EP0358209A2 - Revêtement pour court de tennis - Google Patents

Revêtement pour court de tennis Download PDFInfo

- Publication number

- EP0358209A2 EP0358209A2 EP89116490A EP89116490A EP0358209A2 EP 0358209 A2 EP0358209 A2 EP 0358209A2 EP 89116490 A EP89116490 A EP 89116490A EP 89116490 A EP89116490 A EP 89116490A EP 0358209 A2 EP0358209 A2 EP 0358209A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- binder

- sand

- brick

- covering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000011230 binding agent Substances 0.000 claims abstract description 40

- 239000011449 brick Substances 0.000 claims abstract description 30

- 239000004576 sand Substances 0.000 claims abstract description 24

- 229920001971 elastomer Polymers 0.000 claims abstract description 15

- 239000005060 rubber Substances 0.000 claims abstract description 15

- 239000002245 particle Substances 0.000 claims description 25

- 235000013339 cereals Nutrition 0.000 claims description 18

- 239000000463 material Substances 0.000 claims description 12

- 239000004814 polyurethane Substances 0.000 claims description 11

- 239000000843 powder Substances 0.000 claims description 11

- 229920002635 polyurethane Polymers 0.000 claims description 9

- 235000013312 flour Nutrition 0.000 claims description 8

- 238000000034 method Methods 0.000 claims description 6

- 239000000853 adhesive Substances 0.000 claims description 4

- 230000001070 adhesive effect Effects 0.000 claims description 4

- 238000001035 drying Methods 0.000 claims description 3

- 239000003973 paint Substances 0.000 claims description 3

- 239000004033 plastic Substances 0.000 claims description 3

- 229920003023 plastic Polymers 0.000 claims description 3

- 239000000428 dust Substances 0.000 claims description 2

- 229920000058 polyacrylate Polymers 0.000 claims description 2

- 229920000193 polymethacrylate Polymers 0.000 claims description 2

- 229920000098 polyolefin Polymers 0.000 claims description 2

- 229920005989 resin Polymers 0.000 claims 2

- 239000011347 resin Substances 0.000 claims 2

- 239000003822 epoxy resin Substances 0.000 claims 1

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 claims 1

- 229920000647 polyepoxide Polymers 0.000 claims 1

- 238000004064 recycling Methods 0.000 claims 1

- 239000008187 granular material Substances 0.000 abstract description 2

- 239000010410 layer Substances 0.000 description 51

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 18

- 239000004927 clay Substances 0.000 description 7

- 229910052500 inorganic mineral Inorganic materials 0.000 description 4

- 239000011707 mineral Substances 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 230000001788 irregular Effects 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 239000000758 substrate Substances 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 239000010426 asphalt Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000011065 in-situ storage Methods 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 235000012054 meals Nutrition 0.000 description 2

- 210000002346 musculoskeletal system Anatomy 0.000 description 2

- 230000035699 permeability Effects 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- 239000004593 Epoxy Substances 0.000 description 1

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 239000006004 Quartz sand Substances 0.000 description 1

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 239000002390 adhesive tape Substances 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000006229 carbon black Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 238000013016 damping Methods 0.000 description 1

- 229910001651 emery Inorganic materials 0.000 description 1

- 239000004794 expanded polystyrene Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000005923 long-lasting effect Effects 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 239000013047 polymeric layer Substances 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 229920003051 synthetic elastomer Polymers 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 239000004636 vulcanized rubber Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01C—CONSTRUCTION OF, OR SURFACES FOR, ROADS, SPORTS GROUNDS, OR THE LIKE; MACHINES OR AUXILIARY TOOLS FOR CONSTRUCTION OR REPAIR

- E01C13/00—Pavings or foundations specially adapted for playgrounds or sports grounds; Drainage, irrigation or heating of sports grounds

- E01C13/06—Pavings made in situ, e.g. for sand grounds, clay courts E01C13/003

- E01C13/065—Pavings made in situ, e.g. for sand grounds, clay courts E01C13/003 at least one in situ layer consisting of or including bitumen, rubber or plastics

Definitions

- the invention relates to a tennis court covering according to the preamble of claim 1.

