EP0050102A1 - An anti-corrosive treatment method for sheet steel and similar articles - Google Patents

An anti-corrosive treatment method for sheet steel and similar articles Download PDFInfo

- Publication number

- EP0050102A1 EP0050102A1 EP81850178A EP81850178A EP0050102A1 EP 0050102 A1 EP0050102 A1 EP 0050102A1 EP 81850178 A EP81850178 A EP 81850178A EP 81850178 A EP81850178 A EP 81850178A EP 0050102 A1 EP0050102 A1 EP 0050102A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- treatment method

- corrosive treatment

- fibers

- sheet steel

- adhesive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/02—Processes for applying liquids or other fluent materials performed by spraying

- B05D1/12—Applying particulate materials

- B05D1/14—Flocking

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23F—NON-MECHANICAL REMOVAL OF METALLIC MATERIAL FROM SURFACE; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL; MULTI-STEP PROCESSES FOR SURFACE TREATMENT OF METALLIC MATERIAL INVOLVING AT LEAST ONE PROCESS PROVIDED FOR IN CLASS C23 AND AT LEAST ONE PROCESS COVERED BY SUBCLASS C21D OR C22F OR CLASS C25

- C23F15/00—Other methods of preventing corrosion or incrustation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D2202/00—Metallic substrate

Definitions

- the subject invention concerns an anti--corrosive treatment method for sheet steel, particularly for application in cars, boats, ships and building constructions.

- Prior-art anti-corrosive treatment methods used for cars suffer from a number of disadvantages.

- the prior-art anti-corrosive protection layers have a very limited life, and the treatment therefore must be repeated at regular intervals during the serviceable life of the car itself, usually once a year.

- the extra costs that car owner incur by the necessity of such frequent treatments are quite considerable.

- the protective effect of the treatments is limited, since none of the treatment methods known provides complete rust protection.

- the majority of the anti-rust preparations used hitherto are tacky and consequently messy to work with. Grit and other particles also easily adhere to the applied layer.

- the purpose of the subject invention is to provide a novel anti-corrosive treatment, which is particularly suitable for sheet steel for cars and which does not suffer from any of the drawbacks outlined above.

- the method in accordance with the invention is characterised by applying on the sheet steel surface intended to be exposed to the anti-corrosive treatment a layer ot a Loft and tough adhesive, and by applying flocking fibers on the adhesive layer by means of an electrostatic application method known per se.

- the treatment in accordance with the invention provides complete protection and the protective effects have a duration essentially corresponding to the serviceable life of the car.

- the treatment operation is easy to carry out in practice and the resulting protective layer is neither tacky nor messy. Dirt, grit or other minute particles do not tend to stick or adhere to the protective layer.

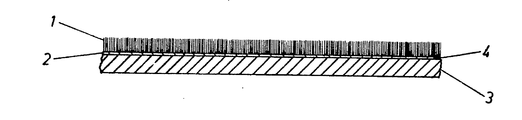

- a layer of flocking fibers 1 has been applied on the surface 4 of the sheet steel 3 with the aid of an adhesive 2.

- the flocking fibers 1 are anchored to the backing in a manner known per se.

- the surface of the sheet steel is coated with a layer of an adhesive 2.

- the sheet steel 3 with the fibers 1 thereon is introduced into an electrostatically magnetic field in which the steel sheet has the positive polarity and the flocking fibers the negative polarity.

- the fibers are flung onto the steel surface and are secured thereto standing on end.

- the method of applying and securing flocking fibers is known and used in various fields, such as in interior decoration, for noise-reducing purposes, heat--insulating purposes, just to mention some of numerous fields of application.

- fhe adhesive used must be soft and tough in order to ensure that no cracks occur in the protective layers when the sheet is exposed to working.

- Adhesives that have proved suitable in this respect are acrylic dispersion adhesives. Such adhesives meet the demands on function and usefulness when applied on sheet steel used for cars. Acrylic dispersion adhesives have not either any tendencies to crack when the sheets on which they are applied are exposed to bending operations.

- the flocking fibers should be short, and suitable lengths for the intended purpose have proved to be lengths in the range of between 0.3 and 0.8 millimeters.

- Nylon fibers are highly suitable on account of the wearing strength of such fibers.

- Ine ⁇ oft surface imparted in accordance with the invention has the added effect that particles bounce away from the sheet without scratching the steel or the acrylic dispersion layer thereon.

- the method described in the afore-going has proved to provide a complete anti-corrosive protection coating that possesses excellent wear resistancy. In addition, it neutralizes galvanic flow.

- the protective coating is easy to keep clean and particles, such as dirt and grit, do not tend to stick to the coating.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Laminated Bodies (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Preventing Corrosion Or Incrustation Of Metals (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE8007113 | 1980-10-10 | ||

| SE8007113A SE8007113L (sv) | 1980-10-10 | 1980-10-10 | Forfarande for rostskyddsbehandling av stalplat och liknande |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0050102A1 true EP0050102A1 (en) | 1982-04-21 |

Family

ID=20341958

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81850178A Withdrawn EP0050102A1 (en) | 1980-10-10 | 1981-10-07 | An anti-corrosive treatment method for sheet steel and similar articles |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0050102A1 (da) |

| JP (1) | JPS5792181A (da) |

| DK (1) | DK443181A (da) |

| FI (1) | FI813118A7 (da) |

| NO (1) | NO813417L (da) |

| SE (1) | SE8007113L (da) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0220533A3 (en) * | 1985-10-30 | 1988-03-30 | Franz Josef Rath | Container for foodstuffs and process for producing the same |

| US7052741B2 (en) * | 2004-05-18 | 2006-05-30 | The United States Of America As Represented By The Secretary Of The Navy | Method of fabricating a fibrous structure for use in electrochemical applications |

| US7211298B2 (en) | 1999-08-10 | 2007-05-01 | Sumitomo Corporation | Electrostatically fiber planted steel sheet and production process therefor |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4218501A (en) * | 1979-02-14 | 1980-08-19 | Taiyo Steel Co., Ltd. | Electrostatic flock-coated metal sheet with excellent corrosion resistance and fabricability |

-

1980

- 1980-10-10 SE SE8007113A patent/SE8007113L/ not_active Application Discontinuation

-

1981

- 1981-10-07 EP EP81850178A patent/EP0050102A1/en not_active Withdrawn

- 1981-10-07 DK DK443181A patent/DK443181A/da not_active Application Discontinuation

- 1981-10-08 FI FI813118A patent/FI813118A7/fi not_active Application Discontinuation

- 1981-10-09 NO NO813417A patent/NO813417L/no unknown

- 1981-10-09 JP JP56160389A patent/JPS5792181A/ja active Pending

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4218501A (en) * | 1979-02-14 | 1980-08-19 | Taiyo Steel Co., Ltd. | Electrostatic flock-coated metal sheet with excellent corrosion resistance and fabricability |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0220533A3 (en) * | 1985-10-30 | 1988-03-30 | Franz Josef Rath | Container for foodstuffs and process for producing the same |

| US7211298B2 (en) | 1999-08-10 | 2007-05-01 | Sumitomo Corporation | Electrostatically fiber planted steel sheet and production process therefor |

| US7052741B2 (en) * | 2004-05-18 | 2006-05-30 | The United States Of America As Represented By The Secretary Of The Navy | Method of fabricating a fibrous structure for use in electrochemical applications |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS5792181A (en) | 1982-06-08 |

| DK443181A (da) | 1982-04-11 |

| SE8007113L (sv) | 1982-04-11 |

| NO813417L (no) | 1982-04-13 |

| FI813118L (fi) | 1982-04-11 |

| FI813118A7 (fi) | 1982-04-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| King | Surface treatment & finishing of aluminium | |

| EP0050102A1 (en) | An anti-corrosive treatment method for sheet steel and similar articles | |

| US3201211A (en) | Stainless steel trim member | |

| EP0040054A1 (en) | Brake disc corrosion protection | |

| US3536459A (en) | Stainless steel composite | |

| US6284059B1 (en) | Cleaning and conversion coating of hot rolled steel articles | |

| US3201210A (en) | Trim member assembly | |

| JPH06184765A (ja) | 溶融亜鉛めっき鋼材構造物の接合面滑り防止処理法 | |

| JP2533000B2 (ja) | 高耐食性表面処理鋼板 | |

| JPS6160884A (ja) | 防錆処理を施した吊橋ケ−ブル用鋼線 | |

| US4755191A (en) | Finishing of hard chromium plated products | |

| JP2000282252A (ja) | 非クロム型表面処理金属材 | |

| JPS58100691A (ja) | 高耐食性表面処理鋼板 | |

| McGaulley et al. | Flash Rusting: Characterization and Effect on Coating Performance. | |

| JPH02122056A (ja) | 合金化溶融亜鉛めっき鋼板 | |

| Wakano et al. | Cosmetic Corrosion Performance of Zinc Alloy Steel Sheets in Automotive Body | |

| West | Protection of ships' hulls | |

| Szawlowska-Wallisch et al. | Anti-Corrosion Protection of Zinc Plated Sheets With Selected Temporary Protection Agents | |

| Krup | The Durability of(Protective) Zinc-Silicate Compositions(on Metal Surfaces) | |

| JPH02228461A (ja) | 合金化処理溶融めっき鋼板及びその製造方法 | |

| Powell | CORROSION PROTECTION OF JOINTING ELEMENTS AND SMALL COMPONENTS IN THE AUTOMOBILE INDUSTRY BY MEANS OF FLUORO-POLYMER COATINGS | |

| Hostetler | Improving the service life of automotive tubing | |

| Bauer et al. | Forming Metallically Surface-Coated Bodywork Panels | |

| Lindsay | The Impact of the Zinc Layer on the Manufacture of Automotive Sheet Steel | |

| JPH0551789A (ja) | 加工後耐蝕性、ED塗装耐蝕性及び耐穴明性に優れたZn−Cr−P系有機複合めつき鋼板 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| 17P | Request for examination filed |

Effective date: 19821020 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: AB RENATUS |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19840503 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: ALM, KJELL CHRISTER |