EP0103484A2 - Filling machine for foaming liquids - Google Patents

Filling machine for foaming liquids Download PDFInfo

- Publication number

- EP0103484A2 EP0103484A2 EP83305347A EP83305347A EP0103484A2 EP 0103484 A2 EP0103484 A2 EP 0103484A2 EP 83305347 A EP83305347 A EP 83305347A EP 83305347 A EP83305347 A EP 83305347A EP 0103484 A2 EP0103484 A2 EP 0103484A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- container

- fill

- sleeve

- tip

- liquid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C3/00—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids

- B67C3/02—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus

- B67C3/22—Details

- B67C3/26—Filling-heads; Means for engaging filling-heads with bottle necks

- B67C3/2608—Filling-heads; Means for engaging filling-heads with bottle necks comprising anti-dripping means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C3/00—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids

- B67C3/02—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus

- B67C3/04—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus without applying pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C3/00—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids

- B67C3/02—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus

- B67C3/22—Details

- B67C3/26—Filling-heads; Means for engaging filling-heads with bottle necks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C3/00—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids

- B67C3/02—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus

- B67C3/22—Details

- B67C3/26—Filling-heads; Means for engaging filling-heads with bottle necks

- B67C2003/2671—Means for preventing foaming of the liquid

Definitions

- the present invention relates to filling of containers, such as bottles, with flowable substances and is particularly directed to thin liquids which readily form suds or foam.

- the present invention is directed to a machine with these features.

- the machine includes a container filling section having a rotating platform on which containers are supported as they are filled.

- the machine also includes an infeed section for feeding empty containers onto the rotating platform.

- the infeed section is equipped with an infeed star assembly capable of receiving and holding empty containers and discharging the empty containers onto the rotating platform.

- the infeed star assembly includes at least one container star mounted on a propelling axis.

- the machine also includes filling means comprising a plurality of filling nozzle assemblies and means for inserting a filler nozzle into an empty container held by the infeed star assembly.

- the filling nozzle assembly comprises as a nozzle an elongated hollow fill sleeve or tube and a fill tip at the first or fill end of the sleeve.

- the fill end of the sleeve is inserted into a container.

- the fill tip is axially slideable relative to the sleeve for opening and closing the fill end of the sleeve.

- the sleeve is biased relative to the fill tip to a closed position.

- the machine also includes means for lowering the sleeve tube and tip into the container and means for raising the sleeve and tip from the container.

- a preventing means such as a collar mounted on the sleeve prevents the sleeve from reaching the bottom of the container as the sleeve and tip approach the bottom of the container.

- the tip and sleeve are axially displaced relative to each other. This opens the fill end of the sleeve against the force of the biasing means.

- Latch means are provided for maintaining the fill end of the sleeve open as the sleeve and tip are raised from the bottom to the top of the container. Means are provided for releasing the latch means when the sleeve is raised almost to the top of the container by the raising means.

- the fill sleeve is lowered to a position almost to the bottom of the container.

- Liquid is continuously introduced into the container through the fill sleeve while simultaneously raising the fill sleeve and tip toward the top of the container so that the bottom of the fill sleeve is below the level of the top of the liquid in the container.

- the liquid is introduced into the container in a controlled volume by a metering piston. Introduction of the liquid into the container is stopped by release of the latch when the bottom of the fill sleeve is raised to a level just below the desired liquid level in the container.

- the machine preferably includes a nozzle star for holding the elongated fill sleeves as they are inserted into empty containers.

- the nozzle star is located above the container star.

- the lower surface of the fill tip is slanted downwardly toward its axial centerline and includes a vacuum port at the lowermost portion of the lower surface of the tip so that drops of liquid remaining on the tip do not drip because they are sucked up as the tip is removed from a container.

- a vacuum shroud cooperates with the tip so that vacuum is pulled at the vacuum port only when the nozzle is closed and out of the container.

- a machine 10 includes a rotating platform or carousel 12 on which a plurality of containers such as plastic bottles 14 are carried to be filled.

- the platform 12 rotates on a central vertical axle 16 which is driven by a main sprocket 18 positioned above the platform 12.

- the main sprocket 18 is driven by a belt 20 powered by a drive gear 22.

- a cam 24 is positioned between the main sprocket 18 and the platform 12. The cam is supported by a support ring 26.

- a plurality of support rods 28 extend downwardly through the main sprocket 18 and are vertically slideable relative thereto. From each slideable support rod 28 there depends a nozzle assembly 30, there being at least as many nozzle assemblies'30 as there are containers 14 on the platform 12. Each support rod 28 has a cam follower 32 mounted thereon.

- the machine 10 includes an infeed section 34 and an outfeed section 36.

- empty containers are taken from a feed belt 38, and delivered by an infeed star assembly 40 onto the rotating platform 12.

- filled containers are taken by an outfeed star assembly 42 and delivered to a container withdraw belt 44. Both the feed belt 38 and the withdraw belt 44 can be table top chains.

- Fig. 1 the container feed belt 38 and container withdraw belt 44 move from a right to a left direction.

- the main sprocket 18 and platform 12 rotate in a counterclockwise direction (looking from above).

