EP0476733B1 - Vorrichtung zur Herstellung von Hängedachrinnen - Google Patents

Vorrichtung zur Herstellung von Hängedachrinnen Download PDFInfo

- Publication number

- EP0476733B1 EP0476733B1 EP91202113A EP91202113A EP0476733B1 EP 0476733 B1 EP0476733 B1 EP 0476733B1 EP 91202113 A EP91202113 A EP 91202113A EP 91202113 A EP91202113 A EP 91202113A EP 0476733 B1 EP0476733 B1 EP 0476733B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rollers

- gutters

- forming die

- sheet metal

- whose

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002184 metal Substances 0.000 claims abstract description 31

- 238000005452 bending Methods 0.000 claims abstract description 20

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 15

- 239000011324 bead Substances 0.000 claims abstract description 14

- 238000000034 method Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 5

- 238000000465 moulding Methods 0.000 description 2

- 241001163841 Albugo ipomoeae-panduratae Species 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000000969 carrier Substances 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 238000013000 roll bending Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000009751 slip forming Methods 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D5/00—Bending sheet metal along straight lines, e.g. to form simple curves

- B21D5/01—Bending sheet metal along straight lines, e.g. to form simple curves between rams and anvils or abutments

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D5/00—Bending sheet metal along straight lines, e.g. to form simple curves

- B21D5/14—Bending sheet metal along straight lines, e.g. to form simple curves by passing between rollers

- B21D5/143—Bending sheet metal along straight lines, e.g. to form simple curves by passing between rollers making use of a mandrel

Definitions

- the invention relates to a device for producing suspended roof gutters by, preferably intermittent, bending forming of sheet metal strips, on one longitudinal edge of which the bead and on the other longitudinal edge of which the water rebate is formed and the central part is shaped as a gutter.

- Forming machines are known for producing suspended roof gutters, downpipes or similar profiles from endless sheet metal strips or strips.

- the sheet metal strips or strips are pulled in the longitudinal direction by a reciprocating pulling slide, during the backward movement of which the sheet metal strip or strips are held by a corresponding device, in the horizontal direction over a forming device and thereby gradually formed and finally in ejected the desired shape (DE-PS 10 91 518, DE-PS 11 10 597, DE-PS 11 70 891).

- Forming machines of this type have largely proven themselves in the processing of flat sheet metal strips or strips into suspended roof gutters or similar profiles, because a relatively precise shaping to the desired profiles is achieved.

- the desired length of the profile for example according to DE-OS 26 29 559, can be cut to length by an automatic cutting device.

- the disadvantage is that the metal strips or strips have to be cooled and lubricated during the forming process.

- the emulsions used for this lead to white rust formation on the surface of the finished profiles, if no special measures are taken to prevent it.

- a bending device for the production of roof gutters from sheet metal blanks which consists of at least three axially parallel, extending over the entire length of the hanging roof gutter to be formed, supported and at least partially driven rollers, which are free and laterally accessible over the entire length of the hanging roof gutter Limit the minimum adjustable width for the sheet metal blank to be bent (DE-OS 29 03 990).

- the disadvantage of this bending device can be seen in the fact that the sheet metal strips must be inserted from the long side between the rollers and thus the attachment of the bead and the water rebate can only take place after the roof gutter has been bent.

- the bending device consists of a form stamp that can be raised / lowered and two bending blocks that can be moved horizontally relative to one another, by means of which the sheet metal strip is bent around the form stamp.

- Flexible, friction-reducing mats consisting of numerous parallel rollers, the length of which corresponds to that of the bending blocks, are arranged on the bending surfaces of the bending blocks.

- the disadvantage of this bending device is the fact that the rollers cause marks on the surface of the sheet metal strip.

- DE-A-26 31 219 (closest prior art) is concerned with the production of gutters, the water fold being bent on one longitudinal edge of a sheet metal strip, then that The middle part of the gutter is formed by screwing the sheet metal strip onto a rounding roller that interacts with a counter-pressure roller and then screwing the bead onto a rotating bead rod.

- the device is only suitable for processing a blank width.

- the diameter of the rounding roller and the positions of the counter-pressure roller and the bead rod must be changed.

- the bead cannot be made within the specified tolerances.

- the invention has for its object to provide a method and a device with which sheet metal strips can be bent with a relatively low technical effort in a simple manner to hanging gutters with semicircular or box-shaped cross-section, preferably according to DIN 18461, with high surface quality and shape accuracy.

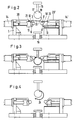

- the solution to this problem consists according to the invention of two arranged in a horizontal plane parallel to each other and displaceable in the horizontal plane perpendicular to their axes, supported at their ends on supporting rollers, preferably non-driven rollers, which can be loaded with constant pressure, with axially parallel over the In the middle between the rollers, a form stamp can be raised / lowered, the length of which corresponds at least to the length of the sheet metal strip to be deformed.

