EP0061973B1 - Dosierventil für Aerosolbehälter mit Abgabe in umgekehrter Lage - Google Patents

Dosierventil für Aerosolbehälter mit Abgabe in umgekehrter Lage Download PDFInfo

- Publication number

- EP0061973B1 EP0061973B1 EP82400566A EP82400566A EP0061973B1 EP 0061973 B1 EP0061973 B1 EP 0061973B1 EP 82400566 A EP82400566 A EP 82400566A EP 82400566 A EP82400566 A EP 82400566A EP 0061973 B1 EP0061973 B1 EP 0061973B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rod

- valve

- opening

- sealing ring

- container

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000000443 aerosol Substances 0.000 title 1

- 239000003380 propellant Substances 0.000 claims description 6

- 238000006073 displacement reaction Methods 0.000 claims description 2

- 238000007789 sealing Methods 0.000 claims 8

- 239000000047 product Substances 0.000 description 13

- 238000005259 measurement Methods 0.000 description 4

- 239000007789 gas Substances 0.000 description 3

- 125000006850 spacer group Chemical group 0.000 description 3

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- 239000002775 capsule Substances 0.000 description 2

- 239000003292 glue Substances 0.000 description 1

- 239000012263 liquid product Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 238000010112 shell-mould casting Methods 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/44—Valves specially adapted for the discharge of contents; Regulating devices

- B65D83/52—Metering valves; Metering devices

Definitions

- the present invention relates to a metering valve, of the type adaptable to a pressurized container, intended to contain a product to be sprayed, containing a propellant gas in solution under pressure, and allowing by pressing a button to release a determined quantity of product.

- a valve of this type is described in particular in French patent 1 287 373 in the name of Mr. Lucien Guillou for "Improvements to metering valves " .

- the valve described in this patent is intended to operate when the container is in the upright position, with the opening at the top.

- the subject of the present invention is in particular a valve of the above type, operating in the inverted position, and making it possible to dispense more precise doses, without variation of the quantity delivered on each expulsion until the bottle is exhausted, and also to allow filling the bottle in better conditions.

- Valves intended for operation with the container in the inverted position are described in documents US-A-3,394,851 (Gorman) and FR-A-2,403,833 (Glaxo).

- the device of the American patent is intended for an insoluble gas, such as nitrogen, contrary to the present invention.

- the return spring of this valve is placed towards the outside of the container, which lengthens the outlet path of the product to be sprayed, and imposes larger dimensions on the valve, which limits its applications.

- FR-A-2 403 833 the return spring of the valve is located in the bottom of the valve, and it follows that the filling of the measurement chamber can be hampered.

- the subject of the invention is a valve of the type in question, in which the return spring of the valve is placed at the bottom of the valve, but in which perfect filling of the measuring chamber is ensured during the entire use of the container. .

- the invention particularly relates to an improvement to the valve described in document FR-A-2 403 833, that is to say a valve intended to be mounted in the opening of a pressurized container, to contain a product to be sprayed containing a propellant in solution under pressure, and to expel precise doses of product when the container is kept in the inverted position with the opening down.

- the valve comprises a valve body of tubular shape, said body forming at its upper part a measurement chamber disposed near the opening of the container, delimited by a wall of generally cylindrical shape, two radial walls constituted by an annular seal greater than central opening and a lower ring seal with central opening, and an axial valve stem extending through the seals and having an upper extension extending outside the valve.

- the rod has an extra thickness between the joints making it possible to close the opening of the lower joint, the rod extending downwards by a thin part passing through the opening of the lower joint and a guide part, the upper part of the rod comprising an axial channel communicating with the outside via a passage, the passage being able by displacement of the rod, to come from one or the other of the sides of the upper seal.

- Said body further forms at its lower part a tubular housing for a return spring bearing on the one hand on the bottom of said housing and on the other hand on a shoulder formed on the rod.

- the improvement consists in that the thin part of the rod is formed by substantially radial ribs which are angularly spaced in a substantially regular manner, said ribs extending in the direction of the bottom of the housing which receives the return spring, to constitute the formed shoulder. on the stem; the aforementioned housing has angularly spaced longitudinal openings in a substantially regular manner and extending over substantially the entire height separating the bottom of the aforementioned housing and the lower seal of the measurement chamber.

- the improvement also consists in that the number of the above-mentioned longitudinal openings is less than that of the above-mentioned radial ribs.

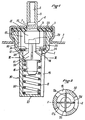

- the valve according to the invention intended to be fixed in the opening of a container such as a bottle or the like, comprises a valve body 1 fixed in a capsule 2 with the interposition of an annular seal 3.

- the capsule 2 is itself crimped onto the neck of a container, not shown, with the interposition of another seal, in a well known manner.

- a container is intended to contain a liquid product, with a pressurized gas (called propellant) soluble in the product.

- propellant pressurized gas

- the operating principle of such a metering valve is well known. It is described in the patents cited above.

- the valve body forms at its upper part a measurement chamber 13 and at its lower part a housing 30 for a return spring.

- the words upper, lower, upper or lower relate to the right position of the container, with the opening upwards.

- valve stem 4 AT the inside of the valve body is arranged a valve stem 4 of which a part 5 extends to the outside, through the seal 3.

- This stem has an axial or longitudinal channel 6 opening at the outer end of the stem and communicating with a radial passage 7.

- the rod 4 is pushed upwards by a spring 8 and comes to bear against the seal 3 by a shoulder 9.

- the passage 7 opens above the seal (possibly in the seal, but not below) so that the bottle is closed, and the product under pressure cannot exit.

- the rod 4 is extended in the interior of the container by an enlarged part or piston 11, for example of the same diameter as the shoulder 9, and an annular seal 12 is disposed at a certain distance from the piston, the central opening 31 of the gasket 12 corresponding to the diameter of the piston 11.

- the container is turned over, placing the opening with the valve at the bottom.

- a closed volume, or chamber 13 which contains a dose, the volume of which is precisely determined, of the product to be sprayed loaded with propellant dissolved under pressure.

- the opening of the passage 7 appears in the chamber 13, and the content thereof is then evacuated by the passage 7 and the channel 6, under the effect propellant which is released as a result of the drop in pressure.

- the rod 4 is released which is returned to its initial position by the return spring 8.

- the chamber 13 is then opened. To reload the dosing chamber, keep the container upside down.

- the product reaches the chamber 13 through at least one opening provided in the bottom of the valve body, below the seal 12.

- the rod 4 advantageously extends by a thinned part 14 having for example a shoulder 15 for the support of the spring.

- the rod 4 ends with a barrel 16 engaged between the turns of the spring and used for guiding and centering the rod 4.

- the thinned part 14 has dimensions such that in the rest position, the piston 11 being released from the seal 12 , the product can easily reach chamber 13.

- the thinned part 14 consists of several radial ribs 17a, 17b, 17c, 17d etc, of constant section or not and extending from the piston 11 to the shoulder 15.

- each rib has the shape clearly visible in Figure 1.

- This arrangement has the advantage of leaving an important passage for the product both during the initial filling of the bottle and during normal use.

- the ribs 17 also maintain the opening of the seal if it were to swell under the influence of the product put into circulation.

- the bottom of the valve body forms a housing 30 for the spring, and this housing has openings 19 extending over the entire available height, that is to say from a neighboring point.

- the number of openings 19 being different from the number of the ribs 17, so as to always have at least one continuous clear passage, avoiding that 'there is a rib opposite each opening.

- the valve stem 4 is in two parts: a first upper part 32 constituted by the external part 5 and the piston 11, and a second part 33 constituted by the thinned part 14, the shoulder 15 and the barrel 16.

- the two parts thus formed are easier to manufacture, with greater precision, by avoiding shell molding.

- the two parts can be assembled by any means: force fitting, with or without glue (as indicated by the dotted line 29), screwing, welding, etc.

- spikes 25 are provided on the valve body 1 and / or on the spacer 23.

- valve body 1 may have radial ribs 26 (left half of Figure 1) which mechanically strengthen the chamber, especially when it is very hollow, to expel large doses.