- the infeed star assembly 40 comprises three stars, a container body star 46, a container neck star 48 mounted above the body star 46, and a top nozzle star 50, all mounted on the same propelling axle 52 to rotate synchronously.

- the propelling axle 52 is driven by a infeed star sprocket 54 that is driven by the chain 20 around the main sprocket 18.

- the outfeed star assembly 42 comprises two stars, a lower container body star 56 and an upper neck star 58, both mounted on a propelling axle 60 driven by an outfeed star sprocket 68, which is driven by the chain 20 around the main sprocket 18.

- Each star comprises a plurality of arms 64 jutting out radially from the center of the star and a plurality of peripheral cavities 66 sized to receive a respective portion of a container or a nozzle.

- Each container star 46, 48, 56, and 58 cooperates with an upper guide 68 of lower guide 70 to hold the containers in a desired position.

- the nozzle star 50 cooperates with a nozzle guide 72 (see Fig. 5) to firmly hold nozzles in position as they are lowered into a container as described below.

- the guides can be provided with bearings 74 to assist the containers and nozzle assembly in moving to their desired position.

- bottles are fed from the container feed belt through the infeed star assembly 40 onto the rotating platform 12.

- a nozzle assembly 30 is inserted thereinto with the aid of the nozzle star 50.

- the container is filled with liquid as it and the nozzle assembly synchronously rotate around to the outfeed section 36, at which point the nozzle assembly is removed from the container, and the container is withdrawn from the platform 12 by the outfeed star assembly 42 and placed onto the container withdraw belt 44.

- the nozzle assembly 30 comprises four basic parts:

- the nozzle assembly 30 is supported by a horizontal mounting bar 104 that is attached to one of the sliding rods 28.

- Liquid is provided to the fill sleeve 94 in a premeasured amount from a device such as a bi-acting piston through the supply nipple 88 and lateral feed orifice 86.

- a device such as a bi-acting piston

- a throttle valve 105 is connected to the supply nipple 88 for throttling the amount of the liquid introduced so that all nozzle assemblies 30 fill at the same rate so they all complete their fill at the same point in the fill cycle.

- O-ring seals 106, 108, 116, 118, and 120, and a biasing spring 122 under compression are provided.

- the biasing spring is between the bottom of the supply body 84 and a spring split collar 124 mounted on the fill sleeve 94.

- Below the spring sleeve collar 124 is a bottle height split collar 126 mounted on the fill sleeve 94.

- the fill sleeve 94 and the rod 90 are sufficiently elongated to reach a position close to the bottom of the container to be filled.

- the fill sleeve 94 is axially, i.e. vertically, displaceable relative to the rod 90 and the tip 92.

- a vacuum line 128 is connected to the vacuum connector 98, which is in communication with a lateral vacuum vent 130 and the vacuum shroud 96.

- the radially inner surface of the vacuum shroud 96 has a vertical vent groove 132 which is in register with a cross vent hole 134 through the tip 92 when the tip is in a closed position as shown in Fig. 2.

- the tip also includes a vertical center vent hole 136 connected to the cross vent hole 134.

- the lowermost wall 138 of the tip and shroud 96 slant downwardly toward the axial centerline of the tip 92, rod 90, and fill sleeve 94, i.e., they appear to be a cone with the tip down.

- the vertical vent hole 136 terminates in a tip orifice 140 at the lowest portion of the lower wall 138 of the tip 92.

- Air vents 142 are provided along the lowermost wall of the vacuum shroud 96.

- Fluid introduced into the fill sleeve 94 is prevented from leaking therefrom into the supply body 84 by 0-rings 106 and 108, and is prevented from leaking through the vacuum shroud by 0-ring 118.

- 0- rings 116 and 120 hold the shrouds vacuum seal.

- the tip 92 is shown in its closed position in Fig. 2 with the tip 92 being biased by the spring 122 into engagement with sealing O-ring 118 mounted at the fill end 144 of the fill sleeve 94.

- Fig. 3A corresponds to the nozzle fill assembly in the position it is in Fig. 2, i.e. before the nozzle assembly has engaged a container 14.

- nozzle comprising the supply sleeve 94 and the tip 92 are just about to enter a container 14. Note that the nozzle is held by the nozzle star 50 and nozzle guide 72. Because of the long length of the nozzle, the nozzle star 50 is of great assistance in insuring that the nozzle goes into a container 14, expecially one with a narrow neck.

- the vacuum shroud 96 seats against the top of the container 14.

- the sleeve 94, rod 90 and tip 92 are axially slideable relative to the shroud.

- the tip 92 and the sleeve 94 move downwardly into the container 14 and continue downward movement as shown in Fig. 3D. No filling has yet occurred because the tip 92 is in tight engagement with sealing orifice 118 under the force of the biasing spring 122.

- Fig. 3E fill begins.

- the lower split collar 126 seats against the top of the vacuum shroud 96, preventing the sleeve 94 from continuing its downward movement.

- the tip 92 continues to move downwardly and is vertically displaced relative to the sleeve, thereby allowing liquid to flow into the container 14.

- no liquid enters into the container 14 until the fill tip 144 of the sleeve is proximate to the bottom of the container. This greatly reduces sudsing and foaming that would occur if the nozzle were opened at the top and lowered to the bottom.

- air vents 142 are open as the tip 92 enters the container 14, i.e., in Fig. 3C, so that air can be vented out of the container 14 as liquid is placed therein. It should also be noted that because the tip 92 is vertically displaced from the vacuum shroud 96, there is no vacuum at the tip 140 because the vent grooves 132 and the vent cross hole 134 are no longer in register. No vacuum loss occurs because of 0-rings 116 and 120. This is energy efficient, and leads to accurate fill because premeasured liquid is not sucked out of the container.

- the latch 100 catches the bottom of the spring split collar 124 as the spring 122 is compressed. This holds the fill sleeve 94 and the tip 92 axially displaced relative to each other until the latch is released so that the nozzle remains in an open position.

- the latch is held in place by a spring 110 ( Figure 2).

- nozzle is being raised from the bottom of the container toward the top of the container.

- the rate at which the nozzle is raised is sufficiently slow that the fill tip remains below the liquid level in the container to avoid foaming and sudsing.

- the latch is released by a release wheel 146 (Fig. 4) that is supported by the cam 24. This releases the tip 92 to move into the position shown in Figs. 2, 3A and 3H, thereby closing the nozzle.

- each nozzle assembly 30 varies as the nozzle assembly rotates with the main sprocket 18 due to the cam follower 32 attached to the support rod 28 following the vertical position of the top of the cam 24.

- nozzle assembly positions as shown in Figs. 3 A-H are provided.

- directly above the infeed star assembly 40 are letters A, B and C in Fig. 4 indicating that at the infeed star assembly, the nozzle assembly moves from the position shown in Fig. 3A to the position shown in Fig. 3B, and then to the position shown in Fig. 3C.

- the nozzle assembly moves from the position shown in Fig. 3G to the position shown in Fig. 3H.

- the cam 24 is provided with an adjustable cam step 148 so that the machine can be used for filling containers to different head spacings.

- the air vents 142 are sized so that the volumetric rate at which air is forced from a container is less than the volumetric rate at which a container is filled with liquid.

- the air vents can be rectangular, 1.63 mm (0.064 inch) by 3.43 mm (0.135 inch) and 25.4 mm (1 inch) long.

- This volumetric rate condition can be met because no vacuum is pulled insider the container when filling.

- flexible containers, and particularly plastic containers tend to bulge. This allows containers to be filled leaving more headroom between the top of the liquid in the container and the top of the container. The more headroom that is allowed, the faster the filling rate that can be obtained.

- the vacuum is not used for withdrawing any excess liquid from the container, which could cause an inaccuracy. It is only used to remove drops from the tip which could contaminate the machinery or the container.

- a machine according to the present invention has many advantages. It permits rapid and accurate fill of containers, even with foamy and sudsy liquids due to the use of the bottom open/top close nozzle assembly. Because of the nozzle star, the flexing elongated nozzle assembly can be used even with narrow neck containers and no dripping centering bells are needed. The anti-drip nozzle tip helps prevent fouling of machinery which can result in inaccurate fills and substantial dowmtime. Since the nozzle is almost completely withdrawn from the container before filling is complete, the volume occupied by the nozzle is minimized. This allows the containers to appear to be almost completely filled. Bottles that appear full sell better on shelves than low fills - a great marketing advantage.

- the present invention has been described in considerable detail with reference to certain preferred versions thereof, other versions are possible.

- the main sprocket 18 can be replaced with a plate having a roller chain tightly stretched around its periphery with the drive gear 22 directly engaging the chain.

- the cam 26 can be supported by vertical rods connected to an overhead frame rather than the ring 26.

- any pre-measuring device or pump can be used. Therefore, the spirit and scope of the appended claims should not necessarily be limited to the description of the preferred versions thereof.

Landscapes

- Filling Of Jars Or Cans And Processes For Cleaning And Sealing Jars (AREA)

- Basic Packing Technique (AREA)

Abstract

A filling nozzle assembly includes an elongated fill sleeve (94) for insertion into a container (14). A fill tip (92) is located at an end of the sleeve and is axially slidable between open and closed positions. A spring 122 biases the tip to its closed position. An apparatus (24, 32) is provided to lower the sleeve into the container during which time a shroud (96) contacts the container inhibiting further insertion of the sleeve, but permitting axial movement of the fill tip, thereby opening same. A latch (100) keeps the fill tip open as the sleeve is withdrawn from the container until the latch is tripped by a release mechanism (146).

Description

- The present invention relates to filling of containers, such as bottles, with flowable substances and is particularly directed to thin liquids which readily form suds or foam.

- Apparatus for filling containers are known and are described in U. S. Patent Nos. 2,512,966; 2,548,589; 2,750,091; 3,056,436; 3,093,165; 3,464,464; 3,559,702; 3,580,299; 3,589,414; 3,771, 574; 3,834,430; 3,978,900; 4,0̸53,0̸0̸13; 4,0̸99,547; and 4,159,608. Such an apparatus is also described in my U. S. Patent No. 3,870,089, issued March 11, 1975.

- It is particularly difficult to rapidly and accurately fill a container with a foaming or sudsy liquid. The air present in foam or suds results in overflowing the container which shortchanges the consumer and contaminates the machine and the exterior of the container.

- Thus, there is a need for a machine for filling a plurality of containers with a foaming or sudsy liquid rapidly and accurately.

- The present invention is directed to a machine with these features. The machine includes a container filling section having a rotating platform on which containers are supported as they are filled.

- The machine also includes an infeed section for feeding empty containers onto the rotating platform. The infeed section is equipped with an infeed star assembly capable of receiving and holding empty containers and discharging the empty containers onto the rotating platform. The infeed star assembly includes at least one container star mounted on a propelling axis.

- The machine also includes filling means comprising a plurality of filling nozzle assemblies and means for inserting a filler nozzle into an empty container held by the infeed star assembly.

- Preferably the filling nozzle assembly comprises as a nozzle an elongated hollow fill sleeve or tube and a fill tip at the first or fill end of the sleeve. The fill end of the sleeve is inserted into a container. The fill tip is axially slideable relative to the sleeve for opening and closing the fill end of the sleeve. The sleeve is biased relative to the fill tip to a closed position.

- The machine also includes means for lowering the sleeve tube and tip into the container and means for raising the sleeve and tip from the container. A preventing means such as a collar mounted on the sleeve prevents the sleeve from reaching the bottom of the container as the sleeve and tip approach the bottom of the container. Thus, as the sleeve reaches a position proximate to the bottom of the container, the tip and sleeve are axially displaced relative to each other. This opens the fill end of the sleeve against the force of the biasing means.

- Latch means are provided for maintaining the fill end of the sleeve open as the sleeve and tip are raised from the bottom to the top of the container. Means are provided for releasing the latch means when the sleeve is raised almost to the top of the container by the raising means.

- In use of this nozzle assembly, the fill sleeve is lowered to a position almost to the bottom of the container. Liquid is continuously introduced into the container through the fill sleeve while simultaneously raising the fill sleeve and tip toward the top of the container so that the bottom of the fill sleeve is below the level of the top of the liquid in the container. The liquid is introduced into the container in a controlled volume by a metering piston. Introduction of the liquid into the container is stopped by release of the latch when the bottom of the fill sleeve is raised to a level just below the desired liquid level in the container.

- The machine preferably includes a nozzle star for holding the elongated fill sleeves as they are inserted into empty containers. The nozzle star is located above the container star.

- Preferably the lower surface of the fill tip is slanted downwardly toward its axial centerline and includes a vacuum port at the lowermost portion of the lower surface of the tip so that drops of liquid remaining on the tip do not drip because they are sucked up as the tip is removed from a container. A vacuum shroud cooperates with the tip so that vacuum is pulled at the vacuum port only when the nozzle is closed and out of the container.

- The combination of a bottom fill/top close nozzle with the nozzle star and the latch mechanism allows containers to be filled rapidly and accurately even with foaming liquids. Moreover, the use of a slanted fill tip with a shroud and a vacuum vent combination helps maintain the cleanliness of the machine without affecting the accuracy of the fill.

- These and other features, aspects, and advantages of the present invention will become better understood with reference to the following description, appended claims, and accompanying drawing where:

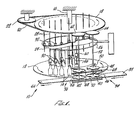

- Fig. 1 is a front perspective view of a machine for filling containers, the machine having features of the present invention;

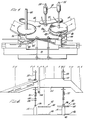

- Fig. 2 is a front elevation view, partly in section, of a nozzle assembly of the machine of Fig. 1;

- Figs. 3 A-H show the nozzle assembly of Fig. 2 during different stages of the cycle used to fill a container;

- Fig. 4 is a front elevation view of a portion of the machine of Fig. 1; and

- Fig. 5 shows in perspective a portion of the infeed and outfeed mechanism of the machine of Fig. 1

- A machine 10 according to the present invention includes a rotating platform or

carousel 12 on which a plurality of containers such asplastic bottles 14 are carried to be filled. Theplatform 12 rotates on a centralvertical axle 16 which is driven by amain sprocket 18 positioned above theplatform 12. Themain sprocket 18 is driven by abelt 20 powered by adrive gear 22. Acam 24 is positioned between themain sprocket 18 and theplatform 12. The cam is supported by asupport ring 26. - A plurality of

support rods 28 extend downwardly through themain sprocket 18 and are vertically slideable relative thereto. From eachslideable support rod 28 there depends anozzle assembly 30, there being at least as many nozzle assemblies'30 as there arecontainers 14 on theplatform 12. Eachsupport rod 28 has acam follower 32 mounted thereon. - The machine 10 includes an

infeed section 34 and anoutfeed section 36. In the infeedsection 34, empty containers are taken from afeed belt 38, and delivered by an infeedstar assembly 40 onto therotating platform 12. At the outfeedsection 36, filled containers are taken by anoutfeed star assembly 42 and delivered to a container withdrawbelt 44. Both thefeed belt 38 and thewithdraw belt 44 can be table top chains. - In Fig. 1, the

container feed belt 38 and container withdrawbelt 44 move from a right to a left direction. Themain sprocket 18 andplatform 12 rotate in a counterclockwise direction (looking from above). - The infeed

star assembly 40 comprises three stars, acontainer body star 46, acontainer neck star 48 mounted above thebody star 46, and atop nozzle star 50, all mounted on thesame propelling axle 52 to rotate synchronously. The propellingaxle 52 is driven by a infeedstar sprocket 54 that is driven by thechain 20 around themain sprocket 18. - The outfeed

star assembly 42 comprises two stars, a lowercontainer body star 56 and anupper neck star 58, both mounted on a propellingaxle 60 driven by anoutfeed star sprocket 68, which is driven by thechain 20 around themain sprocket 18. - Each star comprises a plurality of

arms 64 jutting out radially from the center of the star and a plurality of peripheral cavities 66 sized to receive a respective portion of a container or a nozzle. - Each container star 46, 48, 56, and 58 cooperates with an

upper guide 68 oflower guide 70 to hold the containers in a desired position. Similarly, thenozzle star 50 cooperates with a nozzle guide 72 (see Fig. 5) to firmly hold nozzles in position as they are lowered into a container as described below. The guides can be provided withbearings 74 to assist the containers and nozzle assembly in moving to their desired position. - In use of the machine 10, bottles are fed from the container feed belt through the infeed

star assembly 40 onto therotating platform 12. As a container approaches theplatform 12, anozzle assembly 30 is inserted thereinto with the aid of thenozzle star 50. The container is filled with liquid as it and the nozzle assembly synchronously rotate around to theoutfeed section 36, at which point the nozzle assembly is removed from the container, and the container is withdrawn from theplatform 12 by theoutfeed star assembly 42 and placed onto the container withdrawbelt 44. - As shown in Fig. 2, the

nozzle assembly 30 comprises four basic parts: - ·(1) a supply subassembly 82 comprising a

supply body 84 with alateral feed orifice 86, asupply nipple 88 and an integrally attached center pin orrod 90 with adependent fill tip 92; - (2) a

hollow supply sleeve 94; - (3) a vacuum shroud or

hood 96 with alateral vacuum connection 98; and - (4) a

pivotable latch mechanism 100 pivotally attached to thesupply body 84 bybolts 102. - The

nozzle assembly 30 is supported by a horizontal mountingbar 104 that is attached to one of the slidingrods 28. - Liquid is provided to the

fill sleeve 94 in a premeasured amount from a device such as a bi-acting piston through thesupply nipple 88 andlateral feed orifice 86. Techniques for providing premeasured liquid from a device such as a bi-acting piston during the filling cycle are described in my aforementioned U. S. Patent No. 3,870,089. A throttle valve 105 is connected to thesupply nipple 88 for throttling the amount of the liquid introduced so that allnozzle assemblies 30 fill at the same rate so they all complete their fill at the same point in the fill cycle. - O-

ring seals biasing spring 122 under compression are provided. The biasing spring is between the bottom of thesupply body 84 and aspring split collar 124 mounted on thefill sleeve 94. Below thespring sleeve collar 124 is a bottle height splitcollar 126 mounted on thefill sleeve 94. - The

fill sleeve 94 and therod 90 are sufficiently elongated to reach a position close to the bottom of the container to be filled. Thefill sleeve 94 is axially, i.e. vertically, displaceable relative to therod 90 and thetip 92. - A

vacuum line 128 is connected to thevacuum connector 98, which is in communication with alateral vacuum vent 130 and thevacuum shroud 96. The radially inner surface of thevacuum shroud 96 has avertical vent groove 132 which is in register with across vent hole 134 through thetip 92 when the tip is in a closed position as shown in Fig. 2. The tip also includes a verticalcenter vent hole 136 connected to thecross vent hole 134. Thelowermost wall 138 of the tip andshroud 96 slant downwardly toward the axial centerline of thetip 92,rod 90, and fillsleeve 94, i.e., they appear to be a cone with the tip down. Thevertical vent hole 136 terminates in atip orifice 140 at the lowest portion of thelower wall 138 of thetip 92. Air vents 142 are provided along the lowermost wall of thevacuum shroud 96. - Fluid introduced into the

fill sleeve 94 is prevented from leaking therefrom into thesupply body 84 by 0-rings ring 118. 0-rings - The

tip 92 is shown in its closed position in Fig. 2 with thetip 92 being biased by thespring 122 into engagement with sealing O-ring 118 mounted at thefill end 144 of thefill sleeve 94. - With reference to Figs. 3A-H, these will now be described the operation of the

nozzle assembly 30. Fig. 3A corresponds to the nozzle fill assembly in the position it is in Fig. 2, i.e. before the nozzle assembly has engaged acontainer 14. - In Fig. 3B the nozzle comprising the

supply sleeve 94 and thetip 92 are just about to enter acontainer 14. Note that the nozzle is held by thenozzle star 50 and nozzle guide 72. Because of the long length of the nozzle, thenozzle star 50 is of great assistance in insuring that the nozzle goes into acontainer 14, expecially one with a narrow neck. - As shown in Fig. 3C, as the

nozzle assembly 30 is lowered, thevacuum shroud 96 seats against the top of thecontainer 14. Thesleeve 94,rod 90 andtip 92 are axially slideable relative to the shroud. Thus, thetip 92 and thesleeve 94 move downwardly into thecontainer 14 and continue downward movement as shown in Fig. 3D. No filling has yet occurred because thetip 92 is in tight engagement with sealingorifice 118 under the force of the biasingspring 122. - In Fig. 3E fill begins. The

lower split collar 126 seats against the top of thevacuum shroud 96, preventing thesleeve 94 from continuing its downward movement. However, thetip 92 continues to move downwardly and is vertically displaced relative to the sleeve, thereby allowing liquid to flow into thecontainer 14. Thus, no liquid enters into thecontainer 14 until thefill tip 144 of the sleeve is proximate to the bottom of the container. This greatly reduces sudsing and foaming that would occur if the nozzle were opened at the top and lowered to the bottom. - It should be noted that air vents 142 are open as the

tip 92 enters thecontainer 14, i.e., in Fig. 3C, so that air can be vented out of thecontainer 14 as liquid is placed therein. It should also be noted that because thetip 92 is vertically displaced from thevacuum shroud 96, there is no vacuum at thetip 140 because thevent grooves 132 and thevent cross hole 134 are no longer in register. No vacuum loss occurs because of 0-rings - As shown in Fig. 3E, the

latch 100 catches the bottom of the spring splitcollar 124 as thespring 122 is compressed. This holds thefill sleeve 94 and thetip 92 axially displaced relative to each other until the latch is released so that the nozzle remains in an open position. The latch is held in place by a spring 110 (Figure 2). - In Figs. 3F and 3G, the nozzle is being raised from the bottom of the container toward the top of the container. The rate at which the nozzle is raised is sufficiently slow that the fill tip remains below the liquid level in the container to avoid foaming and sudsing.

- After the

container 14 is filled with liquid, as shown in Fig. 3G, the latch is released by a release wheel 146 (Fig. 4) that is supported by thecam 24. This releases thetip 92 to move into the position shown in Figs. 2, 3A and 3H, thereby closing the nozzle. - This also moves the

vent cross hole 134 into register with thevent groove 132 so that there is a vacuum at thetip orifice 140. Any drops of liquid left on the tip flow toward the tip orifice due to the bottom slanted surface of the tip and are removed therefrom by the vacuum. This prevents drops of liquid from falling onto the containers and the machinery during use. - The vertical position of each

nozzle assembly 30 varies as the nozzle assembly rotates with themain sprocket 18 due to thecam follower 32 attached to thesupport rod 28 following the vertical position of the top of thecam 24. - In Fig. 4, the nozzle assembly positions as shown in Figs. 3 A-H are provided. For example, directly above the

infeed star assembly 40 are letters A, B and C in Fig. 4 indicating that at the infeed star assembly, the nozzle assembly moves from the position shown in Fig. 3A to the position shown in Fig. 3B, and then to the position shown in Fig. 3C. Likewise, at theoutfeed star assembly 42, the nozzle assembly moves from the position shown in Fig. 3G to the position shown in Fig. 3H. - Rather than lowering the nozzle assembly, it is possible to raise the container being filled.

- As shown in Fig. 4, the

cam 24 is provided with an adjustable cam step 148 so that the machine can be used for filling containers to different head spacings. - Preferably the air vents 142 are sized so that the volumetric rate at which air is forced from a container is less than the volumetric rate at which a container is filled with liquid. For example, when filling a 0.83 litre (128 U.S. fluid ounce) container at a rate of 15 litres per minute (4 gallons per minute), the air vents can be rectangular, 1.63 mm (0.064 inch) by 3.43 mm (0.135 inch) and 25.4 mm (1 inch) long. This volumetric rate condition can be met because no vacuum is pulled insider the container when filling. By satisfying this condition, flexible containers, and particularly plastic containers, tend to bulge. This allows containers to be filled leaving more headroom between the top of the liquid in the container and the top of the container. The more headroom that is allowed, the faster the filling rate that can be obtained.

- Preferably, the vacuum is not used for withdrawing any excess liquid from the container, which could cause an inaccuracy. It is only used to remove drops from the tip which could contaminate the machinery or the container.

- A machine according to the present invention has many advantages. It permits rapid and accurate fill of containers, even with foamy and sudsy liquids due to the use of the bottom open/top close nozzle assembly. Because of the nozzle star, the flexing elongated nozzle assembly can be used even with narrow neck containers and no dripping centering bells are needed. The anti-drip nozzle tip helps prevent fouling of machinery which can result in inaccurate fills and substantial dowmtime. Since the nozzle is almost completely withdrawn from the container before filling is complete, the volume occupied by the nozzle is minimized. This allows the containers to appear to be almost completely filled. Bottles that appear full sell better on shelves than low fills - a great marketing advantage.

- Although the present invention has been described in considerable detail with reference to certain preferred versions thereof, other versions are possible. For example, the

main sprocket 18 can be replaced with a plate having a roller chain tightly stretched around its periphery with thedrive gear 22 directly engaging the chain. Also, thecam 26 can be supported by vertical rods connected to an overhead frame rather than thering 26. Also, rather than using a bi-acting piston, any pre-measuring device or pump can be used. Therefore, the spirit and scope of the appended claims should not necessarily be limited to the description of the preferred versions thereof.

