EP0172028B1 - Faserverstärkter anorganischer Körper - Google Patents

Faserverstärkter anorganischer Körper Download PDFInfo

- Publication number

- EP0172028B1 EP0172028B1 EP85305790A EP85305790A EP0172028B1 EP 0172028 B1 EP0172028 B1 EP 0172028B1 EP 85305790 A EP85305790 A EP 85305790A EP 85305790 A EP85305790 A EP 85305790A EP 0172028 B1 EP0172028 B1 EP 0172028B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- fibre

- inorganic composite

- inorganic

- moulded

- threads

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000000835 fiber Substances 0.000 title claims description 56

- 239000002131 composite material Substances 0.000 claims description 46

- 239000007767 bonding agent Substances 0.000 claims description 20

- 238000000034 method Methods 0.000 claims description 11

- 238000004519 manufacturing process Methods 0.000 claims description 7

- 238000001125 extrusion Methods 0.000 claims description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 6

- 239000004760 aramid Substances 0.000 description 6

- 229920003235 aromatic polyamide Polymers 0.000 description 6

- 125000003118 aryl group Chemical group 0.000 description 6

- 239000004568 cement Substances 0.000 description 6

- 150000001408 amides Chemical class 0.000 description 5

- 229920001187 thermosetting polymer Polymers 0.000 description 5

- 238000005452 bending Methods 0.000 description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 4

- 239000011398 Portland cement Substances 0.000 description 3

- 239000004576 sand Substances 0.000 description 3

- 229920000271 Kevlar® Polymers 0.000 description 2

- 229920003369 Kevlar® 49 Polymers 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 239000003822 epoxy resin Substances 0.000 description 2

- -1 etc. Substances 0.000 description 2

- 239000004761 kevlar Substances 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 229920000647 polyepoxide Polymers 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920005989 resin Polymers 0.000 description 2

- 239000011347 resin Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- VILCJCGEZXAXTO-UHFFFAOYSA-N 2,2,2-tetramine Chemical compound NCCNCCNCCN VILCJCGEZXAXTO-UHFFFAOYSA-N 0.000 description 1

- 229930185605 Bisphenol Natural products 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 239000004593 Epoxy Substances 0.000 description 1

- 229920000914 Metallic fiber Polymers 0.000 description 1

- 229910019142 PO4 Inorganic materials 0.000 description 1

- 229920002614 Polyether block amide Polymers 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 229910052910 alkali metal silicate Inorganic materials 0.000 description 1

- 239000004411 aluminium Substances 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- IISBACLAFKSPIT-UHFFFAOYSA-N bisphenol A Chemical compound C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1 IISBACLAFKSPIT-UHFFFAOYSA-N 0.000 description 1

- 239000011400 blast furnace cement Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000000701 coagulant Substances 0.000 description 1

- 239000008119 colloidal silica Substances 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 239000010881 fly ash Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N phenol group Chemical group C1(=CC=CC=C1)O ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 1

- 239000010452 phosphate Substances 0.000 description 1

- 239000011505 plaster Substances 0.000 description 1

- 229920002492 poly(sulfone) Polymers 0.000 description 1

- 229920000768 polyamine Polymers 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229920001470 polyketone Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 229920001021 polysulfide Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 238000010025 steaming Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000002562 thickening agent Substances 0.000 description 1

- 229920001567 vinyl ester resin Polymers 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B23/00—Arrangements specially adapted for the production of shaped articles with elements wholly or partly embedded in the moulding material; Production of reinforced objects

- B28B23/0006—Arrangements specially adapted for the production of shaped articles with elements wholly or partly embedded in the moulding material; Production of reinforced objects the reinforcement consisting of aligned, non-metal reinforcing elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28B—SHAPING CLAY OR OTHER CERAMIC COMPOSITIONS; SHAPING SLAG; SHAPING MIXTURES CONTAINING CEMENTITIOUS MATERIAL, e.g. PLASTER

- B28B3/00—Producing shaped articles from the material by using presses; Presses specially adapted therefor

- B28B3/20—Producing shaped articles from the material by using presses; Presses specially adapted therefor wherein the material is extruded

- B28B3/26—Extrusion dies

- B28B3/2645—Extrusion dies using means for inserting reinforcing members

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C5/00—Reinforcing elements, e.g. for concrete; Auxiliary elements therefor

- E04C5/07—Reinforcing elements of material other than metal, e.g. of glass, of plastics, or not exclusively made of metal

Definitions

- This invention relates to a process for manufacturing a fibre-reinforced inorganic body.

- JP-A-55-85480 there is known a process for manufacturing a fibre-reinforced inorganic body, as disclosed in JP-A-55-85480, in which a fibre body composed of threads is impregnated with an inorganic composite mainly composed of cement, that is the same in kind of material as an inorganic composite to be moulded by extrusion.

- the fibre body is then embedded in the inorganic composite to be moulded by extrusion, thereafter the inorganic composite including the fibre body is extruded, and thereafter the resulting extruded body is subjected to a hardening treatment.

- the foregoing conventional process is, however inconvenient in that the bending strength of the fibre-reinforced inorganic body obtained thereby is not substantially improved as compared with that of a moulded inorganic body not reinforced with the fibre body..

- a process for manufacturing a fibre-reinforced inorganic body wherein a fibre body comprising a plurality of threads is impregnated with a bonding agent and is embedded in an inorganic composite, the inorganic composite including the fibre body is moulded, and the inorganic composite and the bonding agent of the resulting moulded body are hardened.

- This invention has for its purpose to provide a process which produces a fibre-reinforced inorganic body which is improved in its bending strength.

- a process for manufacturing a fibre-reinforced inorganic body wherein at least one fibre body comprising a plurality of threads is impregnated with a bonding agent and is embedded in an inorganic composite, the inorganic composite including the fibre body is moulded, and the inorganic composite and the bonding agent of the resulting moulded body are hardened, characterised in that the inorganic composite including the fibre body is moulded by extrusion, and in that the fibre body is a braided body formed by interweaving a plurality of threads.

- the present invention also provides fibre-reinforced inorganic body comprising a moulded inorganic composite, at least one fibre body comprising a plurality of threads embedded in the moulded inorganic composite, and a hardened bonding agent included in the fibre body and forming a bond between the moulded inorganic composite and the fibre body, characterised in that the fibre body is a braided body formed by interweaving a plurality of the threads.

- the inorganic composite is composed of cement, sand, and water and, if desired, may contain any other kind of inorganic material such as plaster.

- the cement there is preferably used Portland cement, aluminium cement, Portland blast-furnace cement, silica cement, fly- ash cement, etc.

- the inorganic composite there may be optionally present any desired additive such as milling aids, retarders, accelerators, water reducing agents, coagulants, thickness, builders such as an air entraining agent, etc., and aggregate of a suitable size.

- the short fibre there may be used one or more of inorganic fibres such as carbon fibre, glass fibre, ceramic fibre, etc.; organic fibres such as aromatic polyamide fibre such as of straight coordinated aromatic polyamide, aromatic polyether amide, aromatic polysulphide amide, aromatic polysulphone amide, aromatic polymethylene amide, aromatic polyketone amide, aromatic polyamine amide and copolymers thereof, polyester fibre, polyolefin fibre, polyvinyl alcohol fibre, etc.; and metallic fibres such as cold drawn steel wire, steel wire for prestress, or the like.

- Such short fibres are in general several microns to several tens of microns in diameter and 5 to 15 mm in length. These are preferably mixed in the inorganic composite in an amount of up to 2% by volume relative to the inorganic composite.

- the thread can be not only any type of yarn (preferably selected from roving, multifilaments, strand and sliver) but also a monofilament.

- the "thread” is an elongated flexible member.

- the material of the thread is in general the same as that of the short fibre, but may be different therefrom.

- the plurality of threads (of the same kind or of two or more different kinds) are formed into a braided body by interweaving the plurality of threads.

- the braided fibre body may be a cord which is round or square in section, a flat body or a body of other desired shape, for instance, so that the combined integrality of the individual threads thereof can be heightened.

- the thread has protrusions in the longitudinal direction thereof, the frictional resistance between the threads of the braid becomes large, and consequently it becomes easy to transmit to the fibre body a stress applied to the threads, and at the same time the close contact between the fibre body and the inorganic composite is improved.

- thread which is several microns to several tens of microns, and the amount of these threads in the inorganic composite is preferably up to 5% by volume relative to the inorganic composite.

- the inorganic composite there may be embedded at least one braided fibre body, and in the case of the use of a plurality of braided fibre bodies it is preferable that they are so embedded therein as to be distributed uniformly.

- the bonding agent there may be used a . coldsetting or thermosetting resin such as of epoxy type, polyester type, vinylester type, phenolic type, polyimide type, etc.; a coldsetting or thermosetting inorganic bonding agent such as of alkali metal silicate type, colloidal silica type, or phosphate type; or a mixture of a coldsetting or thermosetting organic resin and an inorganic bonding agent.

- a . coldsetting or thermosetting resin such as of epoxy type, polyester type, vinylester type, phenolic type, polyimide type, etc.

- a coldsetting or thermosetting inorganic bonding agent such as of alkali metal silicate type, colloidal silica type, or phosphate type

- a mixture of a coldsetting or thermosetting organic resin and an inorganic bonding agent such as of epoxy type, polyester type, vinylester type, phenolic type, polyimide type, etc.

- a coldsetting or thermosetting inorganic bonding agent such as of alkali metal silicate

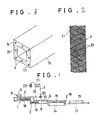

- a vacuum extruder 1 having an upper screw cylinder 3 and a lower screw cylinder 4 in communication with each other via a vacuum chamber 2.

- a hopper 6 for supplying an inorganic composite 5.

- One end of the lower screw cylinder 4 is in communication with a die 10 having a die opening 9 of a predetermined shape, via an adapter 8 for introducing a fibre body 7.

- Short fibres 21 are mixed in the inorganic composite 5 and there is used as the fibre body a braided fibre body 7 (as shown in Figure 2) formed by interweaving a plurality of strand-like threads 22 of total aromatic polyamide fibre and a plurality of braided fibre bodies, each supplied from a corresponding supply source 23.

- the inorganic composite 5 composed of Portland cement, sand and water, mixed with the short fibres 21 of total aromatic polyamide, is supplied to the hopper 6.

- the supplied inorganic composite 5 is moved forwards, while being kneaded, in the upper screw cylinder 3 and is conveyed to the vacuum chamber 2. After being degassed in that chamber 2, it is moved forwards in the lower screw cylinder 4 and is then introduced into the adapter 8.

- a plurality of the braided fibre bodies 7, each formed by interweaving the plurality of strands 22 of total aromatic polyamide, are passed through a dipping tank 12 containing a bonding agent 11 of thermosetting epoxy resin so as to be impregnated therewith, and are then introduced into the adapter 8 so as to be embedded at their predetermined disposed positions in the foregoing inorganic composite 5.

- the inorganic composite 5, which has the short fibres 21 dispersed therein and the disposed fibre bodies 7 embedded therein is extruded through the opening 9 of the die 10, so as to be moulded into a desired shape, for instance, a hollow square shape as shown in Figure 3.

- the resulting extruded body 15 is moved forwards by a conveyor 14 and is cut by a cutter 16 to pieces of a predetermined length in sequence.

- the bodies 15 thus cut are placed on a pallet 17 ahead of the conveyer 14 and are introduced into an autoclave (not shown).

- the bodies 15 are heated in the autoclave so that the inorganic composite 5 including the fibre bodies 7 and the bonding agent 11 existing inside and outside each of the fibre bodies 7 are both cured, and thus there is obtained a fibre-reinforced inorganic body.

- the curing is carried out in the autoclave, but any other curing means such as steaming curing may be used.

- the bonding agent is not limited to a thermosetting one, since a coldsetting bonding agent may also be used.

- a bonding agent composed of 100 parts by weight of bisphenol Alepichloro- hydrin type epoxy resin ("DER 332, Dow Chemical") and 14 parts by weight of triethylenetetramine in an impregnating ratio of 40 parts thereof to 100 parts of the foregoing fibre body.

- a braided fibre body comprising a plurality of interwoven threads is impregnated with a bonding agent

- the same is embedded in an inorganic composite

- the inorganic composite including the braided fibre body is extruded and the inorganic composite and the bonding agent of the resulting extruded mould are hardened, so that the inorganic composite and the fibre body are strongly bonded together through the bonding agent, and consequently there can be obtained easily a fibre body reinforced inorganic body which is improved in its bending strength.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Mechanical Engineering (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Manufacturing Of Tubular Articles Or Embedded Moulded Articles (AREA)

- Devices For Post-Treatments, Processing, Supply, Discharge, And Other Processes (AREA)

Claims (5)

dadurch gekennzeichnet,

daß der anorganische Werkstoff (5) einschließlich des Faserkörpers (7) durch Extrusion verformt wird und daß der Faserkörper (7) ein durch Verweben einer Vielzahl von Fäden (22) gebildeter geflochtener Körper ist.

dadurch gekennzeichnet,

daß der Faserkörper (7) ein durch Verweben einer Vielzahl von Fäden (22) gebildeter geflochtener Körper ist.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| MYPI87001929A MY101615A (en) | 1984-08-16 | 1987-09-25 | Fibre-reinforced inorganic body |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP170025/84 | 1984-08-16 | ||

| JP17002584A JPS6149803A (ja) | 1984-08-16 | 1984-08-16 | 無機質製品の押出製造法 |

| JP143898/85 | 1985-07-02 | ||

| JP14389885A JPS627655A (ja) | 1985-07-02 | 1985-07-02 | 繊維補強無機質製品並びにその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0172028A2 EP0172028A2 (de) | 1986-02-19 |

| EP0172028A3 EP0172028A3 (en) | 1988-07-13 |

| EP0172028B1 true EP0172028B1 (de) | 1991-01-23 |

Family

ID=26475494

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85305790A Expired EP0172028B1 (de) | 1984-08-16 | 1985-08-14 | Faserverstärkter anorganischer Körper |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0172028B1 (de) |

| DE (1) | DE3581451D1 (de) |

| MY (1) | MY101615A (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111206334A (zh) * | 2020-03-18 | 2020-05-29 | 殷石 | 一种高性能合成纤维网 |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH680460A5 (de) * | 1990-11-08 | 1992-08-31 | Gerard Bellac | |

| RU2157757C2 (ru) * | 1994-10-04 | 2000-10-20 | Э. Хашогги Индастриз | Экструдируемое промышленное изделие (варианты) и способ его изготовления (варианты) |

| FR2795111B1 (fr) * | 1999-06-21 | 2002-06-28 | Weber & Broutin Sa | Materiau renforce de construction, produit de revetement et plaque ou dalle en matiere moulee comprenant ledit materiau et leur procede de preparation |

| DE10063461A1 (de) * | 2000-12-19 | 2002-07-04 | Schoeck Bauteile Gmbh | Formteil aus einem formbaren Baustoff, insbesondere als verlorene Schalung sowie Verfahren und Vorrichtung zur Herstellung derselben |

| DE102008040919A1 (de) * | 2008-08-01 | 2010-02-04 | MAX BÖGL Fertigteilwerke GmbH & Co. KG | Verfahren zur Herstellung eines Betonbauteiles mit einer polymergetränkten textilen Bewehrung sowie Betonbauteil mit einer polymergetränkten textilen Bewehrung |

| EP3091135A1 (de) * | 2015-05-04 | 2016-11-09 | Evonik Degussa GmbH | Bewehrungsstab, verfahren zur herstellung und verwendung |

| DE102019107555A1 (de) * | 2019-03-25 | 2020-10-01 | Technische Universität Dresden | Verfahren und Vorrichtung zur Herstellung und Ablage eines textilen Bewehrungsstrangs für ein Betonteil |

| FR3097152B1 (fr) * | 2019-06-14 | 2023-10-20 | Ecole Nat Des Ponts Et Chaussees | Procédé et dispositif de fabrication d’un béton fibré anisotrope |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB592890A (en) * | 1944-10-26 | 1947-10-02 | John Grant Jackson | Improvements in and relating to structural members or bodies reinforced by structural elements |

| CA886637A (en) * | 1968-10-21 | 1971-11-23 | Martens Ernest | Pile extruder |

| DE2753858C3 (de) * | 1977-12-02 | 1980-10-23 | Hermann 7622 Schiltach Schemel | Verfahren zum Herstellen von faserbewehrten Betonformteilen und nach diesem Verfahren hergestellte Formteile |

| DE2805112A1 (de) * | 1978-02-07 | 1979-08-09 | Dietrich Walter | Verfahren und vorrichtung zur herstellung von duennwandigen, einlagenbewehrten bauteilen |

| DE2821490A1 (de) * | 1978-05-17 | 1979-11-22 | Thumm & Co | Bauplatte |

| JPS5940791B2 (ja) * | 1978-12-19 | 1984-10-02 | 株式会社クボタ | 無機質製品の押出製造方法 |

-

1985

- 1985-08-14 DE DE8585305790T patent/DE3581451D1/de not_active Expired - Fee Related

- 1985-08-14 EP EP85305790A patent/EP0172028B1/de not_active Expired

-

1987

- 1987-09-25 MY MYPI87001929A patent/MY101615A/en unknown

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111206334A (zh) * | 2020-03-18 | 2020-05-29 | 殷石 | 一种高性能合成纤维网 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0172028A2 (de) | 1986-02-19 |

| MY101615A (en) | 1991-12-17 |

| EP0172028A3 (en) | 1988-07-13 |

| DE3581451D1 (de) | 1991-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4684567A (en) | Reinforced structural material and reinforced fibrous inorganic structure reinforced therewith | |

| WO2010140845A2 (en) | Fiber reinforced plastic bolt and method for producing the same | |

| EP0033244A3 (de) | Faserverstärkte Materialien und Verfahren zu ihrer Herstellung und Verwendung | |

| EP0172028B1 (de) | Faserverstärkter anorganischer Körper | |

| US4316925A (en) | Fiber reinforced cementitious castings | |

| EP0170499A2 (de) | Verfahren zum Herstellen eines eines Verstärkungsbauteils | |

| GB2111093A (en) | Shaped articles composed of a mineral binder and reinforcing fibres embedded therein | |

| US3898113A (en) | Method of making a continuous strand sheet molding compound | |

| CA1114729A (en) | Process for producing thick reinforced plastic articles | |

| GB1282484A (en) | Improvements in the manufacture of composite articles comprising carbon fibre | |

| KR101950849B1 (ko) | 콘크리트보강용 섬유복합체의 제조방법 및 이의 섬유복합체를 포함하는 콘크리트 | |

| CN110566134B (zh) | 一种纤维复合材料芯绞合金属丝抽油杆及制备方法和应用 | |

| JPS627655A (ja) | 繊維補強無機質製品並びにその製造方法 | |

| JPS6135231A (ja) | 構造用異形補強材の製造法 | |

| KR950009491B1 (ko) | 섬유강화 열가소성 복합수지 성형체의 제조방법 | |

| JPH01174533A (ja) | 構造材料用補強材の製造方法 | |

| KR102119999B1 (ko) | 코팅층을 갖는 시멘트계 재료보강용 합성섬유, 그 제조방법 및 이를 포함하는 콘크리트 | |

| US20240165853A1 (en) | Fiber structural reinforcement with frictional surface coating | |

| JP2694657B2 (ja) | ロックボルトの製造方法 | |

| JPH0520537B2 (de) | ||

| JPH0442965B2 (de) | ||

| JPH0415190B2 (de) | ||

| EP0382181A2 (de) | Mit Glasfasern und Netzen aus Plastikmaterial verstärkte Zementrohrleitung | |

| JPH04344207A (ja) | 補強ネット入り無機質製品の押出成形方法 | |

| Semar | Herstellung SiC-faserverstaerkter Glasverbundkoerper durch das Strangpressverfahren und Untersuchung ihrer charakteristischen mechanischen Eigenschaften.(Manufacture of SiC fibre reinforced compound glass bodies by the extension process and investigation of their characteristic mechanical properties) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): CH DE FR GB LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): CH DE FR GB LI NL |

|

| 17P | Request for examination filed |

Effective date: 19880914 |

|

| 17Q | First examination report despatched |

Effective date: 19891122 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB LI NL |

|

| REF | Corresponds to: |

Ref document number: 3581451 Country of ref document: DE Date of ref document: 19910228 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930706 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19930820 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930824 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19930831 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19931029 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940814 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19940831 Ref country code: CH Effective date: 19940831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19950301 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940814 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19950428 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950503 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |