EP0498947B1 - Moteur à combustion avec récirculation des gaz d'échappement - Google Patents

Moteur à combustion avec récirculation des gaz d'échappement Download PDFInfo

- Publication number

- EP0498947B1 EP0498947B1 EP91120241A EP91120241A EP0498947B1 EP 0498947 B1 EP0498947 B1 EP 0498947B1 EP 91120241 A EP91120241 A EP 91120241A EP 91120241 A EP91120241 A EP 91120241A EP 0498947 B1 EP0498947 B1 EP 0498947B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- exhaust gas

- exhaust

- pipe

- gas feedback

- throttle valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000002485 combustion reaction Methods 0.000 title claims description 11

- 238000011144 upstream manufacturing Methods 0.000 claims description 3

- 239000007789 gas Substances 0.000 description 44

- 230000001419 dependent effect Effects 0.000 description 4

- 239000002184 metal Substances 0.000 description 2

- 230000000903 blocking effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000006866 deterioration Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

- 238000011084 recovery Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D9/00—Controlling engines by throttling air or fuel-and-air induction conduits or exhaust conduits

- F02D9/04—Controlling engines by throttling air or fuel-and-air induction conduits or exhaust conduits concerning exhaust conduits

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N1/00—Silencing apparatus characterised by method of silencing

- F01N1/16—Silencing apparatus characterised by method of silencing by using movable parts

- F01N1/165—Silencing apparatus characterised by method of silencing by using movable parts for adjusting flow area

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features ; Exhaust or silencing apparatus, or parts thereof, having pertinent characteristics not provided for in, or of interest apart from, groups F01N1/00 - F01N5/00, F01N9/00, F01N11/00

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M26/13—Arrangement or layout of EGR passages, e.g. in relation to specific engine parts or for incorporation of accessories

- F02M26/14—Arrangement or layout of EGR passages, e.g. in relation to specific engine parts or for incorporation of accessories in relation to the exhaust system

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M26/52—Systems for actuating EGR valves

- F02M26/59—Systems for actuating EGR valves using positive pressure actuators; Check valves therefor

- F02M26/61—Systems for actuating EGR valves using positive pressure actuators; Check valves therefor in response to exhaust pressure

- F02M26/615—Systems for actuating EGR valves using positive pressure actuators; Check valves therefor in response to exhaust pressure the exhaust back pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M26/00—Engine-pertinent apparatus for adding exhaust gases to combustion-air, main fuel or fuel-air mixture, e.g. by exhaust gas recirculation [EGR] systems

- F02M2026/001—Arrangements; Control features; Details

- F02M2026/004—EGR valve controlled by a temperature signal or an air/fuel ratio (lambda) signal

Definitions

- the invention relates to an internal combustion engine with exhaust gas recirculation according to the preamble of claim 1, in which a controllable amount of exhaust gases dependent on operating conditions is returned to the intake system.

- DE-OS 34 19 917 From DE-OS 34 19 917 it is known to supply a proportion of exhaust gases to the intake air under certain operating conditions. With this recirculation of exhaust gases, a number of positive effects that are becoming increasingly important in internal combustion engine construction, for example minimizing pollutant emissions, are achieved. The best results are achieved with exact control of the quantity of the recirculated exhaust gases in relation to the quantity of the sucked in or supplied fresh gases, taking into account the respective operating conditions such as load, speed, temperature. It is also known from DE-OS 34 19 917 to regulate the amount of exhaust gas recirculation using a plurality of valves and throttle valves in the exhaust gas recirculation line and in the intake system.

- valves or throttle valves in the exhaust gas recirculation line are only suitable for reducing or blocking the maximum flow rate, which depends on the pressure drop between the intake system and the exhaust system.

- the intake cross section can be narrowed, as in the solution mentioned, in order to increase the intake vacuum and thereby the pressure drop between the intake system and the exhaust system.

- a sufficient effective increase in intake vacuum, especially in the Partial load range with low speed relevant for exhaust gas recovery leads to a deterioration of the engine efficiency.

- the invention has for its object to further develop the known exhaust gas recirculation devices in such a way that the maximum exhaust gas recirculation quantity is increased at low speed, in particular in the exhaust gas recirculation-relevant partial load range, without additional complex control and actuation devices.

- the object is achieved by the features of claim 1.

- the invention is therefore based on increasing the recirculation quantity with constant or minimized cross sections of the exhaust gas recirculation line by a temperature-dependent increase in the exhaust gas back pressure, in particular in the exhaust gas recirculation-relevant partial load range.

- a throttle valve or a throttle valve can be arranged immediately after each connection of an exhaust gas recirculation line after the separate exhaust pipes have been brought together.

- several throttle valves can be arranged one behind the other.

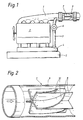

- FIG. 1 representing an internal combustion engine with exhaust gas recirculation

- FIG. 2 a throttle valve according to the invention.

- An exhaust gas recirculation line 3 is connected to an exhaust manifold 1 of an internal combustion engine 2 and opens into the mixing chamber 4, in which the fresh air flowing in from the air filter 5 is mixed with the exhaust gases flowing in via the exhaust gas recirculation line 3.

- the passage of the exhaust gas recirculation line 3 can be controlled by means of a valve 6.

- an intake throttle not shown, arranged upstream of the air filter 5 or arranged between the air filter 5 and the mixing chamber 4 can reduce the intake cross section.

- the valve 6 and the intake throttle are activated as a function of manipulated variables which are formed by evaluating operating parameters such as the load condition, speed and temperature.

- a temperature-dependent throttle valve 7 which is described in more detail in FIG. 2, is arranged downstream of the exhaust gas recirculation line 3 in the exhaust pipe 9.

- This throttle valve 7 consists essentially of at least four struts 8, which are fixed radially or in a star shape in the exhaust pipe 9 and are firmly connected to one another on the central longitudinal axis of the exhaust pipe 9, so that a rigid body dividing the cross section into circular segments is formed in the exhaust pipe 9, the Length extends over the entire length of the throttle valve 7.

- At the upstream ends of the struts 8 are over the entire possible width of the Central longitudinal axis to the wall of the exhaust pipe 9 bimetal plates 10, in the exhaust longitudinal direction against the struts 8, rigidly attached.

- These bi-metal sheets 10 taper downstream in their width in such a way that they completely or almost completely close the respective segment of the circle at low exhaust gas temperatures as shown in FIG. 2 in the curved state.

- a limitation of the maximum dynamic pressure is given by an appropriate design of the thickness and thus the rigidity and the elasticity of the bimetal plates 10, in that the bimetal plates 10 are bent against their closing direction when the intended dynamic pressure is exceeded.

- Changes in the load conditions in the direction of increasing the mean pressure P e lead to an immediate increase in the exhaust gas temperatures and thus with a short time delay for stretching and applying the bi-metal sheets 10 to the struts 8.

- the circle segments are thus released for unhindered exhaust gas passage and the dynamic pressure drops the unthrottled measure. This is sufficient for the small amounts of exhaust gas to be recycled under these operating conditions now there is a slight pressure drop.

- throttle valve 7 is advantageously arranged immediately after the outlet of the exhaust gas recirculation line 3, but the maximum exhaust gas temperature must not exceed the upper limit of the temperature capacity of the throttle valve 7.

- throttle valves 7 according to the invention are either arranged in each exhaust pipe analogous to a single-flow system or a throttle valve 7 after the exhaust pipes have been brought together.

- several throttle valves can be arranged one behind the other.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Exhaust-Gas Circulating Devices (AREA)

Claims (5)

- Moteur à combustion interne (2) avec recyclage de gaz d'échappement, comprenant une conduite de recyclage de gaz d'échappement (3) installée entre le système d'échappement et le système d'admission, une soupape commandée (6) placée dans la conduite de recyclage de gaz d'échappement (3) et une soupape d'étranglement (7) disposée dans le système d'échappement, en aval du raccordement de la conduite de recyclage de gaz d'échappement (3), soupape d'étranglement qui, au-dessous d'une température prédéterminée des gaz d'échappement, coupe dans une large mesure la section droite du tuyau d'échappement (9) et qui, à mesure que la température des gaz d'échappement s'élève, libère cette section droite de façon continue,