- the classic tennis court which consists of broken brick, is still considered by most tennis players because of its elastic properties and its non-slip properties for the player.

- it has the disadvantage that it requires very intensive care and has to be prepared practically every year. This is extremely costly, especially with today's masses of players, so that new solutions were sought which, on the one hand, have the properties of the brick flour tennis court, but on the other hand require as little maintenance as possible.

- a sports field in which an elastic plastic layer is applied to a solid surface and solidified by means of an adhesive. After peeling off this elastic layer, a color layer (red or green) is then applied in order to optically improve the black rubber particles of the elastic layer, which are usually colored with carbon black.

- a color layer red or green

- a tennis court produced in this way is easy to maintain, but has the disadvantages that it is not slip-friendly, ie it becomes smooth after some time and also has an irregular and too elastic ball bounce behavior.

- the latter behavior is partly due to bumps in the elastic surface, but also partly due to the elastic particles that act directly on the ball.

- DE-AS 22 58 566 relates to a floor covering for tennis courts, the lower layer of which consists of an elastic polymeric material (expanded polystyrene), on which an upper open-pore plate layer of a hard mineral (granular fired clay) is applied, which is solidified by a weather-resistant binder and is bound to the lower layer.

- Soft fired clay powder is sprinkled on this clay layer, the interface area between the hard and soft clay powder should be connected to the soft clay powder via the binder that is present in the hard clay powder.

- the tennis court covering described here does not meet the desired requirements that are gentle on the musculoskeletal system of the player, since the hard mineral layer is too thick and therefore too inelastic.

- the invention is therefore based on the object of providing a tennis court surface which, on the one hand, is easy to maintain and, on the other hand, has practically the same ball bouncing behavior as in a conventional brick meal tennis court.

- a tennis court covering which has practically the same positive properties as the conventional broken brick flour tennis court, however practically no longer has to be maintained.

- a tennis court that has been produced according to the method according to the invention only has to be sprinkled in now and then with loose broken brick. Otherwise, it does not need any further care for years. It absorbs all precipitation and, due to its permeability, transfers it to an artificial or natural drainage system provided in the ground, ie it is independent of wind and weather. Even the marking lines can be permanently applied to the sports field surface with plastic paint so that the boundary lines do not have to be renewed over the years.

- the covering according to the invention is expediently applied to a solid base layer, which can be of natural or artificial origin.

- An asphalt or concrete layer which is expediently water-permeable, is advantageously used as the base layer.

- This solid surface is of course the size of a playing field.

- a granulate made from a first elastic polymeric material is first applied to this solid base, which has previously been mixed with a binder in the not yet cured state.

- Suitable polymeric materials are rubber-elastic polymeric materials, which include polyolefins, polyurethanes, possibly in a foamed state, and rubber (vulcanized rubber). Of this material, rubber is preferred which has been comminuted in the usual way (grinding and the like). Such rubber materials include not only natural rubbers, but also the artificial rubber components.

- recycled rubber products which are produced, for example, by processing rubber waste materials from car tires and the like. or obtained from waste products.

- the particle size of the irregularly shaped particles of the first layer can be up to about 4 mm, with about 80% by weight of the particles having a grain size of about 2-4 mm.

- the thickness of the first layer consisting of the rubber-like particles and the binder, is on average about 0.7-1.5, in particular about 1 cm.

- a polyurethane-based binder which can be used to solidify this layer, so that reference is also made to this.

- other binders can also be used, for example based on epoxy, polyacrylate or polymethacrylate. If rubber particles are used, the usual vulcanizing agents can also be used.

- a polyurethane-based adhesive is preferably used, as described, for example, in DE-A 21 56 255.

- These adhesives are mixed with the particles of the first layer in the pourable state, for example in a weight amount of 1: 4 - 1: 6, in particular about 1: 5 binder / particles.

- the latter particles are usually applied in an amount of about 7 kg / m2 of sports field area.

- binder in an amount of 1.4 kg / m2.

- the mass is spread out and leveled using customary methods.

- a second layer as explained below, can then be applied.

- a layer of relatively hard mineral material in particular quartz sand or clinker powder, is applied as the first leveling layer, which layer is solidified with a further binder.

- This second binder is the same or different from the first binder, advantageously the same.

- the use of polyurethane is also particularly preferred here.

- about 1-3 advantageously about 2 kg of sand per m2 of covering are applied to the elastic first covering.

- the grain size of the sand is up to 2 mm, preferably about 80-90% by weight of the sand having a grain size of about 1-2 mm.

- the grain shape should preferably be angular, so that the next finer layer gets better hold.

- the sand is mixed with the liquid, subsequently curing binder, preferably polyurethane, before application, the weight mixing ratio of sand / binder being about 30: 1 to 3: 1, in particular about 10: 1.

- polyurethane in an amount of about 0.1-0.5, in particular about 0.3 kg / m2 of sand surface.

- This sand / binder mixture is also spread out in the usual way as a layer which is then leveled out.

- the sand fills the surface unevenness, which is due to the different size and irregular shape of the rubber-like particles.

- the sand layer After hardening, the sand layer has a thickness of about 1-1.5 mm on average over the elastic layer and is essentially completely flat. "On average” means that somewhat larger layer thicknesses can occur due to the unevenness of the elastic layer to be filled.

- the thickness ratio between the elastic layer (first layer) and the hard mineral layer (second layer) is advantageously in a range from approximately 4: 1 to 10: 1.

- a sand covering produced in this way is not yet suitable for use as it does not slip due to its abrasive properties and also presents an increased risk of injury to the players.

- a third layer is applied as a second leveling layer, which consists of broken brick flour, to which a further binder has been added.

- This binder is advantageously identical to the two binders used above.

- the broken brick flour has a grain size of up to 1 mm, advantageously about 80% having a grain size of about 0.5-1 mm.

- the broken brick flour is advantageously used with liquid polyurethane in the same amounts as for the sand layer, i.e. about 0.3 kg PUR / m2 sports field area is used according to the preferred embodiment.

- this layer adheres to the spaces between the individual grains of sand and is therefore difficult to rub off.

- the adhesion of the broken brick particles which are softer in relation to the sand, is not so strong that this covering would behave like an emery.

- a surface produced in this way has practically the same playing characteristics as a conventional tennis court based on broken brick, i.e. it is suitable for tournament games and is also extremely easy to maintain.

- the boundary lines are applied to the bound brick flour layer with the aid of firmly adhering white paint, for example based on PUR, which can practically not be removed during play.

- a liquid binder such as water and the like, being added to reduce the generation of dust.

- a covering produced in this way is water-permeable due to the low binder content in the respective layers and the selected relatively large grain sizes of the individual particles and absorbs the rain water quantities in the shortest possible time - provided that there is a functioning drainage system.

- the above covering is manufactured in situ and remains connected to the base covering.

- the sports field covering can be factory-made in the form of plates and the like. are produced by the same method, which are then applied to the base covering, the preformed plate being applied to the base surface with the aid of the binder used above.

- the binder used can be the same or different from the binder used to produce the individual plate layers.

- the binder can be spread over the entire base surface or the like in the form of strips. be applied to the base surface. It should only be noted that the water permeability between the base surface and the underside of the plate is not impaired by the binder layer. Such a procedure is advantageously used when the plates are to be permanently connected to the substrate.

- this plate is fastened to the subsurface using known connection systems which allow the plates to be removed again, for example double-sided adhesive tapes and the like.

- connection systems which allow the plates to be removed again, for example double-sided adhesive tapes and the like.

- only the respective plate is fixed in the edge area on the substrate, which is sufficient for fixing the relatively rigid plate on the substrate.

- Such plates can be produced in the usual way in a form in which the individual layers are inserted one after the other and are each cured in the usual way.

- the latter procedure is explained, for example, in DE-A-21 56 255, to the disclosure of which reference is made.

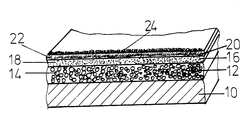

- the only drawing shows a surface for sports fields in perspective, with the front cut.

- the first polymeric layer 12 made of rubber particles 14 is applied, which are solidified with one another with binder in situ.

- the second layer 16 of sand particles 18 is applied, which in turn is solidified with binders.

- the third layer 20 is applied, which contains brick powder particles 22, which are solidified again with binder.

- loose brick powder 24 is sprinkled on, which may be kept slippery by a further, non-hardening binder, but is essentially kept dust-free.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Road Paving Structures (AREA)

- Road Repair (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3830372 | 1988-09-07 | ||

| DE3830372 | 1988-09-07 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0358209A2 true EP0358209A2 (fr) | 1990-03-14 |

| EP0358209A3 EP0358209A3 (en) | 1990-05-16 |

| EP0358209B1 EP0358209B1 (fr) | 1992-08-05 |

Family

ID=6362440

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89116490A Expired - Lifetime EP0358209B1 (fr) | 1988-09-07 | 1989-09-07 | Revêtement pour court de tennis |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0358209B1 (fr) |

| DE (1) | DE58901980D1 (fr) |

| ES (1) | ES2034541T3 (fr) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2246077A (en) * | 1990-07-20 | 1992-01-22 | Frank Bowers | Recreational surface |

| FR2807078A1 (fr) | 2000-03-29 | 2001-10-05 | Envirosport | Revetement de sol sportif, notamment pour courts de tennis et autres jeux de balles |

| AU755765B2 (en) * | 1998-04-14 | 2002-12-19 | Playsoft Pty Ltd | Surface support structure |

| WO2005075741A1 (fr) * | 2004-02-07 | 2005-08-18 | Terraelast Ag | Revetement de sol permeable a l'eau et procede pour fabriquer ce revetement de sol |

| WO2006056764A1 (fr) * | 2004-11-25 | 2006-06-01 | Frank Bowers | Surface recreative synthetique |

| EP1811086A1 (fr) * | 2006-01-18 | 2007-07-25 | Hans-Joachim Schneider | Procédé de fabrication d un revêtement élastique, résistant aux intempéries, non gélif, utilisable pendant toute l année pour des voies, des pleines de jeux et des surfaces sportives. En particulier pour des courts de tennis à l'intérieur et l'extérieur |

| WO2010149973A3 (fr) * | 2009-06-25 | 2011-06-30 | Eco Composite Recycling Ltd | Matériaux |

| DE202011051932U1 (de) | 2011-11-10 | 2013-02-11 | Sportas Gmbh Sportanlagen-Sportbodenbau | Bodenbelag für Sportflächen |

| WO2013068527A1 (fr) | 2011-11-10 | 2013-05-16 | Sportek Ohg | Revêtement de sol pour surfaces de sport et procédé de fabrication dudit revêtement |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11332893B2 (en) | 2019-12-13 | 2022-05-17 | C & M Surfaces, LLC | Method of resurfacing a sports court |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2156255A1 (de) * | 1970-11-09 | 1972-05-18 | Minnesota Mining & Mfg | Als Belag für Sportanlagen geeignetes federndes zusammengesetztes Material |

| DE2258566A1 (de) * | 1972-11-30 | 1974-06-06 | Klaus Dipl-Ing Seppelfricke | Bodenbelag fuer tennisplaetze und dergleichen sportanlagen |

| DE2826206A1 (de) * | 1978-06-15 | 1979-12-20 | Becker Kg Sport | Belag fuer sportplaetze, insbesondere tennisplaetze |

| DE3231231A1 (de) * | 1982-08-21 | 1984-03-01 | C. Voigt Söhne GmbH & Co, 4620 Castrop-Rauxel | Verfahren zur herstellung eines belages fuer sportplaetze, insbesondere tennisplaetze, sowie bewegliche platte zum verlegen auf sportplaetzen, insbesondere tennisplaetzen |

| EP0258871A2 (fr) * | 1986-09-02 | 1988-03-09 | Polytan-Sportbelagsysteme GmbH | Piste |

-

1989

- 1989-09-07 ES ES198989116490T patent/ES2034541T3/es not_active Expired - Lifetime

- 1989-09-07 EP EP89116490A patent/EP0358209B1/fr not_active Expired - Lifetime

- 1989-09-07 DE DE8989116490T patent/DE58901980D1/de not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2156255A1 (de) * | 1970-11-09 | 1972-05-18 | Minnesota Mining & Mfg | Als Belag für Sportanlagen geeignetes federndes zusammengesetztes Material |

| DE2258566A1 (de) * | 1972-11-30 | 1974-06-06 | Klaus Dipl-Ing Seppelfricke | Bodenbelag fuer tennisplaetze und dergleichen sportanlagen |

| DE2826206A1 (de) * | 1978-06-15 | 1979-12-20 | Becker Kg Sport | Belag fuer sportplaetze, insbesondere tennisplaetze |

| DE3231231A1 (de) * | 1982-08-21 | 1984-03-01 | C. Voigt Söhne GmbH & Co, 4620 Castrop-Rauxel | Verfahren zur herstellung eines belages fuer sportplaetze, insbesondere tennisplaetze, sowie bewegliche platte zum verlegen auf sportplaetzen, insbesondere tennisplaetzen |

| EP0258871A2 (fr) * | 1986-09-02 | 1988-03-09 | Polytan-Sportbelagsysteme GmbH | Piste |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2246077A (en) * | 1990-07-20 | 1992-01-22 | Frank Bowers | Recreational surface |

| AU755765B2 (en) * | 1998-04-14 | 2002-12-19 | Playsoft Pty Ltd | Surface support structure |

| FR2807078A1 (fr) | 2000-03-29 | 2001-10-05 | Envirosport | Revetement de sol sportif, notamment pour courts de tennis et autres jeux de balles |

| WO2005075741A1 (fr) * | 2004-02-07 | 2005-08-18 | Terraelast Ag | Revetement de sol permeable a l'eau et procede pour fabriquer ce revetement de sol |

| GB2434991B (en) * | 2004-11-25 | 2009-12-16 | Frank Bowers | Synthetic recreational surface |

| WO2006056764A1 (fr) * | 2004-11-25 | 2006-06-01 | Frank Bowers | Surface recreative synthetique |

| GB2434991A (en) * | 2004-11-25 | 2007-08-15 | Frank Bowers | Synthetic recreational surface |

| EP1939356A3 (fr) * | 2006-01-18 | 2010-05-19 | Hans-Joachim Schneider | Revêtement pour aires de passage, de jeu et de sport, et procédé de fabrication d'un tel revêtement |

| EP1811086A1 (fr) * | 2006-01-18 | 2007-07-25 | Hans-Joachim Schneider | Procédé de fabrication d un revêtement élastique, résistant aux intempéries, non gélif, utilisable pendant toute l année pour des voies, des pleines de jeux et des surfaces sportives. En particulier pour des courts de tennis à l'intérieur et l'extérieur |

| WO2010149973A3 (fr) * | 2009-06-25 | 2011-06-30 | Eco Composite Recycling Ltd | Matériaux |

| US9163364B2 (en) | 2009-06-25 | 2015-10-20 | Sudscape Technologies Limited | Materials |

| AU2010264344B2 (en) * | 2009-06-25 | 2016-02-04 | Sudscape Technologies Limited | Materials |

| DE202011051932U1 (de) | 2011-11-10 | 2013-02-11 | Sportas Gmbh Sportanlagen-Sportbodenbau | Bodenbelag für Sportflächen |

| WO2013068527A1 (fr) | 2011-11-10 | 2013-05-16 | Sportek Ohg | Revêtement de sol pour surfaces de sport et procédé de fabrication dudit revêtement |

| DE102011055235A1 (de) | 2011-11-10 | 2013-05-16 | SPORTAS GmbH | Bodenbelag für Sportflächen, sowie Verfahren zur Herstellung |

| US9353488B2 (en) | 2011-11-10 | 2016-05-31 | Sportek Ohg | Ground covering for sports areas, and method for producing it |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0358209A3 (en) | 1990-05-16 |

| ES2034541T3 (es) | 1993-04-01 |

| DE58901980D1 (de) | 1992-09-10 |

| EP0358209B1 (fr) | 1992-08-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3642610C2 (de) | Wetterfeste Bodenfläche für Sportfelder und Materialmischung zur Erstellung von Sportfeldböden | |

| DE102004006165B4 (de) | Wasserdurchlässiger Bodenbelag und Verfahren zur Herstellung eines Bodenbelags | |

| EP1939356B1 (fr) | Revêtement pour aires de passage, de jeu et de sport, et procédé de fabrication d'un tel revêtement | |

| EP0358209B1 (fr) | Revêtement pour court de tennis | |

| DE4100581A1 (de) | Formkoerper aus vulkanisiertem altgummimaterial | |

| DE2312666A1 (de) | Werkstoff aus gummiabfaellen, insbesondere aus reifenschnitzeln | |

| DE2702866A1 (de) | Verfahren und vorrichtung zur herstellung eines strassenbelages sowie nach diesem verfahren hergestellter, rutschfester strassenbelag | |

| EP2393984B1 (fr) | Enrobé d'asphalte coulé auto-compactable, pour couches de surface de chaussée, couches intermédiaires asphaltiques, couches de liaison asphaltiques et/ou couches d'étanchéité asphaltiques | |

| EP1416009A1 (fr) | Particules de caoutchouc enrobées | |

| DE3109392C2 (fr) | ||

| DE19522091C2 (de) | Wasser- und gasdurchlässige Wege- und Flächenbefestigung hergestellt aus einer Mischung aus körnigen Zuschlagstoffen, Bindemitteln und faserförmigen Materialien bestehenden Mischung und Verfahren zur Herstellung dieser Flächenbefestigung | |

| DE3808250A1 (de) | Strassenbelag aus einem asphaltmischgut mit einer eishemmenden komponente | |

| DE19848029A1 (de) | Kunstharzgebundener Straßenpflaster-Formstein, Verfahren zu dessen Herstellung sowie Verwendung | |

| DE20217142U1 (de) | Ummantelte Gummipartikel | |

| DE3629798A1 (de) | Sportbahn | |

| DE3539204A1 (de) | Baustoff fuer die deckschicht eines sport- und/oder spielplatzes, insbesondere tennisplatzes, verfahren zur herstellung eines solchen platzes, und sport- und/oder spielplatz, insbesondere tennisplatz mit einer deckschicht aus dem baustoff | |

| EP0319702B1 (fr) | Revêtement pour couches portantes et son procédé de fabrication | |

| DE20100678U1 (de) | Witterungsunabhängiger und ganzjährig bespielbarer Belag für Sport- und Spielflächen, insbesondere Tennisplätze | |

| DE2524877A1 (de) | Verfahren zur herstellung von drainage-boden-belaegen | |

| EP2776628A1 (fr) | Revêtement de sol pour surfaces de sport et procédé de fabrication dudit revêtement | |

| DE202011051932U1 (de) | Bodenbelag für Sportflächen | |

| DE202010003569U1 (de) | Tragschicht, Bodenplatte, Bodenplattenanordnung und Sandwichbauwerk | |

| DE3335267A1 (de) | Bodenbelag fuer sportplaetze, insbesondere tennisplaetze | |

| DE3780763T2 (de) | Vielfaeltig verwendbare rennbahn eingerichtet fuer sport, insbesondere fuer reitkunst. | |

| DE1658488C3 (de) | Deckschicht für den mehrschichtigen Belag eines Sportplatzes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB GR IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES FR GB GR IT |

|

| 17P | Request for examination filed |

Effective date: 19901026 |

|

| 17Q | First examination report despatched |

Effective date: 19911007 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE ES FR GB IT |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 58901980 Country of ref document: DE Date of ref document: 19920910 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2034541 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19970807 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19970818 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19970930 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19971119 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980907 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF THE APPLICANT RENOUNCES Effective date: 19980908 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19980907 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990701 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20001009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050907 |