EP0405213A2 - Dispositif d'humidification d'une matière en bande, en particulier du papier - Google Patents

Dispositif d'humidification d'une matière en bande, en particulier du papier Download PDFInfo

- Publication number

- EP0405213A2 EP0405213A2 EP90111004A EP90111004A EP0405213A2 EP 0405213 A2 EP0405213 A2 EP 0405213A2 EP 90111004 A EP90111004 A EP 90111004A EP 90111004 A EP90111004 A EP 90111004A EP 0405213 A2 EP0405213 A2 EP 0405213A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cylinder

- web

- fact

- steam

- lateral surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21G—CALENDERS; ACCESSORIES FOR PAPER-MAKING MACHINES

- D21G7/00—Damping devices

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21F—PAPER-MAKING MACHINES; METHODS OF PRODUCING PAPER THEREON

- D21F7/00—Other details of machines for making continuous webs of paper

- D21F7/003—Indicating or regulating the moisture content of the layer

Definitions

- the present invention relates to a moisturising device for wetting a web of sheet material, in particular a web of paper, translating at high speed, in such a way as to obtain a uniform moisturisation of a desired magnitude, in particular in the transverse direction of the web itself.

- the object of the present invention is that of providing a moisturising device capable of operating at high speed and, by contrast, of obtaining a very precise control of the moisturisation of the web of sheet material, all with low dimensions and low construction and management costs.

- a moisturising device for uniformly moisturising a web of sheet material, in particular paper, characterised by the fact that it comprises in combination: a first rotary cylinder cooperating with the said web; means to permit translation of the said web partly wrapping the lateral surface of the first cylinder; cooling means disposed within the first cylinder; and a condensation chamber within which the first cylinder is partially housed over the whole of its length on the side opposite that cooperating with the said web, in such a way as to define an internal wall of the said chamber with its lateral surface, over an arc of predetermined angle; this chamber being subdivided, in the direction of the axis of rotation of the first cylinder, into a plurality of compartments each of which is provided with means for directing steam towards the said first cylinder.

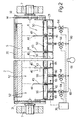

- the reference numeral 1 generally indicates a moisturising device for treating a web of sheet material 2, for example paper, wound on rollers not illustrated for simplicity and which are unrolled in a known way upstream of the device 1, caused to translate with a predetermined speed within the device itself and, for example, rewound on rollers downstream of the device 1 (or else directly fed into a subsequent working stage);

- the device 1, which is formed in a way such as to guarantee an absolutely uniform moisturising of the strip 2 essentially comprises a pair of counter-rotating cylinders 4 and 5 disposed parallel to and adjacent one another, and a condensation chamber 6 within which substantially half the external diameter of the cylinder 5 is housed over the whole of its length; in particular the cylinders 4 and 5 are driven in a known way, not illustrated for simplicity, and are rotatable on respective known supports 7 (of which only that of the cylinder 5 is illustrated for simplicity) about respective axes 8 and 10 disposed parallel to one another and at a distance such as to cause respective outer

- the space 16 is utilised to obtain a first wetting, poorly distributed but of significant magnitude, utilising the principle of the so-called known "gluing press” machinery utilised in the primary working of the paper; for this purpose the device 1 includes a pair of side walls 20 (of which only one is illustrated in Figure 1) disposed in correspondence with the cylinders 4, 5 in such a way as substantially to close the ends of the space 16 themselves with a liquid-tight seal, as well as one or more nozzles 21 acting to feed a jet of water 22 into the space 16; in use, the space 16, being closed from below by the web 2 passing through it, behaves as a vessel in which the water supplied by the jet 22 accumulates, forming a head of predetermined height capable of causing impregnation of the paper sheet 2 notwithstanding that this is moving at a high speed; however this impregnation, as is well known from practical experience derivable from gluing presses, is very non-uniform, and in particular is not regular in

- the opposite side of the cylinder 5 from that which cooperates with the web 2 is housed in the chamber 6 and delimits with its lateral surface 14, over an arc of predetermined angle, equal to about 180°, an upper internal wall of the chamber 6 itself; in particular, the condensation chamber 6 is delimited by a casing 21 disposed with its longitudinal axis parallel to the axis of rotation of the cylinder 5 and provided with an upper opening 22, preferably inclined downwardly towards the cylinder 4, into which the cylinder 5 is inserted and closes, being disposed with its axis of rotation 10 substantially level with the plane of the aperture 22.

- the longitudinal edges of the opening 22 are preferably provided with respective blades 25 projecting obliquely with respect to the lateral surface 14 and cooperating therewith at a predetermined distance therefrom, adjustable by transverse translation of the blades 25 which can be effected in a known way not illustrated for simplicity.

- the cylinder 5 is provided internally with a cooling device comprising a plurality of tubes 30 disposed axially through the cylinder 5 immediately beneath the lateral surface 14 thereof, which are connected to respective supply manifolds 31 and discharge manifolds 32 formed on the head ends of the cylinder 16 which can be supplied in a known way not illustrated for simplicity through the supports 7 in such a way as to define an hydraulic circuit through which flows a stream of coolant fluid, for example water, made to circulate by a pump, not illustrated for simplicity.

- a cooling device comprising a plurality of tubes 30 disposed axially through the cylinder 5 immediately beneath the lateral surface 14 thereof, which are connected to respective supply manifolds 31 and discharge manifolds 32 formed on the head ends of the cylinder 16 which can be supplied in a known way not illustrated for simplicity through the supports 7 in such a way as to define an hydraulic circuit through which flows a stream of coolant fluid, for example water, made to circulate by a pump, not illustrated for simplicity.

- a stream of coolant fluid for

- the condensation chamber 6 is subdivided, in the direction of the axis of rotation 10 of the cylinder 5, into a plurality of compartments 40 delimited within the casing 21 by respective transverse U-shape walls 43 disposed parallel to one another and spaced by predetermined distances, respective curved edges 44 of which cooperate with a minimum clearance with the lateral surface 14 in such a way as to form a labyrinth seal and ensure a substantial fluid-tight sealed subdivision of the compartments 40 from one another.

- each compartment 40 is provided internally with means for directing steam towards the cooled cylinder 5; such means comprise at least one associated nozzle 50 for each compartment 40, orientated in such a way as to be able to direct a jet 53 of saturated steam against a corresponding respective annular portion 52 (two adjacent portions 51 being shown in broken outline in Figure 2) of the lateral surface 14 of the cylinder 5 facing the respective compartment 40 and of width substantially equal thereto.

- the device 1 also includes means for adjusting the rate of flow of steam from the nozzles 50 of each compartment 40 independently of the rate of flow of steam emitted by the nozzles 50 of the other compartments; such means comprise, for example, a steam induction tube system 60 illustrated only schematically, connected to a source of saturated steam 61 under pressure and a series of steam flow rate adjustment valves 64 disposed in series along the tubes 60 one for each compartment 40; preferably, moreover, the valves 64 are controlled in an automatic manner by "feedback" from respective known sensors 65 detecting the moisture content of the web 2, only some of which are illustrated and each of which is mounted in correspondence with one of the portions 52, in such a way as to be able to detect the moisture of the corresponding longitudinal portion of the web 2 passing past this portion 52 or rather, more precisely, through each compartment 40; the sensors 65 are connected in a known way to a central control unit 70 by which, in a known way, the valves 64 are controlled.

- a steam induction tube system 60 illustrated only schematically, connected to a

- the steam emitted from the nozzles 50 condenses on the surfaces of the portions 52 in that the cylinder 5 is cooled by the effect of the passage of the coolant liquid in the tubes 30; consequently there forms on the lateral surface 14 a film of moisture which is drawn into rotation together with the cylinder 5 and which, consequently, is carried into contact with the lower face of the web 2 advancing between the cylinders 4 and 5, that is with the face of the web 2 which cooperates with the cylinder 5; this film of moisture is consequently absorbed by the web 2 during its transit between the cylinders 4 and 5 and is continually reformed on the surface 14, on the part thereof which progressively passes through the chamber 6, by the effect of the condensation of new steam; thanks to the fact that the cylinder 5 rotates at a relatively high speed and, above all, to the fact that the compartments 40 are separated from one another by the walls 43, which extend close to the surface 14 and each of which receives a separate flow of steam, on each portion 52 of the surface 14 there forms a film of moisture obtained from the

