EP0031279B1 - Two-gases burner provided with an anti-internal-inflammation device - Google Patents

Two-gases burner provided with an anti-internal-inflammation device Download PDFInfo

- Publication number

- EP0031279B1 EP0031279B1 EP19800401792 EP80401792A EP0031279B1 EP 0031279 B1 EP0031279 B1 EP 0031279B1 EP 19800401792 EP19800401792 EP 19800401792 EP 80401792 A EP80401792 A EP 80401792A EP 0031279 B1 EP0031279 B1 EP 0031279B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- lance

- handle

- piece

- welding torch

- valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000007789 gas Substances 0.000 title claims description 13

- 206010061218 Inflammation Diseases 0.000 title 1

- 238000003466 welding Methods 0.000 claims description 9

- 230000000694 effects Effects 0.000 claims description 4

- 238000007789 sealing Methods 0.000 claims description 2

- 230000036316 preload Effects 0.000 claims 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 13

- 239000001301 oxygen Substances 0.000 description 13

- 229910052760 oxygen Inorganic materials 0.000 description 13

- HSFWRNGVRCDJHI-UHFFFAOYSA-N alpha-acetylene Natural products C#C HSFWRNGVRCDJHI-UHFFFAOYSA-N 0.000 description 11

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 description 11

- 239000000203 mixture Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 4

- 238000002485 combustion reaction Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000013021 overheating Methods 0.000 description 2

- 240000008042 Zea mays Species 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 229940082150 encore Drugs 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/38—Torches, e.g. for brazing or heating

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/46—Details, e.g. noise reduction means

- F23D14/72—Safety devices, e.g. operative in case of failure of gas supply

- F23D14/82—Preventing flashback or blowback

- F23D14/825—Preventing flashback or blowback using valves

Definitions

- the present invention relates to a two-gas torch provided with an internal anti-ignition device, torch comprising a handle provided with a lance which presents at the rear a tubular nozzle defining a mixing chamber supplied by tap means. and injector means, a torch in which the internal anti-ignition device comprises a shutter which is interposed between the tap means and the injector of one of the two gases, this shutter having a fixed bearing secured to the handle and a bearing mobile formed at the rear of a tubular nozzle and tending to close by the thermal expansion effect of this nozzle in response to an untimely rise in temperature in a region of the mixing chamber situated slightly downstream of the means of injector, said expandable nozzle being surrounded in a spaced manner by a fixed outer casing on which the nozzle is abutted at the front so that the expansion of the nozzle occurs towards the rear era to close the shutter.

- the internal anti-ignition device comprises a shutter which is interposed between the tap means and the injector of one of the two gases, this shutter having

- Torches of this kind are for example described in DE-C-636 528.

- the handle of the torch monolithically constitutes the outer casing and the lance.

- the subject of the present invention is a two-gas torch provided with an internal anti-ignition device, the construction and operation of which are improved, as are the conditions of use.

- a two-gas torch provided with an internal anti-ignition device of the above-mentioned type, is characterized in that the lance is provided fixable on the handle by means of a socket which constitutes the fixed outer casing which precedes the handle while being held in abutment against the front end of the handle.

- the sleeve which constitutes the fixed outer envelope is distinct from the handle. It can therefore, therefore, be chosen at will from a material which is either identical or preferably different from that of the handle and in particular from a material which is not very expandable, which makes it possible to increase the expansion performance of the endpiece comparatively. expandable provided at the rear end of the lance.

- the body can also be freely chosen from a material which is exactly suitable for its function without there being any need to worry about whether this material is easily or hardly expandable.

- the arrangement according to the invention opens the way to the possibility of using with a single handle a whole set of lances having different characteristics and interchangeable with each other.

- the arrangement according to the invention makes it possible to choose for each lance a rear nozzle whose characteristics correspond precisely to expansion performance optimized for each lance.

- the overheating zone is also outside the handle, which is also favorable to the safety of the operator.

- a compressible means is provided to allow the rear end of the lance to continue to expand even after the movable range of the shutter has come into application against the fixed range of the shutter.

- a torch according to the invention (FIG. 1) comprises a handle 10 and a lance 11 which is fixed to this handle 10 by a threaded ring 12.

- the handle 10 comprises (FIGS. 1 and 3) a pair of conduits 13 and 14 adapted to be connected to two sources of gas 15 and 16.

- the conduit 13 is an oxygen conduit connected by a flexible hose 17 to an oxygen cylinder 15 while the conduit 14 is an acetylene conduit connected by a flexible hose 18 to an acetylene cylinder 16.

- the conduits 13 and 14 comprise tap means generally designated by 19. These tap means 19 more particularly comprise a button 20 for adjusting the overall oxygen and acetylene flow rate and a button 21 for dosing the proportion of oxygen and l acetylene in the mixture.

- 13A and 14A show the parts of the conduits 13 and 14 which are arranged downstream of the tap 19 and which are thus located at the front end 22 of the handle 10. This end 22 forms a threaded connection 23 for the ring 12 .

- the lance 11 ends with a spout 24 (FIG. 2) and comprises a bent tube 25 secured to a rear part or base 26, constituting an expandable tubular end piece.

- This rear part 26 of the lance 11 comprises, on the one hand, an axial injector 27 for oxygen and one or more lateral injectors 28 for acetylene.

- the two injectors 27 and 28 are connected to a mixing chamber 29, which is itself connected by a divergent 30 to the lance tube 25.

- This pre-expansion chamber 31 shows an expansion chamber of increasing section in one or more stages (two stages in the example shown in Figure 3).

- This pre-expansion chamber 31 is disposed between the oxygen injector 27 and the zone 32 by which the acetylene injectors 28 are connected to the mixing chamber 29.

- This pre-expansion chamber has the effect of limiting the risks of re-entry of flame.

- seals which are arranged between the rear part 26 of the lance 11 and the handle 10 and which are distributed on either side of the injectors 28.

- the end 13A of the conduit 13 terminates in a chamber 35 which is defined in the connector 22 of the handle around the rear end 26 of the lance 11 and which is limited by the seals sealing 34.

- This chamber 35 communicates with the oxygen injector 27.

- the front end 14A of the acetylene conduit 14 ends, in a similar manner, in a chamber 36 which is formed in the end of the connector 22 of the handle 10 and which is defined between the seals 33 and 34 in communicating with the acetylene injector 28.

- the two gases, oxygen and acetylene, respectively from the two bottles 15 and 16 pass through the pipes 17 and 18 in the conduits 13 and 14 then in the tap means 19 and pass through the ends 13A and 14A of the conduits 13 and 14 in chambers 35 and 36. Then they pass, for oxygen, into the injector 27 and the pre-expansion chamber 31, and, for acetylene, through the injectors 28 into the mixing chamber 29.

- the gas mixture passes through the divergent 30, passes through the tube 25 and reaches the spout 24 where the mixture forms a flame F.

- the two-gas torch according to the invention is provided with an internal anti-ignition device. .

- This internal anti-ignition device comprises a safety means forming a means of stopping or reducing the gas flow.

- the safety means generally designated by 37, is arranged between the tap means 19 and the injector means 27 and 28 and is associated with at least one of the two gases, namely in the example shown, oxygen.

- This safety means is made active in response to an untimely rise in temperature in a predetermined region R situated slightly downstream of the injector means 27 and 28. More particularly, this predetermined region where an untimely rise in temperature is detected located in the rear part 26 of the lance 11.

- the safety means 37 consists of a shutter having a seat element 38 and a closing element 39. These two elements are normally spaced from one another to allow the supply of one of the injectors , namely the injector 27 in the example shown, by one of the conduits, namely the oxygen conduit 13.

- the closing element 39 is adapted to approach the seat 37 by the effect of expansion thermal of the rear part 26 of the lance 11, in response to an untimely rise in temperature in the predetermined region R.

- the seat 38 of the shutter 37 is disposed at the front of the sleeve 10, while the closing element 39 of the shutter 37 is disposed at the rear of the lance 11.

- the lance 11 is mounted by longitudinal stop at 40 and preferably with a fixing by welding on the front end 41 of a bushing42.

- This socket 42 surrounds, in a spaced manner, the rear part 26 of the lance 11.

- the socket 42 is itself abutted longitudinally at 43 by its rear end 44 on the connector 23 of the handle 10.

- the stop 40 is provided downstream of the region R and significantly distant therefrom.

- the sleeve 42 constitutes a fixed outer envelope.

- the ring 12 for mounting the lance 11 on the connector 23 is screwed at .45 onto this connector 23 until it stops longitudinally at 46.

- a helical spring 47 is housed in the ring 12 around the bush 42 and is applied by one of its ends 48 to the ring 12 and by its other end 49 to the bush 42.

- the spring 47 has a predominant prestress on the passive resistances of the seals 33 and 34 but weak enough to avoid an irreparable compaction of the base 26 in the event of overheating.

- the spring 47 can be omitted if the shutter 37, instead of having elements 38, 39 metal on metal, has at least one of these two elements provided elastically deformable.

- the oxygen and acetylene supplied by the cylinders 15 and 16 pass through the conduits 13 and 14, pass through the tap 19 which has been adjusted for an overall flow suitable with a proportion also adjusted by the button 20, and pass through the injectors 27 and 28 to reach the mixing chamber 29 from which the mixture is directed by the divergent 30 in the lance tube 25 and leaves by the spout 24 producing flame F.

- the pre-expansion chamber 31 allows remarkable stability of the flame F outside the torch. It will also be understood that in normal operation and even if the work is intensive, the various parts, including the rear part 26 of the lance and the sleeve 42 are all at the same temperature so that the shutter 37 is open since the rear part 26 of the lance 11 expands in the same way as the bush 42.

- This rear part 26 therefore expands towards the rear, which tends to close at 38, 39 the safety shutter 37.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Gas Burners (AREA)

Description

La présente invention se rapporte à un chalumeau à deux gaz muni d'un dispositif anti-inflammation interne, chalumeau comportant un manche pourvu d'une lance laquelle présente à l'arrière un embout tubulaire définissant une chambre de mélange alimentée par des moyens de robinet et des moyens d'injecteur, chalumeau dans lequel le dispositif anti-inflammation interne comporte un obturateur qui est interposé entre les moyens de robinet et l'injecteur d'un des deux gaz, cet obturateur ayant une portée fixe solidaire du manche et une portée mobile formée à l'arrière d'un embout tubulaire et tendant à se fermer par effet de dilatation thermique de cet embout en réponse à une élévation intempestive de la température dans une région de la chambre de mélange située légèrement à l'aval des moyens d'injecteur, ledit embout dilatable étant entouré de manière espacée par une enveloppe extérieure fixe sur laquelle l'embout est buté à l'avant afin que la dilatation de l'embout se produise vers l'arrière pour fermer l'obturateur.The present invention relates to a two-gas torch provided with an internal anti-ignition device, torch comprising a handle provided with a lance which presents at the rear a tubular nozzle defining a mixing chamber supplied by tap means. and injector means, a torch in which the internal anti-ignition device comprises a shutter which is interposed between the tap means and the injector of one of the two gases, this shutter having a fixed bearing secured to the handle and a bearing mobile formed at the rear of a tubular nozzle and tending to close by the thermal expansion effect of this nozzle in response to an untimely rise in temperature in a region of the mixing chamber situated slightly downstream of the means of injector, said expandable nozzle being surrounded in a spaced manner by a fixed outer casing on which the nozzle is abutted at the front so that the expansion of the nozzle occurs towards the rear era to close the shutter.

Des chalumeaux de ce genre sont par exemple décrits dans le DE-C-636 528. Dans ce document, le manche du chalumeau constitue d'une manière monolithique l'enveloppe extérieure et la lance.Torches of this kind are for example described in DE-C-636 528. In this document, the handle of the torch monolithically constitutes the outer casing and the lance.

La présente invention a pour objet un chalumeau à deux gaz muni d'un dispositif anti-inflam- matlon interne dont la construction et le fonctionnement sont améliorés, de même que les conditions d'utilisation.The subject of the present invention is a two-gas torch provided with an internal anti-ignition device, the construction and operation of which are improved, as are the conditions of use.

Suivant l'invention un chalumeau à deux gaz, muni d'un dispositif anti-inflammation interne du type sus-indiqué, est caractérisé en ce que la lance est prévue fixable sur le manche par l'intermédiaire d'une douille qui constitue l'enveloppe extérieure fixe et qui précède le manche en étant maintenue butée contre l'extrémité avant du manche.According to the invention a two-gas torch, provided with an internal anti-ignition device of the above-mentioned type, is characterized in that the lance is provided fixable on the handle by means of a socket which constitutes the fixed outer casing which precedes the handle while being held in abutment against the front end of the handle.

Grâce à cet agencement, la douille qui constitue l'enveloppe extérieure fixe est distincte du manche. Elle peut donc, de ce fait, être choisie à volonté en une matière soit identique, soit de préférence différente de celle du manche et en particulier en une matière peu dilatable, ce qui permet d'augmenter comparativement les performances de dilatation de l'embout dilatable prévu à l'extrémité arrière de la lance. Par ailleurs, le corps peut être également choisi librement en une matière qui convient exactement à sa fonction sans qu'il y ait lieu de se préoccuper du point de savoir si cette matière est facilement ou difficilement dilatable.Thanks to this arrangement, the sleeve which constitutes the fixed outer envelope is distinct from the handle. It can therefore, therefore, be chosen at will from a material which is either identical or preferably different from that of the handle and in particular from a material which is not very expandable, which makes it possible to increase the expansion performance of the endpiece comparatively. expandable provided at the rear end of the lance. Furthermore, the body can also be freely chosen from a material which is exactly suitable for its function without there being any need to worry about whether this material is easily or hardly expandable.

En outre, l'agencement suivant l'invention ouvre la voie à une possibilité d'utilisation avec un même manche de tout un jeu de lances ayant des caractéristiques différentes et interchangeables les unes avec les autres. L'agencement suivant l'invention permet de choisir pour chaque lance un embout arrière dont les caractéristiques correspondent précisément à des performances de dilatation optimisées pour chaque lance.In addition, the arrangement according to the invention opens the way to the possibility of using with a single handle a whole set of lances having different characteristics and interchangeable with each other. The arrangement according to the invention makes it possible to choose for each lance a rear nozzle whose characteristics correspond precisely to expansion performance optimized for each lance.

On appréciera en outre qu'en présence d'une explosion, celle-ci se produira non pas dans le manche mais en avant de ce manche, ce qui constitue un moindre danger pour l'opérateur.It will also be appreciated that in the presence of an explosion, it will not occur in the handle but in front of this handle, which constitutes less danger for the operator.

On appréciera également qu'en cas de rentrée de flamme, la zone de surchauffe se trouve également en dehors du manche, ce qui est également favorable à la sécurité de l'opérateur.It will also be appreciated that in the event of reentry of flame, the overheating zone is also outside the handle, which is also favorable to the safety of the operator.

Suivant une autre caractéristique, un moyen compressible est prévu pour permettre à l'embout arrière de la lance de continuer à se dilater même après que la portée mobile de l'obturateur soit venue en application contre la portée fixe de l'obturateur.According to another characteristic, a compressible means is provided to allow the rear end of the lance to continue to expand even after the movable range of the shutter has come into application against the fixed range of the shutter.

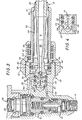

Une forme d'exécution de l'invention est ci-après décrite à titre d'exemple, en référence aux dessins annexés dans lesquels :

- la figure 1 est une vue d'ensemble d'un chalumeau suivant l'intervention ;

- la figure 2 est une vue en coupe à plus grande échelle du bec de lance, suivant la ligne II-II de la figure 1 ;

- la figure 3 est une vue à plus grande échelle encore, de la partie arrière de la lance et de la partie avant du manche et montre le dispositif de sécurité en position d'ouverture pendant un fonctionnement normal ;

- la figure 4 est une vue analogue à une partie de la figure mais dans laquelle le dispositif de sécurité est fermé en réponse à une élévation intempestive de la température.

- Figure 1 is an overview of a torch following the intervention;

- Figure 2 is a sectional view on a larger scale of the spout, along the line II-II of Figure 1;

- Figure 3 is an enlarged view of the rear part of the lance and the front part of the handle and shows the safety device in the open position during normal operation;

- Figure 4 is a view similar to part of the figure but in which the safety device is closed in response to an untimely rise in temperature.

Dans le mode de réalisation représenté aux figures 1 à 4, un chalumeau suivant l'invention (figure 1) comporte un manche 10 et une lance 11 qui est fixée à ce manche 10 par une bague filetée 12.In the embodiment shown in FIGS. 1 to 4, a torch according to the invention (FIG. 1) comprises a

Le manche 10 comporte (figures 1 et 3) une paire de conduits 13 et 14 adaptés à être reliés à deux sources de gaz 15 et 16.The

Plus particulièrement le conduit 13 est un conduit d'oxygène relié par un tuyau souple 17 à une bouteille d'oxygène 15 tandis que le conduit 14 est un conduit d'acétylène relié par un tuyau souple 18 à une bouteille d'acétylène 16.More particularly, the conduit 13 is an oxygen conduit connected by a

Les conduits 13 et 14 comportent des moyens de robinet généralement désignés par 19. Ces moyens de robinet 19 comportent plus particulièrement un bouton 20 pour le réglage du débit global oxygène et acétylène et une touche 21 pour doser la proportion de l'oxygène et de l'acétylène dans le mélange.The

On voit en 13A et 14A les parties des conduits 13 et 14 qui sont disposées à l'aval du robinet 19 et qui sont ainsi situées à l'extrémité avant 22 du manche 10. Cette extrémité 22 forme un raccord fileté 23 pour la bague 12.13A and 14A show the parts of the

La lance 11 se termine par un bec 24 (figure 2) et comporte un tube coudé 25 solidaire d'une partie arrière ou embase 26, constituant un embout tubulaire dilatable.The

Cette partie arrière 26 de la lance 11 comporte, d'une part, un injecteur axial 27 pour l'oxygène et un ou plusieurs injecteurs latéraux 28 pour l'acétylène. Les deux injecteurs 27 et 28 sont reliés à une chambre de mélange 29, laquelle est elle-même reliée par un divergent 30 au tube de lance 25.This

On voit en 31 une chambre de détente de section croissante en un ou plusieurs paliers (deux paliers dans l'exemple représenté à la figure 3). Cette chambre de prédétente 31 est disposée entre l'injecteur d'oxygène 27 et la zone 32 par laquelle les injecteurs d'acétylène 28 sont raccordés à la chambre de mélange 29. Cette chambre de prédétente a pour effet de limiter les risques de rentrée de flamme.31 shows an expansion chamber of increasing section in one or more stages (two stages in the example shown in Figure 3). This

On voit en 33 et en 34 des joints d'étanchéité qui sont disposés entre la partie arrière 26 de la lance 11 et le manche 10 et qui sont répartis de part et d'autre des injecteurs 28.We see at 33 and 34 seals which are arranged between the

Comme on le voit à la figure 3, l'extrémité 13A du conduit 13 aboutit dans une chambre 35 qui est définie dans le raccord 22 du manche autour de l'extrémité arrière 26 de la lance 11 et qui est limitée par les joints d'étanchéité 34. Cette chambre 35 communique avec l'injecteur d'oxygène 27.As seen in Figure 3, the

L'extrémité avant 14A du conduit d'acétylène 14 aboutit, d'une manière analogue, dans une chambre 36 qui est ménagée dans l'extrémité du raccord 22 du manche 10 et qui est définie entre les joints d'étanchéité 33 et 34 en communiquant avec l'injecteur d'acétylène 28.The

Les deux gaz, oxygène et acétylène, issus respectivement des deux bouteilles 15 et 16 passent par les tuyaux 17 et 18 dans les conduits 13 et 14 puis dans les moyens de robinet 19 et passent par les extrémités 13A et 14A des conduits 13 et 14 dans les chambres 35 et 36. Puis ils passent, pour l'oxygène, dans l'injecteur 27 et la chambre de prédétente 31, et, pour l'acétylène, par les injecteurs 28 dans la chambre de mélange 29. Le mélange de gaz franchit le divergent 30, passe, dans le tube 25 et parvient au bec 24 où le mélange forme une flamme F.The two gases, oxygen and acetylene, respectively from the two

Il peut arriver que la flamme F rentre accidentellement à l'intérieur du chalumeau, et, afin d'éviter la propagation d'une telle combustion intempestive, le chalumeau à deux gaz suivant l'invention est pourvu d'un dispositif anti-inflammation interne.It may happen that the flame F accidentally enters the inside of the torch, and, in order to avoid the propagation of such untimely combustion, the two-gas torch according to the invention is provided with an internal anti-ignition device. .

Ce dispositif anti-inflammation interne comporte un moyen de sécurité formant un moyen d'arrêt ou de diminution du débit gazeux. Le moyen de sécurité, désigné dans son ensemble par 37, est disposé entre les moyens de robinet 19 et les moyens d'injecteur 27 et 28 et est associé à l'un au moins des deux gaz, à savoir dans l'exemple représenté, l'oxygène. Ce moyen de sécurité est rendu actif en réponse à une élévation intempestive de la température dans une région prédéterminée R située légèrement en aval des moyens d'injecteur 27 et 28. Plus particulièrement, cette région prédéterminée où est détectée une élévation intempestive de la température est située dans la partie arrière 26 de la lance 11.This internal anti-ignition device comprises a safety means forming a means of stopping or reducing the gas flow. The safety means, generally designated by 37, is arranged between the tap means 19 and the injector means 27 and 28 and is associated with at least one of the two gases, namely in the example shown, oxygen. This safety means is made active in response to an untimely rise in temperature in a predetermined region R situated slightly downstream of the injector means 27 and 28. More particularly, this predetermined region where an untimely rise in temperature is detected located in the

Dans l'exemple représenté, le moyen de sécurité 37 consiste en un obturateur ayant un élément siège 38 et un élément de fermeture 39. Ces deux éléments sont normalement espacés l'un de l'autre pour permettre l'alimentation d'un des injecteurs, à savoir l'injecteur 27 dans l'exemple représenté, par l'un des conduits, à savoir le conduit d'oxygène 13. L'élément de fermeture 39 est adapté à se rapprocher du siège 37 par l'effet de la dilatation thermique de la partie arrière 26 de la lance 11, en réponse à une élévation intempestive de la température dans la région prédéterminée R.In the example shown, the safety means 37 consists of a shutter having a

Plus particulièrement, le siège 38 de l'obturateur 37 est disposé à l'avant du manchon 10, tandis que l'élément de fermeture 39 de l'obturateur 37 est disposé à l'arrière de la lance 11. Comme on le voit à la figure 3, la lance 11 est montée par butée longitudinale en 40 et de préférence avec une fixation par soudure sur l'extrémité avant 41 d'une douille42. Cette douille 42, entoure, de manière espacée, la partie arrière 26 de la lance 11. La douille 42 est, elle même, butée longitudinalement en 43 par son extrémité arrière 44 sur le raccord 23 du manche 10. Comme on le voit à la figure 3, la butée 40 est prévue à l'aval de la région R et notablement éloignée de celle-ci. La douille 42 constitue une enveloppe extérieure fixe.More particularly, the

La bague 12 de montage de la lance 11 sur le raccord 23 est vissée en .45 sur ce raccord 23 jusqu'à butée longitudinale en 46.The

Un ressort hélicoïdal 47, à spires plates, est logé dans la bague 12 autour de la douille 42 et est appliqué par une de ses extrémités 48 sur la bague 12 et par son autre extrémité 49 sur la douille 42.A

Le ressort 47 a une précontrainte prépondérante sur les résistances passives des joints 33 et 34 mais assez faible pour éviter un tassement irrémédiable de l'embase 26 en cas de surchauffe.The

En cas d'élévation intempestive de la température de la région R, la partie arrière 26 de la lance 11 se dilate davantage que la douille 42, ce qui provoque le rapprochement de l'élément de fermeture 39 du siège 38 de l'obturateur 37. On appréciera que le ressort héticoîdat 47 interposé entre l'extrémité arrière 49 de la douille 42 et l'extrémité antérieure 48 de la bague 12 solidaire du manche 10, permet à la partie arrière 26 de la lance de continuer à se dilater même après que l'élément de fermeture 39 de l'obturateur 37 est venu (figure 4) en application sur le siège 38 de cet obturateur 37.In the event of an untimely rise in the temperature of the region R, the

On appréciera que le ressort 47 peut être supprimé si l'obturateur 37, au lieu de présenter des éléments 38, 39 métal sur métal, a au moins un de ces deux éléments prévu déformable élastiquement.It will be appreciated that the

En fonctionnement normal, l'oxygène et l'acétylène alimentés par les bouteilles 15 et 16 passent par les conduits 13 et 14, franchissent le robinet 19 qui a été réglé en vue d'un débit global convenable avec une proportion également réglée par la touche 20, et passent par les injecteurs 27 et 28 pour parvenir à la chambre de mélange 29 d'où le mélange se dirige par le divergent 30 dans le tube de lance 25 et sort par le bec 24 en produisant la flamme F.In normal operation, the oxygen and acetylene supplied by the

On appréciera que la chambre de prédétente 31 permet une stabilité remarquable de la flamme F à l'extérieur du chalumeau. On comprendra également qu'en fonctionnement normal et même si le travail est intensif, les différentes pièces, y compris la partie arrière 26 de la lance et la douille 42 sont toutes à une même température de sorte que l'obturateur 37 est ouvert puisque la partie arrière 26 de la lance 11 se dilate de la même façon que la douille 42.It will be appreciated that the

S'il se produit accidentellement une rentrée de flamme, la flamme séjournera d'abord dans la partie arrière 26 de la lance au voisinage du divergent 30. Il se produit alors un sifflement qui prévient l'opérateur et celui-ci s'empressera de fermer le robinet 29 et de préférence aussi les bouteilles 15 et 16.If a reentry of flame occurs accidentally, the flame will first of all stay in the

Mais si l'opérateur n'agit pas de cette façon, les joints 33 et 34 sont rapidement mis hors service et le front de flamme qui se développe au voisinage du divergent 30 ne tarde pas à remonter dans le manche 10 en le faisant fondre.But if the operator does not act in this way, the

Grâce à l'invention, ce danger se trouve écarté par le fait que la partie arrière 26 de la lance 11 se trouve portée, dans les premières secondes, à une température plus élevée que la douille 42 puisque celle-ci entoure de manière espacée la partie arrière de la lance 11.Thanks to the invention, this danger is avoided by the fact that the

Cette partie arrière 26 se dilate donc vers l'arrière ce qui tend à fermer en 38, 39 l'obturateur de sécurité 37.This

Dès lors, l'arrivée d'oxygène vers l'injecteur 27 tend à se fermer. La proportion du mélange est modifiée et celui-ci n'est plus combustible, ce qui provoque l'extinction de la flamme.Consequently, the supply of oxygen to the injector 27 tends to close. The proportion of the mixture is changed and it is no longer combustible, which causes the flame to go out.

On appréciera que ce remède entièrement automatique intervient dans les toutes premières secondes qui suivent le phénomène intempestif de rentrée de flamme et on évite ainsi les conséquences irrémédiables qui pourraient survenir au bout d'une dizaine de secondes après l'apparition de la rentrée de flamme.It will be appreciated that this fully automatic remedy intervenes in the very first seconds following the untimely phenomenon of reentry of the flame and thus avoids the irremediable consequences which could occur after ten seconds after the appearance of the reentry of flame.

Lorsque la flamme à l'intérieur de la partie arrière 26 de la lance 11 a été éteinte grâce au dispositif de sécurité suivant l'invention et comme il vient d'être dit, la partie arrière 26 de la lance 11 se refroidit, ce qui provoque la réouverture de l'obturateur 37. La proportion propre à la combustion du mélange combustible se trouve alors rétablie et le chalumeau peut être prêt à être rallumé d'une manière normale au bec de lance 24.When the flame inside the

On appréciera la construction particulièrement simple et efficace du chalumeau suivant l'invention muni du dispositif anti-flamme interne.It will be appreciated the particularly simple and effective construction of the torch according to the invention provided with the internal anti-flame device.

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR7930555A FR2471552A1 (en) | 1979-12-13 | 1979-12-13 | TWO-GAS CHALUME WITH INTERNAL ANTI-INFLAMMATION DEVICE |

| FR7930555 | 1979-12-13 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0031279A1 EP0031279A1 (en) | 1981-07-01 |

| EP0031279B1 true EP0031279B1 (en) | 1983-09-14 |

Family

ID=9232728

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19800401792 Expired EP0031279B1 (en) | 1979-12-13 | 1980-12-12 | Two-gases burner provided with an anti-internal-inflammation device |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0031279B1 (en) |

| DE (1) | DE3064850D1 (en) |

| FR (1) | FR2471552A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60111886A (en) * | 1983-11-22 | 1985-06-18 | 新日本製鐵株式会社 | Flame spraying burner |

| EP2843305B1 (en) | 2012-08-07 | 2017-10-11 | Hino Motors, Ltd. | Burner for exhaust gas purification devices |

| WO2014024943A1 (en) | 2012-08-07 | 2014-02-13 | 日野自動車 株式会社 | Burner for exhaust gas purification devices |

| WO2014024942A1 (en) | 2012-08-07 | 2014-02-13 | 日野自動車 株式会社 | Burner |

| CN104603539B (en) | 2012-08-13 | 2017-06-23 | 日野自动车株式会社 | Burner |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE636528C (en) * | 1936-10-10 | I G Farbenindustrie Akt Ges | Mixing nozzle made of highly heat-resistant, good heat-conducting metal for oxy-fuel welding or cutting torches | |

| DE704719C (en) * | 1938-04-17 | 1941-04-05 | Felix Damm | Welding and cutting torches |

| DE819081C (en) * | 1949-10-27 | 1951-10-29 | Felix Damm | Kickback-proof injector welding and cutting torch for operation with a fuel gas-oxygen mixture |

| FR1263362A (en) * | 1960-04-25 | 1961-06-09 | Non-return and explosion-proof valve for autogenous welding equipment | |

| FR2003488A1 (en) * | 1968-03-08 | 1969-11-07 | Messer Griesheim Gmbh | |

| CH543044A (en) * | 1970-09-30 | 1973-10-15 | Roth Alfred | Safety device on welding or cutting torches against overheating in the event of flashbacks |

-

1979

- 1979-12-13 FR FR7930555A patent/FR2471552A1/en active Granted

-

1980

- 1980-12-12 EP EP19800401792 patent/EP0031279B1/en not_active Expired

- 1980-12-12 DE DE8080401792T patent/DE3064850D1/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| EP0031279A1 (en) | 1981-07-01 |

| FR2471552A1 (en) | 1981-06-19 |

| FR2471552B1 (en) | 1983-07-18 |

| DE3064850D1 (en) | 1983-10-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CH619765A5 (en) | ||

| EP0031279B1 (en) | Two-gases burner provided with an anti-internal-inflammation device | |

| EP1106212A1 (en) | Nozzle for fire-fighting | |

| FR2520090A1 (en) | Gas blow lamp for shrinkage of wrapping material - has needle valve to control fuel flow from injector | |

| EP2037174B1 (en) | Handtool with improved gas combustion | |

| CA2046363A1 (en) | Catalytic burner | |

| EP0235028A1 (en) | Igniter fixable inside a rocket nozzle | |

| WO1998059199A1 (en) | Gas appliance such as a thermal weed sprayer | |

| FR2628291A1 (en) | DEVICE FOR BURNING HORNS OF FARMED ANIMALS | |

| EP0059137A1 (en) | Ignition device for fuel injected into a rapidly flowing gas stream | |

| FR2496520A1 (en) | IMPROVEMENTS IN OXY-ACETYLENIC TORCHES | |

| EP0758438B1 (en) | Device for the coordinated control of the flow of at least two gases, and burner comprising such device | |

| EP0354099B1 (en) | Gas-fired hot air heater | |

| EP0007289A1 (en) | Ignition device for oxygen cutting lances | |

| FR2719373A1 (en) | Propulsion unit for riot control grenade | |

| CH616995A5 (en) | ||

| WO2003098109A1 (en) | Torch and device for forming a torch | |

| EP0234633B1 (en) | Energetic stabilizing device for a generator of hot gases | |

| FR2692657A1 (en) | Hand tool with gas ignition device. | |

| FR3113717A1 (en) | Gas injection device for a hot air generator | |

| FR2864206A3 (en) | Oven gas burner element has burner with a mixer pipe, side-pipe, a secondary pipe and a flame bridge with side-pipe linked to and fixed with one end of mixer pipe | |

| FR2505446A1 (en) | Removable nut joint for pipework - has expanding retaining ring concealed in groove allowing unimpeded nut connection | |

| FR2708078A1 (en) | Safety circuit breaker for installations for handling pressurised fluids | |

| FR3114639A1 (en) | Improved fixing method for a spark plug of a hot air generator. | |

| BE636158A (en) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT SE |

|

| 17P | Request for examination filed |

Effective date: 19810720 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19830914 |

|

| REF | Corresponds to: |

Ref document number: 3064850 Country of ref document: DE Date of ref document: 19831020 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19841128 Year of fee payment: 5 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19870901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881118 |