EP0545136B1 - Soft package for tissues - Google Patents

Soft package for tissues Download PDFInfo

- Publication number

- EP0545136B1 EP0545136B1 EP92119598A EP92119598A EP0545136B1 EP 0545136 B1 EP0545136 B1 EP 0545136B1 EP 92119598 A EP92119598 A EP 92119598A EP 92119598 A EP92119598 A EP 92119598A EP 0545136 B1 EP0545136 B1 EP 0545136B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- adhesive

- adhesive label

- region

- pack

- free

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000853 adhesive Substances 0.000 claims description 75

- 230000001070 adhesive effect Effects 0.000 claims description 75

- 239000000463 material Substances 0.000 claims description 16

- 239000011248 coating agent Substances 0.000 claims description 9

- 238000000576 coating method Methods 0.000 claims description 9

- 239000002699 waste material Substances 0.000 claims description 5

- 229920006255 plastic film Polymers 0.000 claims description 4

- 239000000109 continuous material Substances 0.000 claims description 3

- 229920002678 cellulose Polymers 0.000 claims description 2

- 239000001913 cellulose Substances 0.000 claims description 2

- 239000005021 flexible packaging material Substances 0.000 claims description 2

- 239000002985 plastic film Substances 0.000 claims description 2

- 238000004080 punching Methods 0.000 claims description 2

- 239000012790 adhesive layer Substances 0.000 claims 1

- 230000003313 weakening effect Effects 0.000 claims 1

- 238000004519 manufacturing process Methods 0.000 description 6

- 238000004806 packaging method and process Methods 0.000 description 5

- 239000003292 glue Substances 0.000 description 4

- 239000002390 adhesive tape Substances 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/04—Articles or materials wholly enclosed in single sheets or wrapper blanks

- B65D75/06—Articles or materials wholly enclosed in single sheets or wrapper blanks in sheets or blanks initially folded to form tubes

- B65D75/08—Articles or materials wholly enclosed in single sheets or wrapper blanks in sheets or blanks initially folded to form tubes with the ends of the tube closed by folding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

- B65D75/58—Opening or contents-removing devices added or incorporated during package manufacture

- B65D75/5827—Tear-lines provided in a wall portion

- B65D75/5833—Tear-lines provided in a wall portion for tearing out a portion of the wall

- B65D75/5838—Tear-lines provided in a wall portion for tearing out a portion of the wall combined with separate fixed tearing means, e.g. tabs

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S229/00—Envelopes, wrappers, and paperboard boxes

- Y10S229/924—Means to facilitate gripping a tear strip

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S229/00—Envelopes, wrappers, and paperboard boxes

- Y10S229/924—Means to facilitate gripping a tear strip

- Y10S229/926—Pull tab located in a seam

Definitions

- the invention relates to a soft pack for cellulose products, in particular stacks of folded paper handkerchiefs, made from a blank of thin, flexible packaging material, in particular plastic film, which encloses the pack contents on all sides, with a perforation line or other lines of weakness in the area of a pack side, preferably in the area of a front wall limited tear tab is formed, which is partially covered by a large adhesive label with an adhesive-free handle tab for opening and reclosing the soft pack.

- Packaging for folded paper handkerchiefs has been equipped with a reclosable opening aid for some time.

- a tear tab is defined by perforation lines, which can be opened and brought back into the closed position with the aid of an adhesive strip or adhesive label attached to the tear tab.

- the adhesive strips used in known packs are relatively narrow (about 1 cm wide). This is disadvantageous for the handling of the package and for the dimensional stability of the tear tab.

- the advantage of the adhesive tape lies in the cost-effective production by separating it from a continuous web with one-sided adhesive coating.

- the adhesive-free grip end of the adhesive strip is usually produced by a piece of film attached to the side coated with adhesive.

- the object of the invention is to achieve, by designing an adhesive label and by further measures, that the advantages of adhesive labels are retained in the case of such soft packs, the disadvantages of which, in particular the manufacturing outlay, are avoided.

- the soft pack equipped with an adhesive label is characterized in that the adhesive label is separated from a continuous material web with a one-sided adhesive coating by punching without waste.

- the adhesive label is designed according to the invention in such a way that laterally boundaries or side edges correspond to the course of a material web in the width of the adhesive labels.

- the transverse boundaries i.e. transverse edges

- the prerequisite is that the mutually opposite transverse edges of an adhesive label correspond to one another, since the transverse edges of adjacent adhesive labels are produced within the material web with no waste and without waste.

- the transverse edges of an adhesive label are designed in a convex and concave arc shape according to the invention.

- the adhesive-free handle end of the adhesive label is attached during the production of the material web or the coating thereof with adhesive, in which an edge region of the adhesive label is not coated with adhesive.

- the adhesive-free area that is to say the grip tab, is delimited from the remaining part of the adhesive label by a special, in particular colored coating.

- An edge strip in the area of the grip tab is free of glue and free of colored coating.

- the die cut is carried out to separate the adhesive label from the web.

- the adhesive and color-free edge strips allow a margin for making the die cut.

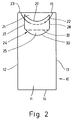

- the exemplary embodiment of a packaging shown in FIGS. 1 and 2 is cuboid.

- Package contents are preferably a stack of folded paper tissues. These are surrounded by an outer covering 10, which usually consists of a thin, thermally sealable (plastic) film. But it can also be made of paper or paper-like material.

- the pack is designed so that the outer envelope forms a front wall 11, a corresponding rear wall, two opposite, narrow, upright side walls 12 and 13 and a bottom wall 14 and an end wall 15.

- the outer casing 10 consists of a rectangular blank. This forms longitudinal tabs (not shown) connected to one another in the region of one of the side walls 12, 13. Furthermore, a special fold is formed in the area of the bottom wall 14 and the end wall 15. This envelope-like fold consists of side tabs 16, 17 and an inner longitudinal tab 18 and an outer longitudinal tab 19. The latter are trapezoidal. In the area of mutual overlap, these folding tabs are connected to one another.

- the packaging designed in this way is provided with an opening aid which has a tear-open tab 21 in the region of the front wall 11.

- the tear tab 21 faces the end wall 15.

- the tear-open tab 21 forms a removal opening adjacent to the end wall 15 in the region of the front wall 11.

- the tear-open tab 21 is delimited by an arcuate perforation line 22.

- the perforation line 22 is severed, so that the tear-open tab 21 comes free from the remaining part of the front wall 11.

- the perforation line 22 ends at an upper transverse edge 23 between the front wall 11 and the front wall 15.

- the tear-open tab 21 interacts with an adhesive label 24.

- This is attached in the area of the tear-open tab 21, in such a way that a lower section is adhesively connected to the front wall 11 outside the tear-open tab 21 and another part.

- a free, lower edge area of the adhesive label 24 is provided with an adhesive-free grip tab 25. This lies freely against the front wall 11 and enables the adhesive label 24 to be gripped in order to open the package.

- the adhesive label 24 is first removed from the front wall 11. When the package is opened for the first time, the perforation line 22 is then severed. The tear tab 21 is released and is moved due to the connection with the adhesive label 24 through this in the open position. For reclosing, the adhesive label 24 is brought back into the position shown in FIGS. 1 and 2 with the tear tab 21.

- the adhesive label 24 consists of a somewhat thicker (plastic) film which is coated with an adhesive on the side facing the front wall 11 or the tear-open tab 21, with the exception of the grip tab 25.

- the adhesive label 24 differs primarily by size, in particular Width of a tape.

- the adhesive label 24 has a width which is at least half the width of the Front wall 11 corresponds. As a result, the predominant part of the perforation line 22 and also the tear-open tab 21 are covered by the adhesive label 24.

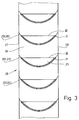

- the adhesive label 24 is produced by separating it from a continuous material web 26. This is provided on one side with a suitable glue applicator with the adhesive. The areas of the grip tab 25 are left out. This is possible, for example, by means of glue application rollers with corresponding interruptions in the glue transfer surfaces.

- the grip tab 25 is also provided with a colored coating on the adhesive side of the adhesive label 24.

- the width of the material web 26 corresponds to the width of the adhesive label 24. This is therefore limited by parallel side edges 27, 28.

- a crosscut die cut separates an adhesive label 24 from the material web 26. This punch cut is made so that transverse edges 29, 30 of the adhesive label also run parallel to one another.

- the adhesive labels are therefore produced without waste.

- the transverse edges 29, 30 are guided in an arc shape to match the course of the perforation line 22 in such a way that they run approximately parallel to the perforation line 22.

- the upper transverse edge 29 is therefore concave and the lower transverse edge 30 is convex.

- the grip tab 25 is thus tongue-shaped for easy grasping.

- the grip tab 25 has a smaller width than the adhesive label 24, so that it is adhesively connected to the front wall 11 in the region of the side edges 27, 28.

- the area of the adhesive label 24 provided with adhesive is delimited from the grip tab 25 by a straight, transverse adhesive edge 32.

- a strip 31 is cut out along the transverse edges 29 and 30 of successive adhesive labels 24 within the material web 26, namely free of adhesive as well as free of colored coating for identifying the grip tab 25.

- the die cut is carried out within this strip 31 .

- the strip 31 expediently has a width of 0.5 mm to 1 mm. It is thereby prevented that an edge strip of the colored coating of the grip tab 25 on the upper transverse edge 29 of an adjacent adhesive label 24 is recognizable when the die cut is not exactly guided. Furthermore, this prevents an edge strip of an area of the adhesive label 24 coated with adhesive coated at the lower transverse edge 30 in the region of the grip tab 25 of the adjacent adhesive label 24 from remaining in the case of a not exactly guided die cut.

- the adhesive labels 24 are expediently produced from the material web 26 within the packaging machine and are transferred to the package immediately after the separation.

- the material web 26 is wound as a bobbin.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Package Frames And Binding Bands (AREA)

- Cartons (AREA)

Description

Die Erfindung betrifft eine Weichpackung für Zellstofferzeugnisse, insbesondere Stapel von gefalteten Papiertaschentüchern, aus einem den Packungsinhalt allseitig umschließenden Zuschnitt aus dünnem, flexiblem Verpackungsmaterial, insbesondere Kunststoff-Folie, wobei im Bereich einer Packungsseite, vorzugsweise im Bereich einer Vorderwand, eine durch Perforationslinie oder andere Schwächungslinien begrenzte Aufreißlasche gebildet ist, die durch ein großflächiges Klebeetikett mit klebstofffreier Grifflasche zum Öffnen und Wiederverschließen der Weichpackung teilweise überdeckt ist.The invention relates to a soft pack for cellulose products, in particular stacks of folded paper handkerchiefs, made from a blank of thin, flexible packaging material, in particular plastic film, which encloses the pack contents on all sides, with a perforation line or other lines of weakness in the area of a pack side, preferably in the area of a front wall limited tear tab is formed, which is partially covered by a large adhesive label with an adhesive-free handle tab for opening and reclosing the soft pack.

Verpackungen für gefaltete Papiertaschentücher sind seit einiger Zeit mit einer wiederverschließbaren Öffnungshilfe ausgerüstet. Im Bereich der Vorderwand der Packung ist durch Perforationslinien eine Aufreißlasche definiert, die mit Hilfe eines an der Aufreißlasche befestigten Klebestreifens oder Klebeetiketts geöffnet und wieder in Schließstellung gebracht werden kann. Die bei bekannten Packungen verwendeten Klebestreifen sind verhältnismäßig schmal (etwa 1 cm breit). Dies ist nachteilig für die Handhabung der Packung sowie für die Formstabilität der Aufreißlasche. Der Vorteil des Klebestreifens (tape) liegt in der kostengünstigen Herstellung durch Abtrennen von einer fortlaufenden Bahn mit einseitiger Klebstoffbeschichtung. Das klebstofffreie Griffende des Klebestreifens wird üblicherweise durch ein auf der mit Klebstoff beschichteten Seite angebrachtes Folienstück erzeugt.Packaging for folded paper handkerchiefs has been equipped with a reclosable opening aid for some time. In the area of the front wall of the pack, a tear tab is defined by perforation lines, which can be opened and brought back into the closed position with the aid of an adhesive strip or adhesive label attached to the tear tab. The adhesive strips used in known packs are relatively narrow (about 1 cm wide). This is disadvantageous for the handling of the package and for the dimensional stability of the tear tab. The advantage of the adhesive tape lies in the cost-effective production by separating it from a continuous web with one-sided adhesive coating. The adhesive-free grip end of the adhesive strip is usually produced by a piece of film attached to the side coated with adhesive.

Die beträchtlich breiteren Klebeetiketten sind zwar in der Handhabung vorteilhaft gegenüber Klebestreifen. Die Herstellung ist jedoch aufwendig, da die Klebeetiketten auf einer Trägerschicht gefertigt und für die Anbringung an der Packung von dieser Trägerschicht abgezogen werden müssen. Das DE-GM 87 08 274.8 zeigt eine Packung mit derartigen Klebeetiketten in verschiedener Ausführung. Durch die besonderen Konturen ist ein erheblicher Materialbedarf bei der Fertigung der Klebeetiketten erforderlich.The considerably wider adhesive labels are advantageous compared to adhesive strips in terms of handling. However, production is complex since the adhesive labels have to be produced on a carrier layer and have to be removed from this carrier layer for attachment to the pack. DE-GM 87 08 274.8 shows a pack with such adhesive labels in various designs. Due to the special contours, a considerable amount of material is required to manufacture the adhesive labels.

Der Erfindung liegt die Aufgabe zugrunde, durch Gestaltung eines Klebeetiketts und durch weitere Maßnahmen zu erreichen, daß die Vorzüge von Klebeetiketten bei derartigen Weichpackungen beibehalten, deren Nachteile, insbesondere der Herstellungsaufwand, jedoch vermieden werden.The object of the invention is to achieve, by designing an adhesive label and by further measures, that the advantages of adhesive labels are retained in the case of such soft packs, the disadvantages of which, in particular the manufacturing outlay, are avoided.

Zur Lösung dieser Aufgabe ist die mit einem Klebeetikett ausgerüstete Weichpackung dadurch gekennzeichnet, daß das Klebeetikett von einer fortlaufenden Materialbahn mit einseitiger Klebstoffbeschichtung durch Stanzen abfallfrei abgetrennt ist.To solve this problem, the soft pack equipped with an adhesive label is characterized in that the adhesive label is separated from a continuous material web with a one-sided adhesive coating by punching without waste.

Zu diesem Zweck ist erfindungsgemäß das Klebeetikett so ausgebildet, daß seitlich Begrenzungen bzw. Seitenränder dem Verlauf einer Materialbahn in der Breite der Klebeetiketten entspricht. Die quergerichteten Begrenzungen, also Querränder, können mit besonderen Konturen versehen sein. Voraussetzung ist aber, daß die einander gegenüberliegenden Querränder eines Klebeetiketts miteinander korrespondieren, da mit einem einzigen Stanzschnitt abfallfrei die Querränder benachbarter Klebeetiketten innerhalb der Materialbahn hergestellt werden. Insbesondere sind die Querränder eines Klebeetiketts erfindungsgemäß konvex und konkav bogenförmig gestaltet.For this purpose, the adhesive label is designed according to the invention in such a way that laterally boundaries or side edges correspond to the course of a material web in the width of the adhesive labels. The transverse boundaries, i.e. transverse edges, can be provided with special contours. However, the prerequisite is that the mutually opposite transverse edges of an adhesive label correspond to one another, since the transverse edges of adjacent adhesive labels are produced within the material web with no waste and without waste. In particular, the transverse edges of an adhesive label are designed in a convex and concave arc shape according to the invention.

Das klebefreie Griffende des Klebeetiketts wird erfindungsgemäß bei der Herstellung der Materialbahn bzw. der Beschichtung derselben mit Kleber angebracht, in dem ein Randbereich des Klebeetiketts nicht mit Kleber beschichtet wird. Des weiteren ist der klebstofffreie Bereich, also die Grifflasche, durch eine besondere, insbesondere farbige Beschichtung von dem übrigen Teil des Klebeetiketts abgegrenzt. Ein Randstreifen im Bereich der Grifflasche ist frei von Kleber und frei von farblicher Beschichtung. In diesem Bereich wird der Stanzschnitt zum Abtrennen des Klebeetiketts von der Bahn ausgeführt. Der klebstoff- und farbfreie Randstreifen läßt einen Spielraum für die Anbringung des Stanzschnittes zu.According to the invention, the adhesive-free handle end of the adhesive label is attached during the production of the material web or the coating thereof with adhesive, in which an edge region of the adhesive label is not coated with adhesive. Furthermore, the adhesive-free area, that is to say the grip tab, is delimited from the remaining part of the adhesive label by a special, in particular colored coating. An edge strip in the area of the grip tab is free of glue and free of colored coating. In this area, the die cut is carried out to separate the adhesive label from the web. The adhesive and color-free edge strips allow a margin for making the die cut.

Weitere Einzelheiten der Erfindung beziehen sich auf die Gestaltung des Klebeetiketts bzw. der Materialbahn in Verbindung mit der Verpackung.Further details of the invention relate to the design of the adhesive label or the material web in connection with the packaging.

Ein Ausführungsbeispiel der Erfindung wird nachfolgend anhand der Zeichnungen näher erläutert. Es zeigt:

- Fig. 1

- eine quaderförmige Weichpackung mit Klebeetikett als Öffnungshilfe in perspektivischer Vorderansicht,

- Fig. 2

- die Vorderseite der Packung gemäß Fig. 1 in Ansicht,

- Fig. 3

- einen Abschnitt einer Materialbahn zum Herstellen von Klebeetiketten.

- Fig. 1

- a cuboidal soft pack with adhesive label as opening aid in a perspective front view,

- Fig. 2

- the front of the pack of FIG. 1 in view,

- Fig. 3

- a section of a material web for the production of adhesive labels.

Das in Fig. 1 und Fig. 2 gezeigte Ausführungsbeispiel einer Verpackung ist quaderförmig ausgebildet. Packungsinhalt ist vorzugsweise ein Stapel von gefalteten Papiertaschentüchern. Diese sind von einer Außenumhüllung 10 umgeben, die üblicherweise aus einer dünnen, thermisch siegelbaren (Kunststoff-)Folie besteht. Sie kann aber auch aus Papier oder papierähnlichem Werkstoff gebildet sein.The exemplary embodiment of a packaging shown in FIGS. 1 and 2 is cuboid. Package contents are preferably a stack of folded paper tissues. These are surrounded by an

Die Packung ist so gestaltet, daß die Außenumhüllung eine Vorderwand 11, eine dazu korrespondierende Rückwand, zwei einander gegenüberliegende schmale, aufrechte Seitenwände 12 und 13 sowie eine Bodenwand 14 und eine Stirnwand 15 bildet.The pack is designed so that the outer envelope forms a

Die Außenumhüllung 10 besteht aus einem rechteckigen Zuschnitt. Dieser bildet im Bereich einer der Seitenwände 12, 13 miteinander verbundene Längslappen (nicht gezeigt). Des weiteren ist eine besondere Faltung im Bereich der Bodenwand 14 sowie der Stirnwand 15 gebildet. Diese kuvertartige Faltung besteht aus Seitenlappen 16, 17 sowie einem inneren Längslappen 18 und einem äußeren Längslappen 19. Letztere sind trapezförmig ausgebildet. Im Bereich einer wechselseitigen Überdeckung sind diese Faltlappen miteinander verbunden.The

Die so ausgebildete Verpackung ist mit einer Öffnungshilfe versehen, die eine Aufreißlasche 21 im Bereich der Vorderwand 11 aufweist. Die Aufreißlasche 21 ist in diesem Falle der Stirnwand 15 zugekehrt. In geöffnetem Zustand bildet die Aufreißlasche 21 eine der Stirnwand 15 benachbarte Entnahmeöffnung im Bereich der Vorderwand 11. Die Aufreißlasche 21 ist bei dem vorliegenden Ausführungsbeispiel durch eine bogenförmige Perforationslinie 22 begrenzt. Bei der erstmaligen Ingebrauchnahme wird die Perforationslinie 22 durchtrennt, so daß die Aufreißlasche 21 von dem übrigen Teil der Vorderwand 11 frei kommt. Die Perforationslinie 22 endet an einer oberen Querkante 23 zwischen Vorderwand 11 und Stirnwand 15.The packaging designed in this way is provided with an opening aid which has a tear-

Die Aufreißlasche 21 wirkt zusammen mit einem Klebeetikett 24. Dieses ist im Bereich der Aufreißlasche 21 angebracht, und zwar derart, daß ein unterer Teilbereich mit der Vorderwand 11 außerhalb der Aufreißlasche 21 und ein anderer Teil mit dieser klebend verbunden ist. Ein freier, unterer Randbereich des Klebeetiketts 24 ist mit einer klebstofffreien Grifflasche 25 versehen. Diese liegt frei an der Vorderwand 11 an und ermöglicht das Erfassen des Klebeetiketts 24 zum Öffnen der Packung. Dabei wird zunächst das Klebeetikett 24 von der Vordewand 11 abgezogen. Beim erstmaligen Öffnen der Packung wird sodann die Perforationslinie 22 durchtrennt. Die Aufreißlasche 21 kommt frei und wird infolge der Verbindung mit dem Klebeetikett 24 durch dieses in Öffnungsstellung bewegt. Zum Wiederverschließen wird das Klebeetikett 24 mit der Aufreißlasche 21 wieder in die in Fig. 1 und Fig. 2 gezeigte Position gebracht.The tear-

Das Klebeetikett 24 besteht aus einer etwas dickeren (Kunststoff-)Folie, die auf der der Vorderwand 11 bzw. der Aufreißlasche 21 zugekehrten Seite mit einem Kleber beschichtet ist unter Aussparung der Grifflasche 25. Das Klebeetikett 24 unterscheidet sich vor allem durch die Größe, insbesondere Breite von einem Tape. Das Klebeetikett 24 hat eine Breite, die mindestens der halben Breite der Vorderwand 11 entspricht. Dadurch ist der überwiegende Teil der Perforationslinie 22 und auch der Aufreißlasche 21 durch das Klebeetikett 24 überdeckt.The

Das Klebeetikett 24 wird durch Abtrennen von einer fortlaufenden Materialbahn 26 hergestellt. Diese wird mit einem geeigneten Leimauftragsgerät einseitig mit dem Kleber versehen. Die Bereiche der Grifflasche 25 werden dabei ausgespart. Dies ist beispielsweise möglich durch Leimauftragswalzen mit entsprechenden Unterbrechungen von Leimübertragungsflächen. Die Grifflasche 25 wird darüber hinaus auf der klebenden Seite des Klebeetiketts 24 mit einer farbigen Beschichtung versehen.The

Die Breite der Materialbahn 26 entspricht der Breite des Klebeetiketts 24. Dieses ist demnach durch parallele Seitenränder 27, 28 begrenzt. Ein quergerichteter Stanzschnitt trennt jeweils ein Klebeetikett 24 von der Materialbahn 26 ab. Dieser Stanzschnitt ist so geführt, daß auch Querränder 29, 30 des Klebeetiketts parallel zueinander verlaufen. Die Klebeetiketten werden demnach abfallfrei hergestellt. Bei dem gezeigten Ausführungsbeispiel sind die Querränder 29, 30 bogenförmig geführt unter Anpassung an den Verlauf der Perforationslinie 22, derart, daß sie annähernd parallel zur Perforationslinie 22 verlaufen. Der obere Querrand 29 ist demnach konkav und der untere Querrand 30 konvex ausgebildet.The width of the

Die Grifflasche 25 ist dadurch zungenförmig gestaltet zum leichten Erfassen. Die Grifflasche 25 hat jedoch eine geringere Breite als das Klebeetikett 24, so daß dieses im Bereich der Seitenränder 27, 28 klebend mit der Vorderwand 11 verbunden ist. Der mit Kleber versehene Bereich des Klebeetiketts 24 ist von der Grifflasche 25 durch einen geradlinig, quer verlaufenden Klebstoffrand 32 abgegrenzt.The

Im Bereich der Grifflasche 25 ist entlang den Querrändern 29 und 30 von aufeinanderfolgenden Klebeetiketten 24 innerhalb der Materialbahn 26 ein Streifen 31 ausgespart, nämlich sowohl frei von Kleber als auch frei von farblicher Beschichtung zur Kennzeichnung der Grifflasche 25. Innerhalb dieses Streifens 31 wird der Stanzschnitt geführt. Der Streifen 31 hat zweckmäßigerweise eine Breite von 0,5 mm bis 1 mm. Es wird dadurch verhindert, daß bei nicht exakt geführtem Stanzschnitt ein Randstreifen der farbigen Beschichtung der Grifflasche 25 am oberen Querrand 29 eines benachbarten Klebeetiketts 24 erkennbar ist. Des weiteren wird dadurch verhindert, daß bei nicht exakt geführtem Stanzschnitt ein mit Kleber beschichteter Randstreifen eines mit Kleber beschichteten Bereichs des Klebeetiketts 24 am unteren Querrand 30 im Bereich der Grifflasche 25 des benachbarten Klebeetiketts 24 verbleibt.In the area of the

Bei der Fertigung von Packungen gemäß Fig. 1 werden zweckmäßigerweise die Klebeetiketten 24 innerhalb der Verpackungsmaschine von der Materialbahn 26 hergestellt und unmittelbar nach dem Abtrennen auf die Packung übertragen. Die Materialbahn 26 ist dabei als Bobine gewickelt.1, the

Claims (6)

- Soft pack for cellulose products, in particular stacks of folded paper handkerchiefs, comprising a blank which encloses the pack contents on all sides and consists of a thin, flexible packaging material, in particular plastic film, a tear-open flap (21) which is bounded by a perforation line (22) or other types of weakening line being formed in the region of a pack side, preferably in the region of a front wall (11), which tear-open flap is partially overlapped by a large-surface-area adhesive label (24) with an adhesive-free grip flap (25) for opening and re-closing the soft pack, characterized by the following features:a) the adhesive label (24) is severed, without producing any waste, from a continuous material web (26), with an adhesive coating on one side, by punching,b) the width of the adhesive label (24) corresponds to the width of the material web (26),c) the adhesive label (24) exhibits rectilinear, parallel side borders (27, 28) which correspond to the side borders of the material web (26), andd) the adhesive label (24) exhibits mutually parallel transverse borders (29, 30) which are not rectilinear, such that a bottom region, extending in the region of the front wall (11) of the pack, of the adhesive label (24) is designed in the form of a tongue, the adhesive-free end region of which forms the grip flap.

- Pack according to Claim 1, characterized in that a convex boundary (transverse border 30) of the adhesive label (24) in the region of the front wall (11) is designed in the form of an arc, in particular approximately in the form of an arc of a circle, and an opposite transverse border (29) in the region of the tear-open flap (21) is designed in a correspondingly concave manner.

- Pack according to Claim 1 or 2, characterized in that the grip flap (25) in the convex region of the adhesive label (24) is designed in an adhesive-free manner, in particular by applying an adhesive layer, while leaving free that surface area of the material web (26) which corresponds to the grip flap (25).

- Pack according to Claim 2, characterized in that, in the region of the grip flap (25), a border-side strip (31) which is in the form of an arc or corresponds to the contour of the transverse edge (30) is free of adhesive, and in that a transversely directed punch cut for severing the adhesive label (24) from the material web (26) is applied in the region of said strip (31).

- Pack according to Claim 3 or 4, characterized in that the adhesive-free grip flap (25) is of a smaller width than the adhesive label (24).

- Pack according to one or more of the preceding claims, characterized in that the transverse borders (29, 30) of the adhesive label (24) run approximately parallel to a perforation line (22) which bounds the tear-open flap (21).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4139924 | 1991-12-04 | ||

| DE4139924A DE4139924A1 (en) | 1991-12-04 | 1991-12-04 | SOFT PACK FOR PAPER HANDKERCHIEFS |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0545136A1 EP0545136A1 (en) | 1993-06-09 |

| EP0545136B1 true EP0545136B1 (en) | 1995-08-02 |

Family

ID=6446217

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92119598A Expired - Lifetime EP0545136B1 (en) | 1991-12-04 | 1992-11-17 | Soft package for tissues |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5307988A (en) |

| EP (1) | EP0545136B1 (en) |

| JP (1) | JP2672239B2 (en) |

| DE (2) | DE4139924A1 (en) |

| ES (1) | ES2075578T3 (en) |

Families Citing this family (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4202258A1 (en) * | 1992-01-28 | 1993-07-29 | Focke & Co | PACKAGE FOR RECEIVING HANDKERCHIEFS, CUTTING THEREFOR AND METHOD FOR PRODUCING SUCH A PACKAGE |

| DE4418485A1 (en) * | 1994-05-27 | 1995-11-30 | Senning Christian Verpackung | Soft film packaging |

| IT1270065B (en) * | 1994-07-04 | 1997-04-28 | Barilla Flli G & R | LABEL FOR FOLDABLE PACKAGING |

| US5443161A (en) * | 1994-07-26 | 1995-08-22 | Jonese; David R. | Disposable baby change kit |

| ITTO940795A1 (en) * | 1994-10-07 | 1996-04-07 | P & G Spa | SEALABLE PACKAGE |

| FR2744014A1 (en) * | 1996-01-26 | 1997-08-01 | Chansard Pascal Gilles | Baby's nappy |

| US9150342B2 (en) | 2003-04-16 | 2015-10-06 | Intercontinental Great Brands Llc | Resealable tray container |

| WO2005110876A1 (en) | 2004-05-11 | 2005-11-24 | Cadbury Adams Usa Llc | Gum slab package with flap retention |

| US7159717B2 (en) | 2004-05-11 | 2007-01-09 | Cadbury Adams Usa, Llc | Packaging design with separate compartments |

| US7971718B2 (en) | 2005-05-09 | 2011-07-05 | Kraft Foods Global Brands Llc | Package for dispensing and retaining gum slabs with adhesive securement |

| ATE507159T1 (en) * | 2004-05-11 | 2011-05-15 | Cadbury Adams Usa Llc | PACKAGING FOR DISPENSING AND HOLDING CHEWING GUM STRIPS WITH ADHESIVE SECURITY |

| ATE435162T1 (en) | 2004-05-11 | 2009-07-15 | Cadbury Adams Usa Llc | PACKAGING WITH INSERTABLE PRODUCT HOLDING ELEMENT |

| US20070199849A1 (en) * | 2004-05-11 | 2007-08-30 | Cadbury Adams Usa Llc. | Package for accommodating an array of consumable products |

| AU2005269994C1 (en) | 2004-07-08 | 2012-07-12 | Intercontinental Great Brands Llc | Reclosable consumable product package assembly |

| US7963413B2 (en) | 2006-05-23 | 2011-06-21 | Kraft Foods Global Brands Llc | Tamper evident resealable closure |

| US8308363B2 (en) | 2006-05-23 | 2012-11-13 | Kraft Foods Global Brands Llc | Package integrity indicator for container closure |

| US20080277408A1 (en) * | 2006-06-13 | 2008-11-13 | Rapala Gregg R | Sheeted cleaning medium and dispenser/receptacle |

| US8114451B2 (en) | 2006-12-27 | 2012-02-14 | Kraft Foods Global Brands Llc | Resealable closure with package integrity feature |

| US8408792B2 (en) | 2007-03-30 | 2013-04-02 | Kraft Foods Global Brands Llc | Package integrity indicating closure |

| DE102008018121A1 (en) * | 2008-04-09 | 2009-10-15 | Lemo Maschinenbau Gmbh | packing bags |

| US7789291B2 (en) * | 2008-06-10 | 2010-09-07 | Printpack Illinois, Inc. | Packaging article and method with particular tearing slit arrangement |

| US20100018974A1 (en) | 2008-07-24 | 2010-01-28 | Deborah Lyzenga | Package integrity indicating closure |

| GB0819200D0 (en) | 2008-10-20 | 2008-11-26 | Cadbury Holdings Ltd | Packaging |

| US20100172604A1 (en) * | 2009-01-06 | 2010-07-08 | Printpack Illinois, Inc. | Reclosable Container with Resealable Flexible Cover and Method for Manufacturing the Same |

| PL2391556T3 (en) | 2009-02-02 | 2016-03-31 | Intercontinental Great Brands Llc | Openable and reclosable sealed package for confectionery products |

| DK2243711T3 (en) | 2009-04-22 | 2012-10-22 | Hoffmann La Roche | Manufacture of tape products with diagnostic aids |

| PL2347971T3 (en) | 2010-01-26 | 2012-11-30 | Biscuit Gle | Resealable packaging for food products and method of manufacturing |

| ES2390568T3 (en) | 2010-03-23 | 2012-11-14 | Generale Biscuit | Closing container for food products and manufacturing method |

| US9656783B2 (en) | 2010-05-18 | 2017-05-23 | Intercontinental Great Brands Llc | Reclosable flexible packaging and methods for manufacturing same |

| ES2525843T3 (en) | 2010-05-18 | 2014-12-30 | Intercontinental Great Brands Llc | Flexible container repeatedly closable and manufacturing methods |

| PL2686251T3 (en) | 2011-03-17 | 2015-10-30 | Intercontinental Great Brands Llc | Reclosable flexible film package, laminate, method and apparatus for manufacture |

| WO2015113030A1 (en) * | 2014-01-27 | 2015-07-30 | The Procter & Gamble Company | Dispensing system for sanitary tissue products |

| US9533813B1 (en) * | 2015-09-27 | 2017-01-03 | Sealstrip Corporation | Re-closable, tamper-resistant, stand-up package |

| EP3611111B1 (en) * | 2018-08-13 | 2021-06-23 | The Procter & Gamble Company | Absorbent article package with enhanced opening and recloseability |

| JP7456878B2 (en) * | 2020-07-31 | 2024-03-27 | 大王製紙株式会社 | sheet packaging |

| JP7456877B2 (en) * | 2020-07-31 | 2024-03-27 | 大王製紙株式会社 | Sheet packaging |

| JP7456880B2 (en) * | 2020-07-31 | 2024-03-27 | 大王製紙株式会社 | Sheet packaging |

| JP7456879B2 (en) * | 2020-07-31 | 2024-03-27 | 大王製紙株式会社 | sheet packaging |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB393199A (en) * | 1932-11-28 | 1933-06-01 | Philip Moffat Robinson | Improvements in packages |

| DE1732309U (en) * | 1956-05-26 | 1956-10-18 | Licentia Gmbh | ADHESIVE TAPE WITH INTERRUPTED RUBBER. |

| US3190443A (en) * | 1962-12-17 | 1965-06-22 | Kingsley Machine Co | Non-sticking lift tabs for quick removal of pressure adhesive labels |

| GB1002932A (en) * | 1963-06-04 | 1965-09-02 | Tetra Pak Ab | A device for applying covering wafers, labels or the like to a continuously or intermittently advanced web of material |

| US3231949A (en) * | 1964-01-31 | 1966-02-01 | Dennison Mfg Co | Paster tabs |

| DE2803475A1 (en) * | 1978-01-27 | 1979-08-02 | Sengewald Karl H | Box-shaped package pref. of polyethylene for paper handkerchiefs - has self adhesive foil with non-adhesive gripper lug fixed to head section |

| AU536262B2 (en) * | 1979-12-03 | 1984-05-03 | Kenji Nakamura | Resealable dispenser container |

| DE7934619U1 (en) * | 1979-12-08 | 1985-06-13 | Christian Senning Verpackungsautomaten Gmbh & Co, 2800 Bre | Soft packaging made from a plastic film, in particular for paper handkerchiefs |

| US4390577A (en) * | 1981-02-26 | 1983-06-28 | Monarch Marking Systems, Inc. | Composite label web |

| IT1152032B (en) * | 1981-08-21 | 1986-12-24 | Teich Ag Folienwalzwerk | PACKAGING WITH GAS SEALED ENVELOPE |

| US4723301A (en) * | 1986-02-03 | 1988-02-02 | Chang Sung Choi | Container resealable sealing device construction |

| US4679693A (en) * | 1986-05-14 | 1987-07-14 | Harold Forman | Label resealing container |

| DE3700988A1 (en) * | 1987-01-15 | 1988-07-28 | Sengewald Karl H | Packaging made of thermoplastic film |

| DE8708274U1 (en) * | 1987-06-12 | 1987-08-13 | Vereinigte Papierwerke AG, 8500 Nürnberg | Resealable packaging made of plastic film |

| US4863064A (en) * | 1987-09-18 | 1989-09-05 | Ifc Non-Wovens, Inc. | Flexible dispenser packet for pre-moistened towelettes |

| JPH0618884Y2 (en) * | 1988-12-26 | 1994-05-18 | 日本製紙株式会社 | Closed paper container with opening device |

| DE3911779A1 (en) * | 1989-04-11 | 1990-10-18 | Focke & Co | FILM PACKAGING FOR PAPER HANDKERCHIEFS |

| DE3915192A1 (en) * | 1989-05-10 | 1990-11-15 | Focke & Co | METHOD AND DEVICE FOR PRODUCING (FILM) PACKAGING AND (FILM) PACKAGING |

| DE9004278U1 (en) * | 1990-04-12 | 1990-06-21 | Feldmühle AG, 4000 Düsseldorf | Resealable, cuboid-shaped film packaging for cellulose wipes |

-

1991

- 1991-12-04 DE DE4139924A patent/DE4139924A1/en not_active Withdrawn

-

1992

- 1992-11-17 EP EP92119598A patent/EP0545136B1/en not_active Expired - Lifetime

- 1992-11-17 DE DE59203104T patent/DE59203104D1/en not_active Expired - Fee Related

- 1992-11-17 ES ES92119598T patent/ES2075578T3/en not_active Expired - Lifetime

- 1992-12-02 US US07/984,473 patent/US5307988A/en not_active Expired - Fee Related

- 1992-12-04 JP JP4325734A patent/JP2672239B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ES2075578T3 (en) | 1995-10-01 |

| US5307988A (en) | 1994-05-03 |

| DE4139924A1 (en) | 1993-06-09 |

| JPH06115575A (en) | 1994-04-26 |

| JP2672239B2 (en) | 1997-11-05 |

| EP0545136A1 (en) | 1993-06-09 |

| DE59203104D1 (en) | 1995-09-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0545136B1 (en) | Soft package for tissues | |

| EP0392224B1 (en) | Carton for paper tissues | |

| EP0475463B1 (en) | Package made from sheet material with tear-off strip | |

| EP0574449B1 (en) | Tubular film bag package, in particular for sanitary towels and the like | |

| EP0401621B1 (en) | Soft package, in particular for paper handkerchiefs | |

| EP0030601B1 (en) | Flexible package made from a plastic foil, particularly for paper handkerchiefs | |

| EP0393395B1 (en) | Foil package, especially for paper handkerchiefs | |

| EP0226958B1 (en) | Cone-shaped package | |

| EP0419770A1 (en) | Soft-package for non-rectangular flat articles | |

| EP0370192A1 (en) | Carton for the receipt of stacked hygienic tissues | |

| EP0374663B1 (en) | Packaging container | |

| EP1051340A1 (en) | Foldable material (cigarette) packaging | |

| EP0547424B1 (en) | Package for paper handkerchiefs | |

| EP0258573B1 (en) | Portable packing bag made of plastic sheet and process for making it | |

| EP0680896B1 (en) | Soft sheet package | |

| EP0446628A1 (en) | Package formed of a flexible sheet for a quadrangular stack of flexible flat objects | |

| EP0378586B1 (en) | Softpack-type cigarette packet and process for producing it | |

| DE60004472T3 (en) | Dispenser pack for individual removal of web-shaped consumer goods | |

| EP0199225B1 (en) | Tearing device to open a container | |

| EP0385064A2 (en) | Foil for the receipt of information carriers for merchandise, packages or the like | |

| EP0451861A1 (en) | Reclosable film package of rectangular block form for containing tissue handkerchiefs | |

| DE29801763U1 (en) | Box of cotton swabs | |

| DD295329A5 (en) | FOIL-) PACKAGING FOR IN PARTICULAR PAPER POCKET POCKETS | |

| DE8911587U1 (en) | Resealable, cuboid-shaped folding box |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE ES FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19930909 |

|

| 17Q | First examination report despatched |

Effective date: 19940102 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19950807 |

|

| REF | Corresponds to: |

Ref document number: 59203104 Country of ref document: DE Date of ref document: 19950907 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2075578 Country of ref document: ES Kind code of ref document: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20041109 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20041117 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20041120 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20041214 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051117 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20051117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20060731 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20051118 |