- the ribs also serve to hold the seal 12 in place. By eliminating the deformation of the chamber, the presence of the ribs makes it possible to have more precise doses.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Nozzles (AREA)

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82400566T ATE8235T1 (de) | 1981-03-30 | 1982-03-29 | Dosierventil fuer aerosolbehaelter mit abgabe in umgekehrter lage. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8106272 | 1981-03-30 | ||

| FR8106272A FR2502732B1 (fr) | 1981-03-30 | 1981-03-30 | Valve doseuse a position inversee pour recipient d'aerosol |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0061973A1 EP0061973A1 (de) | 1982-10-06 |

| EP0061973B1 true EP0061973B1 (de) | 1984-07-04 |

Family

ID=9256749

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82400566A Expired EP0061973B1 (de) | 1981-03-30 | 1982-03-29 | Dosierventil für Aerosolbehälter mit Abgabe in umgekehrter Lage |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4413755A (de) |

| EP (1) | EP0061973B1 (de) |

| AT (1) | ATE8235T1 (de) |

| DE (1) | DE3260319D1 (de) |

| ES (1) | ES272070Y (de) |

| FR (1) | FR2502732B1 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7234460B2 (en) | 2002-09-06 | 2007-06-26 | 3M Innovative Properties Company | Metering valve for a metered dose inhaler providing consistent delivery |

| US7299801B2 (en) | 2002-09-06 | 2007-11-27 | 3M Innovative Properties Company | Metering valve for a metered dose inhaler providing consistent delivery |

Families Citing this family (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8330851D0 (en) * | 1983-11-18 | 1983-12-29 | Fisons Plc | Device |

| GB8503553D0 (en) * | 1985-02-12 | 1985-03-13 | Bespak Plc | Valves for pressurised dispensing containers |

| US4819834A (en) * | 1986-09-09 | 1989-04-11 | Minnesota Mining And Manufacturing Company | Apparatus and methods for delivering a predetermined amount of a pressurized fluid |

| FR2615172B1 (fr) * | 1987-05-11 | 1989-08-18 | Valois | Valve aerosol doseuse utilisable en position inversee |

| FR2615173B1 (fr) * | 1987-05-13 | 1989-08-18 | Valois | Valve doseuse pour liquide charge d'un propulseur liquide ou gaz liquefie, utilisable en position inversee |

| US5231983A (en) * | 1990-01-03 | 1993-08-03 | Minnesota Mining And Manufacturing | Method of and apparatus for the aerosol administration of medication |

| US5450336A (en) * | 1991-03-05 | 1995-09-12 | Aradigm Corporation | Method for correcting the drift offset of a transducer |

| US5404871A (en) * | 1991-03-05 | 1995-04-11 | Aradigm | Delivery of aerosol medications for inspiration |

| US5469750A (en) * | 1991-03-05 | 1995-11-28 | Aradigm Corporation | Method and apparatus for sensing flow in two directions and automatic calibration thereof |

| ES2179068T3 (es) * | 1991-03-05 | 2003-01-16 | Aradigm Corp | Metodo y dispositivo para corregir el desplazamiento de deriva de un detector de presion de flujo. |

| US5392768A (en) * | 1991-03-05 | 1995-02-28 | Aradigm | Method and apparatus for releasing a controlled amount of aerosol medication over a selectable time interval |

| GB2311982B (en) * | 1996-04-09 | 2000-03-08 | Bespak Plc | Improvements in or relating to valves for dispensers |

| US6092698A (en) * | 1999-03-30 | 2000-07-25 | Precision Valve Corporation | High volume aerosol valve |

| FR2798367B1 (fr) * | 1999-09-15 | 2001-11-23 | Valois Sa | Joint de soupape pour valve doseuse |

| EP1461270A2 (de) * | 2001-12-31 | 2004-09-29 | 3M Innovative Properties Company | Ventilschaft für die verwendung in einem dosierventil |

| WO2003057594A1 (en) * | 2001-12-31 | 2003-07-17 | 3M Innovative Properties Company | Gasket for use in a metering valve that limits seal intrusion |

| US6832704B2 (en) | 2002-06-17 | 2004-12-21 | Summit Packaging Systems, Inc. | Metering valve for aerosol container |

| DE10229185A1 (de) * | 2002-06-28 | 2004-02-05 | Thomas Gmbh | Druckregulierventil |

| AU2003286786A1 (en) * | 2002-10-30 | 2004-06-07 | Nektar Therapeutics | Increased dosage metered dose inhaler |

| DE102004034626A1 (de) * | 2004-06-17 | 2006-01-12 | Seaquist Perfect Dispensing Gmbh | Dosierventil und Vorrichtung zur Abgabe einer vorzugsweise kosmetischen Flüssigkeit |

| GB0505082D0 (en) * | 2005-03-11 | 2005-04-20 | Alticosalian Gerald H | A device for storing and dispensing liquid |

| FR2888822B1 (fr) * | 2005-07-21 | 2010-04-02 | Valois Sas | Valve de distribution de produit fluide |

| FR2917073B1 (fr) * | 2007-06-11 | 2012-10-05 | Valois Sas | Valve de distribution de produit fluide et dispositif de distribution de produit fluide comportant une telle valve |

| US9242256B2 (en) * | 2007-07-17 | 2016-01-26 | S.C. Johnson & Son, Inc. | Aerosol dispenser assembly having VOC-free propellant and dispensing mechanism therefor |

| GB0719416D0 (en) * | 2007-10-05 | 2007-11-14 | 3M Innovative Properties Co | Metered dose valve |

| FR2924101B1 (fr) * | 2007-11-26 | 2009-12-04 | Valois Sas | Valve amelioree |

| US8087548B2 (en) * | 2008-05-14 | 2012-01-03 | S.C. Johnson & Son, Inc. | Spray products with particles and improved valve for inverted dispensing without clogging |

| FR3049275B1 (fr) * | 2016-03-23 | 2019-07-19 | Aptar France Sas | Valve doseuse et dispositif de distribution de produit fluide comportant une telle valve |

| GB201702406D0 (en) | 2017-02-14 | 2017-03-29 | Norton (Waterford) Ltd | Inhalers and related methods |

| GB201702408D0 (en) | 2017-02-14 | 2017-03-29 | Norton (Waterford) Ltd | Inhalers and related methods |

| GB201702407D0 (en) | 2017-02-14 | 2017-03-29 | Norton (Waterford) Ltd | Inhalers and related methods |

| FR3065891B1 (fr) * | 2017-05-05 | 2021-12-24 | Aptar France Sas | Valve doseuse et dispositif de distribution de produit fluide comportant une telle valve. |

| FR3131738B1 (fr) | 2022-01-07 | 2024-03-08 | Aptar France Sas | Valve doseuse avec chambre de dosage améliorée |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2886217A (en) * | 1957-05-20 | 1959-05-12 | Riker Laboratories Inc | Dispensing device |

| FR1292114A (fr) * | 1961-06-14 | 1962-04-27 | C I M A Costruzione Impianti E | Soupape doseuse à poussoir pour l'émission de liquides sous pression |

| US3332626A (en) * | 1965-06-21 | 1967-07-25 | Meshberg Philip | Dispensing valve |

| US3394851A (en) * | 1965-09-20 | 1968-07-30 | Sterling Drug Inc | Metered aerosol valve for use with compressed gas |

| US3447551A (en) * | 1967-06-14 | 1969-06-03 | Arthur R Braun | Upside-downside aerosol dispensing valve |

| US3521859A (en) * | 1968-05-31 | 1970-07-28 | Erich W Gronemeyer | Valve |

| US3511418A (en) * | 1968-07-29 | 1970-05-12 | Risdon Mfg Co | Variable capacity aerosol metering valve |

| US3591059A (en) * | 1969-03-10 | 1971-07-06 | Riker Laboratories Inc | Metering valve with air shutoff |

| GB2086845B (en) * | 1977-09-22 | 1982-12-08 | Glaxo Group Ltd | Metering valve |

-

1981

- 1981-03-30 FR FR8106272A patent/FR2502732B1/fr not_active Expired

-

1982

- 1982-03-29 ES ES1982272070U patent/ES272070Y/es not_active Expired

- 1982-03-29 EP EP82400566A patent/EP0061973B1/de not_active Expired

- 1982-03-29 DE DE8282400566T patent/DE3260319D1/de not_active Expired

- 1982-03-29 AT AT82400566T patent/ATE8235T1/de not_active IP Right Cessation

- 1982-03-30 US US06/363,748 patent/US4413755A/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7234460B2 (en) | 2002-09-06 | 2007-06-26 | 3M Innovative Properties Company | Metering valve for a metered dose inhaler providing consistent delivery |

| US7299801B2 (en) | 2002-09-06 | 2007-11-27 | 3M Innovative Properties Company | Metering valve for a metered dose inhaler providing consistent delivery |

| US7748378B2 (en) | 2002-09-06 | 2010-07-06 | 3M Innovative Properties Company | Metering valve for a metered dose inhaler providing consistent delivery |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2502732B1 (fr) | 1985-08-30 |

| DE3260319D1 (en) | 1984-08-09 |

| ES272070U (es) | 1983-10-16 |

| FR2502732A1 (fr) | 1982-10-01 |

| ATE8235T1 (de) | 1984-07-15 |

| US4413755A (en) | 1983-11-08 |

| ES272070Y (es) | 1984-04-16 |

| EP0061973A1 (de) | 1982-10-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0061973B1 (de) | Dosierventil für Aerosolbehälter mit Abgabe in umgekehrter Lage | |

| EP0694483B1 (de) | Behälter zur Aufnahme von mindestens zwei Produkten, zur deren Mischung sowie zur Abgabe dieser Mischung | |

| EP0549049B1 (de) | Abgabevorrichtung für wenigstens ein flüssiges Produkt | |

| EP0551782B1 (de) | In umgekehrter Lage verwendbares Dosierventil | |

| EP0626210B1 (de) | Verteilungseinrichtung einer bestimmten Dosis eines flüssigen oder pastösen Produktes | |

| EP0937505B1 (de) | Verpackungs- und Abgabeeinheit und Verwendung einer solchen Einheit zur Verpackung von kosmetischen, pharmazeutischen oder dermopharmazeutischen Produkten | |

| EP1044893B1 (de) | Vorrichtung zum unmittelbaren Vermischen von mindestens zwei Produkten, von denen eines ein Pulver ist | |

| CA2163357C (fr) | Dispositif doseur destine a delivrer des doses unitaires constantes | |

| CA2262135C (fr) | Ensemble de conditionnement et de distribution d'un produit liquide | |

| FR2615173A1 (fr) | Valve doseuse pour liquide charge d'un propulseur liquide ou gaz liquefie, utilisable en position inversee | |

| EP0526811B1 (de) | Aufbewahrungs- und Ausgabevorrichtung für flüssige oder pastöse Produkte | |

| EP0823389B1 (de) | Druckvorrichtung mit einem geschlitzten Stück aus Schaumstoffmaterial als Druckmittel | |

| FR2640942A1 (en) | Container of the aerosol type for delivering, in the form of a foam, metered quantities of product, particularly of food product | |

| CH422561A (fr) | Distributeur-doseur | |

| FR2559567A1 (fr) | Valve doseuse pour recipient contenant un produit sous pression | |

| EP0406134A1 (de) | Behälter mit elastischer Flasche | |

| EP0312474B1 (de) | Automatischer Spender für pastöse Massen | |

| EP0591043A1 (de) | Mit Druckgas wiederfüllbarer Aerosolverpackungsbehälter | |

| FR2541244A1 (fr) | Dispositif distributeur de doses de substance liquide | |

| EP0605275B1 (de) | Anordnung zur Zerstäubung einer Flüssigkeit mit einer Vordruckpumpe | |

| EP0444990B1 (de) | Abgabevorrichtung für flüssige oder pastöse Produkte, insbesondere für kosmetische Produkte | |

| EP0251939A1 (de) | Verdampfvorrichtung für Duftstoffe | |

| CH545730A (en) | Two part prepn storage container - esp for pharmaceuticals with components separately stored until required for use | |

| FR2731684A1 (fr) | Dispositif de stockage et de distribution d'un produit, tel un produit cosmetique ou un parfum | |

| BE682750A (de) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19821014 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 8235 Country of ref document: AT Date of ref document: 19840715 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3260319 Country of ref document: DE Date of ref document: 19840809 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19900222 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19900228 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19900312 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19900327 Year of fee payment: 9 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19900331 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19910329 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19910330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19910331 Ref country code: CH Effective date: 19910331 Ref country code: BE Effective date: 19910331 |

|

| BERE | Be: lapsed |

Owner name: ETS VALOIS Effective date: 19910331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19911001 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82400566.4 Effective date: 19911009 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20010222 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20010313 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20020328 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Effective date: 20020326 |