EP0571304B1 - Einrichtung zum Herstellen von doppelseitig beschichteten Geweben - Google Patents

Einrichtung zum Herstellen von doppelseitig beschichteten Geweben Download PDFInfo

- Publication number

- EP0571304B1 EP0571304B1 EP93420199A EP93420199A EP0571304B1 EP 0571304 B1 EP0571304 B1 EP 0571304B1 EP 93420199 A EP93420199 A EP 93420199A EP 93420199 A EP93420199 A EP 93420199A EP 0571304 B1 EP0571304 B1 EP 0571304B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- die

- substrate

- coating

- hand

- chamber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004744 fabric Substances 0.000 title claims description 19

- 239000011248 coating agent Substances 0.000 claims abstract description 27

- 238000000576 coating method Methods 0.000 claims abstract description 27

- 238000011144 upstream manufacturing Methods 0.000 claims description 3

- 239000000758 substrate Substances 0.000 claims 7

- 239000000126 substance Substances 0.000 claims 3

- 238000009434 installation Methods 0.000 description 8

- 239000000463 material Substances 0.000 description 4

- 239000010410 layer Substances 0.000 description 3

- 238000000034 method Methods 0.000 description 2

- 230000035515 penetration Effects 0.000 description 2

- 238000003490 calendering Methods 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 239000011247 coating layer Substances 0.000 description 1

- 238000000151 deposition Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 239000000806 elastomer Substances 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B15/00—Removing liquids, gases or vapours from textile materials in association with treatment of the materials by liquids, gases or vapours

- D06B15/08—Removing liquids, gases or vapours from textile materials in association with treatment of the materials by liquids, gases or vapours by scraping

- D06B15/085—Removing liquids, gases or vapours from textile materials in association with treatment of the materials by liquids, gases or vapours by scraping by contact with the textile material

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B1/00—Applying liquids, gases or vapours onto textile materials to effect treatment, e.g. washing, dyeing, bleaching, sizing or impregnating

- D06B1/08—Applying liquids, gases or vapours onto textile materials to effect treatment, e.g. washing, dyeing, bleaching, sizing or impregnating from outlets being in, or almost in, contact with the textile material

Definitions

- the present invention relates to installations used for coating fabrics or other flexible supports with a layer of synthetic material (polyvinyl chloride, resin, elastomer, etc.) with a view to producing a complex having a very high mechanical resistance combined with perfect impermeability.

- synthetic material polyvinyl chloride, resin, elastomer, etc.

- French patent no. 73 35081/2 245 165 FERRARI shows an installation equipped with a coating station comprising, first of all, means suitable for ensuring the longitudinal and transverse tension of the support, these means advantageously being constituted by the clamps or pins of a mobile train longitudinally. This support was thus kept under tension until the final calendering operation.

- the coating station also included at least one die oriented transversely to the direction of continuous advance of the support. This die had two parallel doctor blades offset with respect to each other in the direction of advance of the support, thereby defining a cavity or chamber supplied with coating material, this supply taking place continuously and under controlled pressure.

- the invention mainly consists in making the installation comprise two channels which are arranged in superposition on either side of the support to be coated so as to produce on the latter a double-sided coating.

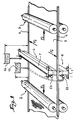

- Fig. 1 is a perspective view schematically illustrating the arrangement of the double-sided coating station of an installation according to the invention.

- Fig. 2 is a partial longitudinal section showing on a larger scale the two opposite dies of the installation according to FIG. 1.

- reference 1 designates the support to be coated, assumed to be constituted by a fabric.

- This fabric 1 is animated by a continuous advance movement, oriented from left to right in FIG. 1.

- the fabric 1 is successively engaged between the superimposed drums of two calenders 2 and 3, arranged to continuously exert on said fabric a controlled tension effect, oriented longitudinally; associated with this longitudinal tension is a transverse tension, operated as in Patent N ° 73 35081/2 245 165 FERRARI, using an oar 4 for holding it wide, the clips or pins are applied to the longitudinal edges of the fabric 1 upstream of the grille 2.

- the coating station also comprises two superimposed dies 5 and 6, the arrangement of which appears on a larger scale in FIG. 2.

- Each die 5 or 6 is formed by a frame 7 permanently fixed to the structure of the station.

- Each frame 7 is associated with an upstream doctor blade 8 whose edge turned towards the fabric 1 has a rounded profile, and a downstream doctor blade 9 whose free edge applied against the fabric 1 has a pointed profile.

- the position of the doctor blades 8 and 9 in the vertical direction can be adjusted precisely, for example using screws such as those shown at 10, so that the application of the free edge of said doctor blades against the two opposite faces of the fabric 1 is capable of being fixed exactly exactly, as a function of various parameters, in particular the thickness of the coating layer to be deposited on each side, it being observed that this adjustment is capable of being carried out in such a way fully autonomous, for each of the two doctor blades of each die.

- the doctor blades 8 and 9 define, with the inner face of the frame 7 and the fabric 1, a cavity 11 intended to form the coating chamber.

- Each of the cavities or chambers 11 is connected, through a series of distributing channels 12 suitably spaced along the length of each die, to a collector 13 supplied by an independent reservoir 14, respectively 15, permanently filled with an appropriate quantity of material coating.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Coating Apparatus (AREA)

- Treatment Of Fiber Materials (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

Claims (6)

- Einrichtung zum Beschichten von horizontal abgespulten Geweben oder anderen, weichen Trägern, gattungsgemäß ausgestattet mit einer Beschichtungsstation, die einerseits Mittel (2-3 und 4) zum Sicherstellen der Längs- und Querspannung des Trägers (1) umfasst, andererseits mindestens eine, hinsichtlich der fortlaufenden Vorschubrichtung der Unterlage quer ausgerichtete Breitschlitzdüse (5,6), die zwei parallele Rakel (8,9) aufweist, von denen die eine gegenüber der anderen in Richtung des Vorschubs der Unterlage zur Bildung einer Höhlung oder Versorgungskammer verlagert ist, zur kontinuierlichen Zuführung des Beschichtungsmaterials und zur Überwachung des Druckes, dadurch gekennzeichnet, daß sie zwei Breitschlitzdüsen (5 und 6) umfasst, die übereinander angeordnet sind, zur doppelseitigen Beschichtung des Trägers (1).

- Einrichung nach Anspruch 1, dadurch gekennzeichnet, daß der gegen den Träger (1) gerichtete Rand der Rakel (8, 9) jeder der Breitschlitzdüsen (5, 6), für die einlaufseitige Rakel (8) als abgerundetes Profil ausgebildet ist, und als spitz zulaufendes Profil für die ablaufseitige Rakel (9).

- Einrichtung nach einem der Ansprüche 1 und 2, dadurch gekennzeichnet, daß die Breitschlitzdüsen (5, 6) ein festes Unterteil (7) umfassen, gegenüber dem die beiden gegeneinander gerichtenen Oberflächen fix sind, wobei die beiden Rakel (8, 9) in ihrer vertikalen Position einstellbar sind.

- Einrichtung nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß jede der Breitschlitzdüsen (5, 6) einen Sammler (13) umfasst, der über eine Reihe von Verteilkanälen (12) mit der Versorgungskammer (11) der Breitschlitzdüsen verbunden ist.

- Einrichtung nach Anspruch 4, dadurch gekennzeichnet, daß jeder Sammler (13) aus einem Vorrratsbehälter (14, 15) mit Beschichtungsmaterial versorgt wird, wobei der Vorrratsbehälter ständig aufgefüllt wird und dessen Höhen-Lage veränderbar ist, um die genaue Regulierung des Druckes des Beschichtungsmaterials in der der Versorgungskammer (11) jeder der Breitschlitzdüsen (5, 6) zu ermöglichen.

- Einrichtung nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß die Mittel zum Spannen gebildet sind, einerseits durch einen Spannrahmen (4), der die längsverlaufenden Ränder des Trägers (1) zurückhält, andererseits durch zwei Walzkalander (2,3), die beiderseits der beiden übereinanderliegenden Breitschlitzdüsen vorgesehen sind.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9206456 | 1992-05-21 | ||

| FR9206456A FR2691482A1 (fr) | 1992-05-21 | 1992-05-21 | Installation pour l'enduction double-face de tissus ou autres supports souples. |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0571304A1 EP0571304A1 (de) | 1993-11-24 |

| EP0571304B1 true EP0571304B1 (de) | 1997-11-12 |

Family

ID=9430214

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93420199A Expired - Lifetime EP0571304B1 (de) | 1992-05-21 | 1993-05-17 | Einrichtung zum Herstellen von doppelseitig beschichteten Geweben |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0571304B1 (de) |

| AT (1) | ATE160185T1 (de) |

| DE (1) | DE69315118T2 (de) |

| ES (1) | ES2110073T3 (de) |

| FR (1) | FR2691482A1 (de) |

| TN (1) | TNSN93057A1 (de) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101185132B1 (ko) | 2006-02-27 | 2012-09-24 | 코오롱인더스트리 주식회사 | 직물의 양면을 연속식으로 코팅하는 방법 |

| CN111648005B (zh) * | 2020-05-19 | 2021-09-24 | 温州佳远生物科技有限公司 | 一种多组分纤维混纺面料及制备方法 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3473512A (en) * | 1968-04-22 | 1969-10-21 | Owens Corning Fiberglass Corp | Coating dies |

| JPS571305B2 (de) * | 1974-06-08 | 1982-01-11 | ||

| GB1604620A (en) * | 1977-11-10 | 1981-12-09 | Britton A | Application of liquid material to webs |

| JPS54114546A (en) * | 1978-02-23 | 1979-09-06 | Ibm | Coating method and apparatus therefor |

| DE2824376A1 (de) * | 1978-06-03 | 1979-12-06 | Bayer Ag | Faserimpraegnierverfahren |

| DE2913053C3 (de) * | 1979-03-31 | 1981-11-19 | Vits-Maschinenbau Gmbh, 4018 Langenfeld | Vorrichtung zum Auftragen von flüssigen Stoffen auf Warenbahnen |

| DE3226652A1 (de) * | 1982-07-16 | 1984-01-19 | Mathias 4815 Schloss Holte Mitter | Verfahren und vorrichtung zum faerben, drucken, behandeln oder beschichten einer warenbahn od.dgl. mit unterschiedlichen faser- oder fadenanteilen |

| CA2015159C (en) * | 1989-05-09 | 1997-02-04 | James Ralph Terry | On line surface and edge coating of fiber glass duct liner |

-

1992

- 1992-05-21 FR FR9206456A patent/FR2691482A1/fr active Granted

-

1993

- 1993-05-17 ES ES93420199T patent/ES2110073T3/es not_active Expired - Lifetime

- 1993-05-17 EP EP93420199A patent/EP0571304B1/de not_active Expired - Lifetime

- 1993-05-17 AT AT93420199T patent/ATE160185T1/de active

- 1993-05-17 DE DE69315118T patent/DE69315118T2/de not_active Expired - Lifetime

- 1993-05-18 TN TNTNSN93057A patent/TNSN93057A1/fr unknown

Also Published As

| Publication number | Publication date |

|---|---|

| ATE160185T1 (de) | 1997-11-15 |

| TNSN93057A1 (fr) | 1994-03-17 |

| ES2110073T3 (es) | 1998-02-01 |

| FR2691482B1 (de) | 1994-07-13 |

| DE69315118D1 (de) | 1997-12-18 |

| FR2691482A1 (fr) | 1993-11-26 |

| EP0571304A1 (de) | 1993-11-24 |

| DE69315118T2 (de) | 1998-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FR2510152A1 (fr) | Procede et dispositif pour realiser une enduction partielle sur un support textile | |

| FR2536432A1 (fr) | Procede pour la fabrication d'etoffes non tissees portant des motifs en creux ou en relief, et etoffes non tissees ainsi obtenues | |

| CA2019476A1 (fr) | Dispositif de coulee pour la coulee de couches de matieres plastiques transparentes avec une bande filtrante coloree dans la masse | |

| FR2657046A1 (fr) | Dispositif pour l'assemblage par pressage des vitrages feuilletes. | |

| CA1158110A (fr) | Procede et dispositif pour l'enduction en continu d'un element en feuille, notamment une bande de papier ou de carton | |

| FR2625937A1 (fr) | Procede et dispositif pour perforer un produit en feuille, et produit perfore ainsi obtenu | |

| EP0571304B1 (de) | Einrichtung zum Herstellen von doppelseitig beschichteten Geweben | |

| EP0179521B1 (de) | Einstellbarer Beschickungsblock für eine Koextrudierdüse | |

| EP0061412A1 (de) | Verfahren und Vorrichtung zur Herstellung von Kunststoffschaumbahnen | |

| WO1998002299A1 (fr) | Materiau d'approvisionnement de machine de fabrication de produit de rembourrage | |

| FR2524513A1 (fr) | Caisse a pate pour machine de fabrication de papier | |

| EP0226687B1 (de) | Verfahren zum Färben von Materialbahnen | |

| WO2008141871A1 (fr) | Buse articulee et procede d ' application d ' une bandelette en materiau viscoelastique qui utilise ladite buse | |

| EP0634516B1 (de) | Verfahren und Vorrichtung zum Herstellen von Kunststoffbeschichtungen, insbesondere für Bodenbeläge | |

| EP3737547B1 (de) | Verfahren zur kontinuierlichen herstellung einer prägefolienbahn und zugehörige anlage | |

| FR2507108A1 (fr) | Procede et dispositif de revetement de feuilles | |

| EP0366773B1 (de) | Verfahren und vorrichtung zum beschichten von parallel liegenden fäden mit kautschuk und so hergestellte matte | |

| EP1824663A2 (de) | Verfahren zur ununterbrochenen herstellung eines flexiblen komplexes und besagter flexibler komplex | |

| CA2137979A1 (fr) | Procede de controle et de reglage de l'egouttage d'une suspension fibreuse sur une table de formation d'une machine a papier et dispositif pour la mise en oeuvre du procede | |

| FR2526332A1 (fr) | Appareil d'application de revetement | |

| FR2565607A1 (fr) | Procede d'embellissement par coloration d'etoffes ou articles similaires et dispositif pour sa mise en oeuvre | |

| FR2699114A1 (fr) | Encrier de machines à imprimer offset ou en relief. | |

| FR2574957A1 (fr) | Procede et dispositif pour le controle et la regulation de l'epaisseur d'un revetement metallique mince depose sur un support | |

| FR3076761A1 (fr) | Outil ameliore de depot en 3 dimensions de matiere par extrusion | |

| FR2600092A1 (fr) | Dispositif mobile pour l'application de bandes de marquage de largeur variable, en particulier sur revetements routiers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19940129 |

|

| 17Q | First examination report despatched |

Effective date: 19960404 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL PT SE |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 160185 Country of ref document: AT Date of ref document: 19971115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19971121 |

|

| REF | Corresponds to: |

Ref document number: 69315118 Country of ref document: DE Date of ref document: 19971218 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2110073 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19980108 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20000516 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20000602 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010616 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010616 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20120425 Year of fee payment: 20 Ref country code: DE Payment date: 20120514 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20120531 Year of fee payment: 20 Ref country code: SE Payment date: 20120523 Year of fee payment: 20 Ref country code: FR Payment date: 20120615 Year of fee payment: 20 Ref country code: GB Payment date: 20120521 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20120522 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20120524 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20120418 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20120424 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69315118 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: MAXIMUM VALIDITY LIMIT REACHED Effective date: 20130517 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V4 Effective date: 20130517 |

|

| BE20 | Be: patent expired |

Owner name: TISSAGE ET ENDUCTION SERGE *FERRARI Effective date: 20130517 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20130516 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 160185 Country of ref document: AT Kind code of ref document: T Effective date: 20130517 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20130730 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20130516 Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20130518 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20130524 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20130518 |