EP0029400B1 - Apparatus for protecting buildings and civil engineering constructions against water and moisture - Google Patents

Apparatus for protecting buildings and civil engineering constructions against water and moisture Download PDFInfo

- Publication number

- EP0029400B1 EP0029400B1 EP80420125A EP80420125A EP0029400B1 EP 0029400 B1 EP0029400 B1 EP 0029400B1 EP 80420125 A EP80420125 A EP 80420125A EP 80420125 A EP80420125 A EP 80420125A EP 0029400 B1 EP0029400 B1 EP 0029400B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tubes

- building

- works

- water

- lattice

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 title claims abstract description 44

- 238000010276 construction Methods 0.000 title description 14

- 230000002093 peripheral effect Effects 0.000 claims abstract description 16

- 230000005484 gravity Effects 0.000 claims abstract description 4

- 239000000463 material Substances 0.000 claims abstract description 4

- 230000009471 action Effects 0.000 claims description 6

- 230000014759 maintenance of location Effects 0.000 claims 1

- 238000009412 basement excavation Methods 0.000 description 6

- 239000002689 soil Substances 0.000 description 5

- 238000009825 accumulation Methods 0.000 description 4

- 230000002349 favourable effect Effects 0.000 description 4

- 230000002706 hydrostatic effect Effects 0.000 description 4

- 230000008595 infiltration Effects 0.000 description 4

- 238000001764 infiltration Methods 0.000 description 4

- 230000006866 deterioration Effects 0.000 description 3

- 230000032258 transport Effects 0.000 description 3

- 239000004568 cement Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000002787 reinforcement Effects 0.000 description 2

- 230000008719 thickening Effects 0.000 description 2

- 235000008733 Citrus aurantifolia Nutrition 0.000 description 1

- 244000060234 Gmelina philippensis Species 0.000 description 1

- 241001080024 Telles Species 0.000 description 1

- 235000011941 Tilia x europaea Nutrition 0.000 description 1

- 241001125843 Trichiuridae Species 0.000 description 1

- 241000618809 Vitales Species 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 238000011001 backwashing Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000004927 clay Substances 0.000 description 1

- 230000003749 cleanliness Effects 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 230000001687 destabilization Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 229940082150 encore Drugs 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000003673 groundwater Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000004571 lime Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 235000019645 odor Nutrition 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 230000001502 supplementing effect Effects 0.000 description 1

- 239000000080 wetting agent Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D31/00—Protective arrangements for foundations or foundation structures; Ground foundation measures for protecting the soil or the subsoil water, e.g. preventing or counteracting oil pollution

- E02D31/02—Protective arrangements for foundations or foundation structures; Ground foundation measures for protecting the soil or the subsoil water, e.g. preventing or counteracting oil pollution against ground humidity or ground water

Definitions

- the present invention relates to a device for protecting buildings and civil engineering works against water and humidity, this device comprising in known manner (see US-A-1,734,777) a peripheral tubular network located outside the building or structure to be protected, and a tubular network present under the building or structure to be protected, the two networks being interconnected by tubes passing through the external walls or their foundations, each network consisting of perforated tubes embedded in a draining material and allowing the capture of water by emergence then its evacuation.

- the present invention avoids these drawbacks by proposing a device for protecting buildings and civil engineering works against water and humidity, of the type indicated in the introduction, in which the tubular network present under the building or structure is a geometrical mesh network present under the entire surface of this building or this structure, said mesh network being connected to tubes of the external peripheral reinforcement by tubes passing substantially horizontally through the external walls or their foundations, so that the mesh network s extending under the entire surface of the building or structure and the external peripheral network are in the same plane, these networks being placed on an excavation bottom in slight slope so that their plane is slightly inclined on the horizontal to allow the evacuation of water by gravity at the low point of all of these networks.

- the mesh structure of the network forming a grid present under the entire surface of the building or structure, ensures water collection at all points, with balanced distribution of flows and offering a plurality of flow paths; it allows the network to maintain its efficiency even in the event of clogging or silting up of one or more tubes. This point is obviously very important because the water collection and evacuation network is made definitively inaccessible and invisible, once the building or structure has been completed, so that the device must maintain its efficiency permanently and indefinitely. Upwelling of water to the surface, and the resulting deterioration, are thus effectively avoided, any thickening of the film of water being immediately channeled by the collection tubes of the mesh network which cleanse the draining layer.

- the peripheral tubular network located outside the walls or foundations and connected to the mesh network, also comprises sheets interconnected tubes located in vertical planes parallel to these walls and extending upwards.

- the mesh network located under the surface of the building or structure has square or rectangular meshes, and. it is made from sections of perforated tubes interconnected by means of cross and / or T connections. Special connections are only necessary to make the connection between any plies of external tubes, parallel to the vertical walls, and the mesh network horizontal.

- tubes and fittings whose characteristics facilitate the assembly, transport and installation of the mesh network, in order to take into account not only economic imperatives, but also the fact that the workforce employed on construction sites is generally unskilled.

- Figures 1 and 2 show, extremely schematically, a rectangular building with its elevation walls or walls (1, 2, 3, 4) and a cross wall (5), this building constituting a construction buried in the soil whose natural level is indicated in (6).