- the device constituted by the cylinder 5 with coolant tubes 30 and condensation chamber 6 with its separate compartments 40, each of which is independently supplied with steam from one or more nozzles 50, makes it possible to obtain a very good control of the transverse moisture rate of the paper sheet 2;

- the moisturising operation which, if it is necessary to provide a large increase in moisture to the sheet 2 (for example 10% or more) would be relatively slow if only water which condenses on the surface 14 were relied on, is accelerated by the use of the space 16 as a vessel for the formation of a head of water directly in contact with the sheet 2 in that the moisturising operation can proceed with the sheet 2 translating at the same speed as that required by the supercalendering so that the device 1 can advantageously be coupled to a supercalender or be inserted in the terminal part of a continuous paper producing machine, eliminating dead times and the necessity for storing moist webs typical of known processes.

- the sheet 2 in its passage between the device 1 receives moisture on both its faces (the lower face absorbs moisture from the cylinder 5, the upper face from the water which lies in the space 16); so that a better distribution of moisture throughout the thickness of the web 2 is also ensured.

Landscapes

- Paper (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT6753789 | 1989-06-30 | ||

| IT8967537A IT1232534B (it) | 1989-06-30 | 1989-06-30 | Dispositivo umidificatore per un nastro di materiale in foglio,in particolare carta |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0405213A2 true EP0405213A2 (fr) | 1991-01-02 |

| EP0405213A3 EP0405213A3 (en) | 1991-09-04 |

| EP0405213B1 EP0405213B1 (fr) | 1995-03-29 |

Family

ID=11303250

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90111004A Expired - Lifetime EP0405213B1 (fr) | 1989-06-30 | 1990-06-11 | Dispositif d'humidification d'une matière en bande, en particulier du papier |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0405213B1 (fr) |

| DE (1) | DE69018135T2 (fr) |

| IT (1) | IT1232534B (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1052329A2 (fr) * | 1999-04-23 | 2000-11-15 | Westvaco Corporation | Système d' humidification pour une bande de papier |

| DE10055999A1 (de) * | 2000-11-11 | 2002-05-23 | Voith Paper Patent Gmbh | Pressanordnung |

| CN112761019A (zh) * | 2020-12-30 | 2021-05-07 | 福建恒安集团有限公司 | 一种用于纸幅的均匀扩散式多级复合加湿系统 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB712717A (en) * | 1951-12-24 | 1954-07-28 | Champion Paper & Fibre Co | Improvements in coated paper manufacture |

| GB1156056A (en) * | 1967-05-03 | 1969-06-25 | Greenbank Engineering Company | Method and Apparatus for Adding Moisture to a Pre-Conditioned Web of Paper. |

| DE2203973A1 (de) * | 1972-01-28 | 1973-08-09 | Erich Pagendarm | Verfahren und vorrichtung zum befeuchten einer bahn |

| GB2127871A (en) * | 1982-09-30 | 1984-04-18 | Beloit Corp | Apparatus and method for control of the cross-machine moisture profile of a paper web |

-

1989

- 1989-06-30 IT IT8967537A patent/IT1232534B/it active

-

1990

- 1990-06-11 EP EP90111004A patent/EP0405213B1/fr not_active Expired - Lifetime

- 1990-06-11 DE DE69018135T patent/DE69018135T2/de not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB712717A (en) * | 1951-12-24 | 1954-07-28 | Champion Paper & Fibre Co | Improvements in coated paper manufacture |

| GB1156056A (en) * | 1967-05-03 | 1969-06-25 | Greenbank Engineering Company | Method and Apparatus for Adding Moisture to a Pre-Conditioned Web of Paper. |

| DE2203973A1 (de) * | 1972-01-28 | 1973-08-09 | Erich Pagendarm | Verfahren und vorrichtung zum befeuchten einer bahn |

| GB2127871A (en) * | 1982-09-30 | 1984-04-18 | Beloit Corp | Apparatus and method for control of the cross-machine moisture profile of a paper web |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1052329A2 (fr) * | 1999-04-23 | 2000-11-15 | Westvaco Corporation | Système d' humidification pour une bande de papier |

| EP1052329A3 (fr) * | 1999-04-23 | 2001-08-16 | Westvaco Corporation | Système d' humidification pour une bande de papier |

| DE10055999A1 (de) * | 2000-11-11 | 2002-05-23 | Voith Paper Patent Gmbh | Pressanordnung |

| CN112761019A (zh) * | 2020-12-30 | 2021-05-07 | 福建恒安集团有限公司 | 一种用于纸幅的均匀扩散式多级复合加湿系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| IT8967537A0 (it) | 1989-06-30 |

| DE69018135D1 (de) | 1995-05-04 |

| DE69018135T2 (de) | 1995-11-23 |

| EP0405213B1 (fr) | 1995-03-29 |

| EP0405213A3 (en) | 1991-09-04 |

| IT1232534B (it) | 1992-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FI72552B (fi) | Foerfarande och anordning foer behandling av bana. | |

| EP0296044B1 (fr) | Contrôle du brillant dans la direction transversale | |

| CA1131011A (fr) | Dispositif injecteur de vapeur pour calandres presseurs jumeles | |

| US5106655A (en) | Cross-directional smoothness controller and method of using the same | |

| US4694587A (en) | Method and apparatus in a twin-wire cylinder drying section of a paper machine | |

| US5569359A (en) | System for reducing blistering of a wet paper web on a yankee dryer | |

| FI91294B (fi) | Laitteisto ja menetelmä rainan tai rainan kanssa yhteydessä olevan koneenosan jäähdyttämiseen | |

| US3127080A (en) | Web turning device | |

| US3770578A (en) | Method for controlling caliper | |

| EP0405213B1 (fr) | Dispositif d'humidification d'une matière en bande, en particulier du papier | |

| JPH1085649A (ja) | 走行する材料ウェブに液状またはペースト状媒体を直接的または間接的に塗布する方法および装置 | |

| CA2381669C (fr) | Procede et dispositif permettant le traitement d'une bande de matiere et le controle du comportement d'une bande de matiere | |

| US5429303A (en) | Steam spray tube with linear acceleration channel | |

| US20160334021A1 (en) | Air seal device for a spray apparatus in a papermaking machine | |

| GB2085328A (en) | Web coating | |

| DE69716601T2 (de) | Verfahren und vorrichtung zur berührungslosen trocknung einer papierbahn oder dergleichen | |

| US12104322B2 (en) | Method and a system for a Yankee cylinder in a tissue machine | |

| JPH0378146B2 (fr) | ||

| US2933825A (en) | Moisture removal system | |

| GB1584770A (en) | Guide device for flexible webs | |

| FI106271B (fi) | Menetelmä paperin käyristymän hallitsemiseksi ja menetelmää soveltava paperi- tai kartonkikonelinja | |

| CA2075993A1 (fr) | Dispositif applicateur de vapeur suivi d'un passage sous vide et methode d'utilisation | |

| GB1246324A (en) | Sterilizing method and apparatus | |

| FI74313C (fi) | Foerfarande och anordning foer breddstraeckning av pappersbanan i en pappersmaskin. | |

| WO1999023308A1 (fr) | Appareil et procede de couchage rapide |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): BE DE FR |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE DE FR |

|

| 17P | Request for examination filed |

Effective date: 19920213 |

|

| 17Q | First examination report despatched |

Effective date: 19931018 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR |

|

| REF | Corresponds to: |

Ref document number: 69018135 Country of ref document: DE Date of ref document: 19950504 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19950630 |

|

| BERE | Be: lapsed |

Owner name: BOSSO CARTE SPECIALI S.P.A. Effective date: 19950630 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960301 |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |