EP0545823A1 - Splitterkörper, Verfahren zu seiner Herstellung und Verwendung für Munition - Google Patents

Splitterkörper, Verfahren zu seiner Herstellung und Verwendung für Munition Download PDFInfo

- Publication number

- EP0545823A1 EP0545823A1 EP92403270A EP92403270A EP0545823A1 EP 0545823 A1 EP0545823 A1 EP 0545823A1 EP 92403270 A EP92403270 A EP 92403270A EP 92403270 A EP92403270 A EP 92403270A EP 0545823 A1 EP0545823 A1 EP 0545823A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- envelope

- machining

- hemispheres

- grooving

- ammunition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42B—EXPLOSIVE CHARGES, e.g. FOR BLASTING, FIREWORKS, AMMUNITION

- F42B12/00—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material

- F42B12/02—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect

- F42B12/20—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect of high-explosive type

- F42B12/22—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect of high-explosive type with fragmentation-hull construction

- F42B12/24—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect of high-explosive type with fragmentation-hull construction with grooves, recesses or other wall weakenings

Definitions

- the invention relates to prefragmented envelopes especially intended for the manufacture of ammunition such as hand grenades.

- the anti-personal ammunition generally used today which contains an explosive dispersing metallic shot are commonly called “grenades", they consist either of closed metallic envelopes, or by an assembly with metallic elements previously shot-blasted or wound in the form son, either by an assembly of metal washers machined or not and forming wholly or partially a closed volume containing explosive which is initiated by a pyrotechnic system during its use.

- Document GB-A-1 167 828 discloses a pre-fragmented casing, the manufacturing process of which comprises the steps of forming two metal discs, grooving at least one surface of the two discs in the form of a network of lines, plastic deformation of the two discs into two hemispheres, then assembly and welding of the two hemispheres into a substantially spherical envelope.

- the object of the invention is to improve the known process in order to obtain good fragmentation. This object is achieved according to the invention because the grooving is obtained by a machining process, that is to say with removal of material.

- the invention differs radically from this teaching in that it recommends machining, that is to say removal of material at the level of the grooving. During subsequent forming by plastic deformation between form and counterform, the voids in the grooves are not filled with metal which would flow back. Thus, the combination of these machining operations and plastic deformation makes it possible to have, along the machining lines, an additional embrittlement due either to tensile stresses, or to shear stresses generated by hemisphere forming. .

- the grooving is done according to a network of lines oriented in two non-parallel directions, for example perpendicular. We thus form small parallelograms (or rectangles) of prefragmentation, that it is easy to provide for equal dimensions. This further distinguishes the invention from the aforementioned GB-A-1 167 828 document, where the grooving is done according to circles and radii of the starting discs.

- the forming operation has the effect of disorganizing the structure of the parallelepipeds between themselves and at the nodes which are not at the pole: there is discontinuity of the lines of embrittlement, which creates a point of discontinuity in the embrittlement.

- the invention also relates to the prefragmented envelope obtained according to the method of the invention.

- the invention therefore relates to the envelope and the method for producing the envelope of a grenade (in particular), by assembling two pre-fragmented half-bodies, which generates a large number of metal fragments when the grenade explodes. having substantially the same masses and the same shapes.

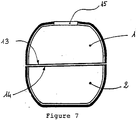

- the envelope, object of the present invention consists of two hemispheres 1 and 2 or similar (see Figures 7 and 1 to 3) obtained by plastic deformation of two previously machined metal discs, as shown in Figures 4a and 4b .

- the prior machining of the metal discs is preferably done by a thermal process (for example with a laser) but can be done by any other process, including by mechanical machining or by machining by electroerosion or chemical erosion as long as it is done with removal of the excavated material.

- This machining consists in making prefragmentation lines 3, as shown in FIGS. 4a and 4b, which can have a hollow shape 4, rounded or not, the bottom rounding being able to have a diameter greater than the width of the groove. , as shown in Figure 4b.

- the prior machining of the discs is done in two non-parallel directions 5 and 6, thus forming small quadrilaterals 16 whose perimeter is machined, which constitutes a prefragmentation of these small quadrilaterals; directions 5 and 6 can be perpendicular; machining is preferably done with constant intervals 17 and 18 in each direction.

- the discs When the discs are machined as shown in FIGS. 4a and 4b, they undergo a substantially hemispherical forming operation by plastic deformation (stamping, embossing, or any other plastic deformation technique) and, after machining of the edges 13 and 14 if necessary ( Figure 7), intended machining to facilitate assembly, they are assembled along an equatorial line 7 ( Figure 1) and welded by thermal fusion process or any other welding process.

- the prefragmentation machining When forming by plastic deformation, the prefragmentation machining is generally placed inside the envelope and forms a network of weakening lines 19 as shown in FIG. 5, but according to another assembly device, it can be placed outside.

- FIG. 6 A partial hemispherical section of an envelope after assembly is shown in FIG. 6 and shows the zones of weakness 10 of the envelope and the lines of ruptures 11 which occur under the effect of strong internal pressure.

- the breaking lines 11 are superimposed on the weakening lines 19 and during the breaking there is formation of an elementary chip which has the dimension of values close to those of a parallelepiped whose edges are close to the values of the intervals 17 and 18 and the thickness of the metal disc shown in Figures 4a and 4b before its plastic deformation.

- the mass of each fragment is constant if during machining, the intervals 17 and 18 are constant, if the thickness of the flat disc shown in FIGS. 4a and 4b is constant and if the material constituting this same disc is homogeneous.

- the behavior of the pre-fragmented casing 8 during the firing of the grenade is as follows.

- the fragments thus formed are projected under the effect of the explosion and the breath of the explosion at high speed in directions substantially equivalent to the line formed by the center of the envelope and the position of the fragment when it fragmentation, and therefore, when the envelope formed or practically closed as in the case of the present invention, there is projection of splinters in all directions, these splinters leaving the point of explosion.

- the shapes, mass and dimensions of the flash make it possible to obtain a predetermined value of effectiveness of a flash when used in anti-personal ammunition and also a predetermined value of vulnerability to against the handler of the grenade if the latter remains uncovered, value obtained as a function of the initial speed of the flash, the coefficient of loss of speed in the air, the mass of the flash and the position of the manipulator relative to the explosion point.

- These values (effectiveness and vulnerability), in the present invention can be adjusted by modifying for example the nature of the explosive, the shape and the mass of the elementary fragments. or possibly the material that constitutes the shards.

- the prefragmented metal envelope object of the present invention can also be used for the development of other anti-personal ammunition and in particular hand grenades, rifle grenades and shells.

- one of the two hemispheres here hemisphere 1

- hemisphere 2 can also be provided with an orifice.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- General Engineering & Computer Science (AREA)

- Welding Or Cutting Using Electron Beams (AREA)

- Aiming, Guidance, Guns With A Light Source, Armor, Camouflage, And Targets (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9115035 | 1991-12-04 | ||

| FR9115035A FR2684753A1 (fr) | 1991-12-04 | 1991-12-04 | Enveloppe prefabriquee pour grenade. |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0545823A1 true EP0545823A1 (de) | 1993-06-09 |

Family

ID=9419670

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92403270A Withdrawn EP0545823A1 (de) | 1991-12-04 | 1992-12-03 | Splitterkörper, Verfahren zu seiner Herstellung und Verwendung für Munition |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0545823A1 (de) |

| FR (1) | FR2684753A1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0918206A3 (de) * | 1997-11-21 | 1999-12-15 | Diehl Stiftung & Co. | Splitterhülle für Munition |

| KR20020038913A (ko) * | 2000-11-20 | 2002-05-24 | 이원명 | 양궁용 화살 |

| US6857372B2 (en) * | 2000-07-28 | 2005-02-22 | Giat Industries | Explosive ammunition with fragmenting structure |

| FR3086746A1 (fr) * | 2018-10-01 | 2020-04-03 | Nexter Munitions | Enveloppe pour munition et munition incorporant une telle enveloppe |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR478480A (fr) * | 1915-04-22 | 1915-12-15 | Thuau Fils | Grenade à main |

| GB1167828A (en) * | 1967-03-31 | 1969-10-22 | Louis Dessart | Explosive Projectile Head. |

| DE2919268A1 (de) * | 1979-05-12 | 1980-11-20 | Rheinmetall Gmbh | Splitterhuelle fuer geschosse, gefechtskoepfe u.dgl. und verfahren zu ihrer herstellung |

| US4774745A (en) * | 1986-11-13 | 1988-10-04 | Carter Research And Development Technological Services Incorporated | Method of producing fragmentation pattern in military projectiles |

-

1991

- 1991-12-04 FR FR9115035A patent/FR2684753A1/fr active Granted

-

1992

- 1992-12-03 EP EP92403270A patent/EP0545823A1/de not_active Withdrawn

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR478480A (fr) * | 1915-04-22 | 1915-12-15 | Thuau Fils | Grenade à main |

| GB1167828A (en) * | 1967-03-31 | 1969-10-22 | Louis Dessart | Explosive Projectile Head. |

| DE2919268A1 (de) * | 1979-05-12 | 1980-11-20 | Rheinmetall Gmbh | Splitterhuelle fuer geschosse, gefechtskoepfe u.dgl. und verfahren zu ihrer herstellung |

| US4774745A (en) * | 1986-11-13 | 1988-10-04 | Carter Research And Development Technological Services Incorporated | Method of producing fragmentation pattern in military projectiles |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0918206A3 (de) * | 1997-11-21 | 1999-12-15 | Diehl Stiftung & Co. | Splitterhülle für Munition |

| US6857372B2 (en) * | 2000-07-28 | 2005-02-22 | Giat Industries | Explosive ammunition with fragmenting structure |

| KR20020038913A (ko) * | 2000-11-20 | 2002-05-24 | 이원명 | 양궁용 화살 |

| FR3086746A1 (fr) * | 2018-10-01 | 2020-04-03 | Nexter Munitions | Enveloppe pour munition et munition incorporant une telle enveloppe |

| EP3633313A1 (de) * | 2018-10-01 | 2020-04-08 | Nexter Munitions | Hülse für munition und munition, die eine solche hülse umfasst |

| US10962339B2 (en) | 2018-10-01 | 2021-03-30 | Nexter Munitions | Shell for ammunition and ammunition including such a shell |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2684753B1 (de) | 1995-05-12 |

| FR2684753A1 (fr) | 1993-06-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3173371A (en) | Expanding bullet with spreader disk | |

| EP2691731B1 (de) | Weniger todbringendes geschoss für eine waffe | |

| FR2578045A1 (fr) | Projectile perforant | |

| FR2632394A1 (fr) | Charge explosive generatrice de noyau | |

| FR2665949A1 (fr) | Projectile a effet cinetique, destine a des cibles blindees et constitue par deux ou plusieurs elements se separant avant l'impact. | |

| FR2514123A1 (fr) | Perfectionnements apportes aux charges militaires agissant contre des cibles en vol ou au sol | |

| EP0545823A1 (de) | Splitterkörper, Verfahren zu seiner Herstellung und Verwendung für Munition | |

| EP1582837B1 (de) | Splittermantel für Explosivgeschosse | |

| FR2549949A1 (fr) | Procede et dispositif pour la conformation d'une onde de detonation | |

| EP0437992B1 (de) | Sprengladung zum Bilden mehrerer Bolzen und/oder Stacheln | |

| EP1766323B1 (de) | Geschoss, insbesondere eine infrastruktur durchschlagende bombe und wanddurchschlagverfahren für das geschoss | |

| EP0357514B1 (de) | Munitionsschutzhülle mit Mitteln, die deren Zerlegen erlauben | |

| EP0138640B1 (de) | Explosive Ladung für militärische Verwendung | |

| EP0329530B1 (de) | Verfahren zum Hervorrufen eines mit Stabilisierungsflossen versehenen Stachels und seine Anwendung in einem Gefechtskopf | |

| EP0561085A1 (de) | Hohlladung zum Durchschlagen einer mit einer reaktiven Vorpanzerung versehenen Panzerplatte | |

| FR2667140A1 (fr) | Dispositif pyrotechnique de production de jets de matiere a tres hautes vitesses et installation a perforations multiples. | |

| WO2014095989A1 (fr) | Charge militaire a eclats et procede de fabrication | |

| FR2671619A1 (fr) | Garniture de charge explosive formant projectile. | |

| EP0091860A1 (de) | Panzerbrechende Hohlladung | |

| FR2704052A1 (fr) | Charge formée multiamorçable. | |

| FR2894331A1 (fr) | Projectile perforant et procede de fabrication d'un tel projectile | |

| EP0999425A1 (de) | Geschoss zur Herstellung von kalibrierten Splittern | |

| EP1429107B1 (de) | Hohlladung | |

| FR2523713A1 (fr) | Charge creuse | |

| EP0376838B1 (de) | Vorrichtung zum Schneiden fester Strukturen auf Abstand durch gezieltes Werfen von Splittern |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES GB IT LI NL PT SE |

|

| 17P | Request for examination filed |

Effective date: 19930614 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: TITANITE SA |

|

| 17Q | First examination report despatched |

Effective date: 19941229 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19950505 |