- Figure 3 appear, in more detail, the foundations with cleanliness concrete (7) and sills (8), above which are erected the walls or elevation walls (1 to 4).

- this mesh network designated as a whole by (10), appearing seen in plan as a grid (see Figure 1).

- this mesh network (10) consists of tubes (11), interconnected by means of cross connectors (12) and having series of perforations (13).

- This network whose square meshes can have a side of between about 0.60 m and 1 m, extends not only over the entire surface of the excavation bottom (9), but also crosses the stringers (8) by reservations (14) provided for in these. It is understood that similar reservations must also be provided at the base of the cross wall (5).

- the bottom of the excavation (9) and the mesh network (10) are slightly cant, the wall (1) corresponding for example to the highest side and the wall (3) to the lowest side, side where will obviously take place drainage.

- the mesh network (10) is embedded in the lower part of a draining layer (15) resting on the excavation bottom (9) and consisting of crushed stones, in the form of carefully determined aggregate.

- the total thickness of this layer (15) can be approximately twice the diameter of the perforated tubes (11) of the mesh network (10).

- a peripheral network supplementing the mesh network (10), with other perforated tubes (16) and other fittings (17) forming plies which extend upward in vertical planes parallel to the walls (1 to 4).

- the shape and height of these layers of tubes (16) which complete the basic network (10) are determined according to the profile of the natural terrain (6), as illustrated in FIG. 2.

- a collector (not shown) collects all of the water collected, and transports it, for example, to the rainwater network or to an installation capable of using this water (heating).

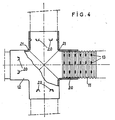

- FIG. 4 shows a tube end (11) and a cross connector (12) of the mesh network (10).

- the tube (11) is ringed and its perforations (13) are formed by slots made in the annular grooves of the tube.

- the connector (12) has, on its four end caps, internal notches (20) which ensure the snap-fastening of one end of the tube (11).

- the tubes and fittings are advantageously made of plastic, and preferably at least the tubes (11) extending in one direction are flexible: the mesh network (10) can then be "pre-assembled” and form a sort of net , rolled up for transport and storage, and then this roller is simply unwound on the excavation bottom (9), so that the laying operations on the site are simplified to the extreme.

- perforations (21) are also provided on the connections (12) of the mesh network, more particularly in the corners of these connections, where there is the risk of water stagnation.

- the device which is the subject of the invention can also be implemented, without appreciable modification and with the same results, in the case of buildings with an armed raft and a peripheral wall, the latter being crossed by the tubes of the mesh network, and also, more generally, in the case of the underwork of various civil engineering works, for example for the foundations of bridge piers. It is also possible to provide two series of internal notches (20) on each end of a fitting (12), in order to obtain better attachment of the ends of the corrugated tubes (11).

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Paleontology (AREA)

- Hydrology & Water Resources (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Environmental & Geological Engineering (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Building Environments (AREA)

- Solid-Sorbent Or Filter-Aiding Compositions (AREA)

- Sewage (AREA)

- Buildings Adapted To Withstand Abnormal External Influences (AREA)

- Revetment (AREA)

Abstract

Description

La présente invention concerne un dispositif de protection des bâtiments et ouvrages de génie civil contre l'eau et l'humidité, ce dispositif comprenant de façon connue (voir US-A-1 734 777) un réseau tubulaire périphérique situé à l'extérieur du bâtiment ou de l'ouvrage à protéger, et un réseau tubulaire présent sous le bâtiment ou l'ouvrage à protéger, les deux réseaux étant raccordés entre eux par des tubes traversant les parois extérieures ou leurs fondations, chaque réseau étant constitué par des tubes perforés noyés dans un matériau drainant et permettant le captage de l'eau par émergence puis son évacuation.The present invention relates to a device for protecting buildings and civil engineering works against water and humidity, this device comprising in known manner (see US-A-1,734,777) a peripheral tubular network located outside the building or structure to be protected, and a tubular network present under the building or structure to be protected, the two networks being interconnected by tubes passing through the external walls or their foundations, each network consisting of perforated tubes embedded in a draining material and allowing the capture of water by emergence then its evacuation.

On rencontre de grandes difficultés pour protéger efficacement de l'eau et de l'humidité les bâtiments et les ouvrages de travaux publics constituant des constructions enterrées.There are great difficulties in effectively protecting buildings and public works works constituting buried constructions from water and humidity.

Pour réaliser cette protection, le procédé actuellement le plus courant consiste à opposer un "barrage" à l'eau, en recouvrant la base des murs et les dallages de revêtements étanches. Ce procédé est très coûteux et il reste imparfait, notamment sous les deux aspects suivants:

- - Les fissurations fréquentes et les traversées ménagées pour les fluides (canalisations d'eau, de gaz, d'électricité) provoquent des discontinuités de l'étanchéité.

- - Le principe même de "barrage" conduit à un emprisonnement de l'eau, alors qu'il serait souhaitable de permettre son écoulement.

- - Frequent cracks and crossings made for fluids (water, gas, electricity pipes) cause leaks.

- - The very principle of "dam" leads to a trapping of water, when it would be desirable to allow its flow.

