EP0117397B1 - Procédé pour remplir un extracteur de cuve - Google Patents

Procédé pour remplir un extracteur de cuve Download PDFInfo

- Publication number

- EP0117397B1 EP0117397B1 EP84100261A EP84100261A EP0117397B1 EP 0117397 B1 EP0117397 B1 EP 0117397B1 EP 84100261 A EP84100261 A EP 84100261A EP 84100261 A EP84100261 A EP 84100261A EP 0117397 B1 EP0117397 B1 EP 0117397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- vessel conveyor

- bulk material

- closure means

- vessel

- pulsed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title claims description 9

- 239000013590 bulk material Substances 0.000 claims abstract description 15

- 239000004570 mortar (masonry) Substances 0.000 claims abstract description 6

- 238000005273 aeration Methods 0.000 claims abstract 3

- 239000000843 powder Substances 0.000 claims abstract 2

- 230000035485 pulse pressure Effects 0.000 claims description 2

- 230000002792 vascular Effects 0.000 description 7

- 238000009423 ventilation Methods 0.000 description 7

- 238000005429 filling process Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 239000011505 plaster Substances 0.000 description 2

- 238000005204 segregation Methods 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 239000004566 building material Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000002045 lasting effect Effects 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D90/00—Component parts, details or accessories for large containers

- B65D90/54—Gates or closures

- B65D90/62—Gates or closures having closure members movable out of the plane of the opening

- B65D90/623—Gates or closures having closure members movable out of the plane of the opening having a rotational motion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D88/00—Large containers

- B65D88/54—Large containers characterised by means facilitating filling or emptying

- B65D88/72—Fluidising devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D90/00—Component parts, details or accessories for large containers

- B65D90/54—Gates or closures

- B65D90/62—Gates or closures having closure members movable out of the plane of the opening

- B65D90/626—Gates or closures having closure members movable out of the plane of the opening having a linear motion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2590/00—Component parts, details or accessories for large containers

- B65D2590/54—Gates or closures

- B65D2590/547—Gates or closures in multiple arrangement

Definitions

- the present invention relates to a vessel conveyor for the pneumatic conveying of, in particular, hard-flowing bulk material from a storage silo, in particular for conveying dry mortars and dry plasters, with a cone closure actuated by means of a pneumatically operating device relative to an inlet cone, and a method for filling this vessel conveyor.

- Vessel conveyors are used for the pneumatic conveyance of bulk goods from storage silos, they are generally filled with the bulk goods from a storage silo via a rotary lock, and then the bulk goods are conveyed from the vessel conveyor to the point of use or packaging point by means of compressed air.

- Such conveyors have already found their way into the building materials sector, so they are also used on construction sites to convey dry mortar and plaster to the processing point via hose lines.

- the operation of such vessel conveyors is discontinuous. Compared to some continuously operating systems, these devices have the advantage that the storage silo is not pressurized and therefore does not have to be designed as a pressure vessel.

- the usual vascular conveyors have disadvantages in that e.g. in the case of poorly flowing bulk materials, especially dry mortar mixtures, the filling of the vessel conveyor from the storage silo is disrupted.

- vibrating and striking devices nor a one-time impact impulse during the opening process of a pneumatically operated cone lock, as known from DE-OS 26 57 742 can overcome this disadvantage.

- Conventional ventilation of the lower part of the silo via nozzles and ring lines is also disadvantageous, because this can lead to segregation of the bulk material, especially in the case of dry mortar and plaster, which has a lasting effect on the workability of the conveyed material.

- the vessel conveyor is expediently designed in such a way that it can be mounted below the outlet of the storage silo, which can be closed by a flap, e.g. by screwing or expediently by suitable clamping devices.

- the conical inlet part of the vessel conveyor has an air-permeable porous lining, as known per se from GB-A-2 039 469. Between this and the conical inlet part there is a cavity with a connection for the compressed air used for ventilation.

- the inlet cone is closed by a cone closure, the pneumatically operating opening mechanism of which is located together with the closing spring inside the vessel conveyor. Further details of the vessel conveyor according to the invention can be seen, for example, from the drawing and the associated description.

- the operation of the vessel conveyor is as follows: After it has been connected to the storage silo, the lines for the ventilation air to the inlet cone and for the pneumatic actuation of the cone closure are pressurized with air at intervals of 1 to 2 seconds and compliance with a pulse pressure / pause ratio of approximately 1: 1 using generally a pressure of 2 bar, loosening of the incoming bulk material and opening of the cone closure taking place depending on the degree of synchronization of ventilation air pressure and cone closure pneumatics.

- the pressure drop during the pulse pause should expediently only be 35 to 40%.

- Adaptation to the flowability of the bulk material can be done by changing the pulse / pause ratio, changing the extent of the pressure drop during the pulse pause and finally by changing the degree of synchronization of the compressed air pulses for ventilation air and cone lock pneumatics. Finally, it is still possible to change the degree of synchronization during the filling process of the vessel conveyor to adapt to the particular flow behavior of the bulk material. Such changes can be made by means of provided manual controls if required, but they can also be made by automatic control depending on the filling level of the vascular conveyor, depending on the time.

- a porous, air-permeable plate can be provided on the bottom of the vessel conveyor, which serves to loosen up the bulk material in the Vascular conveyor serves.

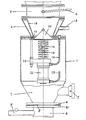

- 1 denotes the vessel conveyor, which has a conically shaped inlet part 2, which is fastened to the lower part of the storage silo 3 by fastening means, not shown.

- the lower part 3 of the storage silo is a flange piece with a built-in flap that can be opened and closed by lever 4.

- the lower part of the vessel conveyor 1 is conical, is provided with a nozzle 5 to which the delivery line is connected and is connected to a flange piece 6, through the nozzle 7 of which the conveying air is supplied.

- a porous plate 9 is arranged, which serves as a ventilation base for the bulk material located in the vessel conveyor during the conveying process.

- the vascular conveyor 1 has a cone closure 10 with respect to the inlet cone, which is sealed by an annular seal 11.

- the cone closure 10 is opened during the filling process via a pneumatic cylinder 12 by means of a piston rod 13 against the force of the spring 14 and is closed accordingly with the aid of spring force and pressurized air on the lower side of the double-acting pneumatic piston.

- the opening and closing mechanism is held by a three-point suspension 15. 16 is the compressed air supply line during the opening process of the cone closure and 17 is the compressed air supply line during the closing process, which leads out of the vessel conveyor 1 at a position not shown.

- the porous, air-permeable lining of the inlet cone is designated by 18.

- Compressed air is fed into the space between the conically shaped inlet part 2 and the porous lining 18 via the nozzle 19 during the filling process in order to loosen up the bulk material in the inlet part.

- the compressed air supply is also pulsed for the pneumatics of the plug lock.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Filling Or Emptying Of Bunkers, Hoppers, And Tanks (AREA)

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84100261T ATE22870T1 (de) | 1983-01-27 | 1984-01-12 | Gefaessfoerderer zur pneumatischen foerderung von schuettgut aus einem vorratssilo. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19833302657 DE3302657A1 (de) | 1983-01-27 | 1983-01-27 | Gefaessfoerderer zur pneumatischen foerderung von schuettgut aus einem vorratssilo |

| DE3302657 | 1983-01-27 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0117397A1 EP0117397A1 (fr) | 1984-09-05 |

| EP0117397B1 true EP0117397B1 (fr) | 1986-10-15 |

| EP0117397B2 EP0117397B2 (fr) | 1990-02-07 |

Family

ID=6189333

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84100261A Expired - Lifetime EP0117397B2 (fr) | 1983-01-27 | 1984-01-12 | Procédé pour remplir un extracteur de cuve |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0117397B2 (fr) |

| AT (1) | ATE22870T1 (fr) |

| DE (2) | DE3302657A1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4008553A1 (de) * | 1990-03-16 | 1991-09-19 | Agrichema Materialflusstechnik | Verladevorrichtung fuer die lose verladung von staubigen schuettguetern |

| DE9015587U1 (de) * | 1990-11-14 | 1991-01-31 | Feldbinder & Beckmann oHG, 2090 Winsen | Drucklufteinlaßrückschlagventil |

| DE4410087C2 (de) * | 1994-03-24 | 1997-08-07 | Mann & Hummel Filter | Verschluß für ein im Unterdruck arbeitendes Fördergerät |

| US6802685B1 (en) * | 1999-02-23 | 2004-10-12 | Bernd Federhen | Device and method for inwardly transferring bulk material into a pneumatic conveyor line |

| RU2323139C2 (ru) * | 2006-04-20 | 2008-04-27 | Закрытое акционерное общество "НОТИС" | Бункер для сыпучих продуктов |

| DE102019118093A1 (de) | 2019-07-04 | 2021-01-07 | Klaus Wilhelm | Vorrichtung, Baukasten und Verfahren zum Behandeln von Schüttgütern |

| CN117184673A (zh) * | 2023-10-20 | 2023-12-08 | 新兴铸管股份有限公司 | 一种防喷仓料仓 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2734782A (en) * | 1956-02-14 | Pneumatic conveyors | ||

| US3776600A (en) * | 1971-06-07 | 1973-12-04 | Thoreson Mc Cosh Inc | Valve for vacuum loader |

| DE2657742A1 (de) * | 1976-12-20 | 1978-06-22 | Mittelmann Gmbh & Co Kg | Verfahren und vorrichtung zur einspeisung eines fuellgutes aus einem aufnahmeraum in einen anderen |

| US4264243A (en) * | 1979-01-04 | 1981-04-28 | Dundee Cement Company | Constant vacuum barge unloading system |

-

1983

- 1983-01-27 DE DE19833302657 patent/DE3302657A1/de not_active Withdrawn

-

1984

- 1984-01-12 EP EP84100261A patent/EP0117397B2/fr not_active Expired - Lifetime

- 1984-01-12 DE DE8484100261T patent/DE3460959D1/de not_active Expired

- 1984-01-12 AT AT84100261T patent/ATE22870T1/de not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| DE3302657A1 (de) | 1984-08-02 |

| EP0117397A1 (fr) | 1984-09-05 |

| EP0117397B2 (fr) | 1990-02-07 |

| ATE22870T1 (de) | 1986-11-15 |

| DE3460959D1 (en) | 1986-11-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3420616C2 (fr) | ||

| EP1382947B1 (fr) | Dispositif de dosage pour pigments pulvérulants | |

| DE2453950A1 (de) | Pneumatische foerderanlage | |

| EP0117397B1 (fr) | Procédé pour remplir un extracteur de cuve | |

| DE2334360B2 (de) | Verfahren und einrichtung zum pneumatischen foerdern von feinpulverigen, zum ansetzen an die rohrwand neigenden produkten | |

| EP0386637B1 (fr) | Appareil doseur pour poudre | |

| EP1000889B1 (fr) | Dispositif pour transférer des produits fluides | |

| DE2717948A1 (de) | Ventilsackfuellvorrichtung fuer flugfaehiges fuellgut und verfahren zum betreiben der vorrichtung | |

| DE19539610C2 (de) | Automatische Förderregulierung an pneumatischen Druckförderanlagen | |

| DE2616430A1 (de) | Verfahren und vorrichtung zum austreiben von schuettgut aus einem innendruckbelastbaren silobehaelter | |

| EP0472924A2 (fr) | Procédé et dispositif pour l'alimentation de matériau à écoulement libre dans l'orifice d'entrée d'une machine de traitement | |

| EP0867389B1 (fr) | Dispositif et procédé de transport pour matière pulvérulente ou granuleuse | |

| DE2136328A1 (de) | Vorrichtung zum pneumatischen beschicken mehrerer abnahmestellen mit gut aus ein oder mehr vorratsbehaeltern | |

| EP3434632A1 (fr) | Dispositif et procédé d'acheminement de matériau constitué d'au moins principalement de particules solides, en particulier poudre, par exemple mortier sec | |

| DE2853106A1 (de) | Anlage zur pneumatischen druckkesselfoerderung hydraulischer baustoffe im berg- und tunnelbau | |

| EP1628897A1 (fr) | Dispositif d'alimentation continue d'une conduite d'alimentation pneumatique, en solide pulverulent | |

| EP0776425B1 (fr) | Dispositif pour l'ouverture et la fermeture d'un clapet | |

| CH638749A5 (de) | Pneumatisch betaetigte zufuehrungsvorrichtung fuer fliessfaehiges material. | |

| DE3708015A1 (de) | Sicherheitseinrichtung fuer druckluftfoerderanlagen | |

| DE3810191A1 (de) | Druckluftentleereinrichtung fuer einen schuettgutbehaelter mit mindestens zwei entleeroeffnungen sowie ein verfahren zur entleerung des schuettgutbehaelters | |

| DE19650457C2 (de) | Trockenspritzverfahren | |

| DE19514377A1 (de) | Verfahren und Anlage zum pneumatischen Fördern pulverförmiger oder körniger Materialien | |

| DE1269097B (de) | Vorrichtung zum pneumatischen Mischen und Foerdern von zum Erhaerten neigenden Gut aus einem stehenden Druckbehaelter | |

| DE1511528A1 (de) | Sackfuellmaschine | |

| DE7027622U (de) | Vorrichtung zum dosieren gekoernten materials. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19840112 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR LI LU NL SE |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 22870 Country of ref document: AT Date of ref document: 19861115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3460959 Country of ref document: DE Date of ref document: 19861120 |

|

| ET | Fr: translation filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: BUEHLER - MIAG GMBH Effective date: 19870713 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: BUEHLER - MIAG GMBH |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19900207 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE FR LI LU NL SE |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| NLR2 | Nl: decision of opposition | ||

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19911128 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19911129 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19911230 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19920110 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19920113 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19920115 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19920130 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19920131 Year of fee payment: 9 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19930112 Ref country code: AT Effective date: 19930112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19930131 Ref country code: CH Effective date: 19930131 Ref country code: BE Effective date: 19930131 |

|

| BERE | Be: lapsed |

Owner name: RHEINISCHE KALKSTEINWERKE G.M.B.H. Effective date: 19930131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19930801 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19930930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19931001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84100261.1 Effective date: 19930810 |