- each sheet metal strip is formed into beads and water folds, and then the middle part of the sheet metal strip is bent into a groove by bending between the die and the rollers.

- rollers are coupled to a drive.

- the die for the production of semicircular suspended roof gutters has an essentially circular cross-section and a recess running over its entire length in the quadrant lying on the water seam side, into which the water seam projects when bending.

- the stamp is essentially trapezoidal, with a lifting / lowering counter-holder, which is located on the long side of the trapezoidal profile, between the rollers below the center.

- profiles of the form stamp can also be used to produce special gutter shapes, such as roof gutters, Berlin gutters or the like.

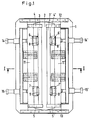

- the bending forming device arranged on the base plate (1) consists of two rollers (3, 3 ') which are arranged axially parallel to one another in a horizontal plane to form a space (2), the ends of which are each in a bearing block (4, 4', 5, 5 ') ) are supported and are supported on support rollers (8.8 ', 9.9', 10.10 ') mounted in fork carriers (6.6', 7.7 ').

- the bearing blocks (4,4 ', 5,5') and the fork brackets (6,6 ', 7,7') are fastened to two brackets (11,11 ') which are mounted parallel to each other and which are mounted on the base plate (1).

- the cross section of the substantially circular shaped die (17) is lowered and the sheet metal strip (23) is continuously formed, the under the one created by means of the hydraulic cylinders (14, 14 ', 15, 15') certain load standing, form-fitting on the sheet metal strip (23) rollers (3,3 ') perpendicular to their axes in the horizontal plane initially up to their maximum possible deflection in the central plane of the die (17) and pushed towards each other after exceeding the central plane, so that the sheet metal strip (23) is pressed firmly against the die (17).

- the water fold (22) projects into the recess (18) made in the upper quadrant of the molding stamp (17).

- the rollers (3, 3 ') are moved apart, the hanging roof gutter (24) springs open, the released form stamp (17) moves up to the starting position and the one hanging with the water fold (22) in the recess (18) Finished roof gutter (24) can be removed from the form stamp (17). Since the downward movement of the molding die (17) is limited, the bead (21) and water fold (22) cannot be deformed by the rollers (3, 3 ').

- the counter-holder (19) located below the center between the rollers (3, 3 ') prevents the sheet-metal strip (23) from bulging downward.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Roof Covering Using Slabs Or Stiff Sheets (AREA)

- Sewage (AREA)

- Making Paper Articles (AREA)

- Devices For Post-Treatments, Processing, Supply, Discharge, And Other Processes (AREA)

- Coating With Molten Metal (AREA)

- Load-Engaging Elements For Cranes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4029723A DE4029723A1 (de) | 1990-09-20 | 1990-09-20 | Verfahren und vorrichtung zur herstellung von haengedachrinnen |

| DE4029723 | 1990-09-20 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0476733A2 EP0476733A2 (de) | 1992-03-25 |

| EP0476733A3 EP0476733A3 (en) | 1992-10-07 |

| EP0476733B1 true EP0476733B1 (de) | 1996-11-27 |

Family

ID=6414568

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91202113A Expired - Lifetime EP0476733B1 (de) | 1990-09-20 | 1991-08-19 | Vorrichtung zur Herstellung von Hängedachrinnen |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0476733B1 (cs) |

| AT (1) | ATE145572T1 (cs) |

| CS (1) | CS285991A3 (cs) |

| DE (2) | DE4029723A1 (cs) |

| DK (1) | DK0476733T3 (cs) |

| HU (1) | HU210397B (cs) |

| YU (1) | YU138191A (cs) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE521864C2 (sv) * | 2001-09-27 | 2003-12-16 | Ortic Ab | Krökverk och sätt att kröka takplåt |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB313328A (en) * | 1928-06-29 | 1929-06-13 | Thomas Andrew Hayward | Improvements in or relating to tubes |

| DE650499C (de) * | 1935-07-28 | 1937-09-24 | Georg Eichner | Werkzeugsatz zur handwerksmaessigen Herstellung von Dachrinnen |

| DE2631219C3 (de) * | 1976-07-12 | 1986-10-23 | Theodor Fricke GmbH & Co, 4402 Greven | Verfahren zum Herstellen von Dachrinnen und Vorrichtung zur Durchführung dieses Verfahrens |

| CA1119469A (en) * | 1979-10-09 | 1982-03-09 | George R. Usher | Apparatus and method for forming seamed tube |