caractérisé en ce que

la soupape d'étranglement (7) est constituée par une soupape bimétallique qui se commande d'elle-même sous l'action de la température de gaz d'échappement et est formée d'une pluralité d'entretoises (8) disposées radialement ou en forme d'étoile dans le tuyau d'échappement (9), en partageant ainsi la section droite libre du tuyau d'échappement (9) en secteurs de disque, entretoises qui s'étendent sur toute la longueur de la soupape d'étranglement (7) et sont reliées entre elles sur l'axe du tuyau d'échappement (9) ainsi que, sur leur côté extérieur, à la paroi du tuyau d'échappement (9), et que, sur les extrémités côté amont des entretoises (8), sont fixées rigidement à la flexion, des lames bimétalliques (10) qui se rétrécissent dans le sens de l'écoulement, ces lames prenant à l'état chaud une forme étendue dans le sens de la longueur du tuyau d'échappement, avec application contre les entretoises (8), dans laquelle elles n'opposent presque pas de résistance à l'écoulement, tandis que, à l'état froid, elles sont courbées de manière que chaque lame bimétallique (10) ferme la section droite d'un des secteurs de disque formés par les entretoises (8) de la section droite du tuyau d'échappement. - Moteur à combustion interne avec recyclage de gaz d'échappement selon la revendication 1, caractérisé en ce que la pression de retenue maximale s'établissant à la fermeture de la soupape d'étranglement (7), est limitée par le choix approprié de la raideur ou de l'élasticité des lames bimétalliques (10).

- Moteur à combustion interne avec recyclage de gaz d'échappement selon la revendication 1, caractérisé en ce que, dans le cas d'un système d'échappement à plusieurs flux ou tuyaux d'échappement, comportant plusieurs conduites de recyclage de gaz d'échappement (3), une soupape d'étranglement (7) est disposée immédiatement après chaque raccordement d'une conduite de recyclage de gaz d'échappement (3).

- Moteur à combustion interne avec recyclage de gaz d'échappement selon la revendication 1, caractérisé en ce que, dans un système d'échappement à plusieurs flux ou tuyaux d'échappement, comportant plusieurs conduites de recyclage de gaz d'échappement (3), une soupape d'étranglement (7) est disposée après la réunion des tuyaux d'échappement séparés.

- Moteur à combustion interne avec recyclage de gaz d'échappement selon la revendication 1, caractérisé en ce que plusieurs soupapes d'étranglement (7) sont montées l'une derrière l'autre.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4104127 | 1991-02-12 | ||

| DE4104127A DE4104127C1 (fr) | 1991-02-12 | 1991-02-12 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0498947A1 EP0498947A1 (fr) | 1992-08-19 |

| EP0498947B1 true EP0498947B1 (fr) | 1993-09-29 |

Family

ID=6424826

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91120241A Expired - Lifetime EP0498947B1 (fr) | 1991-02-12 | 1991-11-27 | Moteur à combustion avec récirculation des gaz d'échappement |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0498947B1 (fr) |

| DE (1) | DE4104127C1 (fr) |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR595814A (fr) * | 1925-03-26 | 1925-10-09 | Perfectionnements aux moteurs à explosions et à combustion interne | |

| DE510960C (de) * | 1928-09-26 | 1930-10-24 | Willy Brandegger Dipl Ing | Einrichtung zur Durchflussregelung in Rohrleitungen |

| GB1043865A (en) * | 1962-07-12 | 1966-09-28 | Michael Guillermo May | Improvements in and relating to internal combustion engines |

| DE7301889U (de) * | 1973-01-19 | 1976-04-22 | Daimler-Benz Ag, 7000 Stuttgart | Brennkraftmaschine mit einer abgasleitung |

| FR2271393A1 (fr) * | 1974-02-01 | 1975-12-12 | Alsacienne Constr Meca | |

| JPS5844847B2 (ja) * | 1975-12-25 | 1983-10-05 | 株式会社日本自動車部品総合研究所 | ナイネンキカンヨウハイキガスジヨウカソウチ |

| DE2750537A1 (de) * | 1977-11-11 | 1979-05-17 | Audi Nsu Auto Union Ag | Verfahren zum vermindern des verbrennungsgeraeusches von dieselmotoren im leerlauf sowie vorrichtung zum durchfuehren des verfahrens |

| DE3419917A1 (de) * | 1983-06-08 | 1984-12-13 | AVL Gesellschaft für Verbrennungskraftmaschinen und Messtechnik mbH, Prof. Dr.Dr.h.c. Hans List, Graz | Brennkraftmaschine |

| DE3722970A1 (de) * | 1986-08-06 | 1988-02-11 | Volkswagen Ag | Verfahren und einrichtung zum reinigen eines partikelfilters, insbesondere eines russfilters |

-

1991

- 1991-02-12 DE DE4104127A patent/DE4104127C1/de not_active Expired - Fee Related

- 1991-11-27 EP EP91120241A patent/EP0498947B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0498947A1 (fr) | 1992-08-19 |

| DE4104127C1 (fr) | 1992-02-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2014887A2 (fr) | Soupape anti-retour et de distribution combinée | |

| EP2211048B1 (fr) | Dispositif de clapets de gaz d'échappement et système de récupération thermique à l'échappement d'un moteur à combustion interne | |

| EP2728156B1 (fr) | Dispositif de réglage pour un moteur à combustion interne | |

| WO2017108162A1 (fr) | Segment de guidage de gaz d'échappement pour un turbocompresseur et procédé de fonctionnement d'un turbocompresseur | |

| DE3738538C2 (de) | Katalysatoreinrichtung zur Abgasreinigung | |

| DE2252980A1 (de) | Treibstoffverteilungssystem fuer gasturbinentriebwerke | |

| WO2021094112A1 (fr) | Moteur à combustion interne comprenant un système d'air secondaire | |

| DE3822954C2 (de) | Abgasrückführeinrichtung | |

| DE102012103311B4 (de) | Ventilvorrichtung für eine Verbrennungskraftmaschine | |

| EP3631187B1 (fr) | Dispositif de recyclage des gaz d'échappement pour un moteur à combustion interne | |

| EP0498947B1 (fr) | Moteur à combustion avec récirculation des gaz d'échappement | |

| DE3404769A1 (de) | Ventil zum einbau in einen kruemmer einer fluidleitung einer brennkraftmaschine | |

| DE102015105219A1 (de) | Regelvorrichtung für einen Abgasführungsabschnitt eines Abgasturboladers | |

| DE2364903C2 (de) | Vergaser für Brennkraftmaschinen | |

| EP2610474B1 (fr) | Soupape de recyclage de gaz d'échappement à basse pression | |

| DE3716661A1 (de) | Vorrichtung zur steuerung mindestens eines drosselquerschnittes an mindestens einer steueroeffnung | |

| DE102020106983B3 (de) | Mischeranordnung und Verfahren zum Betreiben einer Mischeranordnung | |

| EP4022182B1 (fr) | Système de recirculation des gaz d'échappement pour un moteur à combustion interne et procédé de régulation d'un système de recirculation des gaz d'échappement de ce type | |

| WO2019144170A1 (fr) | Procédé de commande de la température des gaz d'échappement d'un moteur à combustion interne | |

| AT520807B1 (de) | Abgasnachbehandlungsvorrichtung für eine brennkraftmaschine | |

| EP3837472B1 (fr) | Agencement à deux brûleurs | |

| DE3113943A1 (de) | "gleichdruckvergaser fuer brennkraftmaschinen" | |

| WO2008095214A1 (fr) | Dispositif de retour d'échappement pour moteur à combustion interne | |

| DE102006003447B4 (de) | Abgaskühler für eine Brennkraftmaschine | |

| DE102017120236B4 (de) | Staudruckklappe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19920401 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): FR GB IT SE |

|

| 17Q | First examination report despatched |

Effective date: 19921030 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): FR GB IT SE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19931020 |

|

| ET | Fr: translation filed | ||

| ITTA | It: last paid annual fee | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 91120241.4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19971112 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19971121 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19971126 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981128 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19981127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990730 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 91120241.4 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051127 |