On observe ainsi, dans les constructions actuelles, des "remontées" d'eau par capillarité, qui sont la cause de détériorations des revêtements de surface, mais aussi d'odeurs désagréables et d'un sentiment d'inconfort.We can thus observe, in current constructions, "backwashing" of water by capillary action, which are the cause of deterioration of the surface coatings, but also of unpleasant odors and a feeling of discomfort.

Pour bien comprendre l'origine de ces effets désagréables et la nature des problèmes à résoudre, il convient de prendre en considération les phénomènes naturels qui se produisent, et qui sont de deux sortes:

- 1. Le colluvionnement: les sols où la présence de l'eau est le plus à redouter sont généralement les sols argileux, ceux qui se trouvent au voisinage de rivières ou d'étangs et soumis aux influences de nappes phréatiques, et enfin les sols dits "rapportés", que l'insuffisance de leur compactage rend particulièrement vulnérables aux infiltrations d'eau et qui présentant ainsi de graves dangers pour l'édification des constructions. Le ruissellement de l'eau dans ces sols provoque ce qu'il est convenu d'appeler le "tri des fines" ou " colluvionnement": l'accumulation aux points bas des sables et limons qui y sont entraînés et déposés par l'action de l'eau occasionne, à plus ou moins longue échéance, le colmatage ou l'ensablement des tubes de drainage et d'évacuation des eaux, ce qui provoque leur accumulation et réunit du même coup les conditions donnant lieu à l'apparition des phénomènes de capillarité.

- 2. La capillarité et ses conséquences: dans tout milieu favorable où elle se trouve plus ou moins emprisonnée, l'eau possède une propriété phénoménale de progression dans toutes les directions. C'est essentiellement un agent mouillant, et dans son infiltration elle entraîne, avec elle, les éléments alcalins introduits notamment dans l'élaboration des chaux et ciments, d'où des détériorations à la surface des carrelages. L'eau trouve également dans les constituants du béton, ou des agglomérés de ciment et terre cuite, des éléments extrêmement favorable à sa progression. De plus, la capillarité a pour conséquence des pressions hydrostatiques ou tensions superficielles de l'eau, qui lui permettent de manifester, en surface, des forces très élevés. A ce sujet, il suffit de noter qu'en hydrostatique, on démontre que la masse d'un gramme d'eau, réduite en une couche de 1/20000 de millimètre d'épaisseur, serait pourtant capable de supporter une charge de 3300 tonnes!

- 1. Colluviation: the soils where the presence of water is most to be feared are generally clay soils, those which are found in the vicinity of rivers or ponds and subject to the influences of groundwater, and finally so-called soils "reported", which the inadequacy of their compaction makes them particularly vulnerable to water infiltration and which therefore presents serious dangers for the construction of constructions. The runoff of water in these soils causes what is known as "sorting of fines" or "colluviation": the accumulation at the low points of the sands and silts which are entrained there and deposited by the action. water causes, sooner or later, the clogging or silting up of the drainage and water evacuation tubes, which causes their accumulation and at the same time meets the conditions giving rise to the appearance of phenomena of capillarity.

- 2. Capillarity and its consequences: in any favorable environment where it is more or less trapped, water has a phenomenal property of progression in all directions. It is essentially a wetting agent, and in its infiltration it carries with it the alkaline elements introduced in particular in the preparation of lime and cements, whence deterioration on the surface of the tiles. Water also finds in the constituents of concrete, or agglomerates of cement and terracotta, elements extremely favorable to its progression. In addition, capillarity results in hydrostatic pressures or surface tensions of the water, which allow it to manifest, at the surface, very high forces. On this subject, it is enough to note that in hydrostatic, it is demonstrated that the mass of a gram of water, reduced to a layer of 1/20000 of a millimeter thick, would however be capable of supporting a load of 3300 tonnes !

Au lieu d'opposer un barrage à l'eau, on peut envisager de la faire circuler sous les bâtiments et ouvrages, en lui interdisant de s'y accumuler ou d'y stagner, ceci notamment en évitant le colluvionnement et en maîtrisant la capillarité de manière à éviter l'apparition de l'eau à la surface des dallages. Le US-A-1 734 777 décrit une tentative allant en ce sens, en proposant un dispositif de protection de bâtiments contre l'eau et l'humidité comprenant un réseau de tubes poreux situé à la périphérie du bâtiment, à l'extérieur de celui-ci, et un réseau de tubes poreux situé sous la surface du bâtiment et raccordé au réseau extérieur par des tubes traversant les fondations, ces réseaux étant reliés à une évacuation. Ce dispositif présente divers inconvénients:

- 1. Le réseau situé sous la surface du bâtiment n'est en fait qu'une simple boucle dont les tubes sont très proches des parois. Ces tubes sont enfouis dans une tranchée remplie d'un matériau drainant qui forme aussi une couche s'étendant sous toute la surface du bâtiment. Ainsi l'action de drainage est réalisée sur le pourtour du bâtiment, mais ne l'est pas efficacement sur l'étendue totale du bâtiment où la couche précitée représente plutôt un risque de stagnation, d'autant plus qu'aucune pente n'est prévue pour permettre un écoulement naturel vers un point bas. De plus, la position du réseau tubulaire "intérieur" présente un risque de déstabilisation de la zone des fondations, vitale pour la construction, en cas de colmatage de l'un des tubes.

- 2. Le réseau périphérique extérieur est situé à un niveau plus élevé que le réseau en boucle situé sous le bâtiment, le raccordement entre ces deux réseaux étant réalisé par des tubes traversant obliquement les fondations. Une telle disposition crée des différences de pression hydrostatique, et elle oblige à évacuer toute l'eau par le réseau situé le plus bas, en prévoyant un collecteur sous le bâtiment. Par ailleurs, l'orientation oblique des tubes de raccordement pose un problème pour la traversée des fondations, en raison du ferraillage très dense du béton dans cette partie de la construction.

- 1. The network located under the surface of the building is in fact only a simple loop whose tubes are very close to the walls. These tubes are buried in a trench filled with a draining material which also forms a layer extending under the entire surface of the building. Thus the drainage action is carried out on the periphery of the building, but is not effectively carried out over the entire extent of the building where the aforementioned layer rather represents a risk of stagnation, all the more since no slope is designed to allow natural flow to a low point. In addition, the position of the "interior" tubular network presents a risk of destabilization of the foundation area, vital for construction, in the event of one of the tubes becoming clogged.

- 2. The external peripheral network is located at a higher level than the loop network located under the building, the connection between these two networks being made by tubes obliquely crossing the foundations. Such an arrangement creates differences in hydrostatic pressure, and it forces all the water to be evacuated via the lowest system, in advance. seeing a collector under the building. Furthermore, the oblique orientation of the connection tubes poses a problem for crossing the foundations, due to the very dense reinforcement of the concrete in this part of the construction.

La présente invention évite ces inconvénients, en proposant un dispositif de protection des bâtiments et ouvrages de génie civil contre l'eau et l'humidité, du type indiqué en introduction, dans lequel le réseau tubulaire présent sous le bâtiment ou l'ouvrage est un réseau maillé géomètrique présent sous toute la surface de ce bâtiment ou de cet ouvrage, ledit réseau maillé étant raccordé à des tubes du ré- sau périphérique extérieur par des tubes traversant sensiblement horizontalement les parois extérieures ou leurs fondations, de sorte que le réseau maillé s'étendant sous toute la surface du bâtiment ou de l'ouvrage et le réseau périphérique extérieur sont dans un même plan, ces réseaux étant posés sur un fond de fouille en léger devers de sorte que leur plan est légére- ment incliné sur l'horizontale pour permettre l'évacuation de l'eau par gravité au point bas de l'ensemble de ces réseaux.The present invention avoids these drawbacks by proposing a device for protecting buildings and civil engineering works against water and humidity, of the type indicated in the introduction, in which the tubular network present under the building or structure is a geometrical mesh network present under the entire surface of this building or this structure, said mesh network being connected to tubes of the external peripheral reinforcement by tubes passing substantially horizontally through the external walls or their foundations, so that the mesh network s extending under the entire surface of the building or structure and the external peripheral network are in the same plane, these networks being placed on an excavation bottom in slight slope so that their plane is slightly inclined on the horizontal to allow the evacuation of water by gravity at the low point of all of these networks.

La structure maillée du réseau, formant un quadrillage présent sous toute la surface du bâtiment ou de l'ouvrage, assure un captage de l'eau en tout point, avec répartition équilibrée des débits et en offrant une pluralité de chemins d'écoulement; elle permet au réseau de conserver son efficacité même en cas de colmatage ou d'ensablement d'un ou de plusieurs tubes. Ce point est évidemment très important du fait que le réseau de captage et d'évacuation des eaux est rendu définitivement inaccessible et invisible, une fois le bâtiment ou l'ouvrage réalisé, de sorte que le dispositif doit conserver en permanence et indéfiniment son efficacité. Les remontées d'eau jusqu'en surface, et les détériorations, qui en résultent, sont ainsi efficacement évitées, tout épaississement de la pellicule d'eau étant immédiatement canalisé par les tubes de captage du réseau maillé qui assainissent la couche drainante. La liaison sensiblement horizontale du réseau maillé situé sous la construction avec le réseau périphérique situé à l'extérieur de la construction, et l'inclinaison légère de l'ensemble, permettant un écoulement orienté et une évacuation relativement rapide, évitant la stagnation, l'eau étant recueillie à l'extérieur au point le plus bas, après traversée des parois extérieures ou de leurs fondations; cette traversée des parois ou des fondations s'effectue sans obstacle hydrostatique, et l'évacuation de l'eau est réalisée par gravité au point le plus bas sans aucun dispositif particulier.The mesh structure of the network, forming a grid present under the entire surface of the building or structure, ensures water collection at all points, with balanced distribution of flows and offering a plurality of flow paths; it allows the network to maintain its efficiency even in the event of clogging or silting up of one or more tubes. This point is obviously very important because the water collection and evacuation network is made definitively inaccessible and invisible, once the building or structure has been completed, so that the device must maintain its efficiency permanently and indefinitely. Upwelling of water to the surface, and the resulting deterioration, are thus effectively avoided, any thickening of the film of water being immediately channeled by the collection tubes of the mesh network which cleanse the draining layer. The substantially horizontal connection of the mesh network located under the construction with the peripheral network located outside the construction, and the slight inclination of the assembly, allowing a directed flow and a relatively rapid evacuation, avoiding stagnation, water being collected outside at the lowest point, after crossing the outside walls or their foundations; this crossing of the walls or foundations is carried out without hydrostatic obstacle, and the evacuation of the water is carried out by gravity at the lowest point without any particular device.

De préférence, et en fonction du terrain naturel et de la profondeur des parties enterrées du bâtiment ou de l'ouvrage concerné, le réseau tubulaire périphérique, situé à l'extérieur des parois ou fondations et raccordé au réseau maillé, comprend en outre des nappes de tubes interconnectés situés dans des plans verticaux parallèles à ces parois et s'étendant vers le haut.Preferably, and depending on the natural terrain and the depth of the buried parts of the building or the structure concerned, the peripheral tubular network, located outside the walls or foundations and connected to the mesh network, also comprises sheets interconnected tubes located in vertical planes parallel to these walls and extending upwards.

Suivant un mode de réalisation particulièrement simple et rationnel, le réseau maillé situé sous la surface du bâtiment ou de l'ouvrage possède des mailles carrées ou rectangulaires, et. il est réalisé à partir de tronçons de tubes perforés interconnectés au moyen de raccords en croix et/ou en T. Des raccords spéciaux sont nécessaires seulement pour réaliser la liaison entre les éventuelles nappes de tubes extérieures, parallèles aux parois verticales, et le réseau maillé horizontal. On pourra choisir des tubes et raccords dont les caractéristiques facilitent l'assemblage, le transport et la pose du réseau maillé, afin de tenir compte non seulement des impératifs économiques, mais aussi du fait que la main-d'oeuvre employée sur les chantiers est généralement peu qualifiée.According to a particularly simple and rational embodiment, the mesh network located under the surface of the building or structure has square or rectangular meshes, and. it is made from sections of perforated tubes interconnected by means of cross and / or T connections. Special connections are only necessary to make the connection between any plies of external tubes, parallel to the vertical walls, and the mesh network horizontal. We can choose tubes and fittings whose characteristics facilitate the assembly, transport and installation of the mesh network, in order to take into account not only economic imperatives, but also the fact that the workforce employed on construction sites is generally unskilled.

De toute façon, l'invention sera mieux comprise, et d'autres caractéristiques de détail seront mises en évidence, à l'aide de la description qui suit, en référence au dessin schématique annexé représentant, à titre d'exemple, un mode de réalisation de ce dispositif:

- Figure 1 est une vue en plan, très schématique, d'un bâtiment protégé contre l'eau et l'humidité grâce au dispositif selon l'invention;

- Figure 2 est une vue en élévation des parties inférieures de ce bâtiment;

- Figure 3 en est une vue partielle, en coupe verticale et à plus grande échelle, montrant plus en détail le réseau maillé sensiblement horizontal de captage et le réseau périphérique extérieur;

- Figure 4 représente, encore à plus grande échelle, un détail de tube et un raccord appartenant au réseau maillé.

- Figure 1 is a very schematic plan view of a building protected against water and humidity by the device according to the invention;

- Figure 2 is an elevational view of the lower parts of this building;

- Figure 3 is a partial view, in vertical section and on a larger scale, showing in more detail the substantially horizontal mesh network of collection and the external peripheral network;

- Figure 4 shows, still on a larger scale, a detail of a tube and a fitting belonging to the mesh network.

Les figures 1 et 2 représentent, de façon extrêmement schématique, un bâtiment de forme rectangulaire avec ses parois ou murs d'élévation (1, 2, 3, 4) et un mur de refend (5), ce bâtiment constituant une construction enterrée dans le sol dont le niveau naturel est indiqué en (6). Sur la figure 3 apparaissent, de façon plus détaillée, les fondations avec le béton de propreté (7) et les longrines (8), au-dessus desquelles sont érigés les parois ou murs d'éle- vation (1 à 4).Figures 1 and 2 show, extremely schematically, a rectangular building with its elevation walls or walls (1, 2, 3, 4) and a cross wall (5), this building constituting a construction buried in the soil whose natural level is indicated in (6). In Figure 3 appear, in more detail, the foundations with cleanliness concrete (7) and sills (8), above which are erected the walls or elevation walls (1 to 4).

Sur le fond de fouille (9) est disposé, selon l'invention, un réseau maillé désigné dans son ensemble par (10), se présentant vu en plan comme un quadrillage (voir figure 1). Comme le montre plus précisément la figure 3, ce réseau maillé (10) est constitué par des tubes (11), interconnectés au moyen de raccords en croix (12) et présentant des séries de perforations (13). Ce réseau, dont les mailles carrées peuvent avoir un côté compris entre environ 0,60 m et 1 m, s'étend non seulement sur toute la surface du fond de fouille (9), mais encore traverse les longrines (8) par des réservations (14) prévues dans ces dernières. On comprend que des réservations similaires doivent être aussi prévues à la base du mur de refend (5).On the excavation bottom (9) is arranged, according to the invention, a mesh network designated as a whole by (10), appearing seen in plan as a grid (see Figure 1). As shown more precisely in FIG. 3, this mesh network (10) consists of tubes (11), interconnected by means of cross connectors (12) and having series of perforations (13). This network, whose square meshes can have a side of between about 0.60 m and 1 m, extends not only over the entire surface of the excavation bottom (9), but also crosses the stringers (8) by reservations (14) provided for in these. It is understood that similar reservations must also be provided at the base of the cross wall (5).

Le fond de fouille (9) et le réseau maillé (10) sont en léger dévers, le mur (1) correspondant par exemple au côté le plus haut et le mur (3) au côté le plus bas, côté où s'effectuera évidemment l'évacuation des eaux.The bottom of the excavation (9) and the mesh network (10) are slightly cant, the wall (1) corresponding for example to the highest side and the wall (3) to the lowest side, side where will obviously take place drainage.

Comme le montre la figure 3, le réseau maillé (10) se trouve noyé dans la partie inférieure d'une couche drainante (15) reposant sur le fond de fouille (9) et constituée de pierres concassées, sous forme de granulat soigneusement déterminé. L'épaisseur totale de cette couche (15) peut être égale environ au double du diamètre des tubes perforés (11) du réseau maillé (10).As shown in Figure 3, the mesh network (10) is embedded in the lower part of a draining layer (15) resting on the excavation bottom (9) and consisting of crushed stones, in the form of carefully determined aggregate. The total thickness of this layer (15) can be approximately twice the diameter of the perforated tubes (11) of the mesh network (10).

Comme le montrent la partie gauche de la figure 3, ainsi que, plus schématiquement, la figure 2, il est prévu, à l'extérieur des longrines (8), un réseau périphérique complétant le réseau maillé (10), avec d'autres tubes perforés (16) et d'autres raccords (17) formant des nappes qui s'étendent vers le haut dans des plans verticaux parallèles aux parois (1 à 4). La forme et la hauteur de ces nappes de tubes (16) qui complètent le réseau de base (10) sont déterminées en fonction du profil du terrain naturel (6), comme l'illustre la figure 2.As shown in the left part of FIG. 3, as well as, more schematically, in FIG. 2, there is provided, outside the stringers (8), a peripheral network supplementing the mesh network (10), with other perforated tubes (16) and other fittings (17) forming plies which extend upward in vertical planes parallel to the walls (1 to 4). The shape and height of these layers of tubes (16) which complete the basic network (10) are determined according to the profile of the natural terrain (6), as illustrated in FIG. 2.

Des raccords spéciaux (18), à quatre embouts non situés dans un même plan, sont en outre prévus sur le bord du réseau maillé (10), pour le raccordement de celui-ci aux nappes de tubes extérieures verticales (16).Special fittings (18), with four end pieces not located in the same plane, are also provided on the edge of the mesh network (10), for the connection of the latter to the plies of vertical outer tubes (16).

Enfin, un dallage (19) est mis en place au-dessus de la couche de pierres concassées (15) dans laquelle est noyé le réseau maillé (10).Finally, a paving (19) is placed above the layer of crushed stones (15) in which is embedded the mesh network (10).

La progression de l'eau est chicanée et freinée dans le "hérisson" formé par la couche (15), de sorte que l'écoulement de l'eau s'effectue lentement vers le point bas résultant du léger dévers mentionné précédemment. Si la quantité d'eau augmente brusquement, elle est captée par émergence dans le réseau maillé (10), à travers les perforations (12) des tubes (11), et canalisée dans ces tubes qui l'évacuent. Ceci évite à la pellicule d'eau de s'épaissir et de causer des détériorations sur le dallage (19) et sur le revêtement de ce dallage. Il est à noter que les "traversées de murs" sensiblement horizontales au niveau des longrines (8) permettent une libre circulation de l'eau sous le bâtiment, évitant toute stagnation. Par ailleurs, les nappes verticales extérieures, formées par les tubes (16), jouent un rôle de protection analogue vis-à-vis des murs (1 à 4) et de leurs soubassements.The progression of the water is baffled and braked in the "hedgehog" formed by the layer (15), so that the water flows slowly towards the low point resulting from the slight slope mentioned above. If the quantity of water increases suddenly, it is captured by emergence in the mesh network (10), through the perforations (12) of the tubes (11), and channeled in these tubes which evacuate it. This prevents the film of water from thickening and causing damage to the paving (19) and to the covering of this paving. It should be noted that the substantially horizontal "wall crossings" at the side rails (8) allow free circulation of water under the building, avoiding any stagnation. Furthermore, the vertical outside layers, formed by the tubes (16), play a similar protective role vis-à-vis the walls (1 to 4) and their bases.

Du côté du point bas, un collecteur non représenté récupère l'ensemble des eaux captées, et les véhicule par exemple vers le réseau d'eaux pluviales ou vers une installation susceptible d'utiliser ces eaux (chauffage).On the low point side, a collector (not shown) collects all of the water collected, and transports it, for example, to the rainwater network or to an installation capable of using this water (heating).

La figure 4 représente une extrémité de tube (11) et un raccord en croix (12) du réseau maillé (10). Le tube (11) est annelé et ses perforations (13) sont constituées par des fentes ménagées dans les gorges annulaires du tube. Le raccord (12) comporte, sur ses quatre embouts, des crans intérieurs (20) qui assurent la retenue par encliquetage d'une extrémité de tube (11). Les tubes et raccords sont avantageusement réalisés en matière plastique, et de préférence au moins les tubes (11) s'étendant suivant une direction sont flexibles: le réseau maillé (10) peut être alors "pré-assemblé" et former une sorte de filet, enroulé pour son transport et son stockage, et ensuite ce rouleau est simplement déroulé sur le fond de fouille (9), de sorte que les opérations de pose sur le chantier se trouvent simplifiées à l'extrême. Suivant une autre caractéristique illustrée sur la figure 4, des perforations (21) sont aussi prévues sur les raccords (12) du réseau maillé, plus particulièrement dans les angles de ces raccords, où existe le risque d'une stagnation de l'eau.Figure 4 shows a tube end (11) and a cross connector (12) of the mesh network (10). The tube (11) is ringed and its perforations (13) are formed by slots made in the annular grooves of the tube. The connector (12) has, on its four end caps, internal notches (20) which ensure the snap-fastening of one end of the tube (11). The tubes and fittings are advantageously made of plastic, and preferably at least the tubes (11) extending in one direction are flexible: the mesh network (10) can then be "pre-assembled" and form a sort of net , rolled up for transport and storage, and then this roller is simply unwound on the excavation bottom (9), so that the laying operations on the site are simplified to the extreme. According to another characteristic illustrated in FIG. 4, perforations (21) are also provided on the connections (12) of the mesh network, more particularly in the corners of these connections, where there is the risk of water stagnation.

Le dispositif objet de l'invention peut aussi être mis en oeuvre, sans modification sensible et avec les mêmes résultats, dans le cas de bâtiments avec radier armé et murette périphérique, celle-ci étant traversée par les tubes du réseau maillé, et aussi, plus généralement, dans le cas du sous-oeuvre d'ouvrages divers de génie civil, par exemple pour le soubassement des piles de ponts. On peut aussi prévoir deux séries de crans intérieurs (20) sur chaque embout d'un raccord (12), pour obtenir un meilleur accrochage des extrémités des tubes annelés (11).The device which is the subject of the invention can also be implemented, without appreciable modification and with the same results, in the case of buildings with an armed raft and a peripheral wall, the latter being crossed by the tubes of the mesh network, and also, more generally, in the case of the underwork of various civil engineering works, for example for the foundations of bridge piers. It is also possible to provide two series of internal notches (20) on each end of a fitting (12), in order to obtain better attachment of the ends of the corrugated tubes (11).

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT80420125T ATE7411T1 (en) | 1979-11-16 | 1980-11-13 | DEVICE FOR PROTECTING BUILDINGS AND STRUCTURES AGAINST WATER AND MOISTURE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR7928864 | 1979-11-16 | ||

| FR7928864A FR2469507A1 (en) | 1979-11-16 | 1979-11-16 | PROCESS FOR PROTECTING CIVIL ENGINEERING BUILDINGS AND WORKS FROM WATER AND MOISTURE |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0029400A1 EP0029400A1 (en) | 1981-05-27 |

| EP0029400B1 true EP0029400B1 (en) | 1984-05-09 |

Family

ID=9232004

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP80420125A Expired EP0029400B1 (en) | 1979-11-16 | 1980-11-13 | Apparatus for protecting buildings and civil engineering constructions against water and moisture |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0029400B1 (en) |

| AT (1) | ATE7411T1 (en) |

| DE (1) | DE3067781D1 (en) |

| ES (1) | ES496895A0 (en) |

| FR (1) | FR2469507A1 (en) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4523875A (en) * | 1982-12-27 | 1985-06-18 | Difiore Dante | Auxiliary drainage system for eliminating water problems associated with a foundation of a building |

| US4534143A (en) * | 1983-10-24 | 1985-08-13 | Midwest Irrigation And Foundation, Inc. | System for controlling the moisture in the subsurface soil surrounding a building |

| SE438344B (en) * | 1984-04-02 | 1985-04-15 | Jan Erik Johansson | DEVICE FOR RELIEFING OF FLOORS IN THE MARKET IN BUILDINGS |

| GB2208465B (en) * | 1987-08-11 | 1991-07-10 | Hepworth Building Prod | Underground drainage |

| US5836115A (en) * | 1996-12-09 | 1998-11-17 | Clay; Randy K. | Foundation waterproofing and drainage system |

| ES2208013B1 (en) * | 2001-07-04 | 2005-07-16 | Paulino Alegre Fidalgo | WALL OF SALVAGUARDA AND CONTROL OF RESERVES OF GROUNDWATER. |

| KR100481148B1 (en) * | 2002-03-20 | 2005-04-07 | 이창남 | Drainage System using Hexa-Tube Connector |

| FR2842549A1 (en) * | 2002-07-16 | 2004-01-23 | Manuf Logie | PROCESS FOR PROTECTING BUILDINGS AGAINST BACKWATER, MEANS FOR IMPLEMENTING THE METHOD AND BUILDING PROVIDED WITH SAID MEANS |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1433205A (en) * | 1920-09-07 | 1922-10-24 | Emery C Hodges | Sanitary foundation |

| US1734777A (en) * | 1928-01-17 | 1929-11-05 | Frank A Pike | System of draining |

| NL6710557A (en) * | 1967-07-31 | 1969-02-04 | ||

| DE2200367A1 (en) * | 1972-01-05 | 1973-07-12 | Spreng & Co Vormals Friedrich | PRE-FABRICATED PART FOR FOUNDATION DRAINAGE |

| US3926222A (en) * | 1973-12-18 | 1975-12-16 | Hancock Brick & Tile Co | Corrugated tubing with integral coupling means thereon |

-

1979

- 1979-11-16 FR FR7928864A patent/FR2469507A1/en active Granted

-

1980

- 1980-11-13 AT AT80420125T patent/ATE7411T1/en not_active IP Right Cessation

- 1980-11-13 DE DE8080420125T patent/DE3067781D1/en not_active Expired

- 1980-11-13 EP EP80420125A patent/EP0029400B1/en not_active Expired

- 1980-11-15 ES ES496895A patent/ES496895A0/en active Granted

Also Published As

| Publication number | Publication date |

|---|---|

| ES8201667A1 (en) | 1982-01-01 |

| FR2469507A1 (en) | 1981-05-22 |

| EP0029400A1 (en) | 1981-05-27 |

| ES496895A0 (en) | 1982-01-01 |

| DE3067781D1 (en) | 1984-06-14 |

| ATE7411T1 (en) | 1984-05-15 |

| FR2469507B1 (en) | 1982-12-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2120941C (en) | Water retention reservoir structure | |

| FR2747265A1 (en) | Plant culture on vertical surface | |

| FR2566031A1 (en) | METHOD AND APPARATUS FOR PRODUCING A RIGID SLAB FOR CARRYING A CONSTRUCTION | |

| EP0029400B1 (en) | Apparatus for protecting buildings and civil engineering constructions against water and moisture | |

| FR2564873A1 (en) | WATERPROOFING METHOD AND DEVICE FOR THE PROTECTION AGAINST WATER OF INFILTRATION OF DISCHARGES | |

| WO2019053615A1 (en) | Retaining wall comprising precast piles and pile for such a wall | |

| EP0286662B1 (en) | Buffer tank with alveolar structure for retaining and regulating natural waters | |

| FR2984376A3 (en) | System for retention of rainwater runoff and revitalization of compacted soil on sloping land, has trench formed in area of compacted soil in slope, where drainage base of cesspool is positioned between side surfaces of trench | |

| US10584471B2 (en) | Integrated retaining wall and fluid collection system | |

| EP0770735B1 (en) | Underground buffer tank for storing and treating rain water | |

| FR2976604A1 (en) | VEGETALIZED ROOF | |

| FR2739882A1 (en) | FLOOR AND WALL DRAINAGE METHOD AND SYSTEM USING A GRANULAR MATERIAL | |

| FR2964452A1 (en) | Heat recovery slab for constructing e.g. paved outer surfaces of dwelling in civil engineering field, has cohesive layer made of continuous/discontinuous concrete, bitumen coated material or self-supporting paving block, and resting on bed | |

| CN106917337B (en) | The technique of road surfacing | |

| BE863944Q (en) | PROCESS FOR MANUFACTURING RETAINING WALLS AND ELEMENTS FOR IMPLEMENTING THIS PROCESS | |

| KR20150002028U (en) | Structure to drain water in slope with s type drain pipe | |

| EP3945182B1 (en) | Pool with tiled bottom | |

| EP1119663B1 (en) | Tubular structure | |

| WO2023098998A1 (en) | System and geocomposite for fluid drainage | |

| KR200387866Y1 (en) | Apparatus for Rainwater Infiltration from the overflow of rainwater storage and utilization using fabricated block wrapped with permeable fabric material | |

| CA1265692A (en) | Storm drain system with incremental catchment | |

| FR2656885A1 (en) | Improved coating for protecting soil subject to erosion, and implementation method | |

| FR3060621A1 (en) | REGARDING AVALER WITH A COUPLED TUBE | |

| FR2514798A1 (en) | STANDARD CONSTRUCTION ELEMENT FOR EARTHWORKS, FOUNDATIONS AND HYDRAULIC WORKS | |

| FR2694773A1 (en) | Groundwater drainage device made of sewn geotextile fibres - comprises centre of fibres less porous than surrounding layers water collector at bottom and ice preventing heat conductor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19810324 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19840509 Ref country code: NL Effective date: 19840509 Ref country code: AT Effective date: 19840509 |

|

| REF | Corresponds to: |

Ref document number: 7411 Country of ref document: AT Date of ref document: 19840515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3067781 Country of ref document: DE Date of ref document: 19840614 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19841130 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19901112 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19901119 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19901121 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19901122 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19901129 Year of fee payment: 11 |

|

| ITTA | It: last paid annual fee | ||

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19911113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19911130 Ref country code: CH Effective date: 19911130 Ref country code: BE Effective date: 19911130 |

|

| BERE | Be: lapsed |

Owner name: CELMETANCHE S.A.R.L. Effective date: 19911130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920801 |