-

1990

- 1990-09-20 DE DE4029723A patent/DE4029723A1/de not_active Withdrawn

-

1991

- 1991-08-09 YU YU138191A patent/YU138191A/sh unknown

- 1991-08-19 DK DK91202113.6T patent/DK0476733T3/da active

- 1991-08-19 AT AT91202113T patent/ATE145572T1/de not_active IP Right Cessation

- 1991-08-19 EP EP91202113A patent/EP0476733B1/de not_active Expired - Lifetime

- 1991-08-19 DE DE59108375T patent/DE59108375D1/de not_active Expired - Fee Related

- 1991-09-19 CS CS912859A patent/CS285991A3/cs unknown

- 1991-09-19 HU HU913008A patent/HU210397B/hu not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| CS285991A3 (en) | 1992-04-15 |

| ATE145572T1 (de) | 1996-12-15 |

| EP0476733A2 (de) | 1992-03-25 |

| DK0476733T3 (da) | 1996-12-16 |

| HU913008D0 (en) | 1992-01-28 |

| DE4029723A1 (de) | 1992-03-26 |

| DE59108375D1 (de) | 1997-01-09 |

| EP0476733A3 (en) | 1992-10-07 |

| YU138191A (sh) | 1995-03-27 |

| HU210397B (en) | 1995-04-28 |

| HUT59997A (en) | 1992-07-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102007059439B3 (de) | Vorrichtung und Verfahren zum Kaltwalzprofilieren von Profilen mit veränderlicher Höhe | |

| DE3529160C2 (cs) | ||

| DE102007012316B9 (de) | Verfahren und Anbiegepresse zum Anbiegen der Randstreifen eines zu einem Schlitzrohr zu formenden ebenen Bleches | |

| DE10232098B4 (de) | Vorrichtung zum Herstellen von Rohren aus Blechtafeln | |

| DE2953278C2 (cs) | ||

| DE2423279B2 (de) | Vorrichtung zum Formbiegen profilierter Langenabschnitte aus einem ebenen Metallstreifen | |

| DE212022000352U1 (de) | Produktionslinie zum hydraulischen Stanzen von Profilen mit mehreren Stationen | |

| DE102010000608B3 (de) | Verfahren und Vorrichtung zum Ziehen und Beschneiden von Platinen | |

| DE2529466B2 (de) | Verfahren und vorrichtung zum herstellen laengsnahtgeschweisster rohre verschiedener durchmesser | |

| DE2209653A1 (de) | Verfahren und Maschine zur Herstellung von Wellen in Metallblech | |

| DE102006025034A1 (de) | Vorrichtung und Verfahren zur Herstellung von Profilkörpern | |

| DE3411023C2 (de) | Vorrichtung zum Herstellen und/oder Bearbeiten von kaschierten Werkstücken | |

| EP0476733B1 (de) | Vorrichtung zur Herstellung von Hängedachrinnen | |

| DE4116521C2 (de) | Verfahren und Vorrichtung zum Erzeugen gekrümmter Abschnitte in Hohlprofilleisten | |

| DE2631219C3 (de) | Verfahren zum Herstellen von Dachrinnen und Vorrichtung zur Durchführung dieses Verfahrens | |

| DE60120947T2 (de) | Verfahren und vorrichtung zum biegen von blechstreifen mit zwei einander gegenüberliegenden flanschen | |

| DE2727287C2 (de) | Vorrichtung zum Biegen profilierter Platten | |

| WO2016079210A1 (de) | Vorrichtung und verfahren zur herstellung von profilen | |

| DE4410105A1 (de) | Rohrbiegepresse zur Herstellung von Schlitzrohren aus Blechtafeln | |

| EP0022136A1 (de) | Schrägwalzenrichtmaschine | |

| DE102014116889B4 (de) | Vorrichtung und Verfahren zur Herstellung von Profilen mit veränderlicher Höhe und/oder Breite | |

| DE2914633A1 (de) | Vorrichtung zum biegen von kunststoff-hohlprofilen verschiedenster querschnittsformen | |

| AT227512B (de) | Vorrichtung zum Verformen von Blechbändern, insbesondere für die Herstellung von Dachrinnen od. ähnl. Erzeugnissen | |

| AT17520B (de) | Kardendeckel-Aufziehmaschine. | |

| DE102007025043B4 (de) | Vorrichtung zum Herstellen von Rohren aus dünnwandigem Material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE DK LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE DK LI |

|

| 17P | Request for examination filed |

Effective date: 19921030 |

|

| 17Q | First examination report despatched |

Effective date: 19940706 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE DK LI |

|

| REF | Corresponds to: |

Ref document number: 145572 Country of ref document: AT Date of ref document: 19961215 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REF | Corresponds to: |

Ref document number: 59108375 Country of ref document: DE Date of ref document: 19970109 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20040603 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20040806 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20040810 Year of fee payment: 14 Ref country code: AT Payment date: 20040810 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050819 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050831 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060301 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |