EP0034522B1 - Machine de façonnage de caisses en carton à court temps de règlage - Google Patents

Machine de façonnage de caisses en carton à court temps de règlage Download PDFInfo

- Publication number

- EP0034522B1 EP0034522B1 EP81400174A EP81400174A EP0034522B1 EP 0034522 B1 EP0034522 B1 EP 0034522B1 EP 81400174 A EP81400174 A EP 81400174A EP 81400174 A EP81400174 A EP 81400174A EP 0034522 B1 EP0034522 B1 EP 0034522B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- printing

- machine

- cardboard

- axis

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000004519 manufacturing process Methods 0.000 title description 3

- 239000003086 colorant Substances 0.000 description 5

- 230000008878 coupling Effects 0.000 description 2

- 238000010168 coupling process Methods 0.000 description 2

- 238000005859 coupling reaction Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000007493 shaping process Methods 0.000 description 2

- 238000005406 washing Methods 0.000 description 2

- 210000001015 abdomen Anatomy 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F5/00—Rotary letterpress machines

- B41F5/24—Rotary letterpress machines for flexographic printing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F21/00—Devices for conveying sheets through printing apparatus or machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2217/00—Printing machines of special types or for particular purposes

- B41P2217/10—Printing machines of special types or for particular purposes characterised by their constructional features

- B41P2217/11—Machines with modular units, i.e. with units exchangeable as a whole

Definitions

- the present insertion relates to machines for forming and printing cardboard boxes and relates more particularly to a machine of this type on which it is possible to make a change of plate on the printers without loss of time detrimental to the performance of the machine.

- the machine of the invention does not have the drawbacks of the aforementioned devices. It is of the type (for example GB-A-637 333) according to which the printer modules are equipped with means allowing lateral translation either of the plate cylinder alone, or of the assembly formed by said plate cylinder and its device inking, and it is characterized in that it is furthermore provided with retractable means for driving the cardboard capable of being put in place when said plate cylinder is retracted laterally so as to continue to perform the driving function cardboard that it provided before its lateral retraction.

- the elements 1, 6 and 7 are conventional elements for this kind of machine so that we will not give a more detailed description. On the other hand, particular attention will be paid, with the aid of all of FIGS. 1 to 6, to the description of the printing elements which are particularly concerned with the invention.

- each printing element (4, 5) comprises two printing modules (8, 9 and 10, 11) each provided with a counterpart cylinder (12, 13, 14, 15), a plate cylinder (16, 17, 18, 19) and a conventional inking device (20, 21, 22, 23).

- each assembly consisting of a plate cylinder and its inking system can be moved laterally, by means of rollers 24 and associated rails 25 hollowed out in the base 26 of each printing element.

- Figures 1 to 3 show, by way of example, the second of these assemblies counted in the upstream-downstream direction, retracted by lateral translation, and we will therefore now give a more precise description thereof, it being understood that this description also applies to the other three.

- the printing module considered 9 comprises a structure constituted by lateral frames 27 and 28.

- a conventional set of gears with toothed wheels 29 makes it possible, in a manner known per se, to communicate with the various cylinders and drive shafts (3, 30, 31, 32, 33, 34, 35, 36) or printing (16, 18, 19) a movement in synchronism with the other elements of the cardboard processing line.

- the removable assembly constituted by the plate cylinder 17 and its conventional inking system shown diagrammatically at 21 is mounted on a separate rigid structure, comprising the uprights 37 and 38, and which can pass through the frame 28 which has an opening 39 Consequently.

- the structure (37, 38) is provided with the lateral displacement rollers 24 mentioned above.

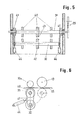

- each printing element (4, 5) further comprises, directly following, in the direction of scrolling upstream-downstream of the carton, to each printing module (8, 9 and 10, 11), a pair of 'shafts (31-31 a, 33-33a and 35-35a, 36-36a) each lined with cardboard drive discs 40 (see also Figures 5 and 6).

- Each of the lower shafts (31, 33, 35, 36) comprises at each end an oscillating lever 41 on which is mounted another drive shaft such as 32, furnished with disks 42 identical to the disks 40, and drives in rotation by the main shaft such as 33 using a conventional belt transmission 43.

- the parallel shafts (33, 32) are spaced apart by a length equal to the longitudinal component the distance separating the axis respectively of the first shaft (33) or its partner (33a) from the axis of the previous printing roller (17) or its counterpart (13).

- each plate holder cylinder, such as 16, and its inking system, such as 20, are made laterally removable, which is preferable when it is desired to make a washing the inking system.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rotary Presses (AREA)

- Making Paper Articles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8002601 | 1980-02-06 | ||

| FR8002601A FR2474952A1 (fr) | 1980-02-06 | 1980-02-06 | Machine de faconnage de caisses en carton a court temps de reglage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0034522A1 EP0034522A1 (fr) | 1981-08-26 |

| EP0034522B1 true EP0034522B1 (fr) | 1983-05-25 |

Family

ID=9238287

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81400174A Expired EP0034522B1 (fr) | 1980-02-06 | 1981-02-04 | Machine de façonnage de caisses en carton à court temps de règlage |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0034522B1 (OSRAM) |

| DE (1) | DE3160333D1 (OSRAM) |

| FR (1) | FR2474952A1 (OSRAM) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58160202A (ja) * | 1982-01-15 | 1983-09-22 | ザ・ミ−ド・コ−ポレ−シヨン | 包装機械 |

| US4449450A (en) * | 1982-07-28 | 1984-05-22 | S.A. Martin | Retractable propulsion apparatus for cardboard box printing machine |

| JPS60151037A (ja) * | 1984-01-20 | 1985-08-08 | 三菱重工業株式会社 | シングルフエ−サ |

| EP1031416B1 (en) * | 1999-02-18 | 2003-05-14 | Ward, Inc. | Flexographic printing machine and method of flexographic printing |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB647613A (OSRAM) * | 1900-01-01 | |||

| DE561429C (de) * | 1928-12-20 | 1932-10-14 | Harris Seybold Potter Company | Papierbahnfoerdervorrichtung fuer Druckmaschinen |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB637333A (en) * | 1946-10-23 | 1950-05-17 | Champlain Company Inc | Enclosed fountain gravure press |

-

1980

- 1980-02-06 FR FR8002601A patent/FR2474952A1/fr active Granted

-

1981

- 1981-02-04 EP EP81400174A patent/EP0034522B1/fr not_active Expired

- 1981-02-04 DE DE8181400174T patent/DE3160333D1/de not_active Expired

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB647613A (OSRAM) * | 1900-01-01 | |||

| DE561429C (de) * | 1928-12-20 | 1932-10-14 | Harris Seybold Potter Company | Papierbahnfoerdervorrichtung fuer Druckmaschinen |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3160333D1 (en) | 1983-07-07 |

| EP0034522A1 (fr) | 1981-08-26 |

| FR2474952A1 (fr) | 1981-08-07 |

| FR2474952B1 (OSRAM) | 1983-10-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0363662B1 (fr) | Dispositif de transport d'éléments en plaque dans une machine rotative d'impression | |

| CH643798A5 (fr) | Trieuse a plateaux mobiles. | |

| CH615864A5 (OSRAM) | ||

| EP0390689A1 (fr) | Appareil de découpage rotatif | |

| EP0132858A1 (fr) | Machine d'impression rotative multicolore pour l'impression recto-verso simultanée | |

| EP0113601B1 (fr) | Imprimeuse rotative offset à format variable | |

| EP0034522B1 (fr) | Machine de façonnage de caisses en carton à court temps de règlage | |

| FR2504451A1 (fr) | Presse rotative | |

| EP0148074B1 (fr) | Dispositif de retournement de papier pour impression verso-recto | |

| EP0013292B1 (fr) | Ecran guide-papier à guide-ruban incorporé, pour imprimante à impact | |

| CH630291A5 (fr) | Imprimeuse rotative pour l'impression en plusieurs couleurs sur des feuilles debitees d'une maniere continue. | |

| FR2501113A1 (fr) | Rotative offset a feuilles | |

| EP0443395B1 (fr) | Machine à refouler et couper en long une bande de matière qui défile | |

| EP0321360B1 (fr) | Appareil d'impression offset fonctionnant en tandem | |

| FR2639581A1 (fr) | Chariot porte-groupe d'impression pour une station d'impression dans des machines rotatives | |

| EP0453984A2 (fr) | Dispositif de taquage de feuilles | |

| FR2470746A1 (fr) | Dispositif de transport de feuilles entre deux groupes d'impression d'une machine a imprimer combinee | |

| EP0027546B1 (fr) | Dispositif d'alimentation en feuilles individuelles | |

| JP2867994B2 (ja) | プリンタの用紙スタック装置 | |

| FR2567075A1 (fr) | Dispositif de deplacement de papier pour imprimante | |

| CN219927250U (zh) | 一种书刊印刷装置 | |

| EP1525095A2 (fr) | Machine a imprimer. | |

| CH689094A5 (fr) | Trieuse de feuilles à plateaux mobiles. | |

| CH690099A5 (fr) | Imprimante à jet d'encre. | |

| FR2468469A1 (fr) | Dispositif d'impression comportant un ou plusieurs tampons disposes sur un element porteur mobile dans le sens vertical |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT |

|

| 17P | Request for examination filed |

Effective date: 19810804 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT |

|

| REF | Corresponds to: |

Ref document number: 3160333 Country of ref document: DE Date of ref document: 19830707 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20000131 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20000202 Year of fee payment: 20 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20010203 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Effective date: 20010203 |