EP0282858B1 - Mechanischer Energiespeicher ohne Verriegelungskraft - Google Patents

Mechanischer Energiespeicher ohne Verriegelungskraft Download PDFInfo

- Publication number

- EP0282858B1 EP0282858B1 EP88103493A EP88103493A EP0282858B1 EP 0282858 B1 EP0282858 B1 EP 0282858B1 EP 88103493 A EP88103493 A EP 88103493A EP 88103493 A EP88103493 A EP 88103493A EP 0282858 B1 EP0282858 B1 EP 0282858B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rod

- axis

- spring

- cage

- roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000008878 coupling Effects 0.000 claims abstract description 6

- 238000010168 coupling process Methods 0.000 claims abstract description 6

- 238000005859 coupling reaction Methods 0.000 claims abstract description 6

- 238000004146 energy storage Methods 0.000 claims abstract description 5

- 230000009471 action Effects 0.000 claims description 4

- 238000005096 rolling process Methods 0.000 description 5

- 230000007246 mechanism Effects 0.000 description 4

- 230000008901 benefit Effects 0.000 description 3

- 230000009467 reduction Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000003100 immobilizing effect Effects 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/22—Power arrangements internal to the switch for operating the driving mechanism

- H01H3/30—Power arrangements internal to the switch for operating the driving mechanism using spring motor

- H01H3/3031—Means for locking the spring in a charged state

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/22—Power arrangements internal to the switch for operating the driving mechanism

- H01H3/30—Power arrangements internal to the switch for operating the driving mechanism using spring motor

- H01H3/3031—Means for locking the spring in a charged state

- H01H2003/3036—Means for locking the spring in a charged state using of balls or rollers in the locking device

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H3/00—Mechanisms for operating contacts

- H01H3/22—Power arrangements internal to the switch for operating the driving mechanism

- H01H3/30—Power arrangements internal to the switch for operating the driving mechanism using spring motor

- H01H3/3052—Linear spring motors

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/11—Tripping mechanism

Definitions

- the present invention relates to a mechanical energy storage device, by means of springs and intended in particular for the actuation of an electric circuit breaker.

- circuit breakers It is known that the mechanical actuation of circuit breakers is carried out for example by means of a compression spring. The energy necessary for the operation is then stored in the banded spring. The spring is kept bandaged by a more or less complex hooking device, which necessarily comprises a hooking member immobilizing a wheel or a cam.

- This document describes a spring device, controlled by pulse, for the operation of electrical devices, in particular switch and disconnector, in a long time relative to the duration of said pulse.

- This device comprises a spring driving, via a cable and a cam, the trigger control shaft. Its rearming is carried out using a shaft provided with a non-return means comprising in particular a ratchet wheel cooperating with a ratchet carrying at its end a hooking roller and driving, by means of a reduction kinematic chain. , said control shaft in the opposite direction to said triggering.

- the pulse causes the permanent locking of the non-return means and authorizes the completion of the trigger.

- the fastening member and the wheel exert a mutual force between them which it is necessary to overcome to unlock the wheel and allow the spring to relax. This effort is all the greater the greater the energy stored in the springs. The greater this effort, the greater the energy of the trigger mechanism to overcome it.

- Document FR-A-2,319,188 discloses a coupling mechanism comprising two springs which can successively relax, thanks to a ball locking member which authorizes the action of the second spring only when the first spring has finished his relaxation.

- this mechanism comprises a rod on which a cage of balls slides. These balls can either penetrate into a groove of the rod (case of attachment between the cage and the rod), or move radially to be housed in a flared part of a fixed sleeve (case of release from the cage and the rod and hooking between the cage and the sleeve).

- the rod is therefore driven first by a single spring and then, after detachment between cage and sleeve, by the action of the two springs.

- a similar ball locking member is known from document DE-A-29 43 104.

- Such a device has the great advantage of being very simple to implement.

- first rod 10 provided at its first end with a flange 11, and at its second end with a nozzle 12.

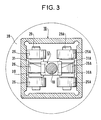

- This first rod 10 is slidably mounted along a longitudinal axis ⁇ inside d 'a bore 13 pierced in a cover 15 which closes a fixed cage 16 at its first end: this cage is here square in shape, and has as axis of symmetry the axis ⁇ . It ends at its second end with a flared part 28.

- the first end of this rod 10 is secured to hooking means constituted here by a rod 18, for controlling the circuit breaker for example, provided with a transverse bore 19 in which, in the engaged position, is introduced a hooking member 100 controlled, for example, by an electromagnet 121 which keeps the first rod 10 in a fixed position when the first spring 17 is banded.