Claims (12)

1. A filling nozzle assembly for filling a container comprising:

a) an elongated fill sleeve having a first end for insertion into the container and for introducing liquid into the container;

b) means for introducing liquid into the fill sleeve;

c) a fill tip at the first end of the fill sleeve and axially slidable (i) to an open position relative to the sleeve for opening the first end of the sleeve, and (ii) to a closed position relative to the sleeve for closing the first end of the sleeve;

d) means biasing the fill tip into the closed position to prevent liquid from flowing out of the fill sleeve;

e) means for lowering the fill sleeve and fill tip toward the bottom of the container;

f) means for raising the fill sleeve and fill tip out of the container;

g) means preventing the sleeve from being lowered to a position proximate to the bottom of the container, the preventing means not interfering with the tip being lowered to a position proximate to the bottom of the container so that the tip can be axially displaced relative to the sleeve to the open position, thereby opening the first end of the sleeve against the force of the biasing means;

h) latch means maintaining the tip in the open position as the sleeve and tip are raised from the bottom of the container; and

i) means for releasing the latch means as the sleeve is raised to the top of the container by the raising means.

2. A machine for filling a plurality of containers simultaneously with a liquid comprising a rotary filler table for supporting the containers during filling, a series of individual filling nozzle assemblies as defined in claim 1 mounted radially above said table for movement relatively between raised, inactive positions, and lowered filling positions.

3. The filling nozzle assembly of any one of the preceding claims wherein the lower surface of the fill tip is slanted downwardly toward the axial centerline of the assembly.

4. The filling nozzle assembly of any one of the preceding claims in which the tip includes a vacuum vent that is operational only when the tip is in a position closing the first end of the fill sleeve.

5. The assembly of any one of the preceeding claims further including a vacuum shroud mounted on the sleeve and axially displaceable relative thereto with the shroud remaining at the top at the container as the fill tip and fill sleeve are lowered into the container, the shroud including air vent means for venting air from the container as it is filled with liquid, the air vent means being sized so that the volumetric rate at which liquid is introduced into the container is greater than the volumetric rate at which air can be vented from the container through the air vent.

6. A method for filling a container with a liquid comprising:

a) lowering a fill sleeve having a fill port adjacent its end into the container without introducing any liquid into the container before the fill port is proximate to the bottom of the container;

b) when the fill port is proximate to the bottom of the container,starting the introduction of liquid into the container through the fill ports;

c) continuously introducing liquid into the container through the fill port while simultaneously raising the fill sleeve so that the fill port is below the top of the liquid in the container, the liquid being introduced into the container in a controlled volume by a metering piston; and

d) stopping the introduction of the liquid into the container when the fill sleeve is raised to a position so that the fill port is almost to the desired liquid level in the container.

7. The method of claim 6 in which the fill port includes closure means and wherein the step of introducing the liquid comprises opening the closure means substantially simultaneously with introducing the liquid into the container with the piston.

8. The method of claims 6 or 7 including the step of establishing a vacuum proximate to the end of the sleeve only when introduction of liquid into the container is stopped.

9. The method of claims 6, 7 or 8 including the step of venting air from the container as it is filled with liquid at a volumetric rate less than the volumetric rate at which liquid is introduced into the container.

10. A filling nozzle assembly for filling a container comprising:

a) a fill sleeve having a first end for insertion into the container and for introducing liquid into the container;

b) means for introducing liquid into the fill sleeve;

c) a fill tip at the first end of the fill sleeve and axially slidable relative thereto for opening and closing the first end of the fill sleeve,

the lower surface of the fill tip being slanted downwardly toward the axial centerline of the tip, the tip including a vacuum vent at its lowermost portion for removing liquid drops from the tip.

the lower surface of the fill tip being slanted downwardly toward the axial centerline of the tip, the tip including a vacuum vent at its lowermost portion for removing liquid drops from the tip.

11. A filling nozzle assembly for filling a container comprising:

a) a fill sleeve having a first end for insertion into the container and for introducing liquid into the container;

b) means for introducing liquid into the . fill sleeve;

c) a fill tip at the first end of the fill sleeve and axially slidable relative'thereto for opening and closing the first end of the fill sleeve,

the tip including a vacuum vent that is operational only when the tip is in a position closing the first end of the fill sleeve.

the tip including a vacuum vent that is operational only when the tip is in a position closing the first end of the fill sleeve.

12. A machine for filling a plurality of containers with liquid comprising:

a) means for holding the containers as the containers are filled;

b) container filling means comprising a plurality of filler nozzles for filling the containers with liquid, the container filling means including means for inserting a filler nozzle into an emplty bottle held by the container holding means; and

c) means for holding the filler nozzles as the filler nozzles are inserted into the empty containers, the nozzle holding means being located above and proximate to the container holding means.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US41750582A | 1982-09-13 | 1982-09-13 | |

| US417505 | 1982-09-13 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0103484A2 true EP0103484A2 (en) | 1984-03-21 |

| EP0103484A3 EP0103484A3 (en) | 1984-05-02 |

Family

ID=23654280

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83305347A Withdrawn EP0103484A3 (en) | 1982-09-13 | 1983-09-13 | Filling machine for foaming liquids |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0103484A3 (en) |

| JP (1) | JPS5984790A (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0166803A1 (en) * | 1984-07-05 | 1986-01-08 | WST Maschinen- und Apparatebau GmbH | Method and device for the bottom-filling of a container |

| US5001550A (en) * | 1988-11-11 | 1991-03-19 | General Electric Co. | Quadruplex encoder and decoder for EDTV system |

| EP0906888A1 (en) * | 1997-09-18 | 1999-04-07 | SEZ Semiconductor-Equipment Zubehör für die Halbleiterfertigung AG | Device for preventing dripping of liquid from a dispensing orifice |

| EP2141115A1 (en) * | 2008-07-01 | 2010-01-06 | Krones AG | Device for filling viscous media |

| US7762430B2 (en) | 2002-12-23 | 2010-07-27 | Deutsche Sisi-Werke Gmbh & Co. Betriebs Kg | Closing element with outlet channel extending in funnel-like manner |

| CN109019487A (en) * | 2018-09-03 | 2018-12-18 | 平顶山市绿禾农业科技开发有限公司 | A kind of Anti-spill fungicide bottle placer |

| CN111453070A (en) * | 2020-04-09 | 2020-07-28 | 马玉春 | A ordinary pressure filling equipment for even filling of medicine |

| WO2021053297A1 (en) * | 2019-09-19 | 2021-03-25 | Pep Technologies | Method and machine for filling a container to a desired liquid level |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0523518Y2 (en) * | 1987-08-12 | 1993-06-16 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3056436A (en) * | 1959-06-24 | 1962-10-02 | Cherry Burrell Corp | Filling head for filling machines |

-

1983

- 1983-09-13 EP EP83305347A patent/EP0103484A3/en not_active Withdrawn

- 1983-09-13 JP JP16911983A patent/JPS5984790A/en active Pending

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0166803A1 (en) * | 1984-07-05 | 1986-01-08 | WST Maschinen- und Apparatebau GmbH | Method and device for the bottom-filling of a container |

| US5001550A (en) * | 1988-11-11 | 1991-03-19 | General Electric Co. | Quadruplex encoder and decoder for EDTV system |

| EP0906888A1 (en) * | 1997-09-18 | 1999-04-07 | SEZ Semiconductor-Equipment Zubehör für die Halbleiterfertigung AG | Device for preventing dripping of liquid from a dispensing orifice |

| US6056208A (en) * | 1997-09-18 | 2000-05-02 | Sez Semiconductor-Equipment Zubehor Fur Die Halbleiterfertigung Ag | Apparatus for preventing dripping from conduit openings |

| US7762430B2 (en) | 2002-12-23 | 2010-07-27 | Deutsche Sisi-Werke Gmbh & Co. Betriebs Kg | Closing element with outlet channel extending in funnel-like manner |

| EP2141115A1 (en) * | 2008-07-01 | 2010-01-06 | Krones AG | Device for filling viscous media |

| US8424575B2 (en) | 2008-07-01 | 2013-04-23 | Krones Ag | Apparatus for bottling viscous media |

| CN109019487A (en) * | 2018-09-03 | 2018-12-18 | 平顶山市绿禾农业科技开发有限公司 | A kind of Anti-spill fungicide bottle placer |

| WO2021053297A1 (en) * | 2019-09-19 | 2021-03-25 | Pep Technologies | Method and machine for filling a container to a desired liquid level |

| FR3101074A1 (en) * | 2019-09-19 | 2021-03-26 | Pep Technologies | Method and machine for filling a container to a desired level of liquid |

| US11745992B2 (en) | 2019-09-19 | 2023-09-05 | Pep Technologies | Method and machine for filling a container to a desired liquid level |

| CN111453070A (en) * | 2020-04-09 | 2020-07-28 | 马玉春 | A ordinary pressure filling equipment for even filling of medicine |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS5984790A (en) | 1984-05-16 |

| EP0103484A3 (en) | 1984-05-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6321677B2 (en) | Container filling machine and container filling method | |

| US20080271812A1 (en) | Rotary filling machine for filling containers with liquids | |

| AU2002211780B2 (en) | Process of bulk filling | |

| US3460589A (en) | Method and apparatus for filling containers with carbonated liquid | |

| GB2220931A (en) | Method and apparatus for filling bottles or the like in counter-pressure filling machines | |

| US11655132B2 (en) | Apparatus for filling a container with a filling product | |

| CA1092557A (en) | Syrup feed system for drink distribution apparatus of the after-mixing type | |

| EP0103484A2 (en) | Filling machine for foaming liquids | |

| US3578038A (en) | Receptacle filling method | |

| AU2002211780A1 (en) | Process of bulk filling | |

| US5040354A (en) | Arrangement for cleaning capping mechanisms of a rotary-type capping machine | |

| US1965246A (en) | Filling apparatus | |

| US4317475A (en) | Liquid filling and level sensing apparatus | |

| US3892264A (en) | Method and apparatus for filling bottles | |

| AU730267B2 (en) | Machine and method for filling containers, in particular bottles | |

| US3580299A (en) | Container filling device | |

| US3105525A (en) | Machine and method for filling containers | |

| US3731716A (en) | Drawback sleeve slide valve | |

| US2232273A (en) | Measuring container filling apparatus | |

| DE3069359D1 (en) | Filling machine and method for automatically filling bottles with high purity liquid | |

| US3548891A (en) | Method and apparatus for filling receptacles | |

| US3404713A (en) | Container filling apparatus | |

| US4750311A (en) | Dispensing head for batching operations | |

| US3330310A (en) | Carton filling apparatus | |

| US2172102A (en) | Container filling machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19841018 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19860402 |