EP0280901A2 - Plunger pump - Google Patents

Plunger pump Download PDFInfo

- Publication number

- EP0280901A2 EP0280901A2 EP88101593A EP88101593A EP0280901A2 EP 0280901 A2 EP0280901 A2 EP 0280901A2 EP 88101593 A EP88101593 A EP 88101593A EP 88101593 A EP88101593 A EP 88101593A EP 0280901 A2 EP0280901 A2 EP 0280901A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- plunger

- pump

- plungers

- pressure

- work

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000001960 triggered effect Effects 0.000 claims description 12

- 230000007246 mechanism Effects 0.000 claims description 5

- 238000006073 displacement reaction Methods 0.000 abstract description 3

- 238000010276 construction Methods 0.000 description 5

- 238000005086 pumping Methods 0.000 description 4

- 238000004140 cleaning Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B1/00—Multi-cylinder machines or pumps characterised by number or arrangement of cylinders

- F04B1/02—Multi-cylinder machines or pumps characterised by number or arrangement of cylinders having two cylinders

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B49/00—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00

- F04B49/22—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00 by means of valves

- F04B49/24—Bypassing

- F04B49/243—Bypassing by keeping open the inlet valve

Definitions

- the invention relates to a plunger pump with at least two plunger work spaces and the same associated, in-phase working plungers or plunger parts, which displace different or equal amounts of the pump medium in their in-phase strokes, and with a triggerable suction valve, which the working space of the larger volume displacing a plunger or Is assigned to the plunger part and, when triggered, remains permanently in the open position, so that when the suction valve is triggered by means of the other plunger or plunger part displacing the smaller volume, a low flow rate with high pressure and when the suction valve is working by means of the work of both plunger or plunger parts large flow with low pressure with unchanged power requirement of the pump allowed to generate.

- Conventional plunger pumps switchable between high and low pressure typically have plungers with two sections of different cross sections, such that a relatively large annular step is formed between the section with the larger cross section and the section with the smaller cross section.

- the section with the smaller cross section arranged as the free end of the plunger works in a first Plunger work space, while the area with the ring step works in a second work space that is sealed off from the first work space.

- Each work area has separate suction and pressure valves, the suction valve of the work area accommodating the ring step portion of the plunger being releasable, so that this pump part is ineffective when the suction valve is triggered and is therefore permanently open. In this case, only the pump part formed by the working space for the free plunger end with the small cross section works.

- the pressure valve of the working area accommodating the ring stage area of the plunger is usually only designed for relatively low pressures, an additional changeover valve arrangement must be present which is triggered during high pressure operation of the pump, ie when the suction valve of the working area accommodating the ring step area of the plunger is activated and thus continuously is open, the pressure valve of this working space shields against the pressure of the flow emerging from the other working space.

- a plunger pump of the type specified above in that the two plunger working spaces are connected to one another by a line with a check valve closing in the direction of the working space of one plunger or plunger part, with the suction side of the pump only via the triggerable suction valve of the working space of one plunger or plunger part and are connected to the pressure side of the pump only via a pressure valve assigned to the plunger work space of the other plunger or plunger part.

- the working spaces of the two different volume-displacing plungers or plunger parts are connected in series, ie the flow rate of the pump passes through both working spaces of the two plungers or plunger parts in each case. Because of this arrangement, only three valves are necessary for the two workrooms.

- the check valve arranged in the line between the plunger work spaces, when the suction valve is triggered, works in the usual way as a suction valve of the plunger work space with the plunger or plunger part displacing the smaller volume, while the work of the other plunger or plunger part remains ineffective due to the triggered suction valve and the pump accordingly only works effectively with the other plunger or plunger part.

- switchover valve arrangements on the pressure side of the pump are also unnecessary. Because due to the series connection of the working spaces, the entire delivery flow generated by the pump emerges at the pressure valve of the working space, which is assigned to the plunger or plunger part displacing the smaller volume. It is therefore unnecessary to summarize the flow rates of the two work spaces by separate measures or to protect a pressure valve of a work space serving to generate a flow rate at low pressure from the high pressure which may be generated.

- the two different volume-displacing plungers or plunger parts are arranged in mutually parallel working spaces, which are arranged in an axial view of a crank engine driving the plungers when the plungers are arranged one above the other or when the plungers are arranged standing next to one another are.

- the two plungers or plunger parts by means of a common crosshead or slide with a common, with the crosshead or slide through connecting rod or the like. drive-connected crank crankshaft crank drive are coupled.

- This design is characterized by its particular compactness.

- the crankshaft can be dimensioned relatively short.

- the two working spaces of the plunger or plunger parts can easily be accommodated in a block whose height or width is less than the height or width of the crankcase.

- this design is characterized in that largely conventional parts can be used for crank mechanisms, crossheads and plungers.

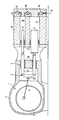

- the pump shown has a crank mechanism 1 with a crankcase 2, a crankshaft 3, connecting rods 4 and crossheads 5, which are displaceably arranged in piston-like manner in crosshead guides 6 and carry out lifting movements in a known manner when the crankshaft 3 rotates.

- Each crosshead 5 is connected to two plungers 7 and 8, which are arranged within associated plunger work spaces 9 and 10, which in turn are arranged as parts of a cylinder block 11 connected to the crankcase 2.

- the plungers 7 and 8 are guided in a known manner in sealing arrangements 12 at the ends of the plunger work spaces 9 and 10 on the crosshead side in order to seal the plunger work spaces 9 and 10 towards the crossheads 5.

- the upper plunger 8 in the figure has a smaller cross section than the lower plunger 7. Accordingly, the plungers 7 and 8 displace different amounts of media during their strokes.

- valve block 13 On the side facing away from the cross heads 5, the cylinder block 11 is connected to a valve block 13 which has a total of three valves for the two plunger work spaces 9 and 10, namely a suction valve connecting the plunger work space 9 with the suction side or a suction line of the pump, not shown 14, a check valve 15 arranged between the plunger work spaces 9 and 10 and allowing only a flow in the direction of the plunger work space 10, and a pressure valve 16 leading from the plunger work space 10 to the pressure side or a pressure line (not shown) of the pump.

- the valves 14 to 16 are schematized as ball valves shown, in principle, however, other valve constructions are possible and generally also useful.

- the suction valve 14 is designed to be releasable, ie the valve body of the suction valve 14 can be kept permanently in the open position by means of a tappet 17. Additional valves are not required for plunger work rooms 9 and 10.

- the plunger working spaces 9 and 10 fill with pump medium which flows in through the valves 14 and 15 opening in the suction stroke, the suction valve 14 being different from the sum of the Plunger work rooms 9 and 10 penetrating currents and the check valve 15 are only penetrated by the current flowing into the plunger work room 10.

- the pressure valve 16 remains closed, because in the plunger work space 10 there is only the pressure on the suction side of the pump which is reduced compared to the pressure side of the pump or a pressure slightly below it.

- the suction valve 14 closes, while the check valve 15 remains open or is again brought into the open position together with the now opening pressure valve 16 because the plunger 7 is now medium displace medium from the plunger work space 10 from the plunger work space 9 and the plunger 8. Accordingly, the check valve 15 is traversed by the medium flowing out of the plunger work space 9, while the pressure valve 16 flows through the sum of the quantities of the pump medium emerging from the plunger work spaces 9 and 10.

- the mode of operation described above is low-pressure operation because the pump works with both plungers 7 and 8 and thus with a relatively large plunger cross section. If the pump is to operate in high pressure mode, the suction valve 14 is triggered by corresponding actuation of the tappet 17 and is thus kept in the open position continuously. Accordingly, the plunger 7 cannot perform any pumping work; rather, the medium sucked in by it in the suction stroke during the pressure stroke is conveyed back through the suction valve 14 to the suction side of the pump. Only the plunger 8 can perform effective pumping work, because the check valve 15 now works in the manner of a conventional suction valve, i.e.

- the check valve 15 opens in the suction stroke of the plunger 8 and closes on its pressure stroke, since in the plunger work space 9, due to the continuously open suction valve 14, only a reduced pressure compared to the pressure in the plunger work space 10 can be present, approximately corresponding to the suction-side pressure of the pump.

- the pressure valve 16 opens during the pressure stroke of the plunger 8 under the influence of the medium displaced by the plunger 8. Since in this phase the pump can only perform effective pumping work with the plunger 8 and works with a relatively small plunger cross section, very high pressures can be generated without increasing the power of a drive unit which drives the crankshaft 3.

- a special feature of the pump shown is that the plunger work rooms 9 and 10 are connected in series, i.e. the entire medium conveyed by the plungers 7 and 8 to the pressure side passes through the plunger work rooms 9 and 10 in succession.

- the plunger work rooms 9 and 10 are connected in series, i.e. the entire medium conveyed by the plungers 7 and 8 to the pressure side passes through the plunger work rooms 9 and 10 in succession.

- the cross head 5 which is only shown schematically, consists essentially of two rod parts 18 with a circular cross section, which are arranged coaxially with the plungers 7 and 8, the rod parts 18 possibly being hollow to reduce weight.

- the rod parts 18 are separately slidably mounted in guide bushings 19, which are arranged in suitable cylinder bores of the crankcase 2.

- the rod parts 18 are connected in the longitudinal direction by means of a yoke 20 without being displaceable relative to one another.

- the yoke 20 is in turn articulated to the connecting rod 4.

- the ends of the rod parts 18 facing away from the yoke 20 are releasably connected in a generally known manner to the plungers 7 and 8 as in conventional pumps, the plungers 7 and 8 being able to have a limited angular mobility, in particular relative to the rod parts 18, so that assembly tolerances in the Alignment of crankcase 2 and cylinder block 11 are unproblematic.

- the invention is not restricted to plunger pumps in the narrower sense. Instead of the plungers shown, other displacement arrangements can also be provided. In principle, this does not change the arrangement of the valves 14 to 16.

- both plungers 7 and 8 with the same cross-sections and to achieve the different displaced quantities per stroke in that the plungers carry out strokes of different sizes, for example by driving-coupled plungers with differently dimensioned crankshaft crankshafts .

- valves 14 to 16 can also be arranged in a corresponding manner in the known pump described at the outset, so that the working space receiving the annular step region of the plunger is connected in series to the other working space, which takes up the free plunger end with a smaller cross section.

- a pump construction is generally less useful because of the large dimension in the longitudinal direction of the plunger.

- a plunger seal must be arranged between the two plunger work spaces and is therefore only loaded by very slight pressure differences when the pump is operated at low pressure when the stepped plunger works effectively in both work spaces, in particular in the pressure stroke. Such is undesirable with regard to a good sealing effect, as is required above all in high-pressure operation, when the plunger does effective pumping work only with its free end, which has a small cross section.

- the pump according to the invention can optionally also be used advantageously as a control pump. Depending on whether the suction valve 14 is triggered or not, the pump then works effectively with both plungers 7 and 8 or only with the plunger 8.

- the pump can work in both operating states of the suction valve on the pressure side against a constant pressure, so that the pump depending on the effective plunger cross section (when the suction valve 14 is triggered, the cross section of the plunger 8; when the suction valve 14 is not triggered, the sum of the cross sections of the plungers 7 and 8) operates with correspondingly different delivery rates and outputs.

- the pump according to the invention can optionally be converted to achieve a particularly large flow rate at a relatively low pressure.

- each pump can be modified to achieve a particularly large delivery rate at low pressure by arranging plungers with an enlarged cross-section, whereby the plunger work spaces must generally also be drilled out in order to be able to arrange the changed plungers.

- Such a modification of a pump is, however, only possible to a limited extent, because due to the incremental size specified by the crank engine, i.e. the distance between the plunger axes or crank cranks in the axial direction of the crankshaft, a maximum possible plunger diameter is specified.

- the diameter of the plunger 8 can be increased considerably, generally at least to the size of the plunger 7, ie the Cylinder block 11 allows the arrangement of a significantly larger plunger 8 and a work space 10 with a correspondingly enlarged cross section.

- a pump with an extraordinarily high throughput can be achieved, if necessary, whereby the triggering device 17 for the suction valve 14 and the check valve 15 between the plunger work spaces 9 and 10 can be dispensed with. All that is needed is a permanently open connection line between the plunger work rooms 9 and 10, which is arranged instead of the check valve 15.

- a one-piece crosshead with a large, possibly oval cross section can also be arranged and connected directly to the plungers 7 and 8 and the connecting rod 4. With such a construction, the yoke 20 is unnecessary.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Details Of Reciprocating Pumps (AREA)

- Reciprocating Pumps (AREA)

Abstract

Description

Die Erfindung betrifft eine Plungerpumpe mit mindestens zwei Plungerarbeitsräumen sowie denselben zugeordneten, gleichphasig arbeitenden Plungern bzw. Plungerteilen, welche bei ihren gleichphasigen Hüben unterschiedliche oder gleiche Mengen des Pumpmediums verdrängen, sowie mit einem auslösbaren Saugventil, welches dem Arbeitsraum des das größere Volumen verdrängenden einen Plungers bzw. Plungerteiles zugeordnet ist und im ausgelösten Zustand dauernd in Offenstellung bleibt, so daß die Pumpe bei ausgelöstem Saugventil mittels des das kleinere Volumen verdrängenden anderen Plungers bzw. Plungerteiles einen geringen Förderstrom mit hohem Druck und bei arbeitendem Saugventil mittels der Arbeit beider Plunger bzw. Plungerteile einen großen Förderstrom mit niedrigem Druck bei unverändertem Leistungsbedarf der Pumpe zu erzeugen gestattet.The invention relates to a plunger pump with at least two plunger work spaces and the same associated, in-phase working plungers or plunger parts, which displace different or equal amounts of the pump medium in their in-phase strokes, and with a triggerable suction valve, which the working space of the larger volume displacing a plunger or Is assigned to the plunger part and, when triggered, remains permanently in the open position, so that when the suction valve is triggered by means of the other plunger or plunger part displacing the smaller volume, a low flow rate with high pressure and when the suction valve is working by means of the work of both plunger or plunger parts large flow with low pressure with unchanged power requirement of the pump allowed to generate.

Pumpen, die Förderströme mit unterschiedlichen Drucken zu erzeugen vermögen, werden beispielsweise in Verbindung mit Spritzgeräten für Reinigungszwecke, beispielsweise zur Reinigung von Müllbehältern od.dgl., benötigt. Mit Spritzstrahlen sehr hohen Druckes können auch hartnäckige bzw. sehr feste Verschmutzungen gelöst werden, während Spritzstrahlen mit geringerem Druck zunächst zur Befeuchtung der Verschmutzungen bzw. zum Wegschwemmen gelösten Schmutzes dienen können.Pumps that are able to generate flow rates with different pressures are required, for example, in connection with spraying devices for cleaning purposes, for example for cleaning garbage containers or the like. Stubborn or very solid dirt can also be removed with spray jets of very high pressure, while spray jets with lower pressure can initially serve to moisten the dirt or to wash away loosened dirt.

Herkömmliche zwischen Hoch- und Niederdruck umschaltbare Plungerpumpen besitzen typischerweise Plunger mit zwei Abschnitten unterschiedlicher Querschnitte, dergestalt, daß zwischen dem Abschnitt mit dem größeren Querschnitt und dem Abschnitt mit dem geringeren Querschnitt eine relativ großflächige ringförmige Stufe gebildet wird. Der als freies Ende des Plungers angeordnete Abschnitt mit dem geringeren Querschnitt arbeitet in einem ersten Plungerarbeitsraum, während der Bereich mit der Ringstufe in einem zweiten, gegenüber dem ersten Arbeitsraum abgedichteten Arbeitsraum arbeitet. Jeder Arbeitsraum besitzt gesonderte Saug- und Druckventile, wobei das Saugventil des den Ringstufenabschnitt des Plungers aufnehmenden Arbeitsraumes auslösbar ist, so daß dieser Pumpenteil bei ausgelöstem und damit dauernd geöffnetem Saugventil unwirksam ist. In diesem Falle arbeitet also nur der durch den Arbeitsraum für das freie Plungerende mit dem geringen Querschnitt gebildete Pumpenteil. Dies bedeutet, daß nur ein relativ kleiner Förderstrom, jedoch mit sehr hohem Druck erzeugt werden kann. Wenn das auslösbare Saugventil normal öffnet und schließt, arbeitet die Pumpe dagegen mit beiden Arbeitsräumen simultan, so daß ein großer Förderstrom, jedoch mit relativ geringem Druck erzeugt werden kann. Druckseitig der Druckventile beider Arbeitsräume sind die Druckleitungen zusammengeführt, so daß beim Niederdruckbetrieb der Pumpe die aus beiden Pumpenarbeitsräumen austretenden Förderströme gemeinsam über eine einzige Leitung dem Verbraucher zugeführt werden können. Da das Druckventil des den Ringstufenbereich des Plungers aufnehmenden Arbeitsraumes in der Regel nur für relativ geringe Drucke ausgelegt ist, muß noch eine zusätzliche Umschaltventilanordnung vorhanden sein, welche beim Hochdruckbetrieb der Pumpe, d.h. wenn das Saugventil des den Ringstufenbereich des Plungers aufnehmenden Arbeitsraumes ausgelöst und damit dauernd geöffnet ist, das Druckventil dieses Arbeitsraumes gegenüber dem Druck des aus dem anderen Arbeitsraumes austretenden Förderstromes abschirmt.Conventional plunger pumps switchable between high and low pressure typically have plungers with two sections of different cross sections, such that a relatively large annular step is formed between the section with the larger cross section and the section with the smaller cross section. The section with the smaller cross section arranged as the free end of the plunger works in a first Plunger work space, while the area with the ring step works in a second work space that is sealed off from the first work space. Each work area has separate suction and pressure valves, the suction valve of the work area accommodating the ring step portion of the plunger being releasable, so that this pump part is ineffective when the suction valve is triggered and is therefore permanently open. In this case, only the pump part formed by the working space for the free plunger end with the small cross section works. This means that only a relatively small flow, but with very high pressure can be generated. On the other hand, if the triggerable suction valve opens and closes normally, the pump works simultaneously with both working spaces, so that a large flow rate can be generated, but with relatively low pressure. On the pressure side of the pressure valves of both work spaces, the pressure lines are brought together, so that when the pump is operated at low pressure, the delivery flows emerging from both pump work spaces can be supplied to the consumer together via a single line. Since the pressure valve of the working area accommodating the ring stage area of the plunger is usually only designed for relatively low pressures, an additional changeover valve arrangement must be present which is triggered during high pressure operation of the pump, ie when the suction valve of the working area accommodating the ring step area of the plunger is activated and thus continuously is open, the pressure valve of this working space shields against the pressure of the flow emerging from the other working space.

Diese bekannte Pumpenkonstruktion ist relativ aufwendig, jedenfalls sind im Hinblick auf die Einsatzzwecke derartiger umschaltbarer Pumpen möglichst preiswürdige Konstruktionen erwünscht.This known pump construction is relatively complex; in any case, constructions that are as inexpensive as possible are desired with regard to the uses of such switchable pumps.

Deshalb ist es Aufgabe der Erfindung, eine möglichst preisgünstige Plungerpumpe zu schaffen, welche zur Erzeugung eines großen Förderstromes mit geringem Druck bzw. zur Erzeugung eines geringen Förderstromes mit Hochdruck umschaltbar ist.It is therefore an object of the invention to provide a plunger pump which is as inexpensive as possible and which can be switched over to generate a large flow rate at low pressure or to generate a low flow rate at high pressure.

Diese Aufgabe wird bei einer Plungerpumpe der eingangs angegebenen Art dadurch gelöst, daß die beiden Plungerarbeitsräume miteinander durch eine Leitung mit in Richtung des Arbeitsraumes des einen Plungers bzw. Plungerteiles schließendem Rückschlagventil, mit der Saugseite der Pumpe nur über das auslösbare Saugventil des Arbeitsraumes des einen Plungers bzw. Plungerteiles und mit der Druckseite der Pumpe nur über ein dem Plungerarbeitsraum des anderen Plungers bzw. Plungerteiles zugeordnetes Druckventil verbunden sind.This object is achieved in a plunger pump of the type specified above in that the two plunger working spaces are connected to one another by a line with a check valve closing in the direction of the working space of one plunger or plunger part, with the suction side of the pump only via the triggerable suction valve of the working space of one plunger or plunger part and are connected to the pressure side of the pump only via a pressure valve assigned to the plunger work space of the other plunger or plunger part.

Erfindungsgemäß sind also die Arbeitsräume der beiden unterschiedliche Volumen verdrängenden Plunger bzw. Plungerteile in Reihe hintereinandergeschaltet, d.h. der Förderstrom der Pumpe durchsetzt in jedem Falle beide Arbeitsräume der beiden Plunger bzw. Plungerteile. Aufgrund dieser Anordnung sind für die beiden Arbeitsräume lediglich drei Ventile notwendig. Dabei arbeitet das in der Leitung zwischen den Plungerarbeitsräumen angeordnete Rückschlagventil bei ausgelöstem Saugventil in üblicher Weise als Saugventil des Plungerarbeitsraumes mit dem das geringere Volumen verdrängenden Plunger bzw. Plungerteil, während die Arbeit des anderen Plungers bzw. Plungerteiles aufgrund des ausgelösten Saugventiles unwirksam bleibt und die Pumpe dementsprechend nur mit dem anderen Plunger bzw. Plungerteil wirksam arbeitet.According to the invention, the working spaces of the two different volume-displacing plungers or plunger parts are connected in series, ie the flow rate of the pump passes through both working spaces of the two plungers or plunger parts in each case. Because of this arrangement, only three valves are necessary for the two workrooms. The check valve arranged in the line between the plunger work spaces, when the suction valve is triggered, works in the usual way as a suction valve of the plunger work space with the plunger or plunger part displacing the smaller volume, while the work of the other plunger or plunger part remains ineffective due to the triggered suction valve and the pump accordingly only works effectively with the other plunger or plunger part.

Sobald die Auslösung des Saugventiles aufgehoben ist und dasselbe in üblicher Weise öffnen und schließen kann, bleibt das Rückschlagventil in der Leitung zwischen den Plungerarbeitsräumen praktisch dauernd geöffnet, da es beim Saughub der beiden Plunger bzw. Plungerteile vom Saugstrom in den Arbeitsraum des das kleinere Volumen verdrängenden Plungers bzw. Plungerteiles und beim Druckhub der Plunger vom Druckstrom aus dem Arbeitsraum des das größere Volumen verdrängenden Plungers bzw. Plungerteiles durchsetzt wird.As soon as the triggering of the suction valve is canceled and can open and close it in the usual way, the non-return valve in the line between the plunger workrooms practically remains open, since during the suction stroke of the two plungers or plunger parts from the suction flow into the workspace of the smaller volume displacing it Plunger or plunger part and during the pressure stroke of the plunger the pressure stream from the working space of the plunger or plunger part displacing the larger volume is penetrated.

Abgesehen davon, daß bei der erfindungsgemäßen Pumpe für die beiden Arbeitsräume der beiden Plunger bzw. Plungerteile nur insgesamt drei Ventile benötigt werden, erübrigen sich auch Umschaltventilanordnungen auf der Druckseite der Pumpe. Denn aufgrund der Hintereinanderschaltung der Arbeitsräume tritt jeweils der gesamte von der Pumpe erzeugte Förderstrom am Druckventil des Arbeitsraumes aus, welcher dem das kleinere Volumen verdrängenden Plunger bzw. Plungerteil zugeordnet ist. Es erübrigt sich also, die Förderströme der beiden Arbeitsräume durch gesonderte Maßnahmen zusammenzufassen bzw. ein Druckventil eines zur Erzeugung eines Förderstromes mit geringem Druck dienenden Arbeitsraumes vor dem gegebenenfalls erzeugten Hochdruck zu schützen.Apart from the fact that in the pump according to the invention only three valves are required for the two working spaces of the two plungers or plunger parts, switchover valve arrangements on the pressure side of the pump are also unnecessary. Because due to the series connection of the working spaces, the entire delivery flow generated by the pump emerges at the pressure valve of the working space, which is assigned to the plunger or plunger part displacing the smaller volume. It is therefore unnecessary to summarize the flow rates of the two work spaces by separate measures or to protect a pressure valve of a work space serving to generate a flow rate at low pressure from the high pressure which may be generated.

Gemäß einer besonders bevorzugten Ausführungsform der Pumpe ist vorgesehen, daß die beiden unterschiedliche Volumen verdrängenden Plunger bzw. Plungerteile in zueinander parallelen Arbeitsräumen angeordnet sind, welche in Achsansicht eines die Plunger treibenden Kurbeltriebwerkes bei liegender Anordnung der Plunger übereinander bzw. bei stehender Anordnung der Plunger nebeneinander angeordnet sind. Dabei ist des weiteren zweckmäßigerweise vorgesehen, daß die beiden Plunger bzw. Plungerteile mittels eines gemeinsamen Kreuzkopfes bzw. Schiebers mit einer gemeinsamen, mit dem Kreuzkopf bzw. Schieber durch Pleuel od.dgl. antriebsverbundenen Kröpfung der Kurbelwelle des Kurbeltriebwerkes antriebsgekoppelt sind. Diese Bauweise zeichnet sich durch besondere Kompaktheit aus. Denn einerseits kann die Kurbelwelle relativ kurz bemessen sein. Andererseits lassen sich die beiden Arbeitsräume der Plunger bzw. Plungerteile ohne weiteres in einem Block unterbringen, dessen Höhe bzw. Breite geringer als die Höhe bzw. Breite des Kurbelgehäuses ist.According to a particularly preferred embodiment of the pump, it is provided that the two different volume-displacing plungers or plunger parts are arranged in mutually parallel working spaces, which are arranged in an axial view of a crank engine driving the plungers when the plungers are arranged one above the other or when the plungers are arranged standing next to one another are. It is also expediently provided that the two plungers or plunger parts by means of a common crosshead or slide with a common, with the crosshead or slide through connecting rod or the like. drive-connected crank crankshaft crank drive are coupled. This design is characterized by its particular compactness. On the one hand, the crankshaft can be dimensioned relatively short. On the other hand, the two working spaces of the plunger or plunger parts can easily be accommodated in a block whose height or width is less than the height or width of the crankcase.

Außerdem zeichnet sich diese Bauweise dadurch aus, daß weitestgehend herkömmliche Teile für Kurbeltrieb, Kreuzköpfe und Plunger verwendet werden können.In addition, this design is characterized in that largely conventional parts can be used for crank mechanisms, crossheads and plungers.

Im übrigen wird hinsichtlich besonders bevorzugter Merkmale der Erfindung auf die Ansprüche sowie die nachfolgende Beschreibung der Erfindung anhand eines in der Zeichnung dargestellten Ausführungsbeispieles verwiesen.For the rest, with regard to particularly preferred features of the invention, reference is made to the claims and the following description of the invention with reference to an embodiment shown in the drawing.

In der Zeichnung zeigt die einzige Figur ein stark schematisiertes Schnittbild der erfindungsgemäßen Pumpe.In the drawing, the single figure shows a highly schematic sectional view of the pump according to the invention.

Die dargestellte Pumpe besitzt ein Kurbeltriebwerk 1 mit einem Kurbelgehäuse 2, einer Kurbelwelle 3, Pleueln 4 sowie Kreuzköpfen 5, welche kolbenartig in Kreuzkopfführungen 6 verschiebbar angeordnet sind und beim Umlauf der Kurbelwelle 3 in bekannter Weise Hubbewegungen ausführen.The pump shown has a crank mechanism 1 with a crankcase 2, a crankshaft 3, connecting rods 4 and crossheads 5, which are displaceably arranged in piston-like manner in

Jeder Kreuzkopf 5 ist mit jeweils zwei Plungern 7 und 8 verbunden, welche innerhalb zugeordneter Plungerarbeitsräume 9 und 10 angeordnet sind, die ihrerseits als Teile eines mit dem Kurbelgehäuse 2 verbundenen Zylinderblockes 11 angeordnet sind. Die Plunger 7 und 8 sind in bekannter Weise in Dichtungsanordnungen 12 an den kreuzkopfseitigen Enden der Plungerarbeitsräume 9 und 10 geführt, um die Plungerarbeitsräume 9 und 10 zu den Kreuzköpfen 5 hin abzudichten. Der in der Figur obere Plunger 8 besitzt einen geringeren Querschnitt als der untere Plunger 7. Dementsprechend verdrängen die Plunger 7 und 8 bei ihren Hüben unterschiedliche Medienmengen.Each crosshead 5 is connected to two plungers 7 and 8, which are arranged within associated

Auf der von den Kreuzköpfen 5 abgewandten Seite ist der Zylinderblock 11 mit einem Ventilblock 13 verbunden, welcher für die beiden Plungerarbeitsräume 9 und 10 insgesamt drei Ventile aufweist, und zwar ein den Plungerarbeitsraum 9 mit der Saugseite bzw. einer nicht dargestellten Saugleitung der Pumpe verbindendes Saugventil 14, ein zwischen den Plungerarbeitsräumen 9 und 10 angeordnetes, nur eine Strömung in Richtung des Plungerarbeitsraumes 10 zulassendes Rückschlagventil 15 sowie ein vom Plungerarbeitsraum 10 zur Druckseite bzw. einer nicht dargestellten Druckleitung der Pumpe führendes Druckventil 16. Die Ventile 14 bis 16 sind schematisiert als Kugelventile dargestellt, grundsätzlich sind jedoch auch andere Ventilkonstruktionen möglich und in der Regel auch zweckmäßig.On the side facing away from the cross heads 5, the

Das Saugventil 14 ist auslösbar ausgebildet, d.h. mittels eines Stößels 17 kann der Ventilkörper des Saugventiles 14 dauernd in Offenstellung gehalten werden. Weitere Ventile werden für die Plungerarbeitsräume 9 und 10 nicht benötigt.The

Die dargestellte Pumpe arbeitet wie folgt:The pump shown works as follows:

Zunächst wird davon ausgegangen, daß der Stößel 17 des Saugventiles 14 seine in Fig. 1 nach unten verschobene Lage einnimmt, derart, daß das Saugventil 14 nicht ausgelöst ist und in üblicher Weise nach Art eines Rückschlagventiles öffnen und schließen kann.First, it is assumed that the

Wenn sich die Plunger 7 und 8 im Saughub in Fig. 1 nach links bewegen, so füllen sich die Plungerarbeitsräume 9 und 10 mit Pumpmedium, welches durch die im Saughub öffnenden Ventile 14 und 15 zuströmt, wobei das Saugventil 14 von der Summe der in die Plungerarbeitsräume 9 und 10 eindringenden Ströme und das Rückschlagventil 15 nur von dem in den Plungerarbeitsraum 10 einfließenden Strom durchsetzt werden. Während dieser Phase bleibt das Druckventil 16 geschlossen, weil im Plungerarbeitsraum 10 nur der gegenüber der Druckseite der Pumpe verminderte Druck auf der Saugseite der Pumpe bzw. ein geringfügig darunter liegender Druck vorliegt.If the plungers 7 and 8 move to the left in the suction stroke in FIG. 1, the

Wenn sich die Plunger 7 und 8 im Druckhub in Fig. 1 nach rechts bewegen, so schließt das Saugventil 14, während das Rückschlagventil 15 geöffnet bleibt bzw. erneut zusammen mit dem nunmehr öffnenden Druckventil 16 in Offenstellung gebracht wird, weil der Plunger 7 nunmehr Medium aus dem Plungerarbeitsraum 9 und der Plunger 8 Medium aus dem Plungerarbeitsraum 10 verdrängen. Dementsprechend wird das Rückschlagventil 15 von den aus dem Plungerarbeitsraum 9 ausströmenden Medium durchsetzt, während durch das Druckventil 16 die Summe der aus den Plungerarbeitsräumen 9 und 10 austretenden Mengen des Pumpmediums strömt.If the plungers 7 and 8 move to the right in the pressure stroke in FIG. 1, the

Bei der oben beschriebenen Betriebsweise handelt es sich um den Niederdruckbetrieb, weil die Pumpe mit beiden Plungern 7 und 8 und damit mit einem relativ großen Plungerquerschnitt arbeitet. Wenn die Pumpe im Hochdruckbetrieb arbeiten soll, wird das Saugventil 14 durch entsprechende Betätigung des Stößels 17 ausgelöst und damit dauernd in Offenstellung gehalten. Dementsprechend kann der Plunger 7 keine Pumparbeit leisten, vielmehr wird das von ihm im Saughub angesogene Medium beim Druckhub wieder durch das Saugventil 14 zur Saugseite der Pumpe zurückgefördert. Wirksame Pumparbeit vermag nur der Plunger 8 zu leisten, denn nun arbeitet das Rückschlagventil 15 nach Art eines herkömmlichen Saugventiles, d.h. das Rückschlagventil 15 öffnet im Saughub des Plungers 8 und schließt bei dessen Druckhub, da im Plungerarbeitsraum 9 aufgrund des dauernd geöffneten Saugventiles 14 nur ein gegenüber dem Druck im Plungerarbeitsraum 10 verminderter Druck etwa entsprechend dem saugseitigen Druck der Pumpe vorliegen kann. Im übrigen öffnet sich beim Druckhub des Plungers 8 das Druckventil 16 unter dem Einfluß des vom Plunger 8 verdrängten Mediums. Da in dieser Phase die Pumpe nur mit dem Plunger 8 wirksame Pumparbeit leisten kann und mit einem relativ geringen Plungerquerschnitt arbeitet, lassen sich ohne Erhöhung der die Kurbelwelle 3 antreibenden Leistung eines Antriebsaggregates sehr hohe Drucke erzeugen.The mode of operation described above is low-pressure operation because the pump works with both plungers 7 and 8 and thus with a relatively large plunger cross section. If the pump is to operate in high pressure mode, the

Eine Besonderheit der dargestellten Pumpe liegt also in der Hintereinanderschaltung der Plungerarbeitsräume 9 und 10, d.h. das gesamte von den Plungern 7 und 8 zur Druckseite geförderte Medium durchsetzt nacheinander die Plungerarbeitsräume 9 und 10. Dadurch werden trotz der zwei Plungerarbeitsräume 9 und 10 lediglich drei Ventile 14 bis 16 benötigt, wobei aufgrund der Auslösbarkeit des Saugventiles 14 jederzeit eine Umschaltung von Niederdruckbetrieb auf Hochdruck betrieb möglich ist. Weitere Maßnahmen sind zur Umschaltung nicht notwendig.A special feature of the pump shown is that the

Der nur schematisiert dargestellte Kreuzkopf 5 besteht im wesentlichen aus zwei gleichachsig zu den Plungern 7 und 8 angeordneten Stangenteilen 18 mit kreisförmigem Querschnitt, wobei die Stangenteile 18 gegebenenfalls zur Gewichtsverminderung rohrartig hohl sein können. Die Stangenteile 18 sind separat in Führungsbuchsen 19 gleitverschiebbar gelagert, welche in passenden Zylinderbohrungen des Kurbelgehäuses 2 angeordnet sind. Kurbelwellenseitig sind die Stangenteile 18 mittels eines Joches 20 ohne Verschiebbarkeit relativ zueinander in Längsrichtung verbunden. Das Joch 20 ist seinerseits gelenkig mit dem Pleuel 4 gekoppelt.The cross head 5, which is only shown schematically, consists essentially of two

Die vom Joch 20 abgewandten Enden der Stangenteile 18 sind in grundsätzlich bekannter Weise wie bei herkömmlichen Pumpen mit den Plungern 7 und 8 lösbar verbunden, wobei die Plunger 7 und 8 insbesondere relativ zu den Stangenteilen 18 eine begrenzte Winkelbeweglichkeit aufweisen können, so daß Montagetoleranzen bei der Ausrichtung von Kurbelgehäuse 2 und Zylinderblock 11 unproblematisch sind.The ends of the

Der Vorteil der dargestellten Anordnung besteht vor allem darin, daß für alle beweglichen Teile praktisch herkömmliche Pumpenteile verwendet werden können.The advantage of the arrangement shown is above all that practically conventional pump parts can be used for all moving parts.

Die Erfindung ist nicht auf Plungerpumpen im engeren Sinne beschränkt. Anstelle der dargestellten Plunger können auch andere Verdrängeranordnungen vorgesehen sein. An der Anordnung der Ventile 14 bis 16 ändert sich dadurch im Prinzip nichts.The invention is not restricted to plunger pumps in the narrower sense. Instead of the plungers shown, other displacement arrangements can also be provided. In principle, this does not change the arrangement of the

Im übrigen sind Abwandlungen der dargestellten Ausführungsform möglich. So ist es grundsätzlich auch möglich, die Plungerarbeitsräume 9 und 10 in Achsrichtung der Kurbelwelle 3 in Reihe hintereinander anzuordnen und jeden Plunger direkt oder über einen gesonderten Kreuzkopf mit einer separaten Kröpfung der Kurbelwelle 3 antriebsmäßig zu koppeln.Otherwise, modifications of the illustrated embodiment are possible. In principle, it is also possible to arrange the

Grundsätzlich ist es des weiteren auch möglich, beide Plunger 7 und 8 mit gleichen Querschnitten anzuordnen und die pro Hub unterschiedlichen verdrängten Mengen dadurch zu erzielen, daß die Plunger unterschiedlich große Hübe ausführen, beispielsweise indem in Reihe angeordnete Plunger mit unterschiedlich bemessenen Kröpfungen der Kurbelwelle antriebsgekoppelt sind.Basically, it is also possible to arrange both plungers 7 and 8 with the same cross-sections and to achieve the different displaced quantities per stroke in that the plungers carry out strokes of different sizes, for example by driving-coupled plungers with differently dimensioned crankshaft crankshafts .

Im übrigen lassen sich die Ventile 14 bis 16 auch bei der eingangs beschriebenen bekannten Pumpe in entsprechender Weise anordnen, so daß der den Ringstufenbereich des Plungers aufnehmende Arbeitsraum in Reihe dem anderen Arbeitsraum vorgeschaltet ist, welcher das freie Plungerende mit geringerem Querschnitt aufnimmt. Allerdings ist eine derartige Pumpenkonstruktion wegen der großen Abmessung in Längsrichtung des Plungers in der Regel weniger zweckmäßig. Im übrigen besteht bei derartigen Pumpen ein gewisser Nachteil darin, daß eine Plungerdichtung zwischen den beiden Plungerarbeitsräumen angeordnet sein muß und deshalb bei Niederdruckbetrieb der Pumpe, wenn der stufenförmige Plunger in beiden Arbeitsräumen wirksam arbeitet, nur durch allenfalls ganz geringfügige Druckdifferenzen belastet ist, und zwar insbesondere im Druckhub. Derartiges ist aber im Hinblick auf eine gute Dichtwirkung unerwünscht, wie sie vor allem beim Hochdruckbetrieb benötigt wird, wenn der Plunger nur mit seinem freien, den geringen Querschnitt aufweisenden Ende wirksame Pumparbeit verrichtet.In addition, the

Die erfindungsgemäße Pumpe kann gegebenenfalls auch mit Vorteil als Regelpumpe eingesetzt werden. Je nachdem, ob das Saugventil 14 ausgelöst ist oder nicht, arbeitet dann die Pumpe wirksam mit beiden Plungern 7 und 8 oder nur mit dem Plunger 8. Dabei kann die Pumpe in beiden Betriebszuständen des Saugventiles druckseitig gegen einen gleichbleibenden Druck arbeiten, so daß die Pumpe je nach dem wirksam arbeitenden Plungerquerschnitt (bei ausgelöstem Saugventil 14 der Querschnitt des Plungers 8; bei nicht ausgelöstem Saugventil 14 die Summe der Querschnitte der Plunger 7 und 8) mit entsprechend unterschiedlichen Fördermengen und Leistungen arbeitet.The pump according to the invention can optionally also be used advantageously as a control pump. Depending on whether the

Im übrigen kann die erfindungsgemäße Pumpe gegebenenfalls zur Erzielung eines besonders großen Förderstromes bei relativ geringem Druck umgerüstet werden.In addition, the pump according to the invention can optionally be converted to achieve a particularly large flow rate at a relatively low pressure.

Grundsätzlich kann zwar jede Pumpe zur Erzielung einer besonders großen Fördermenge bei geringem Druck abgeändert werden, indem Plunger mit vergrößertem Querschnitt angeordnet werden, wobei in der Regel auch die Plungerarbeitsräume aufgebohrt werden müssen, um die veränderten Plunger anordnen zu können. Eine solche Abänderung einer Pumpe ist aber nur in begrenztem Umfange möglich, weil aufgrund des jeweils durch das Kurbeltriebwerk vorgegebenen Stichmaßes, d.h. den Abstand der Plungerachsen bzw. Kurbelkröpfungen in Achsrichtung der Kurbelwelle, ein maximal möglicher Plungerdurchmesser vorgegeben wird.In principle, each pump can be modified to achieve a particularly large delivery rate at low pressure by arranging plungers with an enlarged cross-section, whereby the plunger work spaces must generally also be drilled out in order to be able to arrange the changed plungers. Such a modification of a pump is, however, only possible to a limited extent, because due to the incremental size specified by the crank engine, i.e. the distance between the plunger axes or crank cranks in the axial direction of the crankshaft, a maximum possible plunger diameter is specified.

Bei der erfindungsgemäßen Pumpe kann jedoch aufgrund des relativ großen Abstandes der Achsen der Plunger 7 und 8 der Durchmesser des Plungers 8 erheblich vergrößert werden, in der Regel zumindest auf das Maß des Plungers 7, d.h. der Zylinderblock 11 läßt die Anordnung eines deutlich größeren Plungers 8 sowie eines Arbeitsraumes 10 mit entsprechend vergrößertem Querschnitt zu. Damit kann aber gegebenenfalls eine Pumpe mit außerordentlich hohem Mengendurchsatz erzielt werden, wobei die Auslösevorrichtung 17 für das Saugventil 14 sowie das Rückschlagventil 15 zwischen den Plungerarbeitsräumen 9 und 10 erübrigt werden können. Es genügt also lediglich eine anstelle des Rückschlagventiles 15 angeordnete, dauernd geöffnete Verbindungsleitung zwischen den Plungerarbeitsräumen 9 und 10.In the pump according to the invention, however, due to the relatively large distance between the axes of the plungers 7 and 8, the diameter of the plunger 8 can be increased considerably, generally at least to the size of the plunger 7, ie the

Anstelle des in der Figur dargestellten Kreuzkopfes 5 mit zwei Führungsstangen 18 kann auch ein einteiliger Kreuzkopf mit großem, gegebenenfalls ovalem Querschnitt angeordnet und unmittelbar mit den Plungern 7 und 8 sowie dem Pleuel 4 verbunden werden. Bei einer solchen Bauweise erübrigt sich das Joch 20.Instead of the crosshead 5 shown in the figure with two

Claims (7)

daß die beiden Plungerarbeitsräume (9,10) miteinander durch eine Leitung mit in Richtung des Arbeitsraumes (9) des einen Plungers (7) bzw. Plungerteiles schließenden Rückschlagventil (15), mit der Saugseite der Pumpe nur über das auslösbare Saugventil (14) des Arbeitsraumes (9) des einen Plungers (7) bzw. Plungerteiles und mit der Druckseite der Pumpe nur über ein den Plungerarbeitsraum (10) des anderen Plungers (8) bzw. Plungerteiles zugeordnetes Druckventil (16) verbunden ist.1. Plunger pump with at least two plunger work rooms and the same assigned, in-phase working plungers or plunger parts, which displace different or equal amounts of the pump medium during their in-phase strokes, as well as with a triggerable suction valve, which plunger or plunger part displaces the larger volume is assigned and remains in the open position permanently in the open position, so that when the suction valve is triggered by means of the other plunger or plunger part displacing the smaller volume, a low flow rate with high pressure and when the suction valve is working by means of the work of both plunger or plunger parts a large flow rate with low pressure with unchanged Power required to generate the pump, characterized in that

that the two plunger work spaces (9, 10) with each other through a line with in the direction of the work space (9) of a plunger (7) or plunger part closing check valve (15), with the suction side of the pump only via the triggerable suction valve (14) of the Working space (9) of one plunger (7) or plunger part and is connected to the pressure side of the pump only via a pressure valve (16) assigned to the plunger working space (10) of the other plunger (8) or plunger part.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3706785 | 1987-03-03 | ||

| DE19873706785 DE3706785A1 (en) | 1987-03-03 | 1987-03-03 | PLUNGER PUMP |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0280901A2 true EP0280901A2 (en) | 1988-09-07 |

| EP0280901A3 EP0280901A3 (en) | 1988-12-21 |

| EP0280901B1 EP0280901B1 (en) | 1990-02-07 |

Family

ID=6322168

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88101593A Expired - Lifetime EP0280901B1 (en) | 1987-03-03 | 1988-02-04 | Plunger pump |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0280901B1 (en) |

| JP (1) | JPS63230967A (en) |

| DE (2) | DE3706785A1 (en) |

| ES (1) | ES2012506B3 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015071405A1 (en) * | 2013-11-18 | 2015-05-21 | Robert Bosch Gmbh | Fuel injection pump for an internal combustion engine |

| CN112594181A (en) * | 2020-12-29 | 2021-04-02 | 北京恩萨工程技术有限公司 | Single-plunger pump gate valve based on suction-free function |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5972625B2 (en) * | 2012-03-23 | 2016-08-17 | 住友重機械工業株式会社 | Fluid pressure booster |

| DE102012224308A1 (en) * | 2012-12-21 | 2014-06-26 | Continental Automotive Gmbh | high pressure pump |

| CN109826772B (en) * | 2019-04-03 | 2024-05-28 | 四川轻化工大学 | Continuous flow injection pump system and control method thereof |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT8837B (en) * | 1900-12-10 | 1902-08-25 | Henry Turner | Air or liquid pump. |

| US1322236A (en) * | 1919-11-18 | oe modesto | ||

| FR1180560A (en) * | 1956-08-03 | 1959-06-05 | Dobson Ltd W E & F | Improvements to hydraulic pumps |

| US3311065A (en) * | 1964-10-15 | 1967-03-28 | Plastering Dev Ct Inc | Pumping apparatus |

| DD64353A1 (en) * | 1967-10-06 | 1968-10-20 | Manfred Thierfelder | Piston pump with several pressure stages |

| US4245963A (en) * | 1979-02-09 | 1981-01-20 | Waters Associates, Inc. | Pump |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0437270Y2 (en) * | 1984-12-05 | 1992-09-02 | ||

| JPH0442530Y2 (en) * | 1985-02-25 | 1992-10-07 |

-

1987

- 1987-03-03 DE DE19873706785 patent/DE3706785A1/en not_active Withdrawn

-

1988

- 1988-02-04 DE DE8888101593T patent/DE3860037D1/en not_active Expired - Fee Related

- 1988-02-04 EP EP88101593A patent/EP0280901B1/en not_active Expired - Lifetime

- 1988-02-04 ES ES88101593T patent/ES2012506B3/en not_active Expired - Lifetime

- 1988-03-02 JP JP63047687A patent/JPS63230967A/en active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1322236A (en) * | 1919-11-18 | oe modesto | ||

| AT8837B (en) * | 1900-12-10 | 1902-08-25 | Henry Turner | Air or liquid pump. |

| FR1180560A (en) * | 1956-08-03 | 1959-06-05 | Dobson Ltd W E & F | Improvements to hydraulic pumps |

| US3311065A (en) * | 1964-10-15 | 1967-03-28 | Plastering Dev Ct Inc | Pumping apparatus |

| DD64353A1 (en) * | 1967-10-06 | 1968-10-20 | Manfred Thierfelder | Piston pump with several pressure stages |

| US4245963A (en) * | 1979-02-09 | 1981-01-20 | Waters Associates, Inc. | Pump |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015071405A1 (en) * | 2013-11-18 | 2015-05-21 | Robert Bosch Gmbh | Fuel injection pump for an internal combustion engine |

| CN112594181A (en) * | 2020-12-29 | 2021-04-02 | 北京恩萨工程技术有限公司 | Single-plunger pump gate valve based on suction-free function |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0280901A3 (en) | 1988-12-21 |

| JPS63230967A (en) | 1988-09-27 |

| EP0280901B1 (en) | 1990-02-07 |

| DE3706785A1 (en) | 1988-09-15 |

| ES2012506B3 (en) | 1990-04-01 |

| DE3860037D1 (en) | 1990-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0808422B1 (en) | Process and device for feeding concrete or other thick materials | |

| DE69220202T2 (en) | Double working hydraulic device for punching, cutting, bending etc. | |

| DE2612800C2 (en) | Hydraulic control valve arrangement for a treatment table | |

| DE69505203T2 (en) | Hydraulic circuit | |

| DE2503458A1 (en) | TOGGLE PRESS | |

| DE3048776A1 (en) | PRESSURE CONVERTER | |

| DE69905300T2 (en) | Hydraulic control unit, in particular for the operation of a folding roof of a vehicle | |

| EP0280901B1 (en) | Plunger pump | |

| DE1755697B2 (en) | Hydraulic power steering device for motor vehicles | |

| DE3200531A1 (en) | ARRANGEMENT FOR SUPPLYING A COMPRESSIBLE DRIVE MEDIUM TO A DRIVE | |

| EP1526930A1 (en) | Main cylinder or press cylinder of an extrusion/ tube extrusion press | |

| DE1653406C3 (en) | Hydraulic linkage in a two-cylinder concrete pump | |

| DE3545446C2 (en) | ||

| DE2527829A1 (en) | Automatic treatment gangway handling unit - is programmed by perforated drum working against spring tappet inside housing (NL060177) | |

| DE4032668C1 (en) | Hydraulic cylinder assembly - has small dia. piston guided in bore of large piston, cooperating with two sprung latches | |

| DE10023340A1 (en) | Control valve for switching a hydraulic piston-cylinder unit for driving an oscillating machine part | |

| DE1935253A1 (en) | Hydraulically or pneumatically driven vibration drive | |

| DE8427144U1 (en) | PISTON OR PLUNGER PUMP | |

| DE834530C (en) | Hydraulic working piston | |

| DE3535258A1 (en) | Hydraulic drive apparatus | |

| DE172109C (en) | ||

| DE9217574U1 (en) | Control arrangement for a multi-cylinder slurry pump | |

| DE1477696C3 (en) | Pressure medium-operated drilling tool unit | |

| DE29609608U1 (en) | Welding cylinder | |

| DE2842174A1 (en) | Hydraulic press safety circuit - has two=way control valves coupled with mechanically operated distributing valves |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB IT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES FR GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19890107 |

|

| 17Q | First examination report despatched |

Effective date: 19890623 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT SE |

|

| REF | Corresponds to: |

Ref document number: 3860037 Country of ref document: DE Date of ref document: 19900315 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19941212 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950116 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950119 Year of fee payment: 8 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 88101593.7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19950220 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19950222 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19960204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19960205 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19960205 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19960204 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19961031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19961101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990405 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050204 |