- hooking means constituted here by a rod 18, for controlling the circuit breaker for example, provided with a transverse bore 19 in which, in the engaged position, is introduced a hooking member 100 controlled, for example, by an electromagnet 121 which keeps the first rod 10 in a fixed position when the first spring 17 is banded.

- a second rod 20 is provided at its first end which faces the second end of the first rod, with a flange 21.

- This second rod 20 is slidably mounted along the axis ⁇ , inside a bore 22 drilled in a fixed frame 23.

- a second spring 34 with a flange for example, is arranged around this rod 20 while being fixed on the one hand to the flange 21, and on the other hand to the frame 23.

- Two arms 24 and 24A provided at their first ends with bearings 25, 26 and 25A, 26A, for example with balls, whose axes of rotation 29 and 29A are perpendicular to the axis ⁇ , are mobile, at their second ends, around two axes 27 and 27A, in directions parallel to axes 29 and 29A, which are located symmetrically with respect to the axis ⁇ and integral with the external part of the flange 21.

- the end piece 12 is formed by several symmetrical bearing surfaces with respect to the axis ⁇ , are successively: two first planar bearing surfaces 31 and 31A parallel to the rolling surfaces 30 and 30A, two inclined bearing surfaces 33 and 33A towards the ⁇ axis, and two second planar bearings 32 and 32A parallel to the first.

- the relative ball bearings at each axis 29 (29A) respectively consist of two first bearings 25 (25A) which roll on the rolling surface 30 (30A) inside the cage 16, surrounding a second bearing 26 (26A), of smaller diameter, which rolls on the outer surface of the endpiece 12, that is to say on the surfaces 31, 33 and 32 (31A, 33A and 32A).

- the second spring 34 is self-locked: in fact the first bearings 25 and 25A rest inside the flared part 28 of the cage 16, and the second bearings 26 and 26A rest on the first flat bearings 31 and 31A respectively, which prevents movement of these bearings in the direction 40 shown in FIG. 2.

- the first spring 17 begins to relax by driving the rod 10 in the direction of the arrow 40. Without any thrust which would be due to the second spring 34, the bearings 25, 25A, 26, 26A pass from their first position as shown in Figure 1, to the second position shown in Figure 2. The second bearings 26 and 26A, part of the outer surface then rests on the inclined surfaces 33 and 33A used to transmit to the first rod 10 the thrust of the second spring 34 .

- the device of the invention therefore has the great advantage of allowing the storage of a surplus of mechanical energy due to the second spring 34 without the latter acting on the attachment. In fact, in the engaged position, only the first spring 17 presses on the coupling, the second spring 34 being blocked by the rolling system.

- the invention therefore makes it possible to simplify the mechanical controls of such a device: the thrust due to the first spring being weak, the attachment is simplified and can be direct, which makes it possible to avoid stages of reduction of the stored energy . In addition, this energy can be very important.

- the device of the invention can be used to perform the switching on and off functions of mechanical controls.

Landscapes

- Springs (AREA)

- Supporting Of Heads In Record-Carrier Devices (AREA)

- Materials For Medical Uses (AREA)

- Driving Mechanisms And Operating Circuits Of Arc-Extinguishing High-Tension Switches (AREA)

- Bearings For Parts Moving Linearly (AREA)

- Load-Engaging Elements For Cranes (AREA)

- Current-Collector Devices For Electrically Propelled Vehicles (AREA)

- Hybrid Cells (AREA)

- Battery Mounting, Suspending (AREA)

- Other Liquid Machine Or Engine Such As Wave Power Use (AREA)

- Prostheses (AREA)

- Mechanical Operated Clutches (AREA)

Claims (8)

- Einrichtung zur Speicherung mechanischer Energie mit schwacher Koppelkraft zur Betätigung eines Lastschalters, der mit einer Betätigungsstange (18), die entlang einer Längsachse (Δ) gleitet und mit einer Quernut (19) versehen ist, in die in der Einschaltstellung ein Koppelorgan (100) eingeführt ist, das von einem Elektromagneten (121) gesteuert wird, wobei die Betätigungsstange in Richtung der Längsachse (Δ) durch eine erste Stange (10) verlängert wird, die der axialen Wirkung einer ersten Feder (17) unterliegt, deren Achse mit der Längsachse (Δ) übereinstimmt, wobei die Stange durch Kopplungs- und Blockiermittel mit dem freien Ende einer zweiten Stange (20) verbunden ist, die der axialen Wirkung einer zweiten Feder (34) unterliegt, wobei die Kopplungs- und Blockiermittel mindestens einen Arm (24, 24A), der an einem ersten Ende mit einer Rolleinrichtung, bestehend aus mindestens einer Rolle (25, 25A, 26, 26A) mit senkrecht zur Längsachse (Δ) verlaufender Drehachse, und an einem zweiten Ende um eine Achse (27, 27A) beweglich gelagert ist, die parallel zur Drehachse jeder Rolle (25, 25A, 26, 26A) verläuft und fest mit dem freien Ende der zweiten Stange (20) verbunden ist, und einen feststehenden Käfig (16) aufweisen, der mit mindestens einer Rollbahn (30, 30A) parallel zur Richtung der Längsachse (Δ) und zu den Achsen (29, 29A) jeder Rolle versehen ist und der an seinem der zweiten Stange (20) gegenüberstehenden Abschnitt in mindestens einem erweiterten Abschnitt (28) endet, wobei das zweite Ende der ersten Stange (10) einen Endansatz (12) mit mindestens einem ersten flachen Abschnitt (31, 31A) parallel zur Rolloberfläche (30, 30A) und mit einem verjüngten freien freies Ende aufweist, derart, daß in der geladenen Stellung des Kopplungsorgans (100) jede Rolle zwischen dieser ebenen Lauffläche (31, 31A) und dem erweiterten Abschnitt (28) des Käfigs (16) liegt, so daß die zweite Feder (34) blockiert wird.

- Einrichtung nach Anspruch 1, dadurch gekennzeichnet, daß der Endansatz (12) der ersten Stange (10) eine zweite ebene Lauffläche (32, 32A) parallel zur ersten ebenen Lauffläche (31, 31A) aufweist und von der ersten ebenen Lauffläche durch eine in Richtung zur Längsachse (Δ) geneigte Lauffläche (33, 33A) getrennt ist.

- Einrichtung nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß die Rolleinrichtung aus mindestens einer ersten Rolle (25, 25A), die auf einer Rollbahn (30, 30A) läuft, und einer zweiten Rolle (26, 26A) besteht, die auf den Laufflächen des Endansatzes (12) der ersten Stangen (10) rollen kann.

- Einrichtung nach Anspruch 3, dadurch gekennzeichnet, daß die ersten Rollen (25, 25A) zweimal vorhanden sind und die zweite Rolle (26, 26A) einrahmen, die kleineren Durchmessers ist.

- Einrichtung nach einem beliebigen der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß die Kopplungs- und Blockiermittel zwei Arme (24, 24A) aufweisen, die am freien Ende der zweiten Stange (20) auf Drehachsen schwenkbar gelagert sind, die symmetrisch zur Längsachse (Δ) verlaufen, und daß der Käfig (16) und der Endansatz (12) je zur Längsachse (Δ) symmetrische Körper sind.

- Einrichtung nach einem beliebigen vorhergehenden Anspruch, dadurch gekennzeichnet, daß der Käfig (16) an seinem der ersten Stange (10) gegenüberliegenden Ende, durch einen Deckel verschlossen ist, der von einer in der Längsachse (Δ) liegenden Bohrung (13) durchdrungen ist, in welcher der erste Stab (10) gleiten kann.

- Einrichtung nach Anspruch 6, dadurch gekennzeichnet, daß die erste Feder (17) eine Schraubenfeder ist, die die erste Stange (10) umgibt und zwischen einem ersten Kragen (11), der von der ersten Stange (10) getragen und senkrecht dazu verläuft, und dem Deckel des Käfigs (16) angeordnet ist.

- Einrichtung nach einem beliebigen der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß die zweite Feder (34) eine Schraubenfeder ist, die die zweite Stange (20) umgibt und zwischen einem Kragen (21) am freien Ende der Stange und einem festen Gestell (23) angeordnet ist, wobei dieses Gestell mit einer Bohrung (22) versehen ist, in der diese zweite Stange gleitet.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88103493T ATE89434T1 (de) | 1987-03-17 | 1988-03-07 | Mechanischer energiespeicher ohne verriegelungskraft. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8703637A FR2612570A1 (fr) | 1987-03-17 | 1987-03-17 | Dispositif de stockage d'energie mecanique a force d'accrochage nulle |

| FR8703637 | 1987-03-17 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0282858A1 EP0282858A1 (de) | 1988-09-21 |

| EP0282858B1 true EP0282858B1 (de) | 1993-05-12 |

Family

ID=9349065

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88103493A Expired - Lifetime EP0282858B1 (de) | 1987-03-17 | 1988-03-07 | Mechanischer Energiespeicher ohne Verriegelungskraft |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US4841788A (de) |

| EP (1) | EP0282858B1 (de) |

| JP (1) | JPS63252326A (de) |

| CN (1) | CN1010045B (de) |

| AT (1) | ATE89434T1 (de) |

| BR (1) | BR8801194A (de) |

| CA (1) | CA1292030C (de) |

| DE (1) | DE3880863T2 (de) |

| ES (1) | ES2040768T3 (de) |

| FR (1) | FR2612570A1 (de) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0450058A (ja) * | 1990-06-18 | 1992-02-19 | Takata Kk | シートベルト装置のプリテンショナー |

| US6722216B2 (en) * | 2001-07-17 | 2004-04-20 | Ansul Incorporated | Booster actuator |

| FR2836277B1 (fr) * | 2002-02-19 | 2004-04-16 | Alstom | Mecanisme de commande a ressorts pour disjoncteur a mouvement rectiligne |

| US6657150B1 (en) * | 2002-06-14 | 2003-12-02 | Eaton Corporation | Shorting switch and system to eliminate arcing faults in power distribution equipment |

| US7115828B2 (en) * | 2004-04-30 | 2006-10-03 | Southern States, Inc. | Internally switched electric power interrupter |

| JP4933208B2 (ja) * | 2006-09-29 | 2012-05-16 | 河村電器産業株式会社 | 回路遮断器 |

| GB0622385D0 (en) * | 2006-11-10 | 2006-12-20 | Rolls Royce Plc | Coupling |

| KR101132909B1 (ko) * | 2011-02-08 | 2012-04-03 | 엘에스산전 주식회사 | 회로차단기의 스프링 조작기 |

| US9038742B2 (en) * | 2011-08-02 | 2015-05-26 | Kidde Technologies, Inc. | Suppressant actuator |

| US8757191B2 (en) * | 2011-12-08 | 2014-06-24 | Kiddie Technologies, Inc. | High rate discharge (HRD) valve opening mechanism for a fire and explosion protection |

| US8776820B2 (en) * | 2011-12-08 | 2014-07-15 | Kidde Technologies, Inc. | High rate discharge (HRD) valve incorporating a collet sleeve release mechanism |

| DE102016200587A1 (de) * | 2016-01-19 | 2017-07-20 | Siemens Aktiengesellschaft | Auslöseeinrichtung für ein elektrisches Schaltgerät sowie Einstellverfahren |

| CN111547269B (zh) * | 2020-04-21 | 2021-06-15 | 哈尔滨工业大学 | 小行星探测勘察弹加旋释放装置 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2256965A (en) * | 1940-06-03 | 1941-09-23 | Delaney E Sexton | Remote control for camera shutters |

| BE493992A (de) * | 1949-02-25 | |||

| US3008479A (en) * | 1959-02-10 | 1961-11-14 | Altair Inc | Valves |

| US3080582A (en) * | 1959-11-30 | 1963-03-12 | Kidde Walter Co Ltd | Inflatable dinghies |

| FR1588485A (de) * | 1968-05-03 | 1970-04-17 | ||

| NL158314B (nl) * | 1975-07-24 | 1978-10-16 | Hazemeijer Bv | Elektrische schakelaar. |

| DE2943104A1 (de) * | 1979-10-25 | 1981-05-21 | Westfaelische Berggewerkschaft | Verriegelungsvorrichtung |

| US4460007A (en) * | 1983-01-25 | 1984-07-17 | Pirkle Fred L | Valve mechanism |

-

1987

- 1987-03-17 FR FR8703637A patent/FR2612570A1/fr not_active Withdrawn

-

1988

- 1988-03-07 DE DE8888103493T patent/DE3880863T2/de not_active Expired - Fee Related

- 1988-03-07 EP EP88103493A patent/EP0282858B1/de not_active Expired - Lifetime

- 1988-03-07 AT AT88103493T patent/ATE89434T1/de not_active IP Right Cessation

- 1988-03-07 ES ES198888103493T patent/ES2040768T3/es not_active Expired - Lifetime

- 1988-03-16 BR BR8801194A patent/BR8801194A/pt unknown

- 1988-03-16 JP JP63063074A patent/JPS63252326A/ja active Granted

- 1988-03-16 CA CA000561657A patent/CA1292030C/fr not_active Expired - Fee Related

- 1988-03-17 US US07/169,534 patent/US4841788A/en not_active Expired - Fee Related

- 1988-03-17 CN CN88101330A patent/CN1010045B/zh not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| CA1292030C (fr) | 1991-11-12 |

| FR2612570A1 (fr) | 1988-09-23 |

| BR8801194A (pt) | 1988-10-25 |

| DE3880863D1 (de) | 1993-06-17 |

| DE3880863T2 (de) | 1993-08-26 |

| CN1030966A (zh) | 1989-02-08 |

| ES2040768T3 (es) | 1993-11-01 |

| JPH0584006B2 (de) | 1993-11-30 |

| ATE89434T1 (de) | 1993-05-15 |

| CN1010045B (zh) | 1990-10-17 |

| EP0282858A1 (de) | 1988-09-21 |

| US4841788A (en) | 1989-06-27 |

| JPS63252326A (ja) | 1988-10-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0282858B1 (de) | Mechanischer Energiespeicher ohne Verriegelungskraft | |

| EP0593371B1 (de) | Antrieb für einen Dreistellungsschalter | |

| EP2073228B1 (de) | Kompakte, robuste Steuerung für elektrische Mittel- und Hochspannungsgeräte | |

| FR2781921A1 (fr) | Disjoncteur a tenue electrodynamique et pouvoir de coupure eleves | |

| EP2602804B1 (de) | Betätigungsvorrichtung für die Pole in einer elektrischen Mittelspannungsbetätigungseinrichtung | |

| CA2004937C (fr) | Commande de disjoncteur | |

| WO2016079444A1 (fr) | Système de commande a déclenchement pour pôle de coupure et appareil de coupure | |

| FR2789511A1 (fr) | Installation comportant un appareillage electrique de coupure et un interverrouillage a cable | |

| FR2461097A1 (fr) | Mecanisme de commande pour l'entrainement d'une piece mobile, en particulier d'une soupape champignon de moteur a combustion interne | |

| EP2545573B1 (de) | Hybrid-leistungsschalter unter verwendung eines schalters mit rückstellung an einem abschluss | |

| EP0801406B1 (de) | Steuerung mit gradlinigen Federn für Hochspannungsleistungsschalter | |

| CH666369A5 (fr) | Appareil interrupteur d'urgence commandant un interrupteur electrique. | |

| EP0238847B1 (de) | Betätigungsvorrichtung für Schalter | |

| EP0895260B1 (de) | Schnelle Steuervorrichtung für eine Hochspannungs Schaltvorrichtung, insbesondere Erdungsschalter | |

| FR2697566A1 (fr) | Serrure à pêne basculant. | |

| EP0300881B1 (de) | Zweiganggetriebe mit einer vorausgesetzten stationären Kraft | |

| EP1993115A1 (de) | Steuervorrichtung zur Kontaktherstellung oder -unterbrechung zwischen zwei Teilen und mit dieser Vorrichtung ausgestattetes elektrisches Gerät | |

| FR2696730A1 (fr) | Dispositif de rétraction automatique d'un organe de connexion à un élément séparable ou largable. | |

| EP1178505A1 (de) | Betätigungseinrichtung mit einer Zugkette für elektrische Hochspannungsschalter | |

| EP0091360B1 (de) | Mechanische Fernbedienung für elektrische Motoren mit Explosionsschutz | |

| FR2568718A1 (fr) | Dispositif de deverrouillage a energie de commande reduite pour appareil electrique | |

| FR3093227A1 (fr) | Dispositif de commande de contacts d’une ampoule à vide pour appareil de connexion électrique | |

| FR2497601A1 (fr) | Mecanisme de serrure pour disjoncteur de protection a basse tension | |

| EP0508839A1 (de) | Lösbarer Schlossmechanismus für Schaltgeräte und Schaltgeräte mit solchem Schloss | |

| FR2695971A1 (fr) | Groupe de freinage avec déblocage de secours pour moteurs électriques. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19890320 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: GEC ALSTHOM SA |

|

| 17Q | First examination report despatched |

Effective date: 19910805 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19930512 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19930512 |

|

| REF | Corresponds to: |

Ref document number: 89434 Country of ref document: AT Date of ref document: 19930515 Kind code of ref document: T |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930514 |

|

| REF | Corresponds to: |

Ref document number: 3880863 Country of ref document: DE Date of ref document: 19930617 |

|

| ITF | It: translation for a ep patent filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2040768 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940307 Ref country code: AT Effective date: 19940307 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940308 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940308 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940331 Ref country code: LI Effective date: 19940331 Ref country code: CH Effective date: 19940331 Ref country code: BE Effective date: 19940331 |

|

| BERE | Be: lapsed |

Owner name: S.A. GEC ALSTHOM Effective date: 19940331 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940307 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19941201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 88103493.8 Effective date: 19941010 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050307 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |