EP0334064A1 - Elément dans la distribution d'un moteur à combustion interne - Google Patents

Elément dans la distribution d'un moteur à combustion interne Download PDFInfo

- Publication number

- EP0334064A1 EP0334064A1 EP89103613A EP89103613A EP0334064A1 EP 0334064 A1 EP0334064 A1 EP 0334064A1 EP 89103613 A EP89103613 A EP 89103613A EP 89103613 A EP89103613 A EP 89103613A EP 0334064 A1 EP0334064 A1 EP 0334064A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- component

- control cam

- chrome

- tappet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims abstract description 17

- 238000002485 combustion reaction Methods 0.000 claims abstract description 3

- 239000000463 material Substances 0.000 claims description 3

- 230000002349 favourable effect Effects 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 238000009713 electroplating Methods 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 238000000275 quality assurance Methods 0.000 description 2

- 229910052793 cadmium Inorganic materials 0.000 description 1

- BDOSMKKIYDKNTQ-UHFFFAOYSA-N cadmium atom Chemical compound [Cd] BDOSMKKIYDKNTQ-UHFFFAOYSA-N 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 239000011651 chromium Substances 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 125000004435 hydrogen atom Chemical class [H]* 0.000 description 1

- 238000002372 labelling Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01L—CYCLICALLY OPERATING VALVES FOR MACHINES OR ENGINES

- F01L1/00—Valve-gear or valve arrangements, e.g. lift-valve gear

- F01L1/20—Adjusting or compensating clearance

- F01L1/22—Adjusting or compensating clearance automatically, e.g. mechanically

- F01L1/24—Adjusting or compensating clearance automatically, e.g. mechanically by fluid means, e.g. hydraulically

- F01L1/245—Hydraulic tappets

- F01L1/25—Hydraulic tappets between cam and valve stem

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01L—CYCLICALLY OPERATING VALVES FOR MACHINES OR ENGINES

- F01L1/00—Valve-gear or valve arrangements, e.g. lift-valve gear

- F01L1/12—Transmitting gear between valve drive and valve

- F01L1/14—Tappets; Push rods

- F01L1/16—Silencing impact; Reducing wear

Definitions

- the invention relates to a component in the valve timing drive of an internal combustion engine, against the surface of which a control cam runs, in particular a bucket tappet.

- the invention is based on the object of proposing a surface coating for components of this type which, in addition to favorable wear behavior, also ensures high flexural fatigue strength, compressive strength and thus long service life of the component.

- this aim is achieved in that a chrome layer with a layer thickness of at most 5 ⁇ m, preferably 2.5 ⁇ m, is applied to the surface of the component against which the control cam runs.

- a chrome layer with a layer thickness of at most 5 ⁇ m, preferably 2.5 ⁇ m is applied to the surface of the component against which the control cam runs.

- the chrome layer consists of a plurality of layers applied one after the other, at least the last of which, which forms the sliding surface for the control cam, has microcracks. It has been shown that it is of great importance for the sliding properties on the surface of the chrome layer that there are microcracks in which lubricant can accumulate. On the other hand, for the durability of the chrome layer, it is essential that the first layer, which creates the connection to the material of the component, is free of microcracks, in order to avoid micro-notching and thus starting points for a possible peeling of the layer.

- the micro-crack-free first layer can expediently be applied by electrolytic metal deposition (electroplating) with a current density of approximately 15 A / dm 2, while the outer layer, which has at least 600 cracks / cm, is electroplated with a current density of less than 15 A / dm2 can be applied.

- the chromium-coated component is expediently heated after the electroplating and kept at a temperature of approximately 120 ° C. for four hours before being allowed to cool in air.

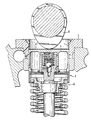

- valve train with a tappet is shown in longitudinal section:

- the tappet 3 which contains a hydraulic valve clearance compensation element in a known manner, is mounted so as to be longitudinally displaceable.

- the control cam 5 runs on the flat bottom 4 of the tappet 3, while the tappet, on the other hand, bears against the shaft 6 of a control valve.

- the bottom 4 of the tappet 3 is provided with a thin chrome layer 7 according to the invention.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Valve-Gear Or Valve Arrangements (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3809702A DE3809702A1 (de) | 1988-03-23 | 1988-03-23 | Bauteil im ventilsteuertrieb einer brennkraftmaschine |

| DE3809702 | 1988-03-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0334064A1 true EP0334064A1 (fr) | 1989-09-27 |

| EP0334064B1 EP0334064B1 (fr) | 1991-12-27 |

Family

ID=6350429

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89103613A Expired - Lifetime EP0334064B1 (fr) | 1988-03-23 | 1989-03-02 | Elément dans la distribution d'un moteur à combustion interne |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US4876996A (fr) |

| EP (1) | EP0334064B1 (fr) |

| DE (2) | DE3809702A1 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0396288B1 (fr) * | 1989-04-20 | 1993-06-16 | Eaton Engine Lifters Spa | Poussoir hydraulique |

| US5267538A (en) * | 1991-06-07 | 1993-12-07 | Ina Walzlager Schaeffler Kg | Mechanical valve tappet for an internal combustion engine |

| DE4498820D2 (de) * | 1993-11-12 | 1997-07-24 | Schaeffler Waelzlager Kg | Stößel für einen Ventiltrieb einer Brennkraftmaschine |

| WO2005121383A1 (fr) | 2004-06-09 | 2005-12-22 | Schaeffler Kg | Composant moteur soumis a des contraintes elevees |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4117425C1 (fr) * | 1991-05-28 | 1992-07-30 | Fa. Carl Freudenberg, 6940 Weinheim, De | |

| DE4220584C2 (de) * | 1992-06-24 | 2001-02-01 | Schaeffler Waelzlager Ohg | Ventiltrieb einer Brennkraftmaschine |

| US5226389A (en) * | 1992-11-04 | 1993-07-13 | Eaton Corporation | Direct acting tappet |

| US5237967A (en) * | 1993-01-08 | 1993-08-24 | Ford Motor Company | Powertrain component with amorphous hydrogenated carbon film |

| US5249554A (en) * | 1993-01-08 | 1993-10-05 | Ford Motor Company | Powertrain component with adherent film having a graded composition |

| DE4302877C2 (de) * | 1993-02-02 | 1996-04-11 | Schaeffler Waelzlager Kg | Stößel |

| US5289804A (en) * | 1993-03-25 | 1994-03-01 | Fuji Oozx Inc. | Tappet in an internal combustion engine |

| US5743224A (en) * | 1993-09-14 | 1998-04-28 | Unisia Jecs Corporation | Valve lifter surface and processing method thereof |

| US6119644A (en) * | 1997-05-22 | 2000-09-19 | Ina Walzlager Schaeffler Ohg | Hydraulic clearance compensation element |

| IT1302651B1 (it) * | 1998-10-13 | 2000-09-29 | Eaton Automotive Spa | Punteria idraulica con perdita di altezza controllata. |

| WO2001048267A1 (fr) * | 1999-12-27 | 2001-07-05 | Nippon Piston Ring Co., Ltd. | Element coulissant |

| JP4059621B2 (ja) * | 2000-09-29 | 2008-03-12 | 日本ピストンリング株式会社 | クロムめっき摺動部材及びその製造方法 |

| US20050084610A1 (en) * | 2002-08-13 | 2005-04-21 | Selitser Simon I. | Atmospheric pressure molecular layer CVD |

| DE10249761A1 (de) * | 2002-10-25 | 2004-05-13 | Ina-Schaeffler Kg | Nockenfolger eines Ventiltriebs einer Brennkraftmaschine |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1044692A (en) * | 1964-02-18 | 1966-10-05 | Daimler Benz Ag | Improvements relating to cam devices |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US32167A (en) * | 1861-04-23 | Thomas h | ||

| US3131470A (en) * | 1960-12-09 | 1964-05-05 | Burgess Norton Mfg Co | Method of making valve lifters |

| DE1425653A1 (de) * | 1963-07-08 | 1969-01-23 | Richard Kuechen Sen | Ventilantrieb mit hydraulischem Spielausgleich |

| US3545415A (en) * | 1967-04-08 | 1970-12-08 | Nippon Piston Ring Co Ltd | Valve lifter with thin plastic coating |

| US4230491A (en) * | 1979-01-08 | 1980-10-28 | Stanadyne, Inc. | Internal combustion engine tappet comprising a sintered powdered metal wear resistant composition |

| US4367701A (en) * | 1979-12-05 | 1983-01-11 | Eaton Corporation | Acting valve gear |

| US4688526A (en) * | 1983-12-07 | 1987-08-25 | Eaton Corporation | Self-contained hydraulic bucket lifter |

| JPS62255507A (ja) * | 1986-04-30 | 1987-11-07 | Hitachi Ltd | バルブリフタ−の製造方法 |

-

1988

- 1988-03-23 DE DE3809702A patent/DE3809702A1/de not_active Withdrawn

-

1989

- 1989-03-02 EP EP89103613A patent/EP0334064B1/fr not_active Expired - Lifetime

- 1989-03-02 DE DE8989103613T patent/DE58900604D1/de not_active Expired - Lifetime

- 1989-03-07 US US07/319,957 patent/US4876996A/en not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1044692A (en) * | 1964-02-18 | 1966-10-05 | Daimler Benz Ag | Improvements relating to cam devices |

Non-Patent Citations (3)

| Title |

|---|

| AUTOMOTIVE ENGINEERING, Band 94, Mai 1986, Seiten 40-45, Society of automotive Engineers, Inc., Dallas, Texas, US; "Valve gear materials: An overview" * |

| PATENT ABSTRACTS OF JAPAN, Band 11, Nr. 330 (M-636)[2777], 28. Oktober 1987; & JP-A-62 111 106 (HITACHI LTD) 22-05-1987 * |

| PATENT ABSTRACTS OF JAPAN, Band 9, Nr. 103 (M-377)[1826], 8. Mai 1985, Seite 153 M 377; & JP-A-59 229 009 (TOYOTA JIDOSHA K.K.) 22-12-1984 * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0396288B1 (fr) * | 1989-04-20 | 1993-06-16 | Eaton Engine Lifters Spa | Poussoir hydraulique |

| US5267538A (en) * | 1991-06-07 | 1993-12-07 | Ina Walzlager Schaeffler Kg | Mechanical valve tappet for an internal combustion engine |

| DE4498820D2 (de) * | 1993-11-12 | 1997-07-24 | Schaeffler Waelzlager Kg | Stößel für einen Ventiltrieb einer Brennkraftmaschine |

| WO2005121383A1 (fr) | 2004-06-09 | 2005-12-22 | Schaeffler Kg | Composant moteur soumis a des contraintes elevees |

Also Published As

| Publication number | Publication date |

|---|---|

| DE58900604D1 (de) | 1992-02-06 |

| EP0334064B1 (fr) | 1991-12-27 |

| US4876996A (en) | 1989-10-31 |

| DE3809702A1 (de) | 1989-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0334064B1 (fr) | Elément dans la distribution d'un moteur à combustion interne | |

| DE102004043550B4 (de) | Verschleißfeste Beschichtung, ihre Verwendung und Verfahren zur Herstellung derselben | |

| DE69800317T2 (de) | Material für Hartstoffüberzüge, damit beschichtetes Gleitelement, und Herstellungsverfahren dazu | |

| EP1781835B1 (fr) | Revetement resistant a l'usure et procede de realisation associe | |

| DE102006029415B4 (de) | Verschleißfeste Beschichtung sowie Herstellverfahren hierfür | |

| DE69700387T2 (de) | Zylinderbüchse, kolben sowie kolbenring eines dieselmotors | |

| DE102009028504C5 (de) | Kolbenring mit einer Beschichtung | |

| DE10083665B3 (de) | Kombination einer Zylinderlaufbuchse und eines Kolbenringes in einer Brennkraftmaschine | |

| DE102004041234A1 (de) | Verschleißfeste Beschichtung und Verfahren zur Herstellung derselben | |

| WO1997016578A1 (fr) | Procede de production d'une surface de frottement sur une piece metallique | |

| WO2009062877A2 (fr) | Revêtement résistant à la corrosion et procédé d'élaboration correspondant | |

| DE102012203432A1 (de) | Motor ohne Zylinderbüchse | |

| DE4019644A1 (de) | Ventilstoessel-struktur | |

| DE3878103T3 (de) | Lager. | |

| DE2926708A1 (de) | Verfahren zur herstellung von werkstuecken mit anpassungsschicht fuer beanspruchung mit extrem hohem flaechendruck und werkstuecke mit solcher anpassungsschicht | |

| EP1637623A1 (fr) | Poudre de pulvérisation, élément de palier d'un dispositif de palier revêtu avec la poudre de pulvérisation | |

| DE19540572C2 (de) | Verfahren zum Herstellen einer im Betrieb eine hydrodynamische Schmierung gewährleistenden Gleitfläche auf einem metallsichen Werkstück, sowie eine Hubkolbenmaschine mit danach hergestellten Zylinderlaufbahnen | |

| DE2921952A1 (de) | Aus aluminium oder einer aluminiumlegierung gefertigter kolben fuer eine verbrennungskraftmaschine | |

| EP3414356A1 (fr) | Système tribologique d'un moteur à combustion interne pourvu d'un revêtement | |

| EP0114655A1 (fr) | Bague d'étanchéité de piston pour un moteur à combustion interne | |

| DE3301366A1 (de) | Kolben fuer brennkraftmaschinen | |

| DE10339711A1 (de) | Kolben mit Kolbenring | |

| DE102005037206A1 (de) | Baueinheit für einen Verbrennungsmotor | |

| DE19852265A1 (de) | Rollenstiftmaterialien für verbesserte Nockenhaltbarkeit | |

| DE3916498A1 (de) | Verfahren zum aufbringen einer phosphat-laufschicht auf eine lagermetallschicht |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19890302 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB |

|

| 17Q | First examination report despatched |

Effective date: 19901123 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19920124 Year of fee payment: 4 |

|

| REF | Corresponds to: |

Ref document number: 58900604 Country of ref document: DE Date of ref document: 19920206 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19930302 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19930302 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19931130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20010316 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20021001 |