Kk | 積層鋳型 |

| US5785107A (en) * | 1995-12-29 | 1998-07-28 | Georg Fischer Disa, Inc. | Apparatus and method for producing multiple cores |

| US5787957A (en) * | 1996-06-28 | 1998-08-04 | Georg Fischer Disa, Inc. | Apparatus and methods for injecting and gassing of sand |

| MX2007008956A (es) * | 2007-07-25 | 2007-09-07 | Enrique Alvarado Murillo | Metodo y molde para moldeo estratificado con compensacion de presion metalostatica. |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1294209A (en) † | 1918-01-22 | 1919-02-11 | John B Walker | Process for producing solid castings and their products. |

| US2205327A (en) † | 1939-06-29 | 1940-06-18 | Williams John | Means for casting metals |

| JPS54110616A (en) † | 1978-02-20 | 1979-08-30 | Nippon Kokan Kk | Method of forming panel zone portion |

| JPS5588953A (en) † | 1978-12-26 | 1980-07-05 | Honda Motor Co Ltd | Shift fork casting device |

| JPS5588952A (en) † | 1978-12-27 | 1980-07-05 | Honda Motor Co Ltd | Casting device of connecting rod |

| US4241492A (en) † | 1978-12-21 | 1980-12-30 | Wells Manufacturing Company | Process for manufacture of valve seat |

| JPH0332446A (ja) † | 1989-06-29 | 1991-02-13 | Riken Corp | 造型鋳型のスタツク装置及びそのスタツク法 |

| SU1687360A1 (ru) † | 1988-11-01 | 1991-10-30 | Институт проблем литья АН УССР | Литейна форма дл получени отливок зубьев ковша экскаватора из высокомарганцевой стали |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2101046A (en) * | 1937-07-01 | 1937-12-07 | Renette Company | Art of casting pistons |

| US3628598A (en) * | 1968-10-23 | 1971-12-21 | Modern Equipment Co | Casting molds |

| US3981344A (en) * | 1974-08-21 | 1976-09-21 | United Technologies Corporation | Investment casting mold and process |

-

1991

- 1991-07-08 ES ES09101593A patent/ES2046078B1/es not_active Expired - Fee Related

-

1993

- 1993-08-02 EP EP93500118A patent/EP0640418B2/de not_active Expired - Lifetime

-

1999

- 1999-05-19 GR GR990401342T patent/GR3030249T3/el unknown

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1294209A (en) † | 1918-01-22 | 1919-02-11 | John B Walker | Process for producing solid castings and their products. |

| US2205327A (en) † | 1939-06-29 | 1940-06-18 | Williams John | Means for casting metals |

| JPS54110616A (en) † | 1978-02-20 | 1979-08-30 | Nippon Kokan Kk | Method of forming panel zone portion |

| US4241492A (en) † | 1978-12-21 | 1980-12-30 | Wells Manufacturing Company | Process for manufacture of valve seat |

| JPS5588953A (en) † | 1978-12-26 | 1980-07-05 | Honda Motor Co Ltd | Shift fork casting device |

| JPS5588952A (en) † | 1978-12-27 | 1980-07-05 | Honda Motor Co Ltd | Casting device of connecting rod |

| SU1687360A1 (ru) † | 1988-11-01 | 1991-10-30 | Институт проблем литья АН УССР | Литейна форма дл получени отливок зубьев ковша экскаватора из высокомарганцевой стали |

| JPH0332446A (ja) † | 1989-06-29 | 1991-02-13 | Riken Corp | 造型鋳型のスタツク装置及びそのスタツク法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0640418A1 (de) | 1995-03-01 |

| GR3030249T3 (en) | 1999-08-31 |

| ES2046078R (de) | 1995-03-16 |

| ES2046078B1 (es) | 1995-10-01 |

| ES2046078A2 (es) | 1994-01-16 |

| EP0640418B1 (de) | 1999-03-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0431770B1 (de) | Vollformgiessen eines Motorblockes aus zwei Legierungen | |

| US7296615B2 (en) | Method and apparatus for determining the location of core-generated features in an investment casting | |

| CN110834067B (zh) | 一种高温合金多孔座铸件浇注熔模及其熔模制作工艺方法 | |

| MXPA05002557A (es) | Procedimiento de fundicion, particularmente para cabeza de cilindros de un motor. | |

| CN106493306B (zh) | 带有齿轮室盖的飞轮壳的铸造方法 | |

| KR100538284B1 (ko) | 메탈중공주조물을제조하는캐스팅몰드및방법과그중공주조물 | |

| JPH09151786A (ja) | 内燃機関用ピストンの製造方法 | |

| EP0640418B2 (de) | Herstellung von Gussstahlgegenständen mit inneren Hohlräumen | |

| CN109822047A (zh) | 一种38w机体的铸造设计方法 | |

| EP0092690A1 (de) | Formkern für das Giessen eines Motorzylinderblockes | |

| CN209935807U (zh) | 一种用于铸造发动机缸体的砂模 | |

| CN108941466A (zh) | V型结构船用气缸体的铸造工艺方法 | |

| US5238216A (en) | Apparatus for modifying thermal gradient for casting in graphite molds | |

| US2820267A (en) | Cylinder head coring | |

| CN110369678A (zh) | 一种风电主轴金属型及铸造系统 | |

| JP2000514898A (ja) | 内燃機関のシリンダ・ヘッドの鋳造による製作のための方法および中子 | |

| CN210387460U (zh) | 一种风电主轴金属型及铸造系统 | |

| CN101417326B (zh) | 一种汽车制动鼓的铸造方法及模具 | |

| US2101046A (en) | Art of casting pistons | |

| CN108515145B (zh) | 一种基于静压铸造半轴的工艺 | |

| CN207086851U (zh) | 一种齿形覆膜砂芯及制作该砂芯的模具 | |

| CN215746346U (zh) | 压铸壳体的模具 | |

| JPH05146866A (ja) | 中空チルドカムシヤフトおよびその製造方法 | |

| Jolly et al. | Use of simulation tools in the practical development of a method for manufacture of cast iron camshafts | |

| CN218460786U (zh) | 一种蠕墨铸铁气缸盖浇注系统 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19940301 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE FR GB GR IE IT PT |

|

| 17Q | First examination report despatched |

Effective date: 19960425 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR GB GR IE IT PT |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 69323740 Country of ref document: DE Date of ref document: 19990408 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19990514 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: ESCO CORPORATION Effective date: 19991202 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| RTI2 | Title (correction) |

Free format text: PRODUCTION OF CAST STEEL PARTS PROVIDED WITH INNER CAVITIES |

|

| RTI2 | Title (correction) |

Free format text: PRODUCTION OF CAST STEEL PARTS PROVIDED WITH INNER CAVITIES |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: ESCO CORPORATION |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| 27A | Patent maintained in amended form |

Effective date: 20041201 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): BE DE FR GB GR IE IT PT |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20050400653 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: PC4A Free format text: ESCO CORPORATION US Effective date: 20050301 |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20080722 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20080828 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080930 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20080827 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20100202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100202 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090803 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100302 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100303 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20120828 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120830 Year of fee payment: 20 Ref country code: IT Payment date: 20120823 Year of fee payment: 20 Ref country code: BE Payment date: 20120827 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20130801 |

|

| BE20 | Be: patent expired |

Owner name: *ESCO CORP. Effective date: 20130802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20130801 |