EP0138562A2 - A towel dispensing apparatus for making externally available and recovering a length of towel - Google Patents

A towel dispensing apparatus for making externally available and recovering a length of towel Download PDFInfo

- Publication number

- EP0138562A2 EP0138562A2 EP84306889A EP84306889A EP0138562A2 EP 0138562 A2 EP0138562 A2 EP 0138562A2 EP 84306889 A EP84306889 A EP 84306889A EP 84306889 A EP84306889 A EP 84306889A EP 0138562 A2 EP0138562 A2 EP 0138562A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- web

- roll

- towel

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47K—SANITARY EQUIPMENT NOT OTHERWISE PROVIDED FOR; TOILET ACCESSORIES

- A47K10/00—Body-drying implements; Toilet paper; Holders therefor

- A47K10/24—Towel dispensers, e.g. for piled-up or folded textile towels; Toilet-paper dispensers; Dispensers for piled-up or folded textile towels provided or not with devices for taking-up soiled towels as far as not mechanically driven

- A47K10/28—Towel dispensers, e.g. for piled-up or folded textile towels; Toilet-paper dispensers; Dispensers for piled-up or folded textile towels provided or not with devices for taking-up soiled towels as far as not mechanically driven dispensing a clean part and taking-up a soiled part, e.g. using rolls; with dispensers for soap or other detergents; with disinfecting or heating devices

Definitions

- the present invention relates to a dispensing apparatus adapted to progressively make available at the outside a length of web material for toweling purpose from a supply roll while an equal length of soiled towel is simultaneously taken up and wound on a second roll, both rolls being housed within the apparatus fastened to a wall.

- Dispensers of this type are well known and widely employed to supply toilets and public lavatories with conventional towels, i.e. of cloth, at the same time meeting the opposing needs of ensuring the availabili ty to any person of a sanitarily acceptable towel and preventing the stealing or undesired using of the material.

- a dispensing apparatus of the said type wherein the recovery of the towel trailing end is obtained by the additional rotation (driven by the accumulator) of one of the rollers provided on the recovery path thus avoiding any possibility of defective operation due to an uneven winding up of the soiled towel that might cause a jamming of the device.

- these members cooperate with lever means provided for dispensing the material according to a non reversible operative sequence.

- FIGs. 1 and 2 there are disclosed the main components of the apparatus. It com prises an outer cabinet or housing, preferably of noulded plastics, formed of three members, namely a rear plate 5 having holes 9 for fastening the appara- tus to a wall 1 by means of screws 8 or the like, and ;wo bent portions or covers 6 and 7, hinged to the plate and completing the housing. More particularly he rear plate 5 extends upward with an arcuated portion 4 connected by hinges 26 to the top arcuated cover 6 for the opening of the housing. Top cover 6 comprises an arcuated and a flat portion , the latter being suitable for engaging the lower cover 7 that in turn is movably connected to the rear plate.

- the parts define together a lower chamber or space housing a coreless supply roll 11 of the towel band to be dispensed and an upper space into which the soiled towel is recovered and wound up to form an upper soiled towel roll 12.

- this roll 12 is shown by dashed lines since the two rolls do not simultaneously co-exist with their maximum sizes.

- Fig. 1 The situation illustrated in Fig. 1 relates to an initial state wherein roll 11 practically has the maximum diameter and only a portion of limited length of the towel web material 40, coming out from the front side of the housing and re-entering into the lower rear part of the same, forms a much smaller roll of soiled towel.

- a metal frame 30 acting as a support means for the mechanisms and as a reinforcement of the rear plate 5.

- the rear plate 5 has two protruding side walls (not shown) with parallel guides 18 frontally provided each with a tooth 19 adapted to engage corresponding slots 21 in the front side of lower cover 7.

- a key lock or 5 similar device blocks the parts together.

- the ends 27 of the lower cover 7 can slide in the guides 18 and are furthermore rotatable for opening the housing by tilting the lower cover in order to introduce a new clean roll.

- Fig. 1 shows the path of towel 40 that unwinds from roll 11, passes through the rubber- )-coated roller 55 and the first drive roller 50 having a fixed shaft, then turns about a pinch roller 70 having a rough or knurled surface and mounted on a movable shaft, and thereafter leaves the housing through a slot formed by a recess in the top cover 6. From here onwards the portion of the web material outside the housing can be used as a towel. The length of this externally access!

- the ble portion is chosen when the machine is loaded, whereas the maximum towel length that can be withdrawn (and recovered)at each pull by the user is adjusted by other means and will be described more in detail later on.

- the web re-enters the housing through a rear slot in proximity of which there are provided two rubber-coated rollers, 57 and 58 respectively, acting as guiding and positioning means.

- Roller 57 is mounted on metal frame 30 and also performs the recovery of the towel trailing end, whereas roller 58 is fastened by brackets 44 to the end of lower cover 7, in a manner similar to roller 55.

- roller 58 is positioned close to roller 57 so as to grip towel 40 as shown in the figure.

- Towel 40 is then wound about a core 45, movable along slots 48 to accommodate the roll 46 to be formed during the use, the diameter of which is progressively increasing.

- the take-up of roll 46 is caused by a roller 60 having a roughed or knurled surface and mounted for rotation on frame 30, which frictionally engages the surface of the upper roll 46 and is rotatively driven by the recovery roller 50.

- At the ends of slots 48 there are provided two cradle supports (one at each side) whereinto the ends of core 45 fall in order to make easier the removal of the wound roll 12.

- Fig. 2 is a top plan view of the apparatus frame with the main mechanisms with the exception of the control multiple lever.

- Metal frame 30 comprises two side parallel plates 31 and 32 between which the aforementioned rollers extend.

- the two plates ara transver 10sely connected by a corrugated sheet iron 33 fastened to the side plates by rivets.

- On the outer sides of these plates there are furthermore mounted the drive and control mechanisms (left or outward side of plate 31) and the mechanism for the recovery of the towel trailing end (right or outward side of plate 32).

- roller 55 is carried by cover 7 below the drive roller 50.

- This roll has a roughed outer surface to engage the cotton tissue of the web forming the towel and its rotation axis 38 is mounted between plates 31 and 32.

- a roller 70 formed of a plurality of smaller rollers or sections 63, rotatably mounted on the same axis 37 and mutually spaced apart in order to better distribute the pull stress applied onto the web 40.

- the axis 37 extends itself between two tabs 305 and 306 having the function of levers and pivoted to the plates 31 and 32 by means of an axis 38.

- roller sections are of aluminum and provid ed with smaller collars or spacers 64 so as to form recesses 67 into which can fit the appendixes or blades 184 of a sensor formed as a curved plate 181 from which blades 184 depend downwards, spaced apart of the same length as between the recesses 67.

- the sensing plate or follower 181 is pivotedly mounted (at 188 - Figgs. 4-7) between plates 31 and 32.

- Roller 60 is similar to roller 50, i.e. with a rough surface to engage the web of material, and is furthermore mechanically and rotatably connected to roller 50.

- rollers 57 and 58 show rollers 57 and 58.

- Roller 57 comprises a plurality of smaller rollers, preferably of rubber, mounted onto a shaft 59, the middle part of which has a non circular cross-section for a better engagement with the rollers..

- levers 305 and 306 are pivoted on the same axis 38 of the drive roller 50 to the inner sides of plates 31 and 32.

- Such levers are equipped with similar slots 318, 319 (see Figgs. 4 to 7) within which the ends of axis 37 of roller 70 can slide.

- Fig. 8 shows the parts mount ed on the outer side of plate 31 whereas Fig. 3 shows only the components on the inner side of the plate 31, which has been partially cross-sectioned for a better under standing.

- axis 38 of roller 50 carries a toothed wheel or gear 110 to which a cam or pawl 120 is fastened.

- Gear 110 meshes with a free toothed wheel 105 having a larger diameter, rotatably mounted on plate 31 and carrying a pinion 108 toward the outside of the frame.

- Pinion 108 engages another toothed wheel 135, internally mounting a pinion 130 fixed thereto, which in turn meshes with the periphery of the toothed wheel 105.

- the shaft of toothed wheel 135 and pinion 130 is the same shaft 77 of roller 70 providing for the take-up of the recovered towel.

- a fixed pin 129 and a number of holes 145 are provided on the periphery of wheel 135.

- a metal strip 127 having two protruding pins 128 can be mounted on wheel 135 by fitting pins 128 in a pair of said holes, one of them being the hole that is nearer to fixed pin 129, so that the pins 128 protrude, together with the pin 129, toward the inner face of wheel 135. This way the length of towel made available to the user at each pull can be varied in a manner similar to the one disclosed in the cited European patent application No. 59893.

- a multiple lever 200 is pivotally mounted on plate 31. It comprises an elongated and shaped arm 206 extending to reach a rectangular window 81 cut in the plate 31 below roller 50, and a strut 212 the end of which can engage a stop catch 120 to prevent the further rotation of roller 50.

- the multiple lever furthermore includes a rocking arm or lever 214, pivotally mounted on body 200 at 207, having a bent and profiled end 209 adapted to engage pins 128, 129 protruding from wheel 135.

- the rocking arm 214 is connected through a spring 216 to an appendix 217 of multi ple lever 200 whereas an arm 213, rigidly secured to the body 200 provides a stop member that limits the elastic return of spring 216.

- Fig. 3 shows the components which are immediately behind the plate 31. They include two similar levers 305 and 306 pivotally mounted on axis 38, only one (305) of them being visible in the figure.

- Lever 305 is provided with an arcuated slot 318 in which the axis 37 of pinch (idle) roller 70 can slide.

- Lever 305 is designed to move in synchronism with the lever 306 mounted on plate 32 and having an identical structure and similar return means that are not described here 5for simplicity.

- the sensing member 181 pivotally mounted on the frame at 188, abuts against roller 70 due to its weight and more particularly when the towel web lays over sections 63, it leans thereon as shown in Fig. 3.

- Figgs. 4 to 7 diagrammatically illustrate the positions of the components.

- the figures are side views from the left of the mechanism wherein the plate 31 has been cut away almost completely to make easier the understand ing of the relationships between the lever 305 and the multiple lever 200 avoiding a large number of additional drawings.

- the dispenser is not yet operating even if the towel web 40 has been introduced between rollers 55, 60 and 70 and,after following a path outside the housing, between rollers 57, 58, 45 and 60.

- the position of levers 305 and 306 is determined both by the return spring 170, shown only in Fig.

- the dispenser After positioning the web and closing the apparatus the dispenser is made ready to use by pulling the web 40 to reach the configuration of Fig. 5.

- Lever 305 (and of course lever 306) has been rotated by a certain angle so as to force the blades 184 to further descend and engage roller 70 through the web.

- the presence of the web anyway prevents the penetration of the blades into the recesses 67 so that levers 305 and 306 can not return to the original position, still maintaining the possibility of a further clockwise rotation.

- the pin 91 cooperating with lever 305 reaches a position at about the center of the corresponding window 81, but anyhow such displacement is not enough for lowering the strut 212 of lever 200 to interfere with the stop catch 120.

- the apparatus is so ready for use.

- Fig. 6 shows the system configuration during the withdrawal. Under the pulling action applied by the towel user to web 40, levers 305 and 306 further tilt toward the right, thus causing pins 91 and 92 to abut onto the inner ledges of the windows 81 and 82 where they stop the levers rotation. Under these circumstances no further obstacle exists to the lowering of arm 206 and the consequent descent of the strut 212 to such a position as to intercept the stop catch 120. As a matter of fact it is the passage of the first fixed pin 129 to cause the lowering (no longer impeded) of lever arm 206 shown in Fig. 6.

- the towel cannot be further withdrawn due to the stopping catch 120 and when the user ceases to pull the system returns to the configuration of Fig. 5 raising again the arm 206 and thereby excluding the strut.

- the system is then ready for another dispensing cycle, while a web length equal to the one dispensed has been taken up and wound over the core 45 by means of the associated rotation of roller 60.

- Fig. 7 there is illustrated the configuration of the system at the end of the web.

- the blades 184 are no longer retained by the fabric and penetrate into the recesses 67 causing a leftward rotation of levers 305 and 306 until pins 91 and 92 come into contact with the outer edge of windows 81 and 82.

- the pins do not abut against such edges as shown in Fig. 7, but they are anyhow blocked at the position shown since the sensing member has now been lowered beyond the returning capability of spring 170.

- a lever 190 controlling an accumulator mounted on plate 32 is released as it will be disclos ied in the following with reference to Fig. 9.

- the energy stored in the accumulator drives into rotation roller 57 that completely recovers the trailing edge of web 40 within the housing.

- Fig. 9 diagrammatically shows the accumulator 150 mounted on the outside of plate 32 and the controlling lever 190.

- the lever or rocker 190 is pivotally mounted at 192 on plate 32 and has one end 197 adapted to abut against the detent surfaces or cams 198 of the accumulator during its loading.

- the other end 195 of the lever faces window 82, symmetrical to window 81 within which it is movable the pin 92, symmetrical to pin 91 and carried by lever 306 symmetrical to lever 305.

- a return spring 193 keeps the end 197 engaged with the detent surfaces 198 preventing the rotation in the direction shown by arrow Z.

- the mechanism is substantially a ratchet gear consenting only rotations opposite to those of arrow Z during the rewinding of roll 46 since the axis 77 ot take-up roller 60 is the same axis of the accumulator.

- the accumulator is not described in detail being of a known type, such as the one disclosed in the already cited European patent application.

- a toothed wheel 160 mounted on plate 32, engages the teeth 155 on the periphery of the accumulator 150.

- the toothed wheel 160 in turn engages a gear 157 coaxial to roller 57 and protruding from plate 32 by means of a unidirec tional clutch device including a choke spring.

- a spring allows for a free rotation of roller 57 during the normal web taking up driven by roller 60,whereas it fastens gear 157 to shaft 59 when the accumulator is released.

- pin 92 (and the corresponding pin 91) can swing from a position at the centre of slot 82 (81) and an abutment position on the inner edge of such slot.

- the return spring 193 keeps the end portion 197 raised so that the rotation of axis 77 lets the accumulator be loaded blocking any backward movement due to the cam surfaces 198.

- the accumulator progressively loads a spiral spring storing energy so that, in the proximity of the web termina tion, the energy stored is enough to drive a winding uprotation Oto recover the web length hanging loose from the apparatus.

Landscapes

- Public Health (AREA)

- Health & Medical Sciences (AREA)

- Body Washing Hand Wipes And Brushes (AREA)

- Unwinding Webs (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Electroplating And Plating Baths Therefor (AREA)

- Cash Registers Or Receiving Machines (AREA)

- Exchange Systems With Centralized Control (AREA)

- Advancing Webs (AREA)

- Storing, Repeated Paying-Out, And Re-Storing Of Elongated Articles (AREA)

- Outer Garments And Coats (AREA)

- Control Of Vending Devices And Auxiliary Devices For Vending Devices (AREA)

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

Abstract

Description

- The present invention relates to a dispensing apparatus adapted to progressively make available at the outside a length of web material for toweling purpose from a supply roll while an equal length of soiled towel is simultaneously taken up and wound on a second roll, both rolls being housed within the apparatus fastened to a wall.

- Dispensers of this type are well known and widely employed to supply toilets and public lavatories with conventional towels, i.e. of cloth, at the same time meeting the opposing needs of ensuring the availabili ty to any person of a sanitarily acceptable towel and preventing the stealing or undesired using of the material.

- In the previous European patent application No. 59893 of the same applicant it has been proposed an apparatus of this type providing, among other things, an energy accumulator progressively loaded at each withdrawal of the material that, at the end of the towel band, takes care of winding up the trailing end thereof, thus avoiding that it hangs outside the apparatus with undesired consequences. Furthermore the apparatus provided for sensing means to control this winding up as well as for a kinematic chain connecting the dispensing means with the recovery means.

- It is also known from U.S. Patent No. 3,893,738 a dispenser wherein an accumulator is progressively loaded in use and the stored energy is used to recover, at each pull, a portion of the soiled towel causing it to adhere to the dispenser lower wall so that it is not visible. This same accumulator also recovers the trailing end of the towel when the supply roll is exhausted.

- It is an object of the present invention to provide an apparatus of the above type including several and useful improvements adapted to make the operation more reliable and the construction easier.

- According to the invention there is provided a dispensing apparatus of the said type wherein the recovery of the towel trailing end is obtained by the additional rotation (driven by the accumulator) of one of the rollers provided on the recovery path thus avoiding any possibility of defective operation due to an uneven winding up of the soiled towel that might cause a jamming of the device.

- According to another characteristic of the invention there are provided improved sensing members acting along the whole width of the roll to detect the passage of the soiled towel trailing end and to consequently release the accumulator.

- According to a further feature of the invention these members cooperate with lever means provided for dispensing the material according to a non reversible operative sequence.

- Finally according to another feature of the invention there are provided rolls at the zone where the towel re-enters and a roll in the dispensing area for a smoother and more reliable working.

- The invention will now be disclosed with reference to a preferred embodiment shown in the attached drawings in which:

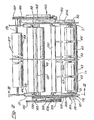

- FIGURE 1 shows a partially schematic cross-section of the apparatus according to the invention where the towel path can be seen;

- FIGURE 2 shows a top view of the apparatus frame and mechanisms from which the multiple lever controlling the dispensed length of towel has been omitted for simplicity;

- FIGURE 3 is a cross-section view along lines III-III of Fig. 2;

- FIGURES 4 to 7 are partial side views, cross-sectioned along various lines, illustrating the operation of the dispenser;

- FIGURE 8 is a side view from the left of the frame with the kinematic chain and the multiple control lever; and

- FIGURE 9 is a side view from the right of the frame showing the drive mechanisms connected to the accumulator.

- With reference now to Figs. 1 and 2 there are disclosed the main components of the apparatus. It com prises an outer cabinet or housing, preferably of noulded plastics, formed of three members, namely a

rear plate 5 havingholes 9 for fastening the appara- tus to a wall 1 by means ofscrews 8 or the like, and ;wo bent portions or covers 6 and 7, hinged to the plate and completing the housing. More particularly herear plate 5 extends upward with an arcuated portion 4 connected byhinges 26 to the toparcuated cover 6 for the opening of the housing.Top cover 6 comprises an arcuated and a flat portion , the latter being suitable for engaging thelower cover 7 that in turn is movably connected to the rear plate. The parts define together a lower chamber or space housing acoreless supply roll 11 of the towel band to be dispensed and an upper space into which the soiled towel is recovered and wound up to form an uppersoiled towel roll 12. In Fig. 1 thisroll 12 is shown by dashed lines since the two rolls do not simultaneously co-exist with their maximum sizes. - The situation illustrated in Fig. 1 relates to an initial state wherein roll 11 practically has the maximum diameter and only a portion of limited length of the

towel web material 40, coming out from the front side of the housing and re-entering into the lower rear part of the same, forms a much smaller roll of soiled towel. Upon exhaustion of thesupply roll 11, almost all the web material will be wound to form theupper roll 12 whereas the lower space will be empty. Between these two spaces there is provided a metal frame 30 acting as a support means for the mechanisms and as a reinforcement of therear plate 5. Therear plate 5 has two protruding side walls (not shown) withparallel guides 18 frontally provided each with atooth 19 adapted to engagecorresponding slots 21 in the front side oflower cover 7. A key lock or 5 similar device, not shown, blocks the parts together. Theends 27 of thelower cover 7 can slide in theguides 18 and are furthermore rotatable for opening the housing by tilting the lower cover in order to introduce a new clean roll. For other details of the housing Ocontruction that are not part of the present invention, reference is made to the cited European patent application No. 59893. - The front end of

cover 7 is equipped with twobrackets 34, spaced apart by a length shorter than the 5cover width, between which asmall rubber roller 55 is rotatably mounted, adapted to properly position the web of_material fromroll 11 by pressing it against adrive roller 50. Fig. 1 shows the path oftowel 40 that unwinds fromroll 11, passes through the rubber- )-coatedroller 55 and thefirst drive roller 50 having a fixed shaft, then turns about apinch roller 70 having a rough or knurled surface and mounted on a movable shaft, and thereafter leaves the housing through a slot formed by a recess in thetop cover 6. From here onwards the portion of the web material outside the housing can be used as a towel. The length of this externally access! ble portion is chosen when the machine is loaded, whereas the maximum towel length that can be withdrawn (and recovered)at each pull by the user is adjusted by other means and will be described more in detail later on. Then the web re-enters the housing through a rear slot in proximity of which there are provided two rubber-coated rollers, 57 and 58 respectively, acting as guiding and positioning means.Roller 57 is mounted on metal frame 30 and also performs the recovery of the towel trailing end, whereasroller 58 is fastened bybrackets 44 to the end oflower cover 7, in a manner similar toroller 55. When thecover 7 is 5closed as shown in Fig. 1 and thetowel 40 has been reintroduced and positioned into the housing,roller 58 is positioned close toroller 57 so as to griptowel 40 as shown in the figure.Towel 40 is then wound about acore 45, movable alongslots 48 to accommodate theroll 46 to be formed during the use, the diameter of which is progressively increasing. The take-up ofroll 46 is caused by aroller 60 having a roughed or knurled surface and mounted for rotation on frame 30, which frictionally engages the surface of theupper roll 46 and is rotatively driven by therecovery roller 50. At the ends ofslots 48 there are provided two cradle supports (one at each side) whereinto the ends ofcore 45 fall in order to make easier the removal of thewound roll 12. - Fig. 2 is a top plan view of the apparatus frame with the main mechanisms with the exception of the control multiple lever. Metal frame 30 comprises two side

parallel plates corrugated sheet iron 33 fastened to the side plates by rivets. On the outer sides of these plates there are furthermore mounted the drive and control mechanisms (left or outward side of plate 31) and the mechanism for the recovery of the towel trailing end (right or outward side of plate 32). - As stated before the rubber-coated

roller 55 is carried bycover 7 below thedrive roller 50. This roll has a roughed outer surface to engage the cotton tissue of the web forming the towel and itsrotation axis 38 is mounted betweenplates roller 70 formed of a plurality of smaller rollers orsections 63, rotatably mounted on thesame axis 37 and mutually spaced apart in order to better distribute the pull stress applied onto theweb 40. Theaxis 37 extends itself between twotabs plates axis 38. Preferably the roller sections are of aluminum and provid ed with smaller collars orspacers 64 so as to formrecesses 67 into which can fit the appendixes orblades 184 of a sensor formed as acurved plate 181 from whichblades 184 depend downwards, spaced apart of the same length as between therecesses 67. Also the sensing plate orfollower 181 is pivotedly mounted (at 188 - Figgs. 4-7) betweenplates Roller 60 is similar toroller 50, i.e. with a rough surface to engage the web of material, and is furthermore mechanically and rotatably connected toroller 50. On the contrary thecore 45 is free to rotate withinguide slots 48 which are preferably formed onplastics inserts 99, and can further slide along them as the roll of wound material increases its diameter. Fig. 2shows rollers Roller 57 comprises a plurality of smaller rollers, preferably of rubber, mounted onto ashaft 59, the middle part of which has a non circular cross-section for a better engagement with the rollers.. - Finally the two metal tabs operating as levers, 305 and 306 respectively, are pivoted on the

same axis 38 of thedrive roller 50 to the inner sides ofplates similar slots 318, 319 (see Figgs. 4 to 7) within which the ends ofaxis 37 ofroller 70 can slide. - With reference to Figgs. 3 and 8 the drive and take-up mechanism for the towel will be described. More particularly, Fig. 8 shows the parts mount ed on the outer side of

plate 31 whereas Fig. 3 shows only the components on the inner side of theplate 31, which has been partially cross-sectioned for a better under standing. With reference to Fig. 8,'it can be noted thataxis 38 ofroller 50 carries a toothed wheel orgear 110 to which a cam orpawl 120 is fastened.Gear 110 meshes with a freetoothed wheel 105 having a larger diameter, rotatably mounted onplate 31 and carrying apinion 108 toward the outside of the frame. Pinion 108 engages anothertoothed wheel 135, internally mounting apinion 130 fixed thereto, which in turn meshes with the periphery of thetoothed wheel 105. The shaft oftoothed wheel 135 andpinion 130 is thesame shaft 77 ofroller 70 providing for the take-up of the recovered towel. Moreover a fixedpin 129 and a number ofholes 145 are provided on the periphery ofwheel 135. Ametal strip 127 having two protrudingpins 128 can be mounted onwheel 135 by fittingpins 128 in a pair of said holes, one of them being the hole that is nearer to fixedpin 129, so that thepins 128 protrude, together with thepin 129, toward the inner face ofwheel 135. This way the length of towel made available to the user at each pull can be varied in a manner similar to the one disclosed in the cited European patent application No. 59893. - A

multiple lever 200 is pivotally mounted onplate 31. It comprises an elongated andshaped arm 206 extending to reach arectangular window 81 cut in theplate 31 belowroller 50, and astrut 212 the end of which can engage astop catch 120 to prevent the further rotation ofroller 50. The multiple lever furthermore includes a rocking arm orlever 214, pivotally mounted onbody 200 at 207, having a bent and profiledend 209 adapted to engagepins wheel 135. The rockingarm 214 is connected through aspring 216 to anappendix 217 ofmulti ple lever 200 whereas anarm 213, rigidly secured to thebody 200 provides a stop member that limits the elastic return ofspring 216. - The cross-section of Fig. 3 shows the components which are immediately behind the

plate 31. They include twosimilar levers axis 38, only one (305) of them being visible in the figure.Lever 305 is provided with anarcuated slot 318 in which theaxis 37 of pinch (idle)roller 70 can slide. - The other end of the lever has a

stop pin 91 adjusted to abut against the edges of awindow 81 cut into theplate 31. Finally anappendix 178 of the lever provides for a connection (at 173) with the frame through aspring 170. The other end of the spring is secured to the frame at 174 and the spring is housed in agroove 175 cut in theplate 31.Lever 305 is designed to move in synchronism with thelever 306 mounted onplate 32 and having an identical structure and similar return means that are not described here 5for simplicity. - The sensing

member 181, pivotally mounted on the frame at 188, abuts againstroller 70 due to its weight and more particularly when the towel web lays oversections 63, it leans thereon as shown in Fig. 3. - ) For an easier understanding, the operation of the dispenser will be firstly illustrated with reference to Figgs. 3 to 8, whereas the energy accumulating device and the mechanism for recovering the trailing end portion of the towel, mounted on the outer side of the

plate 32, will be described later. - Figgs. 4 to 7 diagrammatically illustrate the positions of the components. The figures are side views from the left of the mechanism wherein the

plate 31 has been cut away almost completely to make easier the understand ing of the relationships between thelever 305 and themultiple lever 200 avoiding a large number of additional drawings. In Fig. 4 the dispenser is not yet operating even if thetowel web 40 has been introduced betweenrollers rollers levers return spring 170, shown only in Fig. 3 and in no further drawing to avoid and unduly complicated 5illustration, and by the abutment ofpins windows blades 184 of thesensing member 181 are resting on the surface ofroller 70 since the presence of the web prevents theblades 184 from penetrating intogaps 67. )Furthermore thearm 206 oflever 200,because ofpin 91, keeps thestrut 212 oflever 200 far from thestop catch 120 as also shown in Fig. 8 and the rockingarm 214, biased byspring 216, abuts against thestop 213. - After positioning the web and closing the apparatus the dispenser is made ready to use by pulling the

web 40 to reach the configuration of Fig. 5. Lever 305 (and of course lever 306) has been rotated by a certain angle so as to force theblades 184 to further descend and engageroller 70 through the web. The presence of the web anyway prevents the penetration of the blades into therecesses 67 so thatlevers pin 91 cooperating withlever 305 reaches a position at about the center of the correspondingwindow 81, but anyhow such displacement is not enough for lowering thestrut 212 oflever 200 to interfere with thestop catch 120. The apparatus is so ready for use. - Fig. 6 shows the system configuration during the withdrawal. Under the pulling action applied by the towel user to

web 40,levers windows arm 206 and the consequent descent of thestrut 212 to such a position as to intercept thestop catch 120. As a matter of fact it is the passage of the first fixedpin 129 to cause the lowering (no longer impeded) oflever arm 206 shown in Fig. 6. From now onwards the withdrawal of the web can continue until thesurface 121 of the stop catch abuts againststrut 212, thus stopping the rotation and the towel dispensing. The choice of the toothed wheel diameters univocally binds a (multiple) rotation of theroller 50 to the dispensed web length. The additional possibility of mounting 3thepins 128 into different holes onwheel 135 allows for the change of the length of towel that is dispensed and recovered each time. In fact, as can be seen in Fig. 8, only one of thepins 128 onstrip 127 is effective to the adjustment, the other one having a Ssupport function being mounted,on an inner circumference. - The towel cannot be further withdrawn due to the stopping

catch 120 and when the user ceases to pull the system returns to the configuration of Fig. 5 raising again thearm 206 and thereby excluding the strut. The system is then ready for another dispensing cycle, while a web length equal to the one dispensed has been taken up and wound over the core 45 by means of the associated rotation ofroller 60. - With reference to Fig. 7 there is illustrated the configuration of the system at the end of the web. When the trailing edge of the

web 40 has passed beyond theroller 70, theblades 184 are no longer retained by the fabric and penetrate into therecesses 67 causing a leftward rotation oflevers pins windows spring 170. In such a position alever 190 controlling an accumulator mounted onplate 32 is released as it will be disclos ied in the following with reference to Fig. 9. The energy stored in the accumulator drives intorotation roller 57 that completely recovers the trailing edge ofweb 40 within the housing. - Fig. 9 diagrammatically shows the

accumulator 150 mounted on the outside ofplate 32 and the controllinglever 190. The lever orrocker 190 is pivotally mounted at 192 onplate 32 and has oneend 197 adapted to abut against the detent surfaces orcams 198 of the accumulator during its loading. Theother end 195 of the lever faceswindow 82, symmetrical towindow 81 within which it is movable thepin 92, symmetrical to pin 91 and carried bylever 306 symmetrical to lever 305. Areturn spring 193 keeps theend 197 engaged with the detent surfaces 198 preventing the rotation in the direction shown by arrow Z. The mechanism is substantially a ratchet gear consenting only rotations opposite to those of arrow Z during the rewinding ofroll 46 since theaxis 77 ot take-uproller 60 is the same axis of the accumulator. The accumulator is not described in detail being of a known type, such as the one disclosed in the already cited European patent application. Atoothed wheel 160, mounted onplate 32, engages theteeth 155 on the periphery of theaccumulator 150. Thetoothed wheel 160 in turn engages agear 157 coaxial toroller 57 and protruding fromplate 32 by means of a unidirec tional clutch device including a choke spring. Such a spring allows for a free rotation ofroller 57 during the normal web taking up driven byroller 60,whereas it fastensgear 157 toshaft 59 when the accumulator is released. - As long as the

towel web 40 lays overpinch roll 70 and the apparatus is working (Figgs. 5 and 6), pin 92 (and the corresponding pin 91) can swing from a position at the centre of slot 82 (81) and an abutment position on the inner edge of such slot. Under these conditions thereturn spring 193 keeps theend portion 197 raised so that the rotation ofaxis 77 lets the accumulator be loaded blocking any backward movement due to the cam surfaces 198. Thereby the accumulator progressively loads a spiral spring storing energy so that, in the proximity of the web termina tion, the energy stored is enough to drive a winding uprotation Oto recover the web length hanging loose from the apparatus. When the system is in the configuration of Fig. 7 wherein pins 91 and 92 are led towards the front part of the apparatus as can be seen in Fig. 9, thelever end portion 197 is lowered thereby releasing the accumulator that can now rotate for a number of turns in the direction of the arrow Z and drive thegear 157 and thereforeroller 57, this latter completely recovering the towel tail portion at the outside. The tail portion of the soiled towel is recovered into the apparatus without being wound upon the formedroll 12. In this way the apparatus prevents any defective working that might be caused by an incorrect winding,since the system does not attempt to wind the tail portion over theroll 12, but only carries it into the free space available under this roll.

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84306889T ATE41297T1 (en) | 1983-10-14 | 1984-10-09 | TOWEL DISPENSER THAT DISPENSES AND RETRACES A SPECIFIC LENGTH OF TOWELS FOR USE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT23309/83A IT1169575B (en) | 1983-10-14 | 1983-10-14 | APPARATUS TO MAKE OUTDOOR ACCESSIBLE AND RECOVER A PORTION OF TAPE USED FOR TOWELS AND SIMILAR |

| IT2330983 | 1983-10-14 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0138562A2 true EP0138562A2 (en) | 1985-04-24 |

| EP0138562A3 EP0138562A3 (en) | 1985-06-19 |

| EP0138562B1 EP0138562B1 (en) | 1989-03-15 |

Family

ID=11205929

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84306889A Expired EP0138562B1 (en) | 1983-10-14 | 1984-10-09 | A towel dispensing apparatus for making externally available and recovering a length of towel |

Country Status (9)

| Country | Link |

|---|---|

| EP (1) | EP0138562B1 (en) |

| JP (1) | JPS60137331A (en) |

| AT (1) | ATE41297T1 (en) |

| DE (1) | DE3477129D1 (en) |

| DK (1) | DK491784A (en) |

| ES (1) | ES536742A0 (en) |

| FI (1) | FI844025L (en) |

| IT (1) | IT1169575B (en) |

| NO (1) | NO844084L (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1053712A1 (en) * | 1999-05-21 | 2000-11-22 | Steiner Company International S.A. | Towel dispenser for a continuous band |

| CN108371507A (en) * | 2018-03-21 | 2018-08-07 | 宁波依心智能科技股份有限公司 | A kind of stop mechanism for towel machine and its control method |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3858953A (en) * | 1973-10-01 | 1975-01-07 | Steiner American Corp | Towel dispenser |

| US3893738A (en) * | 1973-04-30 | 1975-07-08 | Steiner American Corp | Retractable towel cabinet |

| EP0059893A2 (en) * | 1981-02-27 | 1982-09-15 | Steiner Company International S.A. | Apparatus for controlling the winding up and unwinding on rolls of toweling or the like |

-

1983

- 1983-10-14 IT IT23309/83A patent/IT1169575B/en active

-

1984

- 1984-10-09 EP EP84306889A patent/EP0138562B1/en not_active Expired

- 1984-10-09 AT AT84306889T patent/ATE41297T1/en not_active IP Right Cessation

- 1984-10-09 DE DE8484306889T patent/DE3477129D1/en not_active Expired

- 1984-10-11 ES ES536742A patent/ES536742A0/en active Granted

- 1984-10-12 FI FI844025A patent/FI844025L/en not_active Application Discontinuation

- 1984-10-12 NO NO844084A patent/NO844084L/en unknown

- 1984-10-12 DK DK491784A patent/DK491784A/en not_active Application Discontinuation

- 1984-10-15 JP JP59216029A patent/JPS60137331A/en active Granted

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3893738A (en) * | 1973-04-30 | 1975-07-08 | Steiner American Corp | Retractable towel cabinet |

| US3858953A (en) * | 1973-10-01 | 1975-01-07 | Steiner American Corp | Towel dispenser |

| EP0059893A2 (en) * | 1981-02-27 | 1982-09-15 | Steiner Company International S.A. | Apparatus for controlling the winding up and unwinding on rolls of toweling or the like |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1053712A1 (en) * | 1999-05-21 | 2000-11-22 | Steiner Company International S.A. | Towel dispenser for a continuous band |

| CN108371507A (en) * | 2018-03-21 | 2018-08-07 | 宁波依心智能科技股份有限公司 | A kind of stop mechanism for towel machine and its control method |

| CN108371507B (en) * | 2018-03-21 | 2023-12-29 | 宁波依心智能科技股份有限公司 | Towel machine and control method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| DK491784A (en) | 1985-04-15 |

| FI844025A0 (en) | 1984-10-12 |

| JPH047212B2 (en) | 1992-02-10 |

| DE3477129D1 (en) | 1989-04-20 |

| IT8323309A1 (en) | 1985-04-14 |

| IT8323309A0 (en) | 1983-10-14 |

| IT1169575B (en) | 1987-06-03 |

| EP0138562B1 (en) | 1989-03-15 |

| ES8600910A1 (en) | 1985-10-16 |

| NO844084L (en) | 1985-04-15 |

| ATE41297T1 (en) | 1989-04-15 |

| JPS60137331A (en) | 1985-07-20 |

| ES536742A0 (en) | 1985-10-16 |

| DK491784D0 (en) | 1984-10-12 |

| FI844025L (en) | 1985-04-15 |

| EP0138562A3 (en) | 1985-06-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5294192A (en) | Dispenser for rolled sheet material | |

| US4552315A (en) | Rolled web dispenser | |

| US4487375A (en) | Roll transfer mechanism for web material dispenser | |

| CA2576909C (en) | Dispenser for multiple rolls of sheet material | |

| US4203562A (en) | Flexible sheet material dispensing of rolls in succession | |

| EP0288211A1 (en) | Continuous towel cabinets | |

| FI58258C (en) | HANDDUKSUTMATNINGSANORDNING | |

| US20060236836A1 (en) | Dispensing device for paper sheets obtained by manual cutting from a continuous band with triggering mechanism for a spare roll | |

| EP0138562B1 (en) | A towel dispensing apparatus for making externally available and recovering a length of towel | |

| KR20120007336A (en) | Apparatus for opening and closing dual blind sheets | |

| EP1053712A1 (en) | Towel dispenser for a continuous band | |

| FI91825B (en) | Fabric towel dispenser with two interconnected towel units | |

| US3502383A (en) | Toweling dispenser with loop control | |

| US3265454A (en) | Towel cabinet | |

| EP0534792B1 (en) | Towel cabinet | |

| EP0272357B1 (en) | Towel dispenser | |

| JPS60144262A (en) | Towel dispenser | |

| JPS60144266A (en) | Towel dispenser | |

| JPH0142204B2 (en) | ||

| JPS60142825A (en) | Towel distributor | |

| JPS60144272A (en) | Towel dispenser | |

| JPS60144263A (en) | Towel dispenser | |

| JPH0357769B2 (en) | ||

| JPS6319176B2 (en) | ||

| JPS60144269A (en) | Towel dispenser |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB LI LU NL SE |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19850611 |

|

| 17Q | First examination report despatched |

Effective date: 19860207 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19890315 Ref country code: AT Effective date: 19890315 |

|

| REF | Corresponds to: |

Ref document number: 41297 Country of ref document: AT Date of ref document: 19890415 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3477129 Country of ref document: DE Date of ref document: 19890420 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19891031 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19950913 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960917 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960923 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19970501 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19970501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971031 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980701 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19990917 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19990920 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19991015 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001031 |

|

| BERE | Be: lapsed |

Owner name: S.A. STEINER CY INTERNATIONAL Effective date: 20001031 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20001009 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010629 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |